Introduction

The aviation industry's pursuit of sustainable aviation fuels (SAFs) as an alternative to traditional jet fuels is gaining momentum. With the industry setting ambitious goals of reaching net-zero carbon emissions by 2050, SAFs derived from renewable sources like crops and household waste offer a practical solution.

However, challenges such as limited supply and potential land use changes need to be addressed. Technological advancements like Unifuel.tech's Flexiforming technology are emerging as potential solutions to overcome these hurdles. This article dives into the world of renewable fuels, exploring the potential of SAFs, biojet fuels, synthetic jet fuels, hydrogen-based fuels, and electric propulsion in reducing the aviation industry's environmental impact.

Conventional Aviation Fuel

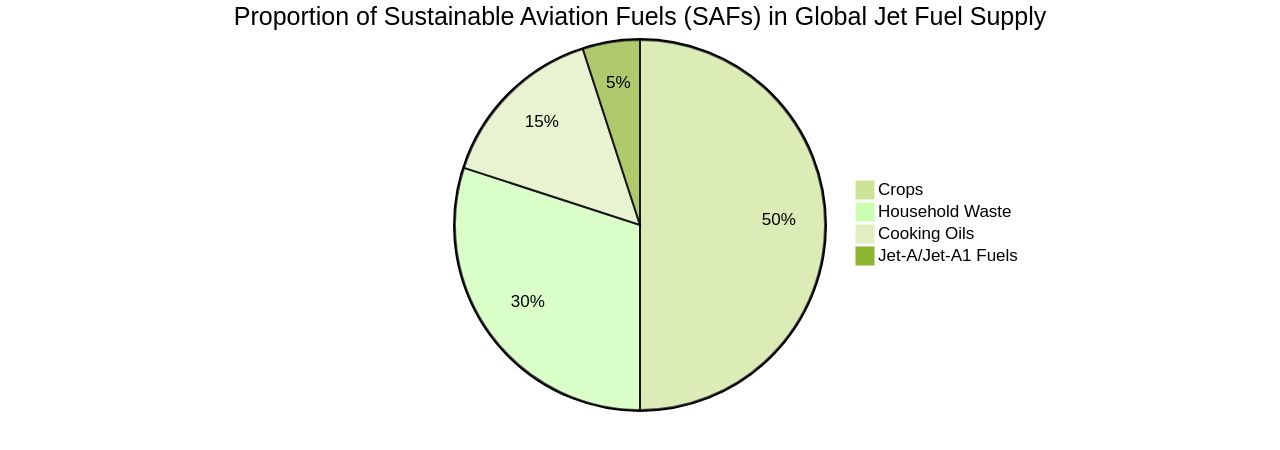

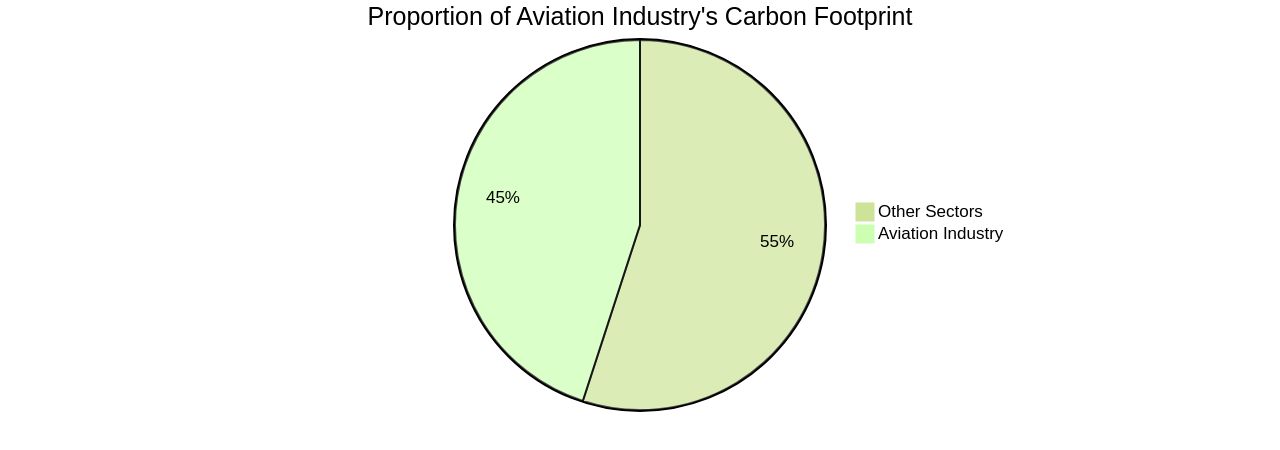

The aviation sector, which accounts for 2-3% of all anthropogenic global warming, is actively pursuing sustainable aviation fuels (SAFs) as an alternative to traditional Jet-A or Jet-A1 fuels. These SAFs, derived from various sources such as crops, household waste, and cooking oils, can be used by existing aircraft, making them a practical solution for the industry's aspiration of reaching net-zero carbon dioxide emissions by 2050. Virgin Atlantic, for instance, has already made progress in this area, completing the first transatlantic flight entirely powered by SAFs.

Nevertheless, the journey to sustainability has its obstacles. SAF production can trigger land use changes, potentially leading to increased pollution. Plus, the current SAF supply is far from meeting the industry's fuel demands, contributing only 0.2% of the global jet fuel supply in 2022.

However, technological advancements are emerging to address these challenges. For instance, Universal Fuel Technologies has developed Unifuel.tech, a solution featuring Flexiforming technology. This allows operators to determine their decarbonization pace, and can be implemented in an idle hydrotreater or reformer, minimizing capital expenditure and carbon intensity.

Unifuel. Tech optimizes Flexiforming's application based on operator's feed, target products, and existing facilities information. While SAFs offer a promising path towards reducing the aviation industry's environmental footprint, their effectiveness will hinge on a variety of factors, including technological innovations like Unifuel.tech and supportive government policies.

Sustainable Aviation Fuels (SAF)

Types of aircraft fuel, specifically Sustainable Aviation Fuels (SAFs), have emerged as the main solution to reduce carbon emissions in the aviation industry. These renewable fuels can be derived from multiple sources including biomass, waste oils, synthetic processes, and even waste gases. Used cooking oil, municipal waste, agricultural residues, and renewable electricity are just some examples of the diverse feedstocks for SAFs.

The aviation sector, responsible for a significant 2-3% of global CO2 emissions, is on the path to decarbonization. SAFs are the key tool for this transition, despite the nascent stage of the technology and the associated costs. The International Civil Aviation Organization has set ambitious goals of achieving net-zero carbon emissions by 2050 for the aviation industry, emphasizing the importance of different types of aircraft fuel, such as Sustainable Aviation Fuels (SAFs), in this process.

However, the broader implementation of SAFs is hindered by factors such as cost and supply constraints. At present, SAF costs are about 3-4 times higher than conventional jet fuel, and they constitute a minor fraction of total aviation fuel consumption. To make a substantial impact on the industry's carbon emissions, SAF production and usage must be significantly scaled up.

Furthermore, it is vital to comprehend that there are different types of aircraft fuel available. For example, Safe lack the aromatic compounds found in traditional jet fuels, essential for fuel performance and compatibility with current aircraft systems. Further technological advancements are needed to address the limitation that restricts the blending ratio of types of aircraft fuel, such as sustainable aviation fuels (SAFs), with conventional jet fuel to a maximum of 50%.

It is here that solutions like flexiforming, offered by Unifuel.tech, come into play.

This technology allows operators to control their decarbonization pace and can be installed in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. Unifuel.tech, owned by Universal Fuel Technologies, requires details about the operator's feeds, target products, and existing facilities to find the optimal application for flexiforming. In essence, while SAFs present a significant potential in reducing the aviation industry's carbon footprint, their wider adoption depends on overcoming considerable technological, economic, and supply chain hurdles.

Biojet Fuels

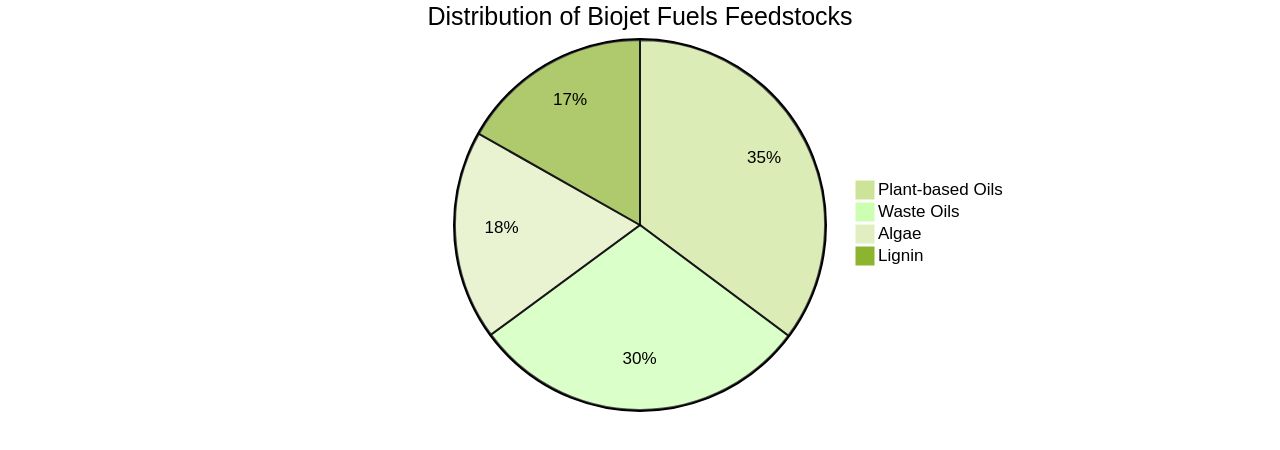

Biojet fuels, a sustainable aviation fuel (SAF) alternative, have come into prominence due to their compatibility with current aircraft and comparable performance to traditional aviation fuel. Derived from diverse biological feedstocks such as waste oils, algae, and plant-based oils, these biofuels undergo esterification and hydroprocessing, transforming them into aviation-grade fuel.

The recent breakthrough of converting lignin, a renewable substance abundant in plant and tree cell walls, into aviation biofuel, is particularly promising for cost-effective and scalable production. As the aviation industry, responsible for about a quarter of global CO2 emissions in 2021, strives to attain carbon neutrality by 2050, biojet fuels emerge as a feasible solution.

Electric planes, though progressing, are still far from facilitating mass air travel. In this context, the Bioenergy Technologies Office (BETO) of the US Department of Energy is propelling research, development, and demonstration initiatives to tackle hurdles to the broad implementation of low-carbon SAF.

Even with obstacles like substantial initial investment and economic uncertainties, the biofuel market, particularly in Europe, is projected to experience swift growth, propelled by rising air cargo transport demand and government policies endorsing biofuels. The creation of sustainable aviation fuel is not just an ecological necessity but also a burgeoning worldwide opportunity.

A solution like Flexiforming, provided by Unifuel.tech, enables operators to control their decarbonization pace. Flexiforming can be utilized in an idle hydrotreater or reformer, lowering capital expenditure and carbon intensity. By offering details about feeds, target products, and existing facilities, Unifuel. Tech can identify an optimal application for Flexiforming. Universal Fuel Technologies owns the rights to Unifuel.tech.

Synthetic Jet Fuels

Types of aircraft fuel, including Synthetic Paraffinic Kerosene (SPK) or synthetic jet fuels, are becoming increasingly essential in the aviation industry's pursuit of sustainability. These fuels, known as types of aircraft fuel, are derived from non-petroleum carbon feedstocks like biomass or natural gas, and they mirror the composition of conventional jet fuel while offering a significant reduction in greenhouse gas emissions. Sustainable Aviation Fuels (SAFs) are being considered as a potential pathway to achieve net-zero carbon emissions by 2050, as the aviation industry tackles its carbon footprint, which accounts for about 2% of global emissions. These Sustainable Aviation Fuels (SAFs) are one of the types of aircraft fuel that could help reduce carbon emissions.

However, this ambitious goal hinges on several factors including the adaptation of global aircraft fleets, fueling infrastructure, and airports. To overcome the challenge of ensuring sustainable fuel availability at the aircraft's destination, the industry has broadened the definition of Safe to include various blends with traditional jet fuels that meet specific emission reduction targets. For instance, ORLEN plans to manufacture 70,000 tonnes of synthetic fuels annually by 2030, demonstrating a tangible commitment to sustainable fuel production.

Furthermore, the possibilities for synthetic fuel production are being expanded by technological advancements such as Unifuel.tech's flexiforming process, which allows for a wider range of feedstocks including various types of aircraft fuel. This process enables the conversion of various types of plant sugars into synthetic aromatics, allowing for adaptation to the availability of resources worldwide. It is similar to the different types of aircraft fuel used for flying. Consequently, synthetic jet fuels, supported by innovative technologies like flexiforming, exemplify a promising route towards decarbonizing the aviation sector.

Hydrogen-Based Fuels

Hydrogen-based fuels are emerging as a promising avenue for the future of aviation fuel. These fuels can be generated from renewable resources, such as electrolysis, and their combustion results in only water vapor, eliminating carbon emissions.

However, several challenges, including storage, infrastructure, and safety, need to be addressed for widespread adoption. Airbus, in collaboration with ArianeGroup, has tested a complete system for feeding hydrogen to an aeronautical gas turbine engine.

The Hyperion project aims to develop practical hydrogen commercial airliners by 2035, with the hydrogen stored as a supercooled liquid in cryogenic tanks. Furthermore, the HY4, the world’s first hydrogen-electric passenger aircraft, first took off in 2016, demonstrating the feasibility of this technology.

Despite these advancements, the cost of new aircraft and infrastructure, along with the price of renewable hydrogen, pose substantial economic challenges. The UK Civil Aviation Authority has launched a Hydrogen Challenge to understand the potential of hydrogen fuel and to address the risks to aviation safety. Meanwhile, airports like Stuttgart and Budapest are taking proactive steps towards decarbonization, with Stuttgart Airport's CEO, Ulrich Heppe, acknowledging hydrogen's central role in sustainable travel. Organizations such as Hydrogen Airport are facilitating airports in their transition to hydrogen, offering tailor-made feasibility studies, including assessment of hydrogen needs, supply chain modeling, and cost estimates.

Electric Propulsion

The aviation industry is on the cusp of a paradigm shift, with the advent of electric propulsion technology poised to bring about significant transformations. Electric aircraft, powered by batteries or fuel cells, are emerging as a promising solution to drastically reduce carbon emissions and noise pollution. However, the technology currently faces constraints with respect to battery capacity and energy density, which limit the size and range of electric aircraft.

The More Electric Aircraft concept presents an intriguing prospect for future aircraft designs, offering an array of potential benefits in terms of efficiency. The objective is to transition from systems employing non-electric power, such as hydraulic and pneumatic systems, to electric systems. This change would enhance numerous aspects of aircraft operation, including efficiency, emissions, reliability, and maintenance costs.

The Department of Energy (DOE) has recently allocated $15 million to 12 teams to develop batteries and energy storage systems with energy density four times higher than current technologies. This initiative aims to enable the electrification of aircraft that can transport up to 100 passengers for 1,000 miles. Moreover, a team of engineers at MIT is developing a 1-megawatt motor, a potential key to electrifying larger aircraft.

Despite the challenges, the aviation industry seems to be on the right trajectory. As Kevin Michaels, managing director of Aerodynamic Advisory, an aviation consulting firm, puts it, the industry eventually found its way after the advent of automobiles, and it is likely to do the same with electric aviation. The focus now is on making batteries more powerful or lighter to match the efficiency of conventional aircraft.

As of May 2022, there were over 170 ongoing electric aviation projects globally, according to Scientific American. These endeavors aim to address the energy requirements for getting an aircraft into the air and keeping it there, thus contributing to making planes more fuel-efficient. With the right advancements, electric propulsion technology could indeed revolutionize the aviation industry.

Conclusion

In conclusion, the aviation industry's pursuit of sustainable aviation fuels (SAFs) as an alternative to traditional jet fuels is gaining momentum. SAFs derived from renewable sources offer a practical solution for the industry's goal of reaching net-zero carbon emissions by 2050.

However, challenges such as limited supply and potential land use changes need to be addressed. Technological advancements like Unifuel.tech's Flexiforming technology are emerging as potential solutions to overcome these hurdles.

This technology allows operators to control their decarbonization pace and can be implemented in existing facilities, minimizing capital expenditure and carbon intensity. SAFs, including biojet fuels, synthetic jet fuels, hydrogen-based fuels, and electric propulsion, all have the potential to significantly reduce the aviation industry's environmental impact.

However, each comes with its own set of challenges that need to be addressed for wider adoption. Biojet fuels offer a promising solution but face obstacles such as cost and supply constraints.

Synthetic jet fuels mirror conventional jet fuel composition but require adaptation of global fleets and infrastructure. Hydrogen-based fuels show promise but require addressing challenges in storage, infrastructure, and safety. Electric propulsion technology has the potential to revolutionize the industry but faces limitations in battery capacity and energy density. Overall, while there are challenges to overcome, technological advancements like Flexiforming offer hope for the widespread adoption of sustainable aviation fuels. With continued innovation and supportive government policies, the aviation industry can make significant progress towards achieving its sustainability goals and reducing its environmental footprint.