Introduction

The aviation industry is facing increasing pressure to reduce its carbon emissions and find sustainable solutions. One of the most promising options is Sustainable Aviation Fuel (SAF), which offers a drop-in solution that requires minimal changes to existing infrastructure. However, the production and supply of SAFs still pose challenges.

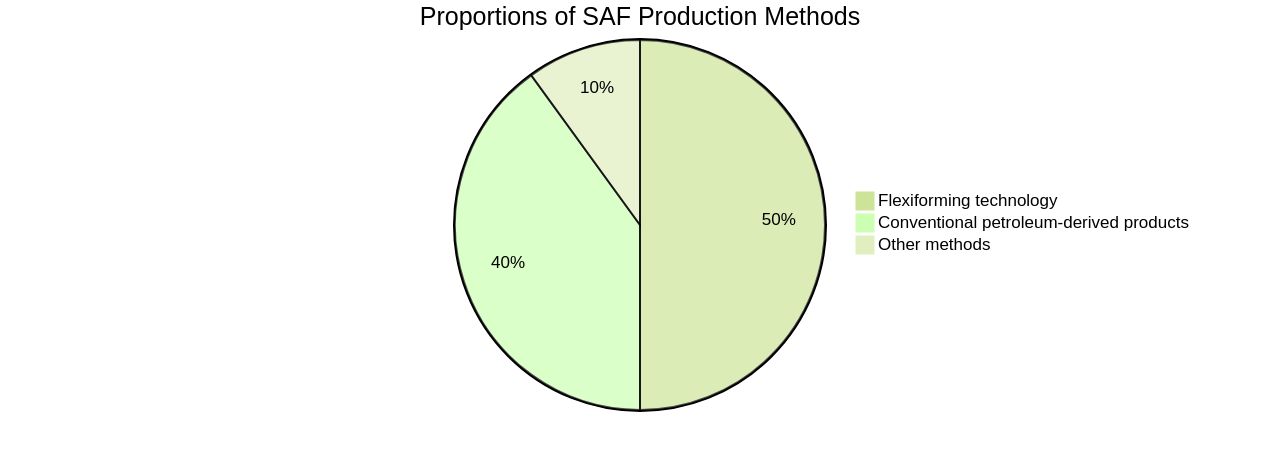

In this context, Unifuel.tech's Flexiforming technology is emerging as a game-changing solution. This technology, deployed in idle hydrotreaters or reformers, allows operators to control their decarbonization pace while reducing capital expenditure and carbon intensity. With a proactive approach and quick response time, Unifuel.tech is contributing to the development and implementation of SAFs, paving the way for a more sustainable future in aviation.

Background and Previous Estimates

The aviation industry, known for its substantial CO2 emissions, is on a mission to lessen its environmental impact. Sustainable Aviation Fuel (SAF) is currently the most promising and scalable solution to reduce greenhouse gas emissions from aircraft.

Even though electric and hydrogen-fueled planes are on the horizon, they are yet to become commercially viable on a large scale. In contrast, SAFs, which require minimal changes to existing aircraft and airport infrastructure, are a viable 'drop-in' solution.

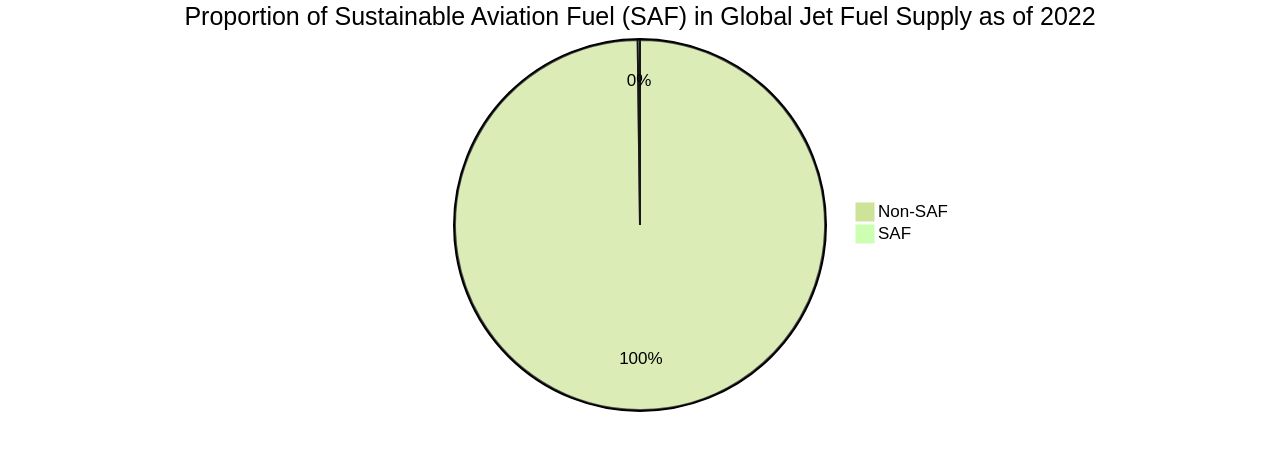

However, SAFs are still in their infancy, and their supply needs to be significantly ramped up. As of 2022, SAFs made up less than 0.2% of the global jet fuel supply.

The production process of these alternative fuels also poses challenges, as it can lead to CO2 emissions, either from the energy required or their ecosystem impact. Nevertheless, the goal set by the International Civil Aviation Organization to achieve net-zero carbon emissions by 2050 makes the development and implementation of SAFs a necessity.

In this landscape, innovative solutions like Unifuel.tech's Flexiforming technology are playing a pivotal role. Flexiforming is a technology that can be deployed in idle hydrotreaters or reformers, reducing both capital expenditure and carbon intensity. This gives operators control over their decarbonization pace. Unifuel.tech, a subsidiary of Universal Fuel Technologies, is known for their quick response time to inquiries, ensuring optimal applications of Flexiforming can be identified based on feeds, target products, and existing facilities. This proactive approach is contributing to a broader exploration of fuel types, carbon intensities, market conditions, and potential costs across the SAF landscape, setting the stage for a more sustainable future in aviation.

Methodology of the Study

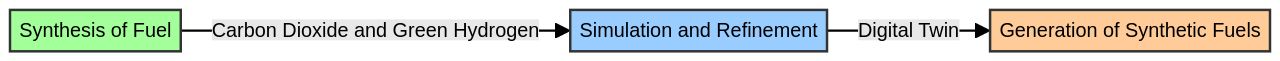

The burgeoning demand for air travel coupled with its 2.5% contribution to global carbon emissions compels a shift towards sustainable aviation fuels (SAFs). In this context, Flexiforming technology, which synthesizes fuel from carbon dioxide and green hydrogen, emerges as a game-changing solution. Companies such as ORLEN have adopted this technology, with ambitious goals of producing 70 thousand tonnes of SAF annually by 2030.

The technology leverages a 'digital twin' of a production facility for simulating and refining production processes, with a focus on economically and environmentally sustainable synthesis techniques. The synthetic fuels generated by this method bear a striking resemblance to traditional petroleum-based products, implying they can drastically cut greenhouse gas emissions without the need for altering current combustion engine vehicles. Unifuel.tech, a subsidiary of Universal Fuel Technologies, takes this technology a step further with its Flexiforming solution.

This technology, deployable in an idle hydrotreater or reformer, offers operators the flexibility to dictate their decarbonization pace, while simultaneously reducing capital expenditure and carbon intensity. Unifuel.tech's responsive customer service, with a 24-hour response time, ensures that any queries or concerns about the feeds, target products, and existing facilities, for optimal application of Flexiforming, are promptly addressed. This, coupled with its parent company's strong brand rights and clear terms of use, make Unifuel.tech's Flexiforming a promising solution in the aviation industry's pursuit of carbon neutrality.

Sampling Strategy and Data Collection

The aviation industry, contributing approximately 2% of global carbon emissions, is actively exploring effective decarbonization strategies. Despite the current higher costs compared to traditional jet fuel, a significant development in this pursuit has been the production of Sustainable Aviation Fuel (SAF) using Flexiforming technology.

This technology is being harnessed by companies like ORLEN and Yokogawa to develop integrated solutions for synthetic fuel production. Central to these initiatives is the application of a 'digital twin' of production facilities, a virtual replica that facilitates the simulation and optimization of production processes.

With ambitious goals, ORLEN aims to produce 70,000 tons of synthetic fuels annually by the end of 2030, addressing a significant portion of Sweden's projected SAF demand. Operators can determine their pace of decarbonization using Unifuel.tech's Flexiforming technology, which provides flexibility and ensures safety.

This technology can be deployed in idle hydrotreaters or reformers, reducing both capital expenditure and carbon intensity. Synthetic fuels are produced by combining hydrogen, generated via electrolysis powered by renewable energy, with carbon dioxide molecules from industrial processes, significantly reducing greenhouse gas emissions. These fuels closely resemble conventional petroleum-derived products and can be used without technical modifications to current combustion engines, making them an ideal alternative in the pursuit of the aviation industry's sustainability goals. Unifuel.tech, owned by Universal Fuel Technologies, offers a promising solution for operators aiming to decarbonize at their own pace. The company's provision of prompt responses to inquiries within 24 hours contributes to the ongoing research and technological development aimed at enhancing Saf's efficiency and affordability.

Results

Unifuel.tech's Flexiforming technology emerges as a transformative solution in the production of Sustainable Aviation Fuel (SAF), offering a cost-effective and efficient approach to carbon reduction. The aviation industry accounts for 2.5% of global CO2 emissions, and SAF production via Flexiforming is a key measure towards carbon neutrality. Take the strategic alliance between ORLEN and Yokogawa, for instance, which is set to establish a 70 thousand tonne annual capacity for synthetic fuels by 2030.

This partnership denotes a decisive shift towards synthetic fuel production, amalgamating green hydrogen and carbon dioxide to yield fuels akin to conventional petroleum-derived products. This not only curbs greenhouse gas emissions but also obviates the need for technical modifications in existing combustion engine vehicles. Flexiforming technology's compatibility with existing storage, transport, and distribution infrastructure further accentuates its suitability for SAF production.

This circumvents the requirement for infrastructure modifications, which can entail additional costs and logistical complications. The technology's deployment in an idle hydrotreater or reformer also curtails capital expenditure and carbon intensity. Synthetic fuels production also holds significant promise in markedly reducing industrial emissions of greenhouse gases.

This is facilitated by merging hydrogen, produced via renewable energy-powered electrolysis, with carbon dioxide molecules sourced from a range of industrial processes. In essence, the integration of Flexiforming technology is not only eco-friendly but also economically feasible, making it a potent solution for the aviation industry's quest for carbon neutrality. Unifuel.tech, the provider of this technology, offers personalized solutions based on the operator's feeds, target products, and existing facilities, promising to respond to inquiries within 24 hours.

Conclusion

Unifuel.tech's Flexiforming technology is revolutionizing the production of Sustainable Aviation Fuel (SAF), offering a cost-effective and efficient approach to carbon reduction in the aviation industry. This technology allows operators to control their decarbonization pace while reducing capital expenditure and carbon intensity.

Its compatibility with existing infrastructure makes it a practical solution for SAF production without requiring significant modifications. Flexiforming produces synthetic fuels that closely resemble traditional petroleum-based products, enabling seamless integration into current combustion engines without technical modifications.

Unifuel.tech's proactive approach and quick response time contribute to the exploration of different fuel types, carbon intensities, market conditions, and potential costs across the SAF landscape. With ambitious goals set by companies like ORLEN, there is a clear shift towards carbon reduction in the aviation industry.

Unifuel.tech's Flexiforming technology offers scalability and efficiency, making it a promising tool for operators aiming to decarbonize at their own pace. In conclusion, Unifuel.tech's Flexiforming technology is an ideal option for sustainable aviation fuel production. Its cost-effectiveness, compatibility with existing infrastructure, and ability to produce synthetic fuels resembling traditional petroleum-based products position it as a transformative solution for the aviation industry's journey towards carbon neutrality. By embracing these innovative solutions, the aviation industry is taking significant strides towards building a more sustainable future.

Join the sustainable aviation fuel revolution with Unifuel.tech's Flexiforming technology today!