Introduction

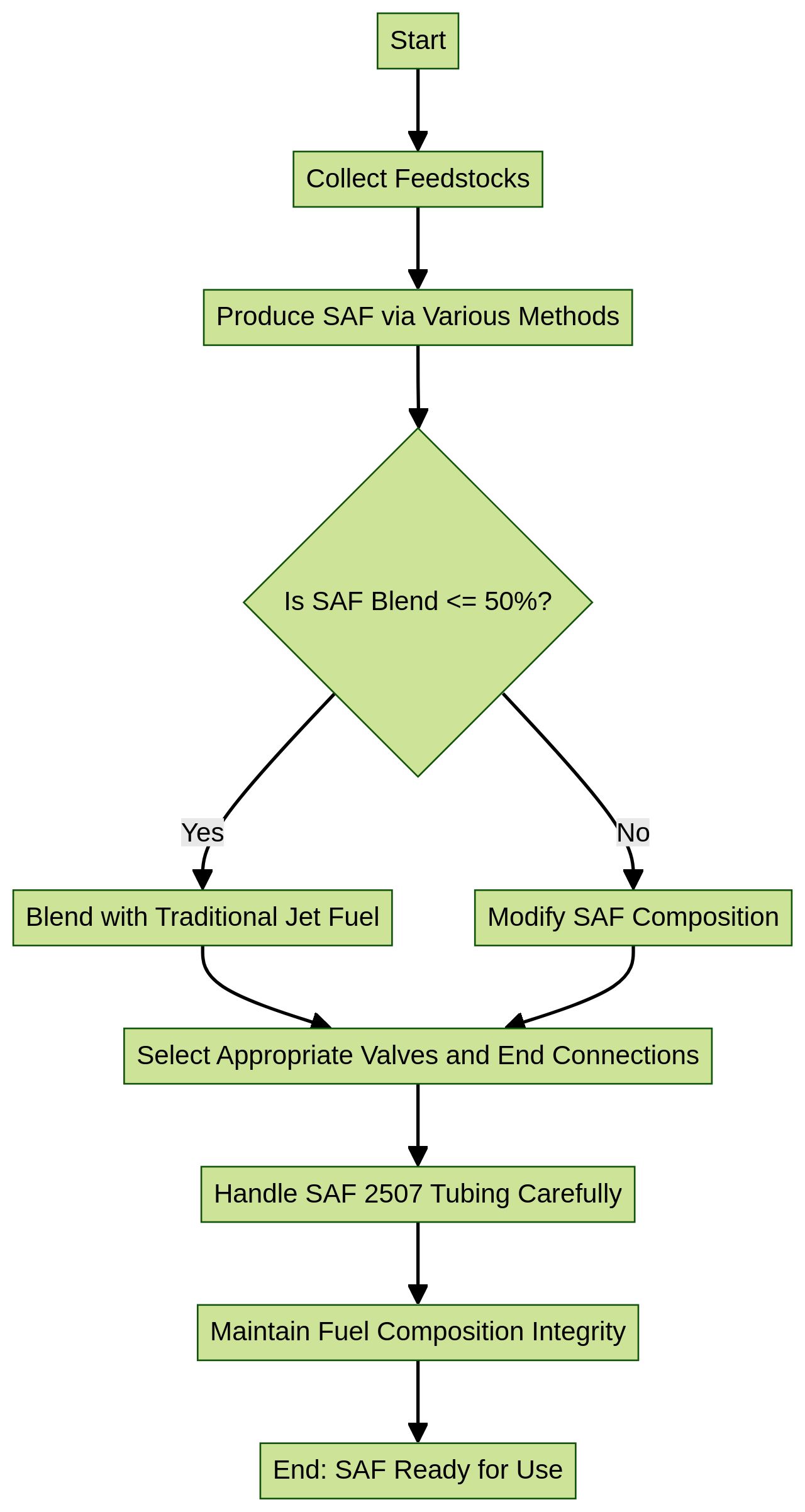

The aviation industry's commitment to combatting climate change is driving the demand for Sustainable Aviation Fuel (SAF). With a goal of achieving net-zero carbon emissions by 2050, the industry is exploring innovative technologies and solutions to make SAF a viable pathway towards sustainability.

This article delves into various aspects of SAF production, including the role of flexiforming technology in reducing carbon intensity, the challenges in selecting valves and end connections for SAF 2507 tubing, and the optimization of refining processes through specialized valves. It also highlights the importance of SAF 2507 super duplex stainless steel tubing in enhancing the efficiency and sustainability of SAF production. With a technical and analytical tone, this article provides insights and analysis for industry professionals in the renewable fuels sector.

The Need for SAF in the Aviation Industry

Sustainable Aviation Fuel (SAF) is at the forefront of the aviation industry's efforts to combat climate change. As the sector aims for net-zero carbon emissions by 2050, Saf's role is increasingly pivotal.

The Virgin Atlantic Boeing 787's flight from London to New York, powered entirely by SAF from waste cooking oils and fats, achieved a 70% reduction in carbon emissions, exemplifying the potential of SAF in real-world applications. This flight, Flight 100, not only transported passengers but also symbolized the industry's commitment to sustainability.

With companies like Airbus targeting all aircraft to be SAF-capable by 2030, the push for a sustainable aerospace sector is clear. Addressing current obstacles like cost and supply, innovative technologies are emerging.

Unifuel.tech, with its flexiforming technology, offers a solution that enables operators to adjust their decarbonization pace. This technology can be integrated into existing idle hydrotreaters or reformers, offering a cost-effective reduction in carbon intensity. Unifuel.tech's commitment to rapid customer service, responding within 24 hours, and their ability to tailor flexiforming applications based on specific feeds, target products, and facilities, showcase a tailored approach to SAF production. Owned by Universal Fuel Technologies, Unifuel.tech's details and terms of use are accessible on their website, inviting industry stakeholders to explore this innovative decarbonization technology. As the aviation industry explores various avenues like electric propulsion and hydrogen operations, the integration of technologies like flexiforming is instrumental in ensuring that SAF continues to be a viable pathway towards the 2050 net-zero goal.

Challenges in Medium-Pressure Instrument Ball Valves and End Connections for SAF 2507 Tubing

The process of refining Sustainable Aviation Fuel (SAF) necessitates a meticulous approach to hardware selection, particularly when it comes to the valves and end connections that interact with SAF 2507 tubing. These components must be engineered to not only withstand the unique chemical properties of SAF but also to maintain the integrity of the fuel's composition. Alfa Laval, a leader in heat transfer, separation, and fluid handling, underscores the importance of innovation and optimization in developing solutions that can meet the environmental objectives while tackling the industry's most demanding challenges.

Prudentia Engineering, with its extensive experience in the chemicals, energy, and minerals processing industries, emphasizes the criticality of practical outcomes across the project life cycle, leveraging their expertise in process engineering to support projects in the burgeoning critical minerals industry. This level of precision engineering is vital as hot tapping – the technique of connecting new valves or fittings to existing pipelines while they remain operational – involves significant risks. Potential hazards, such as blowouts or hydrocarbon releases, necessitate a comprehensive understanding of the pressures at play and the materials used.

With Bosch Rexroth's new Hydraulics Training Center focusing on hydraulics, electric drives, and control technology, the industry is poised to address these challenges through advanced training and skill development. This commitment to education and hands-on experience equips professionals to navigate the evolving landscape of SAF production, ensuring that each valve and connection designed for SAF 2507 tubing is not only effective but also safe and sustainable. As the SAF market grows, backed by the strong consensus that oil companies should prioritize supplying SAF, the collaborative efforts of various stakeholders in the SAF value chain become increasingly crucial to foster innovation and scale up SAF usage.

Beta Testing a New Valve for SAF Production

The quest for optimizing Sustainable Aviation Fuel (SAF) refining processes recently experienced a significant leap forward with the introduction of specialized valves by a prominent aerospace company. These valves, meticulously engineered for SAF production, underwent rigorous beta testing to ensure they meet the unique demands of this innovative fuel type. SAF, a key player in reducing aviation emissions, has traditionally been limited in its blending capabilities with conventional jet fuels due to the absence of aromatics.

However, with advancements in bio-based aromatics, such as those from the BioForming process, there is now potential to use SAF at higher blend ratios, up to 100%, without compromising fuel performance or safety. This is a pivotal development considering the traditional jet fuel specifications set by ASTM international standards, which require a certain percentage of aromatics to maintain fuel integrity and performance. The new valve technology is a testament to the industry's commitment to overcoming technical barriers and advancing towards a more sustainable future in aviation fuel.

The successful beta testing is a harbinger of the potential for full-scale implementation, paving the way for increased utilization of SAF in the aviation sector. This aligns with global efforts to meet stringent emission targets by 2050, as SAF production is intrinsically linked to lower lifecycle greenhouse gas emissions compared to traditional jet fuels. The integration of such technologies is crucial in transitioning to a greener aviation industry, as underscored by the planned SAF output in Sweden, which aims to cater to a significant portion of the country's jet fuel demand by 2030.

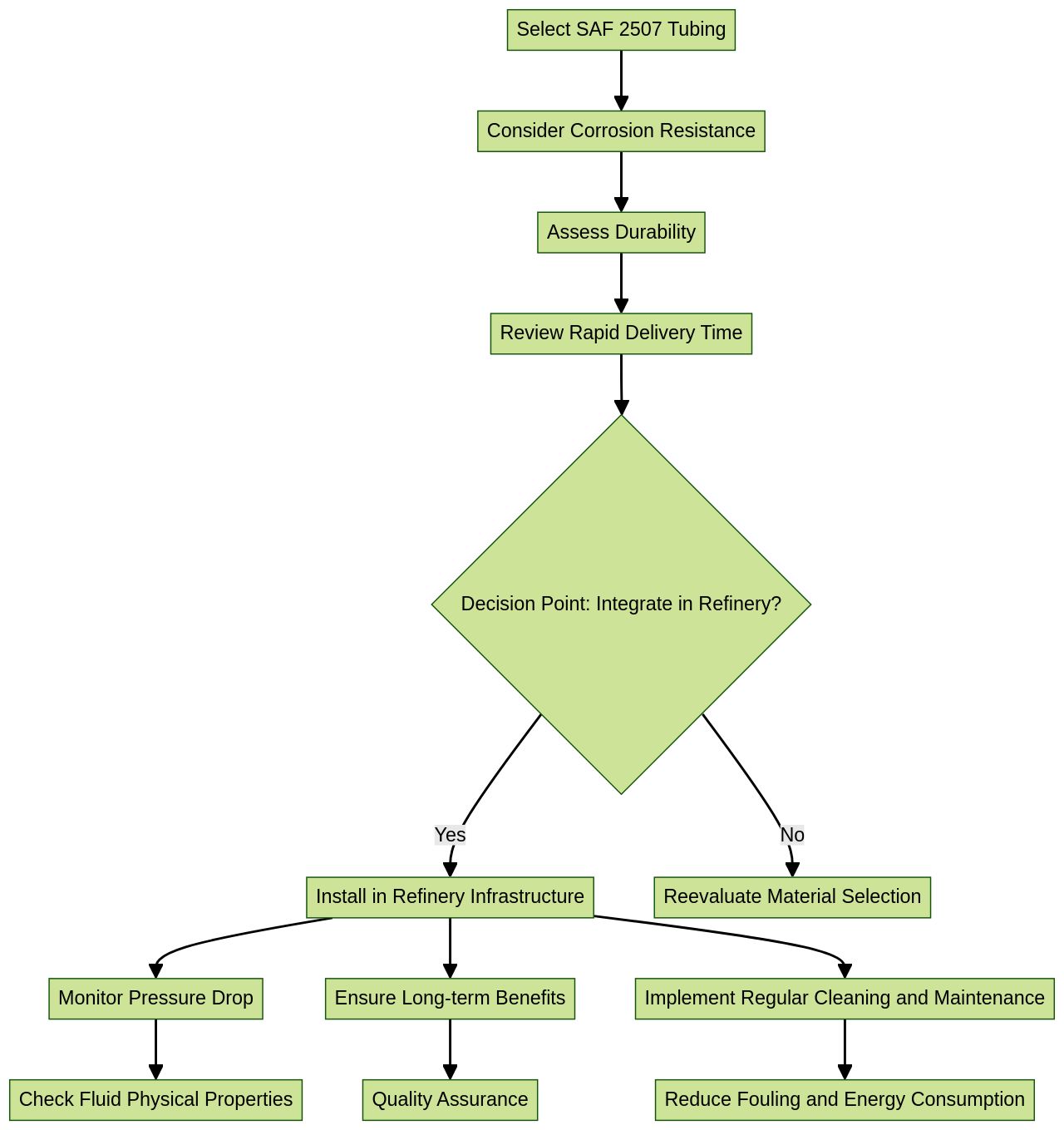

Finding the Right Connection for SAF 2507 Tubing

The integration of SAF 2507 super duplex stainless steel tubing within the refining process is a testament to the industry's innovative strides in enhancing the efficiency and sustainability of SAF production. This material is celebrated for its exceptional resistance to corrosion, particularly in harsh environments, which is imperative for the longevity and reliability of the infrastructure.

The added durability and strength of SAF 2507 tubing ensure that it can withstand the rigors of the refining process, which often involves aggressive chemicals and high temperatures. Utilizing this advanced tubing technology not only streamlines the operational aspects but also aligns with the broader objectives of reducing greenhouse gas emissions.

It is a shining example of how technical ingenuity is being leveraged to meet the rigorous demands of sustainable aviation fuel production, offering a robust solution that complements the existing refinery frameworks. Moreover, with the capability for rapid delivery within four to six weeks, the adoption of SAF 2507 tubing minimizes downtime and expedites the transition towards renewable fuel production, which is essential in the context of the growing demand for sustainable fuel sources. The decision to incorporate such technology is backed by the broader industry trend of optimizing current refinery capacities rather than constructing new ones, a move that is both economically and environmentally prudent. As refineries consider the shift to renewable fuel production, the choice of materials like SAF 2507 becomes increasingly pertinent, particularly for facilities that are strategically located near abundant feedstock supplies and wish to maintain a competitive edge in the burgeoning market for renewable fuels.

Conclusion

In conclusion, the aviation industry's commitment to combat climate change is driving the demand for Sustainable Aviation Fuel (SAF) as a viable pathway towards achieving net-zero carbon emissions by 2050. The successful Virgin Atlantic flight powered by SAF exemplifies its potential in reducing carbon emissions. Careful selection of valves and end connections for SAF 2507 tubing is crucial to ensure the integrity of SAF production.

Companies like Alfa Laval and Prudentia Engineering emphasize innovation and optimization to meet environmental objectives. The beta testing of specialized valves designed for SAF production signifies the industry's dedication to overcoming technical barriers. With advancements in bio-based aromatics, higher blend ratios of SAF can be achieved without compromising fuel performance or safety.

The integration of SAF 2507 super duplex stainless steel tubing enhances efficiency and sustainability in SAF production. Its exceptional resistance to corrosion ensures longevity and reliability in harsh environments, streamlining operations and reducing greenhouse gas emissions. As refineries optimize current capacities, materials like SAF 2507 become crucial for facilities strategically located near abundant feedstock supplies.

The adoption of this technology minimizes downtime, accelerates renewable fuel production, and maintains a competitive edge in the growing market for sustainable fuels. Through technological advancements and strategic collaborations, the aviation industry is making significant progress towards a more sustainable future with SAF as a key player in achieving net-zero carbon emissions by 2050. By embracing innovative solutions and optimizing processes, the industry is driving towards its sustainability goals.