Introduction

Decarbonizing the aviation sector is a challenging task, but Sustainable Aviation Fuels (SAF) offer a promising solution. However, the nascent stage of SAF technology and high production costs have hindered its widespread adoption. In Sweden, a country known for its environmental stewardship, progress is being made in SAF production, aiming to meet 20% of the country's SAF requirement by 2030.

Advancements in SAF technology, such as Unifuel.tech's flexiforming, show promise in reducing costs and carbon intensity. This article explores the various SAF technology pathways, factors influencing pathway selection, and the environmental impact assessment of SAF production. It also highlights Sweden's efforts and the importance of policy and investment decisions in promoting SAF production.

Background: Sustainable Aviation Fuels (SAF) and the Swedish Context

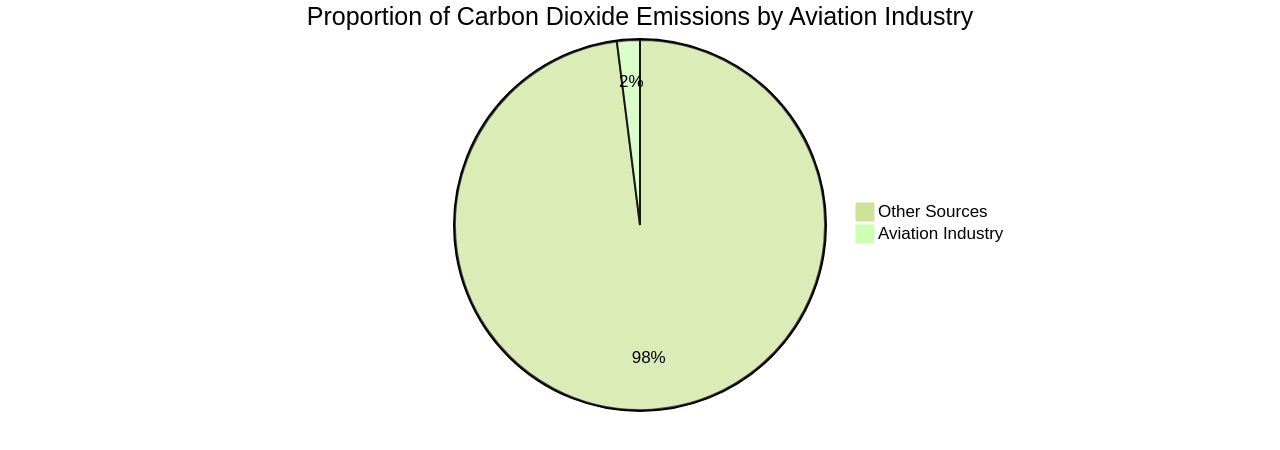

Decarbonizing the aviation sector, responsible for 2-3% of global CO2 emissions, is a formidable task. The transition primarily hinges on Sustainable Aviation Fuels (SAF), synthesized from renewable feedstocks.

However, the nascent stage of SAF technology and associated costs are significant barriers. Regardless, the International Civil Aviation Organization is committed to achieving net-zero carbon emissions by 2050.

Sweden, known for its environmental stewardship, is making progress in SAF production. The projected annual production of 80,000 tons of SAF approximates to about 5% of Sweden's total jet fuel demand, and 20% of its expected SAF requirement by 2030.

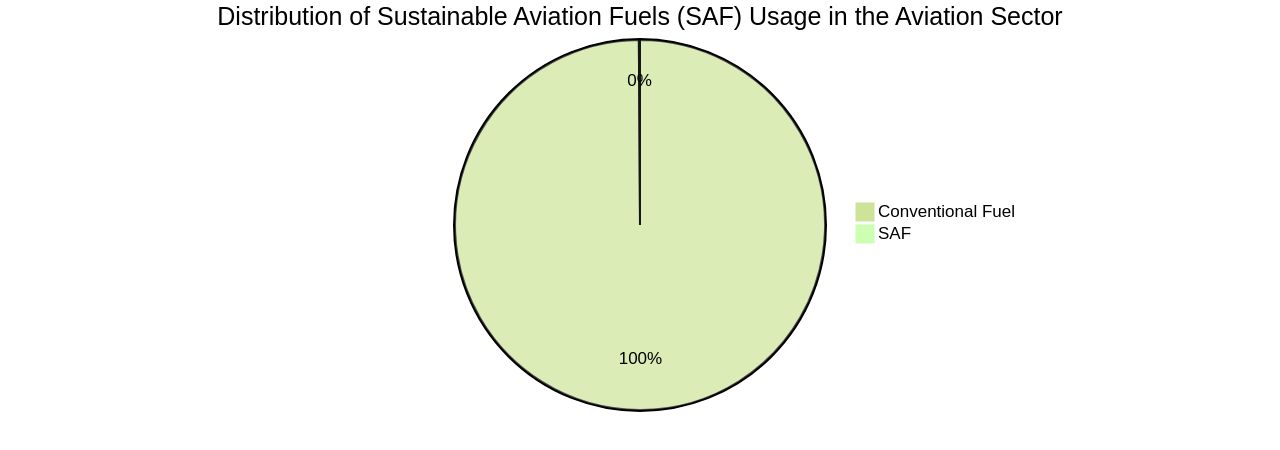

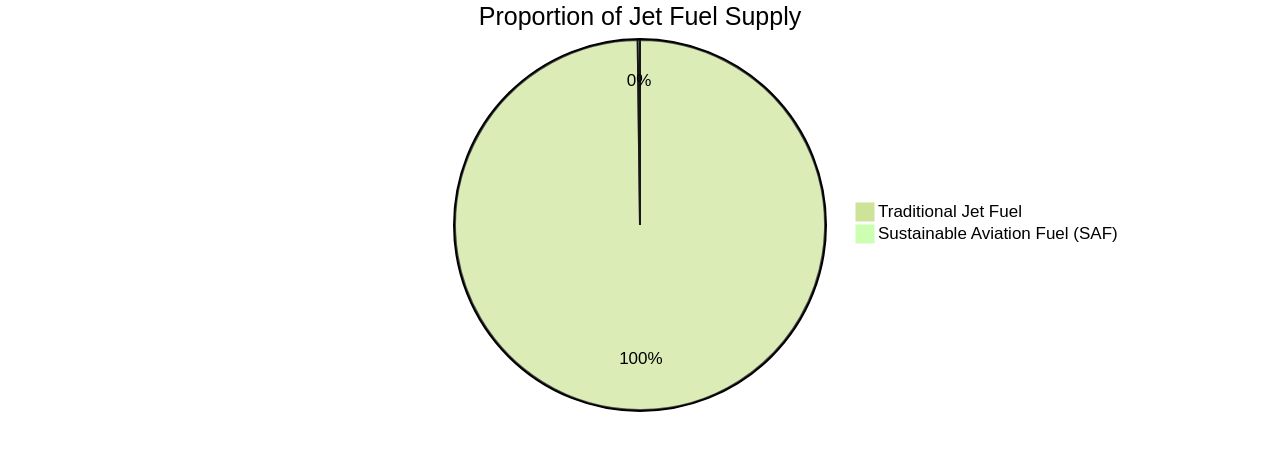

Despite its potential to cut in-flight emissions by 75-95%, SAF constitutes less than 0.1% of all fuel used, primarily due to the inadequate supply and high production costs. To illustrate, the first transatlantic flight fully powered by SAF, operated by Virgin Atlantic, marked a significant milestone.

Yet, the cost of SAF production remains 2-5 times higher than conventional fuel. Abraham Foss, CEO of Avinor, suggests that adopting hydrogen as a key energy carrier has potential in the aviation decarbonization process.

This shift towards sustainable fuels is crucial and necessitates the joint effort of industry stakeholders. While current limitations exist, advancements in SAF technology, such as Unifuel.tech's flexiforming, indicate a positive path towards a more sustainable aviation future. Flexiforming, a technology offered by Unifuel.tech, allows operators to control their decarbonization pace. It can be deployed in an idle hydrotreater or reformer, thereby reducing capital expenditure and carbon intensity. By considering the operator's feeds, target products, and existing facilities, Unifuel.tech can find an optimal application for flexiforming, contributing to the evolution of SAF production. Despite the existing challenges, the advancements in SAF technology such as flexiforming signify a positive trajectory towards a more sustainable future in aviation.

SAF Technology Pathways: Feedstock Supply, Feedstock Conversion, and Fuel Synthesis

The production of sustainable aviation fuel (SAF) is a complex process that involves careful feedstock sourcing, conversion, and fuel synthesis. The selection of appropriate technological pathways at each stage is vital for ensuring efficient and sustainable production.

In a rapidly changing global energy system, SAF emerges as the primary method for reducing emissions in the aviation industry. These fuels are derived from a wide variety of feedstocks, including biomass, waste products, natural oils and fats, and other carbon sources.

The uptake of SAF is accelerating globally, particularly in Europe, the UK, and the USA. However, with global SAF production being limited, demand is anticipated to exceed supply.

This raises concerns about affordability, sustainability, and competition for feedstocks. A recent report by Carbon Direct, in collaboration with Apple, provides a thorough overview of fuel types, carbon intensities, sustainability criteria, and costs associated with SAF.

It also offers insights into potential SAF production pathways and opportunities for reducing greenhouse gas emissions. However, there are solutions like flexiforming offered by Unifuel.tech that can help operators control their decarbonization pace. This technology can be implemented in an idle hydrotreater or reformer, thereby reducing capital expenditure and carbon intensity. Unifuel.tech, a subsidiary of Universal Fuel Technologies, urges interested parties to provide information about their feeds, target products, and existing facilities to find the optimal application for flexiforming. The process from feedstock selection to final fuel synthesis is intricate but crucial in determining the sustainability and efficiency of SAF production.

Factors Influencing SAF Technology Pathway Selection

The selection of Sustainable Aviation Fuel (SAF) technology pathways is a multifaceted process that encompasses various critical elements. These elements range from the sustainability and availability of feedstock to the scalability of production, the efficiency of conversion processes, and the environmental footprint of the chosen pathways.

Collective efforts are being made globally, as exemplified by the Council initiative in Canada that aims to foster collaboration and innovation in the SAF sphere. Such alliances aid in overcoming the economic viability of diverse SAF feedstocks and the competition from other sectors for biofuel feedstock.

The aviation industry contributes significantly to global carbon emissions, a factor that necessitates the development of new greener ways to produce kerosene without resorting to fossil fuels. The global race is on to achieve this objective, with some success in sight.

However, the targeted 100% sustainable hydrocarbon fuel for aircraft remains elusive due to the stringent regulations that govern aviation fuels. Despite the high level of readiness of most relevant technologies for SAF production, the supply of sustainable aviation fuel is currently insufficient.

To bridge this gap, a concerted industry effort is needed, involving each stakeholder playing their designated role as new business archetypes evolve along the SAF value chain. Moreover, the Scenario Planning approach is being utilized in the research and development (R&D) sector to comprehensively evaluate all factors influencing the SAF production goal. This method, unlike the simple Forecast Planning method, allows for the construction of a robust strategic plan for SAF production. The aviation sector's transition to net zero CO2 emissions by 2050 will require significant contributions from SAF, technology, and operational efficiency improvements. The role of SAF varies widely, reflecting the uncertainties regarding potential supportive government action, the level of investments, cost of production, and profit potential, as well as access to feedstocks.

Socio-Technical System (STS) Approach for SAF Pathways Selection and Environmental Impact Assessment

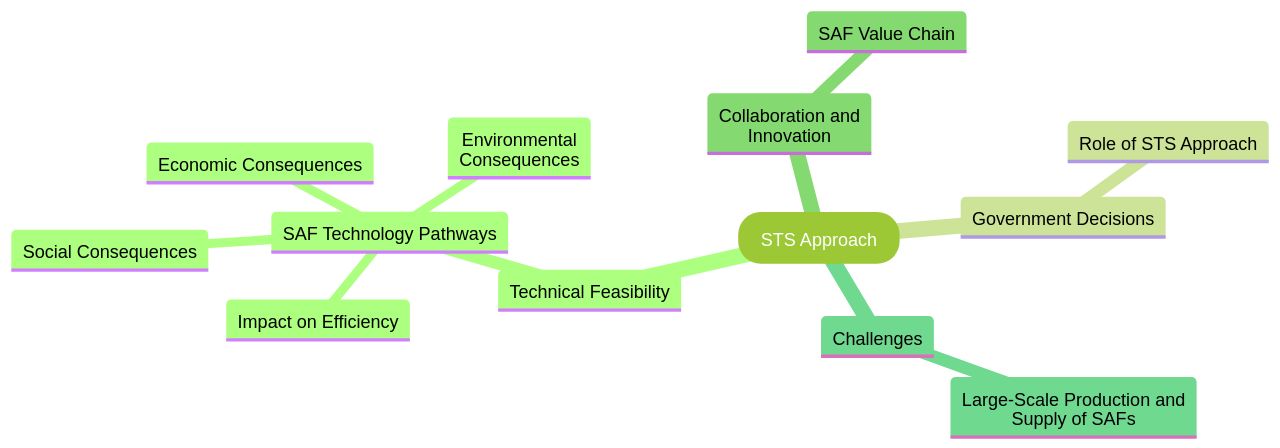

The adoption of the socio-technical system (STS) approach in the selection of Sustainable Aviation Fuel (SAF) technology pathways contributes to a holistic understanding of their impact. It allows for an in-depth evaluation of the technical feasibility and efficiency of these pathways, as well as the broader social, economic, and environmental consequences of their implementation.

This methodology can notably enhance the understanding of the cumulative impacts of several smaller developments, thereby improving the coherence between projects. It also raises awareness about unsustainable development options, preventing costly mistakes and conflicts.

The credibility of government decisions is enhanced using this approach, fostering public trust and support for plan implementation. Furthermore, the STS approach has been instrumental in identifying resilience outcomes for different contexts globally, thereby promoting the adoption of technology and fostering innovation in sectors such as agriculture, training, and finance.

It has been pivotal in developing a framework based on the findings gathered and in sharing knowledge on best practices. In the context of SAF, the STS approach can help in understanding the challenges of large-scale production and the measures needed to increase its supply.

As stated by industry experts, alternative fuels, while currently making up less than 0.2% of the global jet fuel supply, are an attractive solution for the aviation industry. However, expanding the supply of SAFs remains a significant challenge. To overcome this, a platform for the SAF value chain to collaborate and innovate is being established. The ultimate goal is to increase SAF usage and production, thereby reducing greenhouse gas emissions. This initiative is a clear testament to the potential of the STS approach in fostering collaboration and driving innovation in the safe domain.

Selected SAF Technology Pathways in Sweden

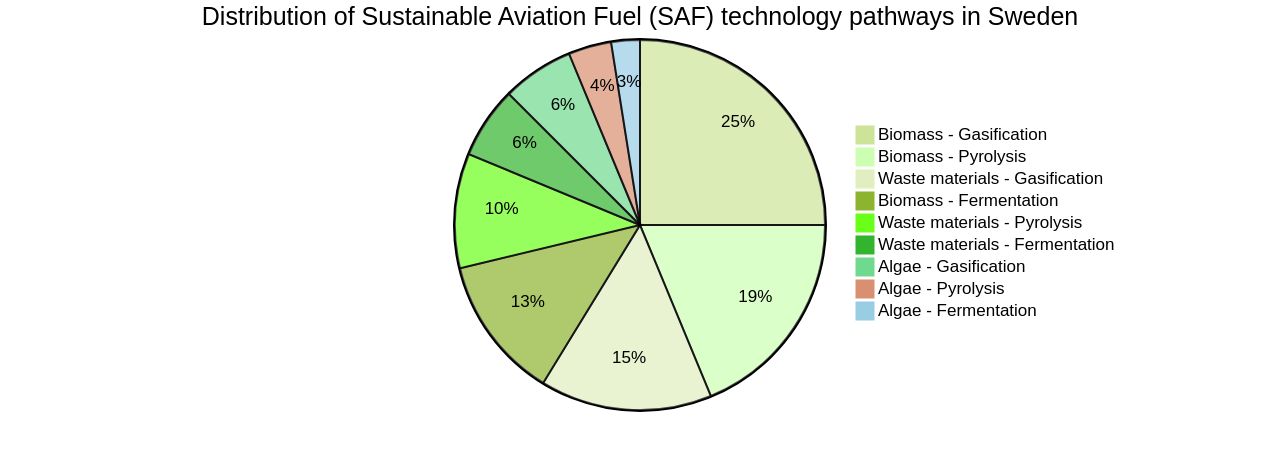

Sweden, a nation renowned for its inventive prowess and capacity to cultivate advanced systemic innovation, is pioneering the exploration of multiple sustainable fuel pathways for aviation (SAF) technology. These pathways utilize diverse feedstocks including biomass, waste materials, and algae to produce sustainable fuel.

Sweden's commitment to harnessing the full potential of sustainable fuel production is reflected in their use of conversion processes such as gasification, pyrolysis, and fermentation. This initiative is in line with the International Civil Aviation Organization's goal of achieving net zero carbon emissions by 2050, considering the aviation sector accounts for two to three percent of global CO2 emissions and is one of the toughest industries to decarbonize.

By producing 80,000 tons per year of sustainable fuel in Sweden, it is estimated that it will meet about 5% of the country's total jet fuel demand today and is projected to meet 20% of the Swedish sustainable fuel requirement by 2030. This ambitious project, while still in its early stages, promises a significant reduction in carbon dioxide emissions, although the exact reduction percentage remains to be determined. Demonstrating a strong commitment to the transition towards a fossil-free future, the SkyFuelH2 facility, anticipated to commence construction in 2025, has the potential to begin supplying the aviation industry with sustainable fuel as early as 2028.

Environmental Impact Assessment of SAF Technology Pathways

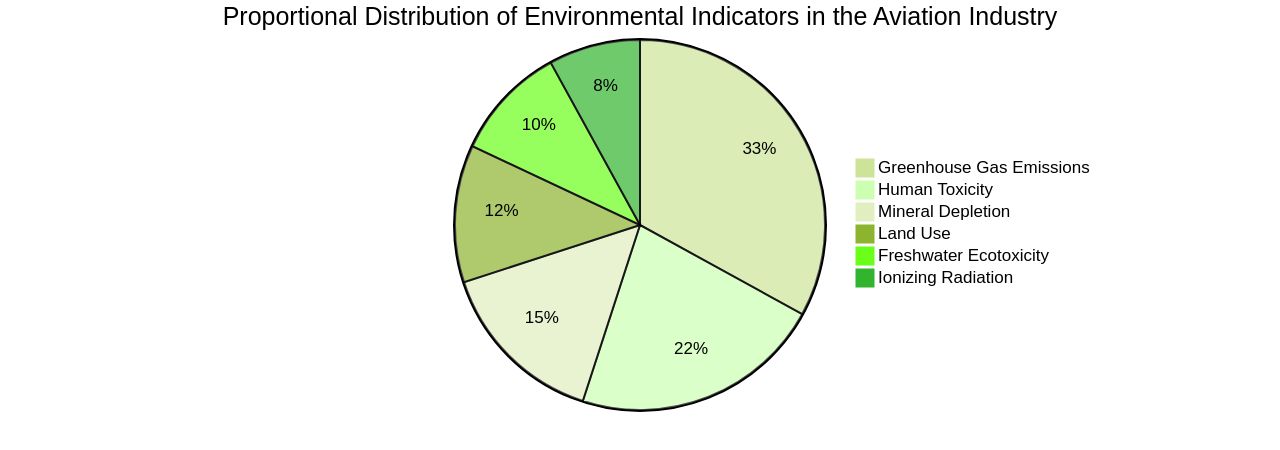

In the quest for sustainable aviation fuel (SAF), a comprehensive environmental impact analysis of potential technology pathways is crucial. This analysis scrutinizes the potential effects of these pathways on several environmental indicators such as greenhouse gas emissions, mineral depletion, ionizing radiation, land use, freshwater ecotoxicity, and human toxicity.

The findings from these assessments are pivotal in guiding the decision-making processes to prioritize pathways with minimal environmental burden. The increasing global uptake of SAF, particularly across Europe, the UK, and the USA, is a testament to the industry's commitment to reducing emissions.

However, substantial challenges remain, including maintaining a consistent feedstock supply and competition for feedstock and biorefinery capacity between renewable diesel and SAF. Therefore, it is crucial to optimize resource allocation.

The aviation industry, which accounts for about 2% of global carbon dioxide emissions, is looking at SAF as a primary means of emissions abatement. However, the actual impact of SAF will depend on a multitude of factors. Therefore, it is essential to understand the full range of fuel types, carbon intensities, sustainability criteria, and costs associated with SAF to make informed decisions. While strides are being made, there is a long way to go, as the US produced enough sustainable fuel to meet less than 0.2 percent of the airline industry’s jet fuel consumption in the last year.

Global Warming Potential of SAF vs. Jet Fuel

The global warming potential (GWP) of Sustainable Aviation Fuel (SAF) and traditional jet fuel underscores the environmental advantages of SAF production. Research indicates that SAF can drastically curtail greenhouse gas emissions compared to its conventional counterpart, resulting in a lower GWP.

Saf's potential in climate change mitigation is underlined by this observation. SAFs, as drop-in solutions, are appealing to the aviation industry because they necessitate minimal modifications to aircraft and airport infrastructure.

SAFs have been the propellant in several test flights over the past year, demonstrating their viability. Despite this, in 2022, they accounted for less than 0.2% of the worldwide jet fuel supply, indicating a significant gap in the supply of climate-friendly alternative fuels.

The expansion of SAF supply is a key challenge to their widespread adoption. The process of producing SAFs ideally absorbs so much carbon that the carbon dioxide emissions from the combustion are essentially nullified. However, the real-world scenario often deviates from this ideal, with the production of alternative fuels sometimes linked to carbon dioxide emissions due to the energy needed for their creation or their impact on carbon-emitting ecosystems. The aviation industry, responsible for 2-3% of global CO2 emissions and one of the hardest to decarbonise, views Safe as a primary tool for decarbonisation. The International Civil Aviation Organization has set a target for the industry to achieve net-zero carbon emissions by 2050, a goal that SAFs can play a significant role in achieving.

Mineral Depletion Potential, Ionizing Radiation, Land Use, Freshwater Ecotoxicity, and Human Toxicity Impact of SAF vs. Jet Fuel

The sustainability of Sustainable Aviation Fuel (SAF) production isn't solely reliant on its Global Warming Potential (GWP). Other environmental indicators, such as mineral depletion potential, ionizing radiation, land use, freshwater ecotoxicity, and human toxicity impacts, are crucial in assessing its viability.

SAF tends to outperform jet fuel in these areas, further cementing its potential as a sustainable fuel choice. However, SAF has yet to be widely available, causing it to be 3 to 4 times more costly than traditional jet fuel.

Currently, a minuscule fraction of the kerosene used by commercial airlines is replaced by SAF. To make a significant dent in aviation's overall carbon emissions, more passengers need to contribute to the procurement of additional SAF, which is then added to the fuel system at various airports.

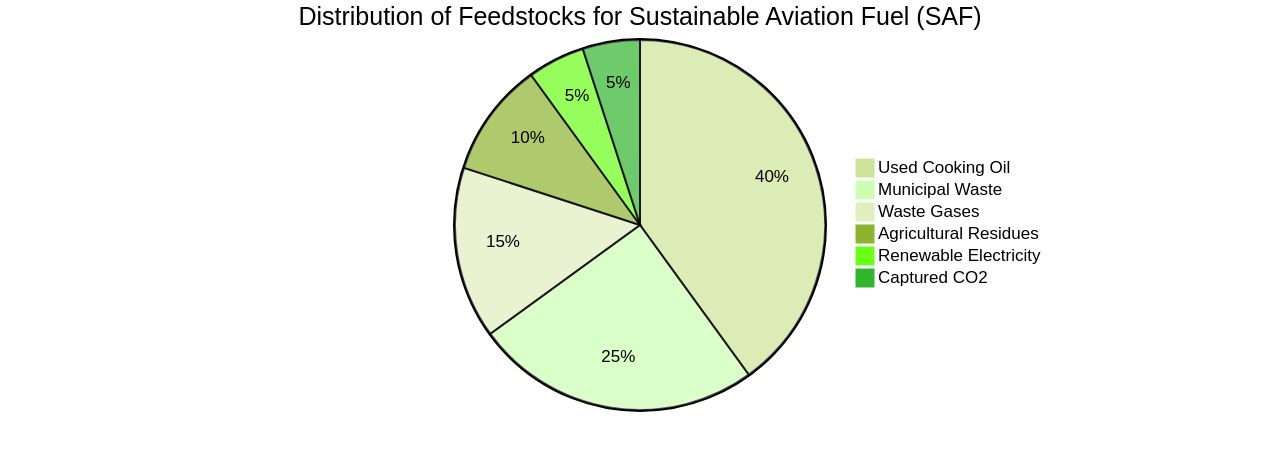

Various feedstocks can be used to produce SAF, including used cooking oil, municipal waste, waste gases, and agricultural residues. Interestingly, it can also be created using renewable electricity and captured atmospheric carbon dioxide.

The majority of SAF currently in use is derived from used cooking oil. The aviation industry, responsible for between two and three percent of global CO2 emissions, is one of the hardest sectors to decarbonize. SAFs are viewed as a primary tool in this endeavor, despite the technology still being in its early stages. The International Civil Aviation Organization aims for the industry to achieve net zero carbon emissions by 2050. Despite alternative fuels being attractive to the aviation industry due to their drop-in solution nature, they constituted less than 0.2% of the global jet fuel supply in 2022. This indicates a significant need for progress in supplying alternative fuels that genuinely benefit the climate.

Impact of Electricity Generation on SAF Environmental Burden

The aviation industry, accounting for approximately 2% of global carbon dioxide emissions and about 4% of all human-induced global warming, is keen on reducing its environmental footprint. They believe the answer lies in sustainable aviation fuels (SAF), which are derived from a variety of feedstocks like biomass, waste products, natural oils, fats, other carbon sources, and hydrogen.

These fuels can be utilized by existing aircraft, aiding the sector in achieving its net-zero carbon dioxide emissions target by 2050. However, the actual environmental impact of these alternative fuels depends on numerous factors, including their production process.

For instance, the creation of SAF requires substantial electricity, and the source of this power - whether renewable or not - significantly influences the overall environmental burden. Sweden, where renewable energy sources are abundant, leverages clean energy for SAF production, thereby enhancing its sustainability.

Moreover, the life cycle assessment of an existing, two-seater, all-electric aircraft reveals that after just one quarter of the aircraft's expected lifespan, the climate impact is lower than that of a fossil fuel-based aircraft, provided green electricity is used. However, this does come with the downside of increased mineral resource scarcity. Despite these challenges, the global uptake of SAF, particularly across Europe, the UK, and the USA, is increasing. Nevertheless, with demand expected to surpass supply due to limited global production, key concerns around affordability, sustainability, and competition for feedstocks remain.

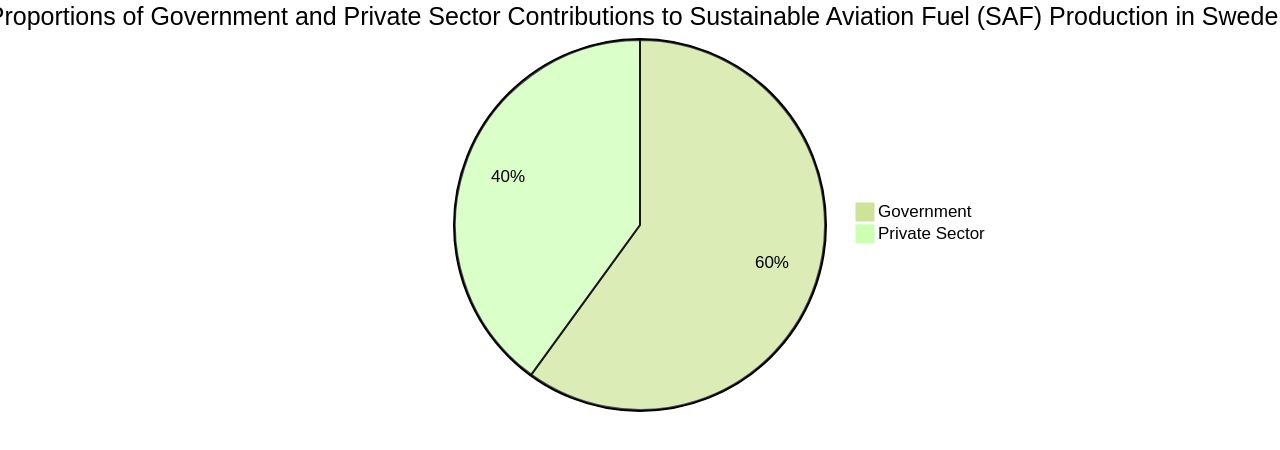

Policy and Investment Decision Making for SAF Production in Sweden

The push for sustainable aviation fuel (SAF) production in Sweden is being fuelled by a mix of government incentives and private sector investments. The government's role is pivotal in shaping an environment conducive for SAF production through the implementation of tax breaks, grants, and regulations that promote SAF usage. Simultaneously, the private sector has been making significant contributions to the growth of the SAF industry through investments in research, development, and infrastructure.

These investments are vital for the evolution of the industry, keeping in mind that the technology behind Safe is still in its infancy stage, even though they are considered the primary tool for decarbonising the aviation sector, which contributes to 2-3% of global CO2 emissions. The International Civil Aviation Organization's goal of achieving net zero carbon emissions by 2050, further underscores the importance of SAFs. Sweden's efforts in this regard are also aligned with the European Union's ReFuelEU Aviation initiative, part of the 'Fit for 55' package, aimed at reducing net greenhouse gas emissions by at least 55% by 2030 as compared to 1990 levels.

Private sector entities like Swedavia and Avinor are also playing a significant role in this transition. Swedavia's ambition is to create climate-smart airports and is driving towards a future of sustainable air transport, with plans to phase out fossil fuels. Similarly, Avinor's focus is on hydrogen as a key energy carrier in future fossil-free aviation, highlighting the collaborative efforts between Norway and Sweden in this area.

Conclusion

In conclusion, the article highlights the challenges and advancements in Sustainable Aviation Fuels (SAF) production. Sweden is making progress in SAF production, aiming to meet 20% of the country's SAF requirement by 2030.

Advancements like Unifuel.tech's flexiforming show promise in reducing costs and carbon intensity. The selection of appropriate technological pathways for SAF production is vital for efficiency and sustainability.

The socio-technical system (STS) approach provides a holistic understanding of SAF technology pathways' feasibility and broader consequences. Environmental impact assessments play a crucial role in prioritizing pathways with minimal environmental burden.

Policy incentives and private sector investments drive SAF production in Sweden. Government support creates an enabling environment, while private sector contributions fuel research and development. In summary, collaboration among industry stakeholders and policy support are critical for widespread adoption of SAF as a key solution for decarbonizing aviation. With advancements in technology and continued efforts towards sustainability, SAF has the potential to revolutionize aviation fuel production.

Join Universal Fuel Technologies today and be a part of the revolution in aviation fuel production!