Introduction

The intricacies of aviation economics are largely driven by the cost of airplane fuel per gallon. A comprehensive comprehension of the components of fuel costs is imperative for airlines and other aviation operators, enabling the optimization of plant operations and facilitating informed decision-making to strike a balance between costs and efficiency.

In this article, we will delve into the factors influencing airplane fuel costs per gallon, including crude oil prices, refining and distribution costs, and the broader economic and regulatory environment. We will also explore the challenges and potential solutions in the production of sustainable aviation fuel. Join us as we navigate through the complex world of airplane fuel cost analysis and its implications for the renewable fuels industry.

Understanding Airplane Fuel Cost per Gallon

The intricacies of aviation economics are largely driven by the cost of airplane fuel per gallon. A comprehensive comprehension of the components of fuel costs is imperative for airlines and other aviation operators, enabling the optimization of plant operations and facilitating informed decision-making to strike a balance between costs and efficiency.

A collaborative research by the University of California, Irvine, University of Southern California, and University of California, Los Angeles, sheds light on the environmental and financial impacts of airline fuel consumption. The research accentuates the need for airlines to make cost-minimizing decisions in response to fluctuating fuel prices.

Airlines can adjust their durable aircraft capital stock's utilization and composition to conserve fuel and subsequently lower emissions. The annual synthetic aviation fuel (SAF) production of 80,000 tons meets approximately 5% of Sweden's total jet fuel demand, signifying a promising stride towards carbon dioxide emissions reduction.

However, the exact reduction percentage remains undetermined. Unifuel.tech's technology, flexiforming, offers a solution to this problem.

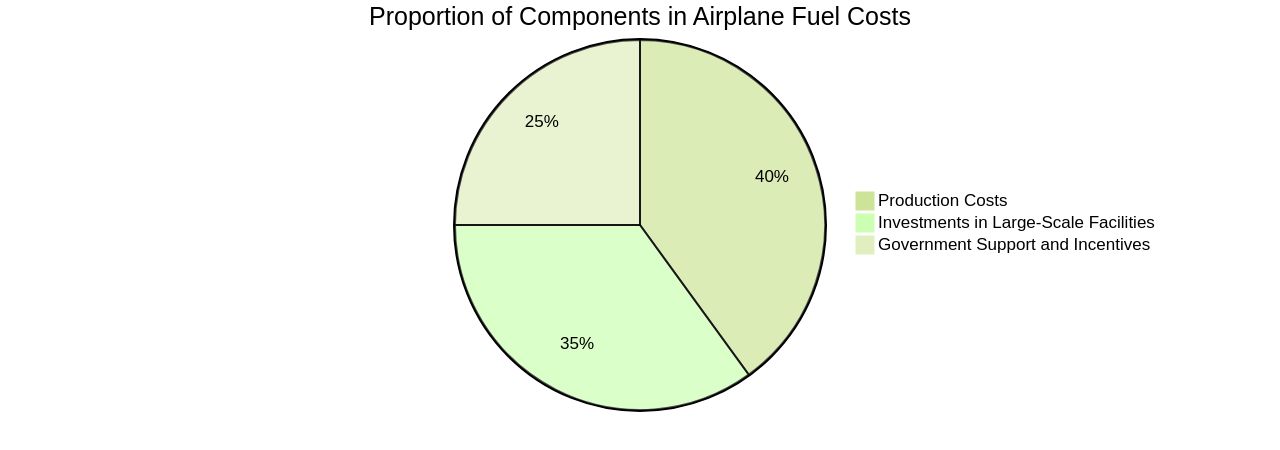

It provides the operator with the flexibility to determine their decarbonization rate. This technology can be deployed in an idle hydrotreater or reformer, reducing capital expenditure and carbon intensity. To find the optimal application for flexiforming, Unifuel.tech gathers information about the operator's feeds, target products, and existing facilities. The cost of SAF production currently stands between two to four times that of conventional fuel. Until production costs decrease, government support and incentives will be required. The main hurdle on the production side is mobilizing investments to construct new large-scale facilities that will enhance SAF production capacity to meet the additional demand and lower costs.

Fuel Price Components

Airplane fuel costs per gallon are influenced by a multitude of factors. The cost of aircraft fuel is one of the key elements affecting airlines' operating expenses.

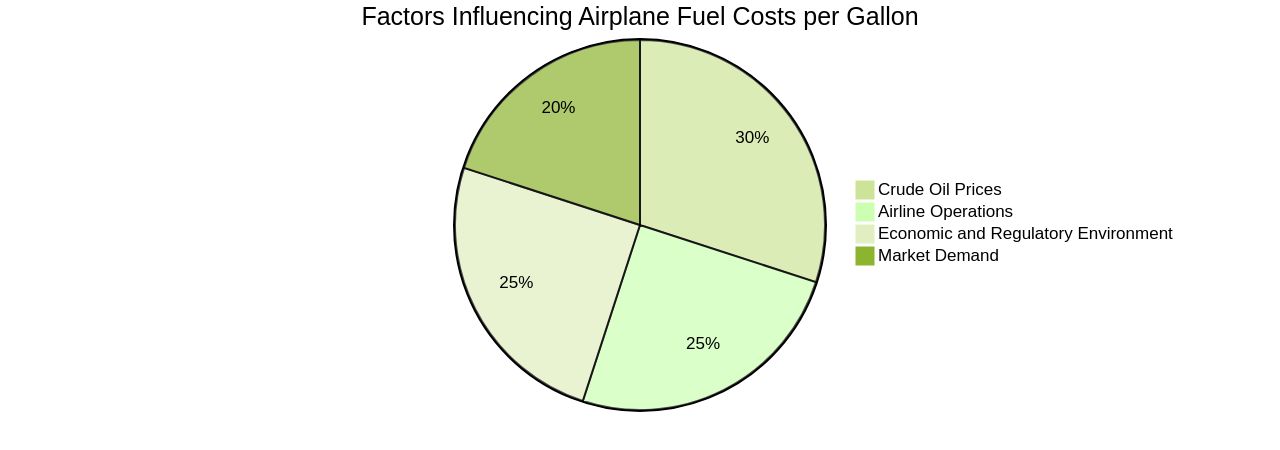

The recent spike in jet fuel prices, which soared by nearly 23% in less than a month, as reported by the International Air Transport Association (IATA) and S&P Global Commodity Insights, illustrates this impact. Fuel costs are not only influenced by crude oil prices but also by market dynamics such as passenger demand, particularly in high-growth regions like Asia Pacific.

Furthermore, changes in operations aimed at conserving fuel can significantly affect the cost equation. Airlines' strategic decisions on the use of their fleet, for instance, can lead to lower emissions and fuel consumption, thereby reducing costs.

However, the high cost associated with aircraft fuels can be a barrier to market progress. This is especially true in the context of bio-jet fuel, a type of fuel that aims to reduce pollution levels and make air travel more sustainable. The COVID-19 pandemic has further complicated the picture, with travel restrictions leading to a reduction in passenger numbers and, consequently, a drop in demand for air travel. This has resulted in fluctuations in fuel prices due to a lack of supply. In conclusion, understanding the cost of airplane fuel per gallon requires a comprehensive analysis of various factors, including crude oil prices, market demand, airline operations, and the broader economic and regulatory environment.

Crude Oil Prices

The cost of aviation fuel is intrinsically tied to the price of crude oil, its primary raw material. Any fluctuations in crude oil prices can directly influence the cost per gallon of jet fuel, compelling airlines to continually monitor and analyze these prices. This vigilance allows them to anticipate potential shifts in fuel costs and adjust their operations to maintain cost-efficiency.

A surge in crude oil prices, as seen when Brent International closed at $90.04 per barrel, can significantly impact fuel costs. This was also the case when West Texas Intermediate futures settled at $86.69 per barrel. These price hikes were influenced by decisions like Saudi Arabia extending its unilateral production cuts until December, and Russia reducing its exports by 300,000 barrels per day through year-end.

Consequently, airlines may need to reconsider their fuel hedging strategies, especially with the recent rise in jet fuel prices from around $2.80 to $3.05 a gallon. This increase is not only due to a rise in oil prices but also due to refinery disruptions in various parts of the world. Although airlines may consider passing on these costs to consumers through increased flight prices, the recent return of passenger numbers to near pre-pandemic levels provides some optimism for the industry.

However, the high cost associated with aircraft fuels could potentially hinder market progress. Lastly, the growth of global petroleum consumption, driven by economic growth and a return to pre-pandemic travel patterns, especially for international flights, is worth noting. The forecasted increase in global petroleum consumption is 1.4 million b/d in 2024 and 1.2 million b/d in 2025.

Refining and Distribution Costs

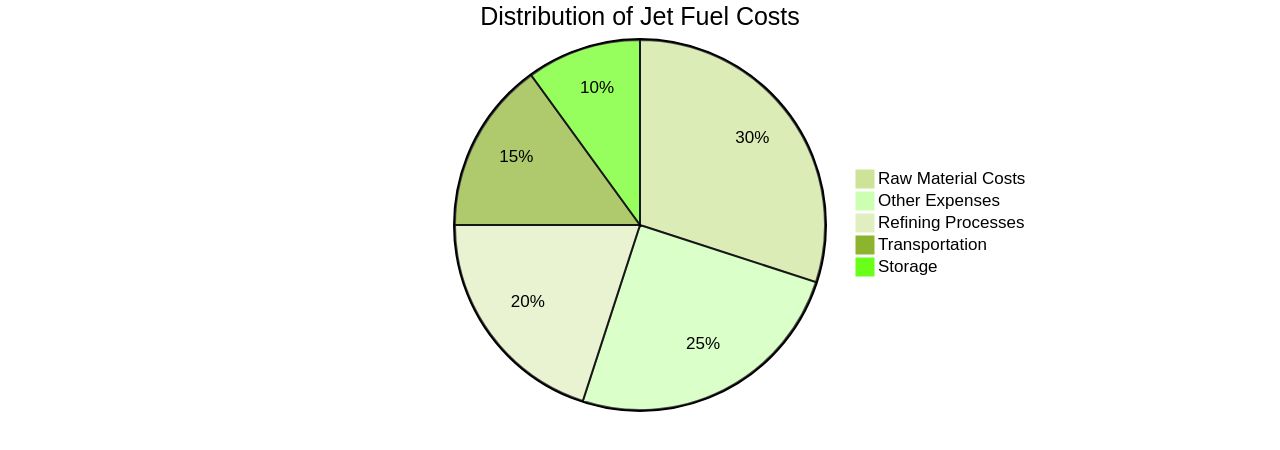

The cost of jet fuel per gallon is not solely dependent on the raw material itself, but also involves additional expenses related to refining processes, transportation, and storage. These costs are influenced by several factors, including the location of refineries, the efficiency of distribution networks, and market conditions.

Airlines are constantly seeking ways to minimize costs and reduce environmental impact. One approach is to adjust operations to conserve fuel, which can lead to lower emissions.

However, the capital structure of the airline industry, predominantly composed of long-lived, durable aircraft, makes this a challenging task. Moreover, the refining industry has found it more cost-effective to increase the capacity of existing refineries, rather than constructing new facilities.

However, this isn't always a viable option, particularly for smaller refineries lacking economies of scale. This has led to the closure of less competitive refineries and a pivot towards renewable fuels production.

Alternative fuels, capable of blending with or replacing petroleum-based kerosene, are attractive but present their own challenges. Current supplies are scarce and cost 2-5 times more than conventional jet fuel, limiting their widespread adoption. The U.S. is striving to improve this, aiming to produce enough sustainable fuel to meet 100% of the airline industry’s jet fuel consumption by 2050. To achieve this, refiners are exploring innovative production methods, with companies like Twelve aiming to scale production to 1 million gallons of fuel a year. However, this still represents a small fraction of the industry's needs, with global airlines consuming 95 billion gallons of jet fuel in 2019. The challenge, therefore, lies in scaling the sustainable aviation fuel industry while overcoming the associated cost, supply, and technological challenges.

Conclusion

In conclusion, understanding the cost of airplane fuel per gallon requires a comprehensive analysis of various factors. These factors include crude oil prices, market demand, airline operations, and the broader economic and regulatory environment.

Fluctuations in crude oil prices directly influence the cost per gallon of jet fuel, compelling airlines to monitor and analyze these prices to maintain cost-efficiency. The refining and distribution costs associated with jet fuel production also impact its overall price, with challenges arising from the capital structure of the airline industry and the need for innovative production methods.

The high cost associated with aircraft fuels, especially in the context of sustainable aviation fuel (SAF), poses a barrier to market progress. Government support and incentives are crucial until production costs decrease.

The growth of global petroleum consumption, driven by economic growth and a return to pre-pandemic travel patterns, further emphasizes the importance of finding sustainable fuel solutions. Efforts are being made to scale up SAF production and meet industry demands. However, current supplies are limited and more expensive than conventional jet fuel. Refiners are exploring innovative production methods, but scaling the sustainable aviation fuel industry remains a challenge due to cost, supply, and technological hurdles. Overall, it is essential for airlines and aviation operators to navigate through these complexities in order to optimize their operations, strike a balance between costs and efficiency, and contribute to reducing carbon emissions in the renewable fuels industry.