Introduction

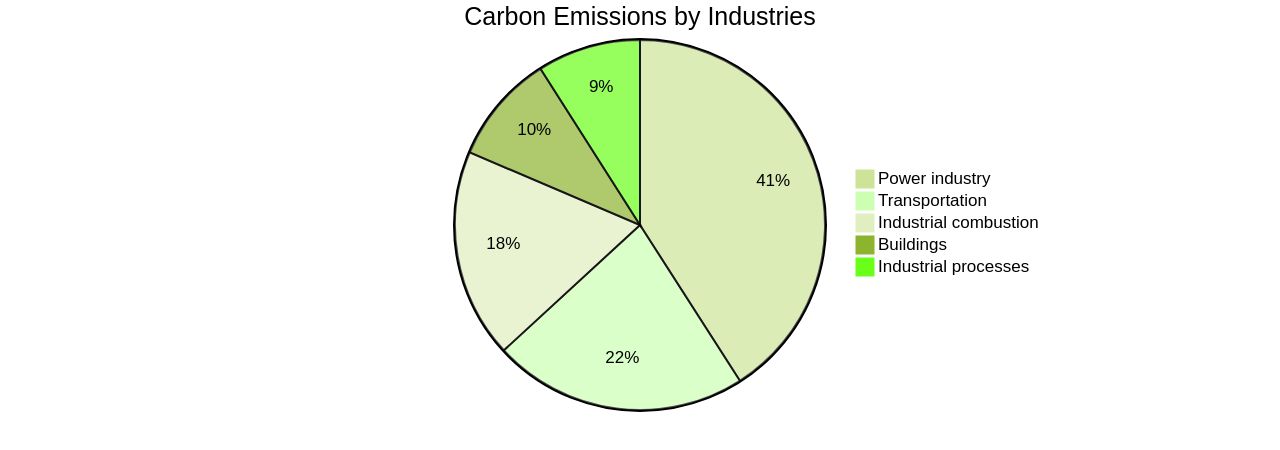

The imperative of decarbonizing the aviation industry, which contributes 2-3% of global CO2 emissions, is met with the promise of Sustainable Aviation Fuel (SAF). Derived from renewable resources, SAF has the potential to reduce CO2 emissions by up to 80% compared to conventional jet fuel.

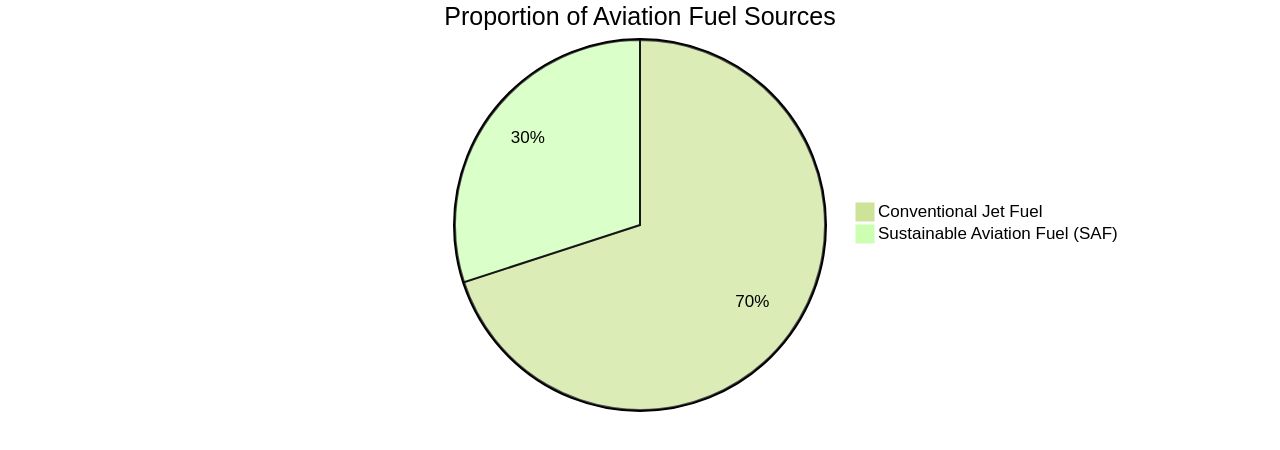

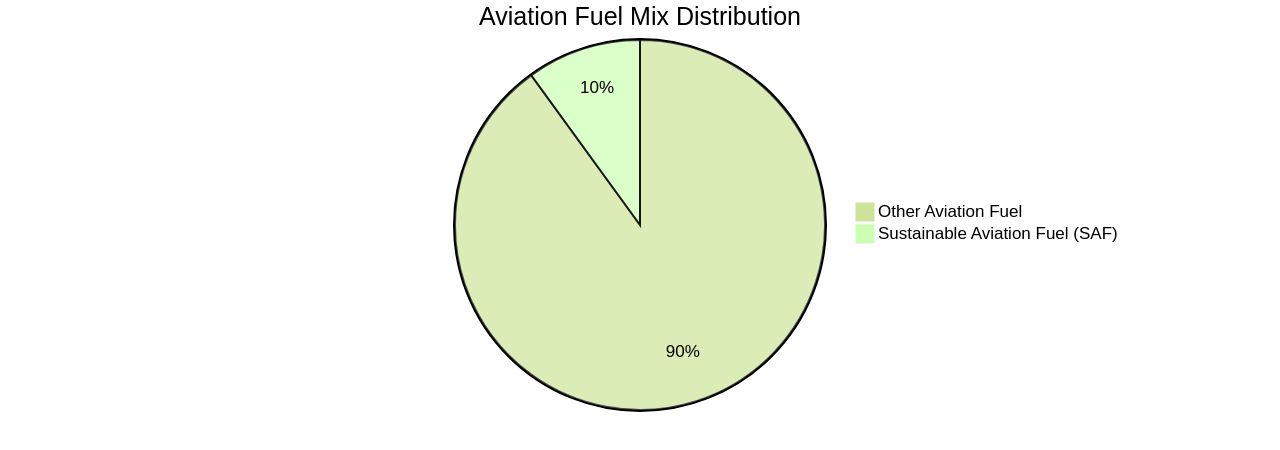

However, the nascent SAF industry faces challenges such as high production costs and limited supply, which currently restricts SAF to less than 0.1% of global aviation fuel use. Despite these hurdles, the industry could generate up to 153,000 jobs in the US and support an additional 250,000 in the broader economy at peak production.

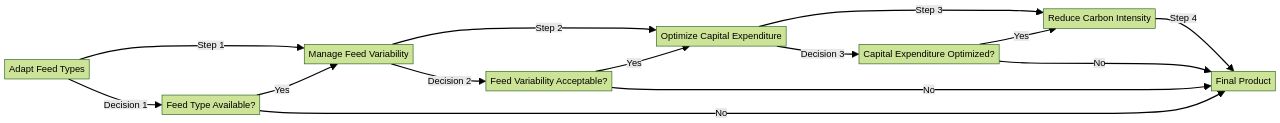

In this dynamic landscape, Unifuel.tech's Flexiforming technology stands out as a potential catalyst for change. Flexiforming allows plant operators to adjust feed types and proportions, facilitating the management of feed variability and supporting consistent fuel production. The technology can be retrofitted into existing facilities, such as idle hydrotreaters or reformers, which could lead to reductions in both capital expenditure and carbon intensity. With a promise of a swift response time to inquiries, Unifuel.tech positions itself as an agile partner in the push towards a more sustainable aviation sector.

Background and Context

The imperative of decarbonizing the aviation industry, which contributes 2-3% of global CO2 emissions, is met with the promise of Sustainable Aviation Fuel (SAF). Derived from renewable resources, SAF has the potential to reduce CO2 emissions by up to 80% compared to conventional jet fuel.

However, the nascent SAF industry faces challenges such as high production costs and limited supply, which currently restricts SAF to less than 0.1% of global aviation fuel use. Despite these hurdles, the industry could generate up to 153,000 jobs in the US and support an additional 250,000 in the broader economy at peak production.

The advancement of SAF technology and investment is essential for meeting the International Civil Aviation Organization's goal of net-zero carbon emissions by 2050. In this dynamic landscape, Unifuel.tech's Flexiforming technology stands out as a potential catalyst for change.

Flexiforming allows plant operators to adjust feed types and proportions, facilitating the management of feed variability and supporting consistent fuel production. The technology can be retrofitted into existing facilities, such as idle hydrotreaters or reformers, which could lead to reductions in both capital expenditure and carbon intensity. With a promise of a swift response time to inquiries, Unifuel. Tech positions itself as an agile partner in the push towards a more sustainable aviation sector.

Factors Affecting SAF Price per Gallon

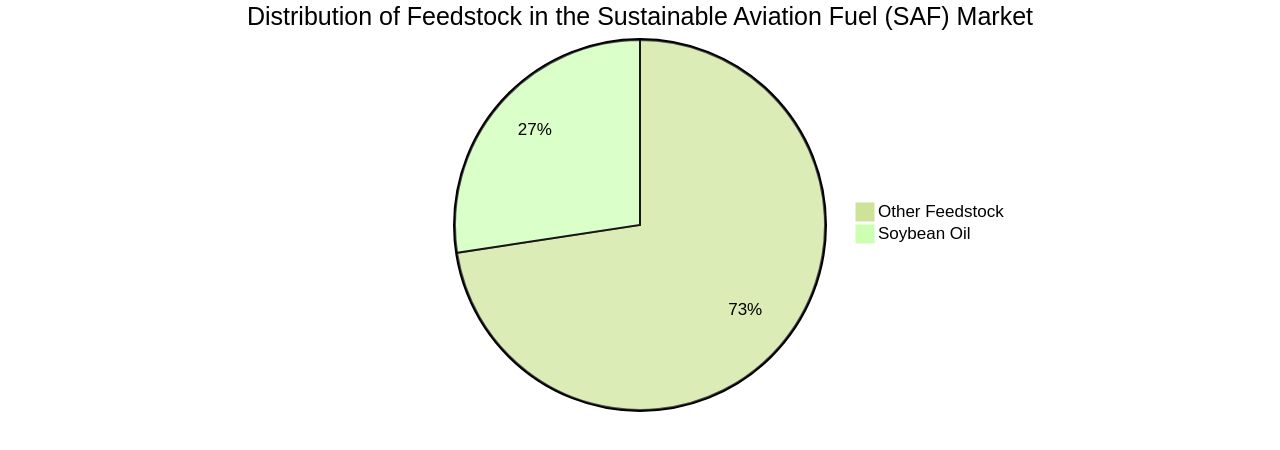

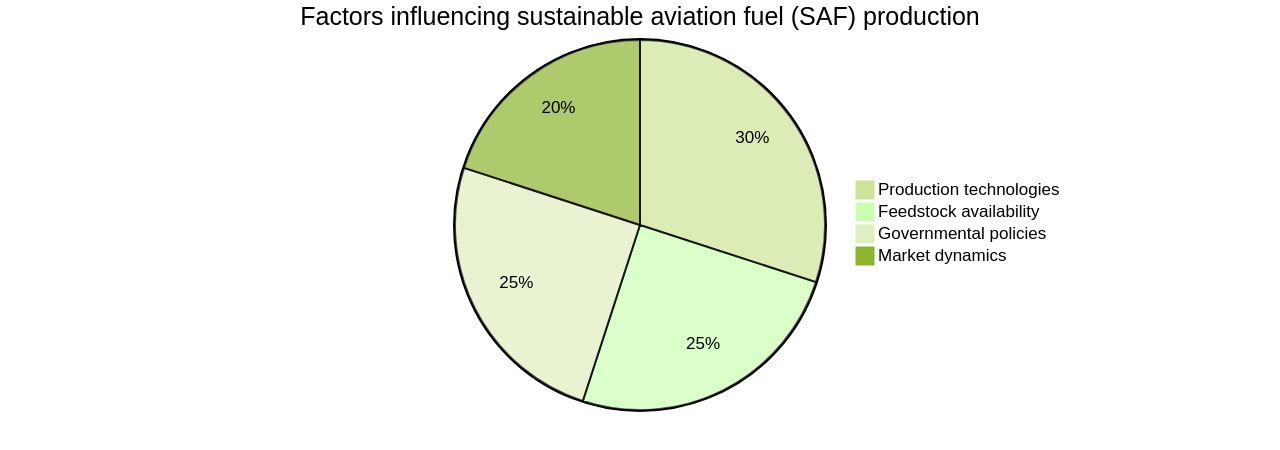

Navigating the complexities of sustainable aviation fuel (SAF) economics requires a granular understanding of various elements that contribute to its production and market viability. Feedstock availability, a critical factor, is highlighted by the burgeoning use of soybean oil, which now commands a substantial 27.4% market share—a significant increase of 18.2 percentage points over two years.

This underscores the importance of selecting the right feedstock in a rapidly evolving market. Technological advancements are imperative in this landscape, where efficiency gains are directly proportional to cost reductions.

As production scales up, economies of scale become increasingly influential, allowing larger operations to produce SAF more cost-effectively. In this regard, Unifuel.tech's flexiforming solution offers a strategic advantage.

By enabling operators to retrofit idle hydrotreaters or reformers, the technology facilitates a tailored approach to decarbonization, optimizing feedstock use while minimizing both capital expenditure and carbon intensity. Policy frameworks and incentives are also pivotal in shaping the SAF market.

For example, regulations that mandate emissions-reducing additives can inadvertently raise production costs. The strategic location of production facilities in relation to feedstock sources is another determinant of profitability, with those situated near abundant sources of soybean or used cooking oil gaining a competitive advantage. Moreover, the energy and agricultural sectors' broader trends, particularly the shift toward cleaner fuel alternatives, exert a significant influence on SAF pricing. Amidst these considerations, Unifuel.tech's commitment to responsive customer service, ensuring a 24-hour response time, facilitates swift implementation of flex forming technology, tailored to the unique specifications of an operator's feeds and target products. This positions Unifuel. Tech as a key player in the transition to more sustainable fuel production practices.

Feedstock Availability and Cost

As the Sustainable Aviation Fuel (SAF) market rapidly evolves, the industry is seeking innovative approaches to manage feedstock cost and availability, which are critical factors in SAF pricing. While traditional feedstocks like used cooking oil and animal fats are subject to market volatility, alternative sources such as fast-growing eucalyptus in the Southern U.S. are gaining attention for their potential to provide low-cost biomass.

The USDA's long-term projections indicate a significant shift towards biofuel production, with an estimated 49 percent of soybean oil production dedicated to biofuels by the year beginning October 1, 2024. Refining industry trends suggest a preference for expanding capacity within existing facilities rather than constructing new ones, with larger refineries benefiting from economies of scale.

This strategic shift has led to an increase in U.S. refinery capacity over time, even as the number of operational refineries declines. Owners of less competitive refineries are exploring conversions to renewable fuel production in response to the growing demand for renewable fuels, driven by environmental concerns and supportive government policies.

The aviation sector's quest for sustainability is exemplified by recent advancements in SAF technology, including the development of a process for bio-based aromatics, allowing for greater volumes of SAF to be used in aircraft. This innovation has enabled historic milestones such as the first 100% SAF Transatlantic crossing by a commercial airline. Despite these breakthroughs, SAF still represents a small fraction of global aviation fuel. Industry experts like Virgin's Weiss emphasize the need for increased investment and regulatory support to scale SAF production sustainably, without overtaxing agricultural resources and ecosystems.

Production Technology

Unifuel.tech's Flexiforming technology stands at the forefront of Sustainable Aviation Fuel (SAF) production, offering a transformative approach to feedstock management and fuel synthesis. Its capacity for flexibility in feedstock types and ratios ensures that operators can dynamically adjust production in response to market changes, a critical capability given the variable nature of feedstock availability due to geographical and climatic influences. The technology's adeptness at processing a variety of feedstocks, from corn to used cooking oil, is particularly beneficial in regions such as the United States, which rely on these materials for biofuel production.

The collaboration between ORLEN and Yokogawa exemplifies the nuanced approach to synthetic fuel production, integrating renewable hydrogen with captured industrial carbon dioxide, thus aligning with emission reduction goals. Flexiforming also facilitates the inclusion of bio-based aromatics into SAF, enabling the potential use of 100% SAF in aviation and surpassing the constraints of conventional jet fuel blends. These innovative strides are already in motion, as evidenced by IðunnH2's commitment to produce e-kerosene by 2028 and Icelandair's agreement to procure this fuel, representing significant progress towards the aviation industry's decarbonization objectives.

With the transport sector as a major CO2 emitter, the application of Flexiforming technology and synthetic fuel production are concrete measures aimed at meeting the International Civil Aviation Organization's 2050 net-zero carbon emissions target. Unifuel.tech's rapid response to inquiries, within 24 hours, and their request for specific information on feeds, target products, and existing facilities, underscore their commitment to customizing Flexiforming applications to meet operators' decarbonization goals. The deployment of this technology in idle hydrotreaters or reformers presents a cost-effective and carbon-efficient solution, substantiating Unifuel.tech's role in driving the transition to a more sustainable aviation sector.

Economies of Scale

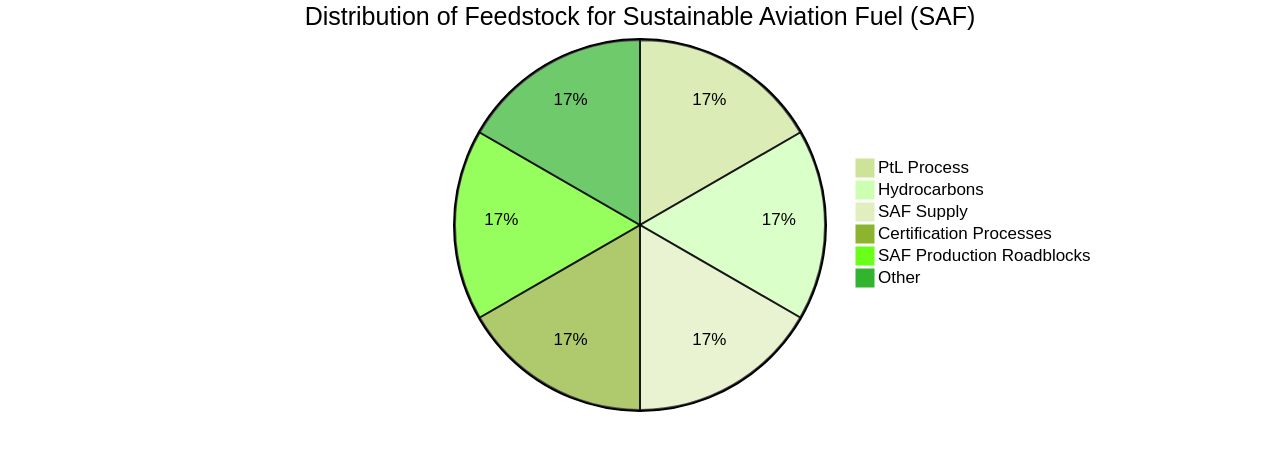

Sustainable Aviation Fuel (SAF) remains a cornerstone in the aviation industry's efforts to curtail its carbon footprint. Although SAF has the potential to drastically reduce carbon emissions, it is currently a small portion of the total aviation fuel mix. The sector's commitment to achieving net-zero emissions by 2050 is challenged by the emerging state of SAF technology and the elevated costs tied to its production.

A constrained SAF supply, with production in its early stages and limited to a few producers, further complicates the situation. In Sweden, the ambition to produce 80,000 tons of SAF annually underscores the market's potential for expansion. Nevertheless, the Power-to-Liquid (PtL) process, capable of cutting emissions by up to 94%, is underutilized due to production hurdles.

The quest for supply is also hindered by the unsustainable nature of certain biomass feedstocks, which can have an environmental impact comparable to fossil fuels and create competition for food resources. Addressing these challenges, Unifuel.tech presents flexiforming technology, enabling operators to tailor their decarbonization trajectory. This innovative approach can be integrated into dormant hydrotreaters or reformers, thus minimizing capital expenses and reducing carbon intensity.

Unifuel.tech's commitment to rapid response times and personalized application of flexiforming technology based on clients' feedstock, target outputs, and existing infrastructure, paves the way for more efficient and scalable SAF production. This technology empowers small to medium-sized refineries to pivot towards renewable fuel production, potentially benefiting from the flexiforming solution without the need for extensive capital investment. Through such technological advancements and industry collaboration, the aviation sector can progress towards a more sustainable mode of operation.

Government Policies and Incentives

The Sustainable Aviation Fuel (SAF) domain is evolving rapidly, with technologies like Unifuel.tech's Flexiforming playing a pivotal role. Flexiforming is a cutting-edge process that enables plant operators to adapt feed types and proportions to manage feed variability, a crucial aspect in the face of fluctuating fuel prices and market dynamics.

This technology allows for a tailored approach to decarbonization, facilitating the use of idle hydrotreaters or reformers, thus optimizing capital expenditure and reducing carbon intensity. Universal Fuel Technologies, the innovator behind Unifuel.tech, ensures that, by providing critical information about an operator's feeds, target products, and existing facilities, an optimal application for Flexiforming can be determined, aligning with the industry's push towards carbon neutrality.

The proactive response time promised by Universal Fuel Technologies—within 24 hours to inquiries—reflects the industry’s urgency in adopting SAF and scaling up production to meet environmental targets. The integration of Flexiforming into the SAF value chain exemplifies the commitment to innovation and sustainability, addressing the need for environmentally conscious production techniques. With the Financing Our Energy Future Act in place, the financial accessibility for renewable projects like those incorporating Flexiforming technology is greatly enhanced, potentially revolutionizing SAF production and utilization. This aligns with the broader environmental objectives and supports the aviation industry's journey towards the International Civil Aviation Organization's 2050 net-zero emissions target.

Case Study Analysis

Sustainable aviation fuel (SAF) has emerged as a pivotal tool in the aviation sector's quest to reduce carbon emissions, with the industry accounting for approximately 2-3% of global CO2 emissions. The scale of SAF production is influenced by a myriad of factors including feedstock availability, production technologies, and market dynamics, all under the watchful eye of governmental policies.

Despite being in its infancy and facing high costs, the potential of SAF cannot be overstated, with the capacity to achieve up to 100% reduction in emissions compared to conventional jet fuels. In Sweden, for instance, the planned annual SAF output is poised to satisfy a significant portion of the country's jet fuel demand by 2030, highlighting the role of SAF in meeting future fuel requirements.

Meanwhile, Australia's SAF Roadmap, developed in collaboration with Boeing, underscores the necessity for new biomass sources to fuel the industry, emphasizing the co-benefits and trade-offs of different feedstocks. Yet, the high expense of SAF—currently three to four times more costly than kerosene—poses a significant challenge.

This cost disparity is exacerbated by the limited scale of current SAF production, with a handful of producers worldwide. As a result, the contribution of SAF to aviation's overall carbon emissions remains minimal.

The International Civil Aviation Organization has set ambitious goals for the sector to achieve net-zero carbon emissions by 2050. Realizing this vision will require concerted efforts to foster innovation, scale production, and enhance the use of SAF globally.

Stakeholders are urged to join forces to create solutions that will enable the widespread adoption of SAF, as echoed by the Council's initiative to establish a platform for the SAF value chain collaboration. Universal Fuel Technologies, through Unifuel.tech, presents an innovative approach with their flexiforming technology, which facilitates the adjustment of decarbonization pace for operators. This solution can be integrated into existing idle hydrotreaters or reformers, optimizing the use of infrastructure and reducing both capital expenditure and carbon intensity. With the promise of a rapid 24-hour response to inquiries, Unifuel. Tech positions itself as a responsive partner in the SAF industry, eager to collaborate on customizing flexiforming applications that align with specific feedstock characteristics and production goals. Ultimately, the journey to economically viable SAF production will be a collaborative endeavor, demanding a deep understanding of the chemistry of fuels and combustion, and the interplay between technological advancements, policy frameworks, and market forces.

Data and Methodology

In the quest to align with global carbon emission reduction targets, PT Pertamina has undertaken a robust analysis of its marketing strategy for sustainable aviation fuel (SAF). The approach adopted a qualitative design research methodology supplemented by case studies, drawing from both primary sources, including interviews with industry experts, and secondary sources such as corporate data and sector reports.

This dual-pronged strategy enabled a comprehensive exploration of internal and external business environments through SWOT and PESTEL analyses, among others. The study recognized the pressing need for SAF in the aviation sector, especially given that current aircraft models lack the ability to switch to electrification or alternative fuels like green hydrogen in the short term.

With the industry contributing approximately 2% to global carbon emissions and projected growth, the push for SAF becomes even more critical. The research underscored the significant reductions in carbon dioxide emissions achievable with electrofuels compared to conventional fossil fuels, although precise quantification of these reductions remains a challenge.

Furthermore, the economic feasibility of SAF production was scrutinized, revealing that augmenting existing refinery capacities could be more cost-efficient than new constructions, particularly for smaller-scale operations. The study incorporated industry data to model economic impacts on SAF pricing, essential for assessing the viability of large-scale production against the backdrop of increased global demand. The findings suggest that the successful adoption of SAF hinges on a nuanced interplay of environmental imperatives, market forces, and strategic business planning, coupled with supportive policies and regulations to facilitate the transition to sustainable fuels. Notably, the industry's goal to achieve carbon neutrality by 2050 positions SAF as a critical component, albeit with challenges related to its current scarcity and high cost.

Findings

Unifuel. Tech is revolutionizing the SAF production landscape with their innovative flexiforming technology, designed specifically to address the challenges of refinery adaptation for renewable diesel and SAF production. This technology allows for the utilization of idle hydrotreating or reforming units, presenting a significant cost advantage by reducing capital expenditures.

Furthermore, flexiforming empowers operators with the ability to tailor the decarbonization process to their unique requirements, offering a personalized solution that factors in the operator's feedstock, target products, and the specifics of their existing facilities. The integration of flexiforming technology into existing refinery infrastructure is a strategic move towards enhancing SAF production capacity economically. By leveraging this technology, refineries can efficiently transition to producing lower carbon intensity fuels without the need for constructing new facilities, thus contributing to the industry's goal of achieving net-zero carbon emissions by 2050.

In addition to the technical benefits, Unifuel.tech's commitment to responsive customer service, with a promise to reply within 24 hours, underscores their dedication to supporting the industry's transition to sustainable aviation fuels. As the demand for SAF grows and the industry seeks to minimize its environmental impact, technologies like flexiforming by Unifuel. Tech are poised to play a pivotal role in scaling up production while mitigating ecosystem, biodiversity, and water resource concerns.

Conclusion

Unifuel.tech's Flexiforming technology offers a potential game-changing solution in the aviation sector's decarbonization efforts. By integrating into existing facilities and providing operators control over their decarbonization pace, Flexiforming reduces capital expenditure and carbon intensity. This addresses the challenges of early-stage Sustainable Aviation Fuel (SAF) technology and high production costs.

The economics of SAF production are influenced by factors such as feedstock availability and cost, production technology, economies of scale, and government policies. Flexiforming enhances production efficiency and yield, contributing to more sustainable aviation fuels. Government policies and incentives play a significant role in promoting SAF production.

Mandates, tax credits, and supportive programs can balance production costs and drive the adoption of SAF. Unifuel.tech's responsive customer service further supports industry progress. Collaboration, innovation, and understanding the complex interplay of factors involved are crucial for achieving economically feasible SAF production.

The transition to biofuels must be carefully managed to ensure sustainability. In conclusion, Unifuel.tech's Flexiforming technology holds promise for accelerating the transition to SAF and contributing significantly to decarbonization efforts in the renewable fuels industry. With its potential for reducing costs, carbon intensity, and capital expenditures, Flexiforming offers operators greater control over their decarbonization pace while supporting the industry's goal of achieving net-zero carbon emissions by 2050.