Introduction

The quest for sustainable aviation fuels (SAFs) is a key focus in the aviation industry's efforts to reduce carbon emissions. One promising option is electrofuels, which have the potential to significantly decrease CO2 emissions. With the aviation sector under pressure to find greener alternatives to fossil-derived kerosene, SAFs like electrofuels are crucial for near-term decarbonization.

This article explores the challenges and opportunities in the production of aviation biofuels, as well as the economic viability and policy implications. It also highlights the role of Unifuel.tech's flexiforming technology in advancing the adoption of SAFs. Join us as we delve into the technical insights and analysis of the renewable fuels industry.

Background and Motivation

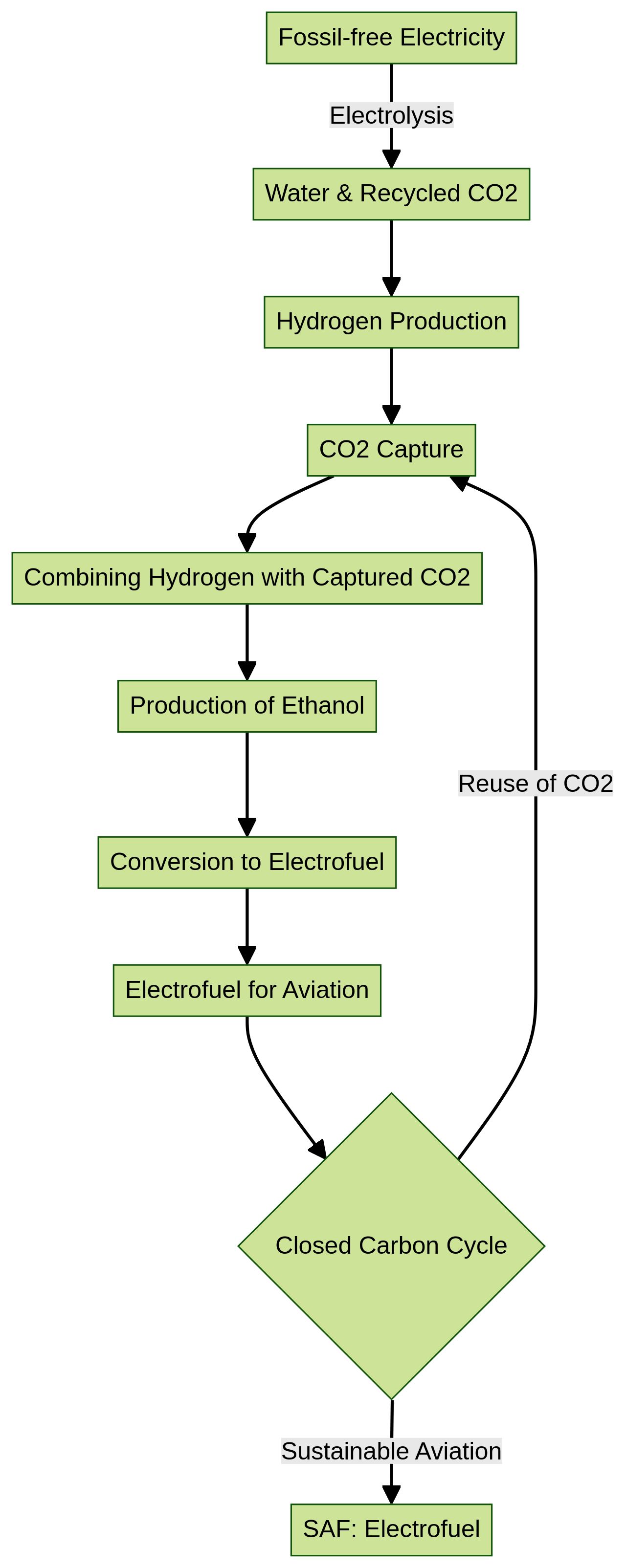

The quest for sustainable aviation fuels (SAFs), including electrofuels, is pivotal in the aviation industry's efforts to slash its carbon emissions. Electrofuels stand out for their potential to significantly reduce CO2 emissions. Though the exact figures are not available, there is consensus on their substantial impact, with a single production facility in Sweden poised to reclaim 200,000 tons of CO2 annually from a district heating plant for electrofuel synthesis.

The process harnesses fossil-free electricity and water, sidestepping the use of virgin fossil feedstocks and contributing to a circular carbon economy. Amid regulatory demands for aviation fuels with specific chemical and physical properties, electrofuels offer a sustainable path forward. The aviation sector, which accounted for approximately 2% of global carbon emissions, is under pressure to find greener alternatives to fossil-derived kerosene.

While electric and hydrogen-electric planes are in development, Safe like electrofuels are crucial for near-term decarbonization efforts. Governments worldwide are promoting biofuels through policies such as blending mandates and tax credits, aiming for up to 65% reductions in greenhouse emissions. The expansion of the biofuel market not only mitigates environmental impact but also bolsters economies by creating jobs and supporting agriculture.

Europe, with its aggressive decarbonization strategies, is expected to lead the biofuel market growth. The Bioenergy Technologies Office (BETO) of the US Department of Energy is actively supporting the transition to Safe, recognizing the role of biofuels in military aviation and the burgeoning air cargo sector. The push for Safe also presents challenges, such as the competition for biomass feedstocks and the vast land requirements for crop-based biofuels.

Nonetheless, innovations like Unifuel.tech's flexiforming technology, which enables operators to tailor their decarbonization pace, are paving the way for a transformative era in aviation biofuels. Deployable in existing infrastructure, such as an idle hydrotreater or reformer, flexiforming reduces both capital expenditure and carbon intensity. With Unifuel.tech's commitment to rapid response and tailored optimization based on specific operational needs, the integration of such innovations is poised to address technological, regulatory, and economic factors in the SAF landscape.

Aviation Biofuel Production Processes and Feedstocks

The quest for carbon-neutral aviation has led to significant innovations in sustainable aviation fuels (SAFs), particularly in the realm of bio-based aromatics. These advancements have enabled airlines to test flights using 100% SAF, a critical milestone in the industry's decarbonization efforts. Although the exact reduction in carbon dioxide emissions with electrofuel usage over traditional fossil fuels has yet to be quantified, it's evident that the impact is substantial.

Electrofuel, a form of SAF, is produced using a carbon-neutral process involving fossil-free electricity, water, and recycled carbon dioxide, sidestepping the use of virgin fossil feedstocks. This method holds the promise of leaving fossil resources untouched, thereby preventing new fossil carbon emissions. In Sweden, plans are underway to establish a production facility by 2030 that will harness fossil-free electricity and captured carbon dioxide to create electrofuel, demonstrating a scalable model for SAF production.

Moreover, the development of Safe has economic benefits, with the potential to create up to 153,000 U.S. jobs in the industry. However, challenges persist, including the need for large-scale production and the competition for feedstocks, which could inadvertently increase the demand for palm oil and contribute to deforestation. To overcome these barriers and fulfill the demand for SAF, it is crucial to diversify feedstock sources, leveraging technologies such as flexiforming offered by Unifuel.tech, a product of Universal Fuel Technologies, and exploring the potential of waste lignin as a resource.

Flexiforming technology allows operators to tailor their decarbonization rate and can be integrated into existing infrastructure, such as idle hydrotreaters or reformers, thus reducing both capital expenditure and carbon intensity. With a promise of a 24-hour response time for inquiries, Unifuel. Tech stands as a proactive partner in the aviation sector's quest to meet stringent quality standards and double fuel consumption sustainably by 2050.

Economic Viability of Aviation Biofuel Production

The aviation industry's quest for carbon neutrality by 2050 hinges on the integration of sustainable aviation fuels (SAF), yet achieving this goal is not without its hurdles. As the world witnesses a surge in SAF uptake, particularly in Europe, the UK, and the USA, the reality of limited production looms, threatening to outpace supply.

In this context, Australia emerges as a key player with its substantial production of feedstocks, positioning it to potentially lead in SAF production. The challenge, however, is monumental: the vast amount of biomass required for SAF production could necessitate land equal to the combined area of five U.S. states.

This stark reality underscores the need for innovative solutions in feedstock sourcing to avoid untenable land use. The aviation sector, a notable contributor to global CO2 emissions, is exploring alternative fuels, but with the current limitations of electrification and green hydrogen for long-haul flights, SAF remains the primary pathway for emissions reduction.

Despite this, the biofuel market is poised for rapid growth, driven by the aviation sector's decarbonization efforts and the military's adoption of biofuels. However, the economic landscape is complex, with high initial investments for biorefineries and uncertain global conditions. Nevertheless, the potential benefits of SAF, including up to a 65% reduction in greenhouse emissions and a bolstered agricultural industry through the demand for biofuel crops, are compelling. With governments worldwide implementing policies to promote biofuels, such as blending mandates and tax credits, the shift towards SAF is gaining momentum. As the industry strives to overcome the challenges of scale and cost, the future of aviation biofuels hinges on collaborative efforts and technological advancements, such as the Flexiforming technology offered by Unifuel.tech, to realize the vision of a greener, sustainable aviation industry.

Deterministic Analysis of Aviation Biofuel Production

The future of aviation fuel is pivoting towards the use of sustainable aviation fuels (SAF) like electrofuel, which are pivotal in the decarbonization of the aviation sector. Although the combustion of electrofuel releases carbon dioxide, it's considered a sustainable option because its production inputs are fossil-free electricity, water, and recycled carbon dioxide, effectively making it a closed carbon cycle. Notably, the production of electrofuel is planned near the Forsmark nuclear power plant in Sweden, leveraging the plant's grid connection for fossil-free electricity, which is instrumental in the electrolysis process to produce hydrogen.

This hydrogen is then combined with captured carbon dioxide to create ethanol, eventually being converted into electrofuel. Such innovative practices are essential in an industry where close to 12% of all CO2 emissions stem from aviation, and the demand for air travel is only expected to grow. The challenges of scaling SAF production are multifaceted, involving complex pre-treatment systems and a variety of source materials.

Deterministic analysis is vital in understanding these complexities and optimizing production processes. This is particularly important when considering the vast amount of biomass needed to sustain the aviation industry. For instance, the idea of using sugar cane for biofuel would require an area equivalent to several US states.

Moreover, the need for aromatics in aviation fuel is a limiting factor for the use of SAF. However, recent developments in producing bio-based aromatics have enabled the possibility of using 100% SAF, as demonstrated by various airlines. Still, there are significant challenges in data collection and model calibration for assessing the environmental impact of biofuel production.

For example, the lack of comprehensive data on diesel consumption in sugar cane farming reflects the difficulty in accurately measuring the greenhouse gas (GHG) impact of biofuels. The variability in estimates of GHG impact highlights the need for robust data and models to inform sustainable fuel production. As the aviation industry seeks to fulfill its pledge for carbon neutrality by 2050, the role of SAF, including electrofuel, becomes increasingly crucial.

Flexiforming technology, as developed by Unifuel.tech, presents a promising solution by enabling the use of existing infrastructure to produce SAF with reduced capital expenditure and carbon intensity. Operators interested in advancing their decarbonization efforts can explore flexiforming applications tailored to their specific feeds, target products, and existing facilities, with the assurance of a swift response from the Unifuel. Tech team.

Stochastic Analysis of Aviation Biofuel Production

The evolution of aviation biofuel production is a dynamic landscape shaped by the sophisticated interplay of feedstock availability, market trends, and technological progress. It demands rigorous analytical approaches, with stochastic modeling playing a critical role in navigating the uncertainties inherent in these processes.

By employing stochastic simulations, the aviation sector can develop more resilient risk management strategies, ensuring a stable trajectory for the adoption of biofuels. Moreover, the intricate biofuel production chain, with its myriad of operational steps, necessitates a deep analytical understanding.

Data analytics emerge as a key instrument in deciphering the complex relationships between production variables and outcomes. This optimization is vital for enhancing biofuel yields and, as a result, for reducing aviation emissions in response to fuel cost volatility.

An integrated portfolio approach to managing the airline industry's capital stock—its fleet of aircraft—can lead to more fuel-efficient operations. This strategy, highlighted in recent studies, suggests that conscientious changes in airline operations can significantly mitigate the climate-change externality associated with airline fuel consumption. In the realm of innovation, the exploration of genetically engineered photosynthetic microorganisms holds promise for synthetic sustainable aviation fuel (SAF) production. By harnessing solar energy and carbon dioxide, these microorganisms could revolutionize SAF production, aligning with the industry's goal of decarbonization and the global pursuit of greener aviation solutions.

Sensitivity Analysis of Aviation Biofuel Production

Sensitivity analysis is indispensable in assessing the economic and environmental feasibility of aviation biofuels, taking into account the variability of feedstock prices, policy changes, and market dynamics. Utilizing Aspen Process Economic Analyzer, we can determine the financial metrics of biofuel projects, which highlight the significant influence of product price on the net present value (NPV). For example, capital costs have been estimated at $71 million, with operating costs at $303 million per year, and a projected NPV of $235 million, influenced heavily by product pricing.

The creation of biofuels involves a complex array of steps and operations, each affected by numerous variables such as pre-treatment systems and extraction methods. Optimizing these processes requires a deep dive into production data, employing analytical tools like MATLAB, Python, and WEKA to develop predictive models. These models, supported by principal component analysis, enable us to understand and manipulate the parameters impacting biofuel yields.

With the aviation industry's commitment to reducing emissions and the limitations on electrification for long-haul flights, sustainable aviation fuel (SAF) has become the focus. However, challenges in scaling SAF production persist. For instance, the PtL process, which boasts CO2 emission savings of up to 94%, is still in its infancy, and the supply of green electricity needed for such technologies is expected to be limited.

Furthermore, the adoption of SAF is influenced by macroeconomic factors such as job creation and rural economic development. The recent trans-Atlantic crossing by a commercial airline using 100% SAF underscores the potential of bio-based aromatics to increase SAF volumes in aviation fuel. Yet, there are concerns about the sustainability of feedstock sources, with some experts cautioning against the use of crop-based biofuels due to their potential environmental impact and competition for land use.

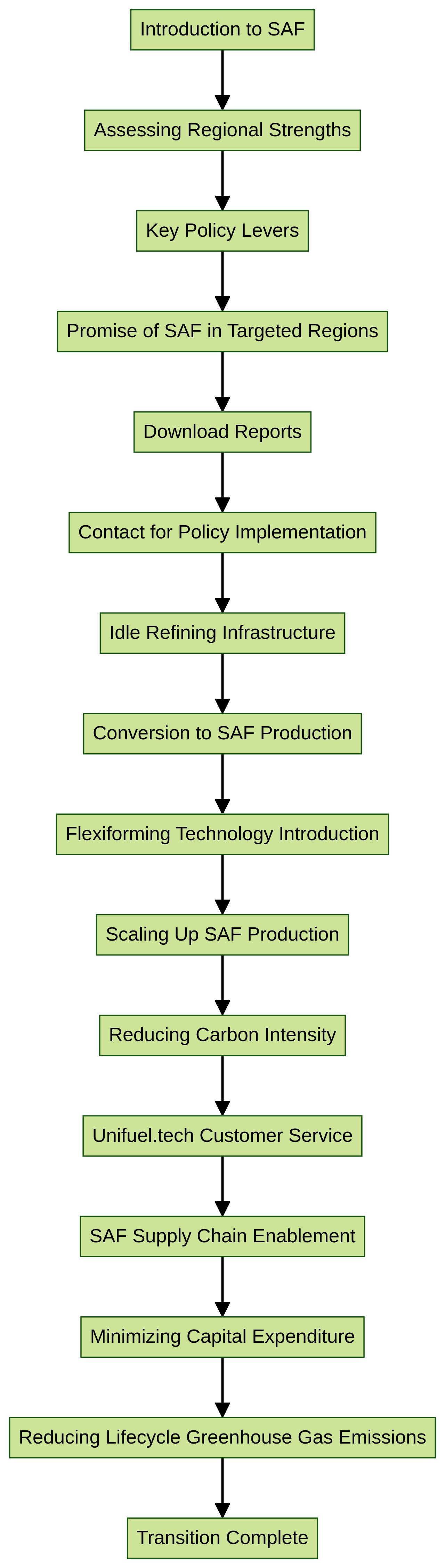

Policy Analysis for Aviation Biofuel Production

The aviation industry's transition to sustainable aviation fuels (SAF) is gaining momentum, propelled by a synergy of policy incentives and technological innovations. While the US and Europe are setting ambitious decarbonization goals, the actual deployment of SAF at scale encounters several barriers, including production constraints and feedstock sustainability issues.

In this context, the introduction of flexiforming technology by Unifuel.tech, a branch of Universal Fuel Technologies, represents a significant breakthrough. Flexiforming enables the conversion of idle refining infrastructure, such as hydrotreaters or reformers, into SAF production facilities.

This approach minimizes capital expenditure while also diminishing carbon intensity, aligning economic incentives with environmental goals. Unifuel.tech's commitment to a rapid response time, promising feedback within 24 hours to queries, underscores the company's dedication to customer service and to facilitating the aviation industry's decarbonization pathway.

By tailoring the flexiforming application to the unique needs of operators, including their feeds and target products, Unifuel. Tech is positioning itself as a key enabler in the SAF supply chain. The measures taken by Unifuel. Tech not only respond to the demand for more sustainable fuel options but also provide a practical solution to the challenge of scaling up SAF production without exacerbating lifecycle greenhouse gas emissions.

Conclusion

In conclusion, the pursuit of sustainable aviation fuels (SAFs) is vital for reducing carbon emissions in the aviation industry. SAFs, such as Unifuel.tech's flexiforming technology, show great potential in significantly decreasing CO2 emissions.

These fuels are crucial for near-term decarbonization efforts while alternative options like electric and hydrogen-electric planes are still under development. Challenges in aviation biofuel production include biomass feedstock competition and land requirements for crop-based biofuels.

However, Unifuel.tech's flexiforming technology offers a practical solution by allowing operators to customize their decarbonization rate, reducing both capital expenditure and carbon intensity. This integration into existing infrastructure makes SAF adoption more feasible.

Economic viability plays a key role in SAF production. The expansion of the biofuel market not only mitigates environmental impact but also supports job creation and agricultural development.

Governments worldwide are implementing policies to promote biofuels, driving the shift towards SAFs. Deterministic analysis and stochastic modeling are crucial in understanding the complexities of aviation biofuel production and optimizing processes.

These analytical approaches help navigate uncertainties and develop resilient risk management strategies. Policy analysis highlights the synergy between policy incentives and technological innovations in driving the transition to SAFs. Unifuel.tech's flexiforming technology stands out as a breakthrough by repurposing idle refining infrastructure into SAF production facilities, reducing costs while aligning economic incentives with environmental goals. In summary, sustainable aviation fuels are essential for achieving carbon neutrality in the aviation industry. Innovations like Unifuel.tech's flexiforming technology offer practical solutions to overcome challenges in SAF production and accelerate the adoption of greener alternatives. With government support and ongoing technological advancements, the future of aviation biofuels looks promising for creating a sustainable and environmentally friendly aviation sector.