Introduction

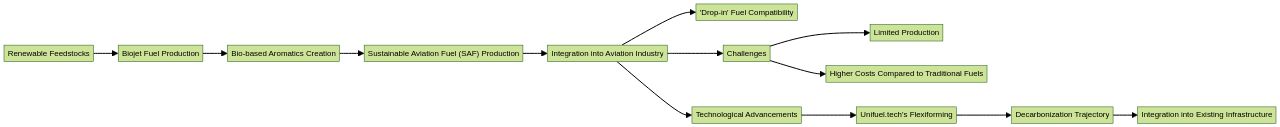

The trajectory of the aviation industry towards a more sustainable future is marked by the innovative development of biojet fuels. Derived from renewable feedstocks, these fuels are poised to play a pivotal role in reducing the sector's carbon footprint.

A breakthrough in this area is the creation of bio-based aromatics, which has enabled the use of sustainable aviation fuel (SAF) in greater proportions, including the milestone achievement of 100% SAF flights across the Atlantic by airlines like Virgin Atlantic. The significance of SAF in aviation's environmental strategy is underscored by its practicality as a 'drop-in' fuel, meaning it can seamlessly replace conventional jet fuel without extensive modifications to aircraft or infrastructure.

This compatibility is crucial, given the stringent specifications for aviation fuel quality and the reliance on a globally available fueling network. However, challenges remain in terms of production scale and cost. Despite these obstacles, the potential for substantial carbon emission reduction is undeniable, and advancements in technologies like Unifuel.tech's Flexiforming offer promising solutions. In this article, we will explore the advancements in sustainable aviation, feedstocks and production routes for biojet fuel, performance characteristics of biojet fuels, and the challenges and opportunities in biojet fuel production.

Advancements in Sustainable Aviation

The trajectory of the aviation industry towards a more sustainable future is marked by the innovative development of biojet fuels. Derived from renewable feedstocks, these fuels are poised to play a pivotal role in reducing the sector's carbon footprint. A breakthrough in this area is the creation of bio-based aromatics, which has enabled the use of sustainable aviation fuel (SAF) in greater proportions, including the milestone achievement of 100% SAF flights across the Atlantic by airlines like Virgin Atlantic.

The significance of SAF in aviation's environmental strategy is underscored by its practicality as a 'drop-in' fuel, meaning it can seamlessly replace conventional jet fuel without extensive modifications to aircraft or infrastructure. This compatibility is crucial, given the stringent specifications for aviation fuel quality and the reliance on a globally available fueling network. The introduction of SAF, however, is not without challenges.

The current production of SAF is minuscule, representing a fraction of total jet fuel consumption, and costs substantially more than traditional fuels. Yet, its potential for substantial carbon emission reduction is undeniable. As Christian Poulsen, COO of Copenhagen Airport, highlights, 'It's an important discovery that sustainable aviation fuel has an impact on air quality... it helps reduce CO2 emissions, so this is another significant benefit of shifting aviation to sustainable fuels.'

With air traffic expected to grow annually by 5%, and even more in regions like East Asia, the full environmental impact of aviation must be assessed both globally and locally. The industry's commitment to becoming carbon neutral by 2050 hinges on the successful integration of SAF and advancements in technologies. Among such advancements is Unifuel.tech's Flexiforming technology, a Universal Fuel Technologies innovation that empowers operators with the ability to tailor their decarbonization trajectory.

Flexiforming can be integrated into existing infrastructure, such as idle hydrotreaters or reformers, to reduce both capital expenditure and carbon intensity. Unifuel. Tech engages with stakeholders promptly, providing swift responses to inquiries and working closely to assess the optimal application of Flexiforming based on the operator's specific feeds, target products, and existing facilities.

Feedstocks and Production Routes for Biojet Fuel

The global aviation industry's quest for sustainability is driving a significant increase in the demand for sustainable aviation fuel (SAF). With the aviation sector's commitment to emission reduction, the challenge is to scale up the production of SAF from various feedstocks.

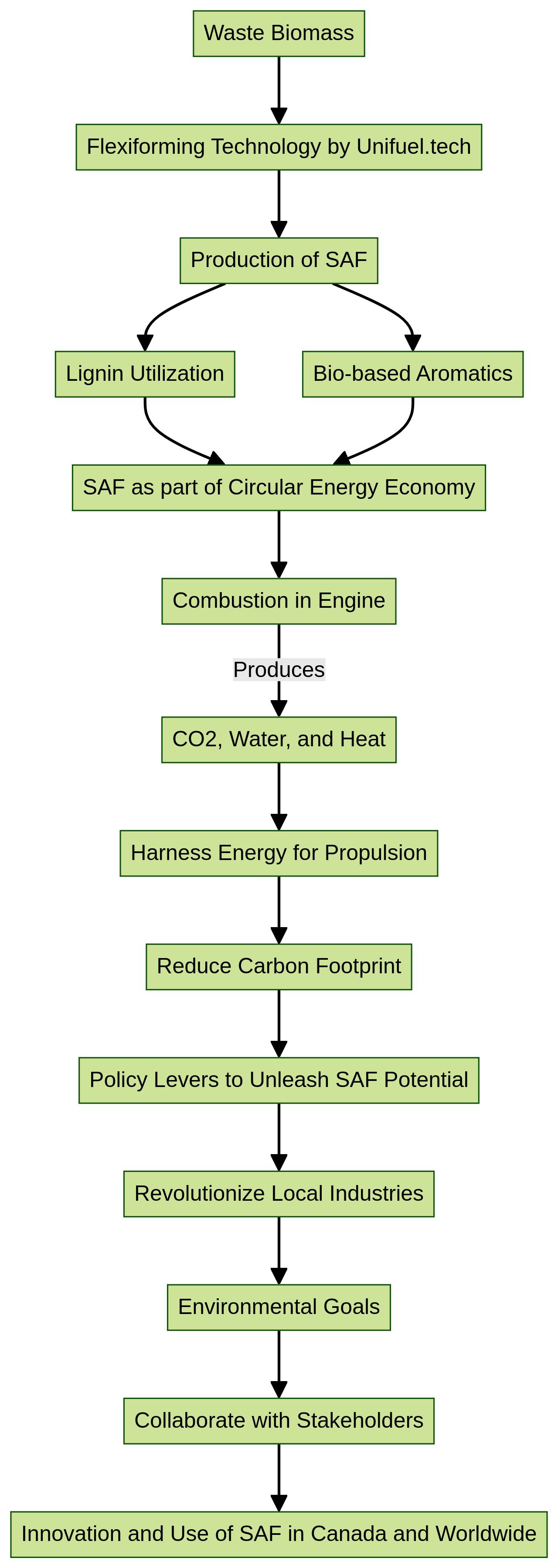

Waste biomass, with its lower cost of around $60 per ton, provides an economically viable option, yet the production of SAF remains costly compared to conventional jet fuel, resulting in limited production. However, technological advancements are offering promising solutions to these economic hurdles.

One such innovation is the flexiforming technology provided by Unifuel.tech, a branch of Universal Fuel Technologies. Flexiforming enables the use of existing infrastructure, such as idle hydrotreaters or reformers, to produce SAF, thereby reducing both capital expenditure and carbon intensity.

This technology facilitates a tailored approach to decarbonization, adapting to the specific needs of operators based on their available feeds and desired products. Unifuel.tech's prompt response to inquiries, within 24 hours, and the comprehensive analysis of an operator's current facilities ensure a customized and efficient integration of flexiforming. The potential of this technology, alongside other developments such as bio-based aromatics and the utilization of lignin, positions the industry closer to the goal of carbon-neutral aviation fuel. With the projected increase in jet fuel consumption by 2050, such innovations are vital in the journey towards a sustainable and carbon-neutral aviation sector.

Performance Characteristics of Biojet Fuels

Biojet fuels, or sustainable aviation fuels (SAF), have undergone rigorous testing to ensure they meet the stringent performance and safety standards required for aviation. While they have proven to exhibit performance on par with conventional jet fuels, the energy density of biojet fuels is somewhat lower. This discrepancy necessitates a careful examination of the implications for aircraft operations and fuel efficiency.

The aviation industry, contributing approximately 2% of global carbon emissions, is on a quest for greener alternatives to fossil fuels. In this pursuit, SAF has emerged as a critical element, with industry leaders like Airbus aiming to make their aircraft fully SAF-capable by 2030. The recent successful 100% SAF Transatlantic flight by Virgin Atlantic underscores the potential of SAF as a 'drop-in' solution, minimizing the need for extensive modifications to existing infrastructure.

Adopting SAF is not without its challenges. The fuel's composition must align with the meticulous specifications for jet fuel, which includes the need for aromatics. Innovations in producing bio-based aromatics now allow for higher SAF blending ratios, even up to 100% usage, as demonstrated by United Airlines and Emirates Airline.

Research indicates that a 1% reduction in aircraft mass can lead to a 0.75% decrease in fuel consumption, highlighting the importance of optimizing fuel efficiency. Additionally, the combustion behavior of SAF is a critical factor, as it dictates the engine's performance and emissions output. As the industry moves towards SAF, comprehensive studies on its ignition, combustion, and emissions are essential to ensure compatibility with diesel engines and to achieve the desired benefits of increased power, reduced fuel consumption, and lower emissions.

Challenges and Opportunities in Biojet Fuel Production

Biojet fuels are pivotal in the aviation sector's transition towards a low-carbon future. Navigating the complexities of feedstock procurement, cost-effective production, and regulatory compliance is challenging, but the integration of innovative technologies like flexiforming offers a promising solution.

This advanced technique, pioneered by Universal Fuel Technologies, empowers operators to tailor their decarbonization trajectory, capitalizing on idle assets such as hydrotreaters or reformers to minimize capital outlays and carbon footprint. The aviation industry, accounting for around 2% of worldwide carbon emissions, is actively seeking sustainable alternatives.

The use of bio-based aromatics is enhancing the feasibility of fully sustainable aviation fuel (SAF), with successful trans-Atlantic flights by leading airlines underscoring Saf's potential. Furthermore, initiatives by the Bioenergy Technologies Office (BETO) fortify the sector with R&D support, fostering the expansion of low-carbon SAF.

Europe is at the forefront of the biofuel market, driven by stringent policies and increased demand for air cargo transit. The aviation industry's use of biofuels is anticipated to grow significantly, supported by a collective goal of achieving carbon neutrality by 2050. Research breakthroughs in areas like lignin digestion and plant gene-stacking are foundational to a sustainable aviation trajectory. As the sector works to balance fuel regulations with environmental responsibilities, the strategic application of technologies such as flexiforming by Universal Fuel Technologies is set to accelerate the adoption of biojet fuels, with the company ensuring rapid responsiveness to inquiries regarding optimal technology deployment.

Conclusion

In conclusion, the aviation industry is making significant progress towards a more sustainable future through the development of biojet fuels. These fuels, derived from renewable feedstocks, are playing a pivotal role in reducing the sector's carbon footprint.

The use of sustainable aviation fuel (SAF) has reached milestone achievements like 100% SAF flights across the Atlantic, highlighting its practicality as a seamless replacement for conventional jet fuel. Challenges remain in terms of production scale and cost, but the potential for substantial carbon emission reduction is undeniable.

Technological advancements like Unifuel.tech's Flexiforming offer promising solutions by integrating existing infrastructure and reducing both capital expenditure and carbon intensity. This tailored approach empowers operators to adapt to their specific needs.

The demand for sustainable aviation fuel is growing, with waste biomass emerging as an economically viable feedstock option. However, further technological advancements are needed to scale up production and overcome economic hurdles.

Innovations like flexiforming technology and the utilization of lignin bring us closer to achieving carbon-neutral aviation fuel. Biojet fuels undergo rigorous testing to meet stringent performance and safety standards required for aviation.

While their performance aligns with conventional jet fuels, careful consideration is needed regarding energy density implications for aircraft operations and fuel efficiency. Navigating complexities in feedstock procurement, cost-effective production, and regulatory compliance presents challenges in biojet fuel production. However, innovative technologies like flexiforming minimize capital outlays and carbon footprint. The industry's commitment to sustainability is reinforced by research support from organizations like the Bioenergy Technologies Office (BETO) and stringent policies driving Europe's biofuel market. By strategically applying technologies like flexiforming, we can accelerate the adoption of biojet fuels and work towards achieving carbon neutrality by 2050. In summary, advancements in sustainable aviation, feedstocks and production routes for biojet fuel, performance characteristics of biojet fuels, and challenges and opportunities in biojet fuel production are shaping a more sustainable future for the aviation industry. Through innovative technologies and a collective commitment to reducing carbon emissions, we are moving closer to greener alternatives in aviation.