Introduction

Technological advancements in Hydroprocessed Esters and Fatty Acids (HEFA) have revolutionized the production of Sustainable Aviation Fuel (SAF), offering a promising solution to reduce carbon emissions in the aviation industry. This article explores the capabilities of HEFA technology and its impact on SAF production, highlighting its efficiency in transforming renewable feedstocks into high-quality SAF that meets industry standards.

From improved fuel performance to the integration of bio-based aromatics, HEFA technology is driving the industry towards a greener future. However, challenges and the need for further research and innovation remain on the path to widespread adoption. Join us as we delve into the world of HEFA technology and its role in shaping the future of aviation sustainability.

HEFA Technology: A Game Changer for SAF Production

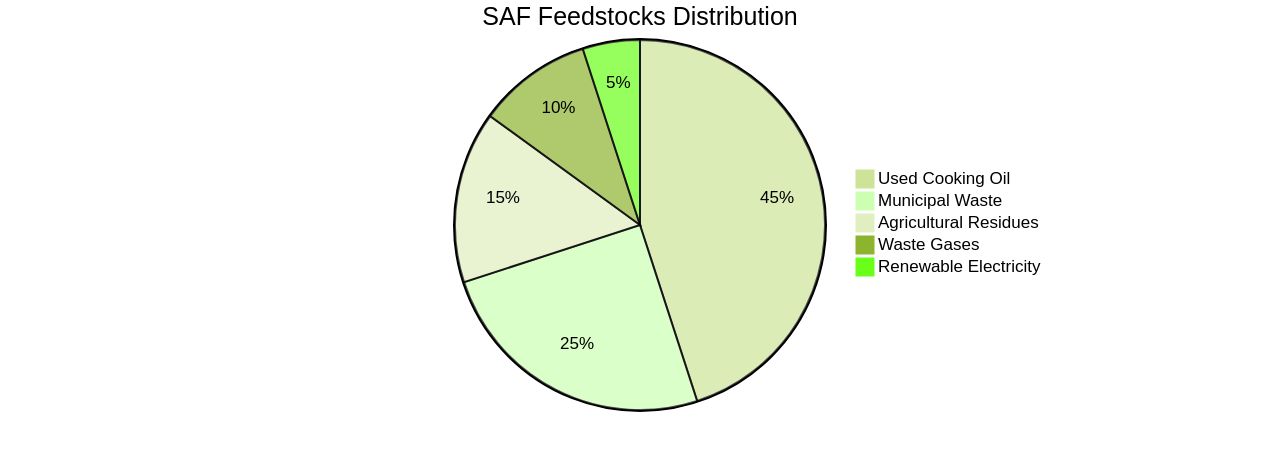

Technological strides in Hydroprocessed Esters and Fatty Acids (HEFA) have significantly advanced the production of Sustainable Aviation Fuel (SAF), providing a promising pathway to reducing aviation's carbon footprint. HEFA technology efficiently transforms a variety of renewable feedstocks, including vegetable oils and animal fats, into high-caliber SAF that aligns with the aviation industry's rigorous standards.

Its benefits are underscored by impressive yields and minimal sulfur content, coupled with superior performance traits, positioning it as a sustainable and effective option for SAF production. Recent breakthroughs have enabled the integration of bio-based aromatics into SAF, addressing a critical challenge in the fuel's compositional requirements.

Traditional jet fuel contains aromatics that are absent in SAF, affecting freeze points, viscosity, and compatibility with aircraft seals. Innovations now allow for the inclusion of these necessary components, paving the way for up to 100% SAF usage in flights, as demonstrated by Virgin Atlantic's historic trans-Atlantic flight.

This leap forward is not only technologically significant but also essential for the aviation sector's goal of net-zero emissions by 2050. The potential of HEFA technology and 100% SAF usage is further exemplified by the planned SAF output in Sweden, which is set to meet 5% of the country's current jet fuel demand and 20% by 2030. Such advancements reflect a collective industry effort, as emphasized by Julie Kitcher of Airbus, to make all aircraft 100% SAF-capable by 2030 and to cultivate a robust global SAF market. However, the journey toward large-scale SAF production and adoption is fraught with challenges, including the need for a comprehensive understanding of the economic feasibility and technological readiness across different production pathways. With the highest level of readiness and lowest conversion costs, HEFA emerges as a leading technology for SAF production, although a detailed comparison of various pathways is still needed to fully realize its potential.

Improving Feedstock Flexibility with HEFA

The advent of Flexiforming technology by Unifuel. Tech represents a substantial stride in the field of HEFA technology for SAF production.

Flexiforming offers a customizable approach to decarbonization, enabling operators to adjust the pace at which they reduce their carbon footprint. By utilizing existing infrastructure, such as idle hydrotreaters or reformers, Flexiforming presents an economical solution that minimizes capital expenditures while simultaneously decreasing carbon intensity.

This innovation has the potential to revolutionize the sustainable aviation fuel landscape by providing a flexible and scalable method to utilize a wide array of feedstocks. As a result, it addresses the critical challenge of supply chain resilience and supports the utilization of diverse waste materials, aligning with sustainability goals and the push towards a circular economy.

The swift response time of Unifuel. Tech to inquiries ensures that operators can quickly explore how Flexiforming can be integrated into their existing facilities to enhance SAF blends. This aligns with the industry's aspiration to increase the use of SAF, as demonstrated by Virgin Atlantic's landmark 100% SAF-powered Transatlantic flight. The projected CO2 emissions reduction of up to 94% through processes like PtL emphasizes the urgency for innovative solutions like Flexiforming to overcome scaling challenges. The commitment to decarbonization is mirrored in global projects such as Sweden's planned electrofuel facility, and Flexi forming technology could play a significant role in meeting these ambitious targets.

Enhancing Fuel Performance and Sustainability

Recent advancements in HEFA technology for SAF production are setting a precedent for the aviation industry's journey towards a greener future. HEFA's breakthrough lies in its ability to formulate a drop-in fuel, which seamlessly integrates with existing engines and infrastructure, negating the need for expensive alterations.

The utilization of renewable feedstocks in SAF production plays a pivotal role in diminishing greenhouse gas emissions, a stark contrast to traditional jet fuels. The significance of this technology is underscored by the International Civil Aviation Organization's ambitious target of net-zero carbon emissions by 2050, a goal echoed by industry leaders.

The Virgin Atlantic-led consortium's demonstration of a 100% SAF transatlantic flight epitomizes the potential of SAF as a direct substitute for fossil fuels. This milestone is supported by the fact that aviation contributes to 2-3% of global CO2 emissions, and SAF is increasingly recognized as the primary tool for the sector's decarbonization.

Adding to this momentum, Unifuel. Tech introduces Flexiforming, a technology that enhances the flexibility of decarbonization for operators.

By leveraging idle hydrotreaters or reformers, Flexiforming reduces both capital expenditure and carbon intensity, aligning with the industry's sustainability efforts. This innovation could serve as a cornerstone for scaling up SAF production, addressing one of the challenges of limited supply. With Airbus's commitment to making their fleet entirely SAF-capable by 2030 and Virgin Atlantic's CEO advocating for more investment and regulatory support, the industry is poised for transformation. Additionally, the recent use of e-SAF for an Airbus A320neo on its delivery flight from Toulouse to Delhi showcases the practical application of this technology without the need for new infrastructure. However, challenges persist in the form of technological maturity, particularly in the production of aromatic components essential for fuel specifications. Unifuel.tech's rapid response to inquiries and their adaptability to existing facilities suggest a path forward in overcoming these hurdles and fulfilling the projected global jet fuel demand.

Future Outlook and Continued Innovation

Technological strides in the realm of Hydroprocessed Esters and Fatty Acids (HEFA) have significantly advanced Sustainable Aviation Fuel (SAF) production, signaling a shift towards a more sustainable aviation industry. Notwithstanding these advances, achieving a fully decarbonized aviation sector remains a complex endeavor that demands persistent innovation and research to enhance the efficiency and sustainability of SAF production. This includes the exploration of novel feedstock options and the refinement of conversion processes, coupled with the integration of cutting-edge technologies to augment yields while mitigating environmental repercussions.

The BioForming® technology, exemplified by BioForm® SAK, showcases how SAF can be produced without necessitating extensive modifications to existing aircraft or fuel infrastructure, thus offering a 100% SAF solution that aligns with current jet fuel standards. The potential of such technology to significantly curtail carbon emissions represents a pivotal moment for both the aviation sector and global environmental initiatives. Furthermore, the ongoing collaboration between various stakeholders is crucial for fostering innovation and scaling up the use of SAF, as evidenced by the collective efforts in Canada to create a platform for the SAF value chain.

The Section 9003 program's modernization could further expedite the adoption of advanced biofuels, bolstering the United States' position in the global energy market for these fuels. With a current SAF output approximating 5% of Sweden's total jet fuel demand and the potential to meet 20% of its SAF requirements by 2030, the trajectory for SAF production is indeed promising, inching us closer to a more sustainable aviation future. Adding to these advancements, Unifuel.

Tech introduces Flexiforming technology, allowing operators to tailor their decarbonization pace. Deployable in dormant hydrotreaters or reformers, it offers a cost-effective reduction in carbon intensity. Unifuel.tech's commitment to rapid response and customer service, with a 24-hour inquiry reply, ensures that operators receive tailored solutions for their specific needs, feeds, and facilities, reinforcing the momentum towards a sustainable aviation landscape.

Conclusion

In conclusion, HEFA technology is revolutionizing Sustainable Aviation Fuel (SAF) production by efficiently converting renewable feedstocks into high-quality SAF that meets industry standards. The integration of bio-based aromatics into SAF, made possible by HEFA technology, is paving the way for up to 100% SAF usage in flights, aligning with the industry's goal of achieving net-zero emissions by 2050.

HEFA stands out as a leading option for SAF production due to its high readiness level and low conversion costs. Flexiforming technology by Unifuel.tech enhances feedstock flexibility and offers a cost-effective solution for decarbonization.

Collaboration among stakeholders is key to fostering innovation and scaling up SAF usage globally. In summary, HEFA technology offers promising prospects for SAF production, bringing us closer to a greener future in aviation. Continued research and collaboration are essential for realizing the full potential of HEFA technology in shaping a sustainable aviation industry.