Introduction

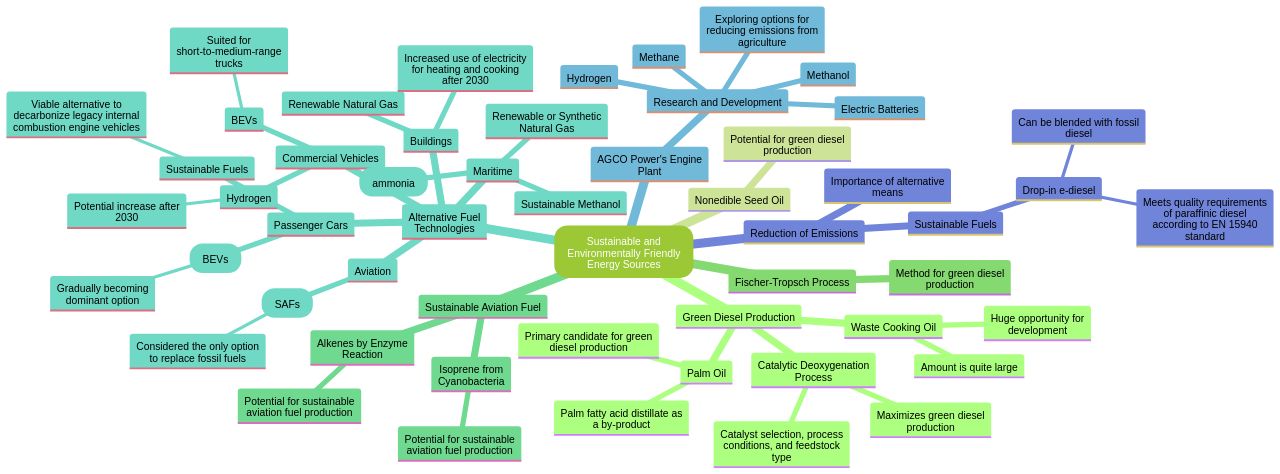

The production of renewable fuels in the aviation industry is gaining momentum as a means to reduce greenhouse gas emissions and enhance sustainability. This article explores various aspects of renewable aviation fuel, including traditional production processes, emerging green business models, and the challenges and prospects of biofuel production from different feedstocks.

It also delves into the role of hydroprocessing, gasification, and catalysts in the production of renewable aviation fuels. As the aviation industry strives to achieve its net-zero carbon emission goals, understanding the technical and economic aspects of renewable fuels is crucial.

Traditional Jet Fuel Production Processes

The manufacturing process of conventional jet fuel is multi-faceted, involving the distillation of crude oil into various fractions based on their boiling points. The fraction known as kerosene is specifically utilized for jet fuel production.

The fuel then undergoes further refinement, such as hydrotreating and catalytic cracking, to eliminate impurities and enhance its quality. However, the recent emergence of Sustainable Aviation Fuel (SAF) has initiated a paradigm shift in the industry.

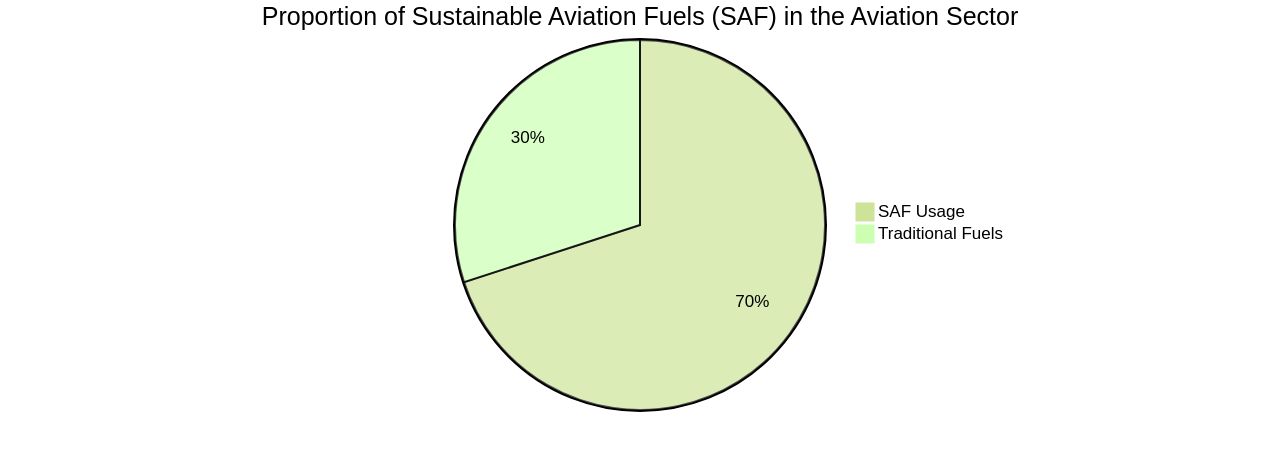

SAF can substitute or be blended with petroleum-based kerosene without necessitating modifications to existing jet engines. Nevertheless, the procurement of SAF presents a challenge due to its limited availability and significantly higher cost.

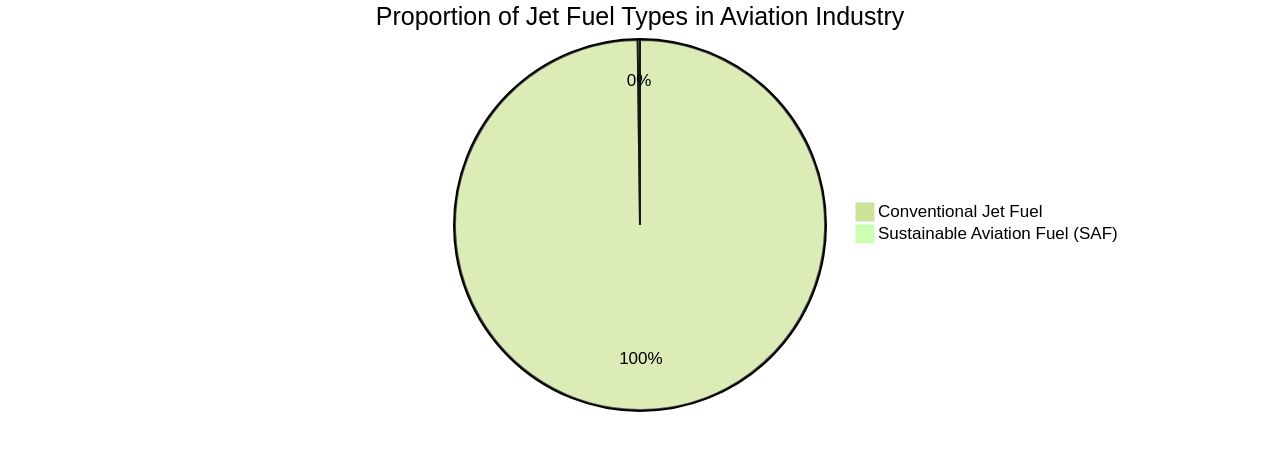

The production of SAF in the U.S. was merely a minuscule fraction of the total jet fuel consumption by major U.S. airlines in a year. Despite these challenges, the U.S. aims to amplify its SAF production nearly twenty-fold by the end of the decade.

The development of bio-based aromatics has facilitated the production of 100% SAF, which has been successfully tested by several airlines. However, currently, only a maximum of 50% SAF can be mixed with traditional jet fuel due to the absence of aromatics in SAF. Aromatics, although comprising a minor percentage of the fuel, play a crucial role in maintaining fuel quality and interacting with polymer seals in the jet’s fueling system. Therefore, to meet global Jet A fuel specifications, synthetic fuels are required to contain between 8-25% aromatics. In conclusion, while SAF presents a practical solution to decarbonizing global aviation, it alone cannot achieve this objective. The term 'SAF' has become an umbrella term for various blends of SAF with traditional jet fuels, and only those blends that reduce emissions by a specific percentage can be officially termed SAF.

Emergence of Green Business Models: The Case of Algae Biofuel for Aviation

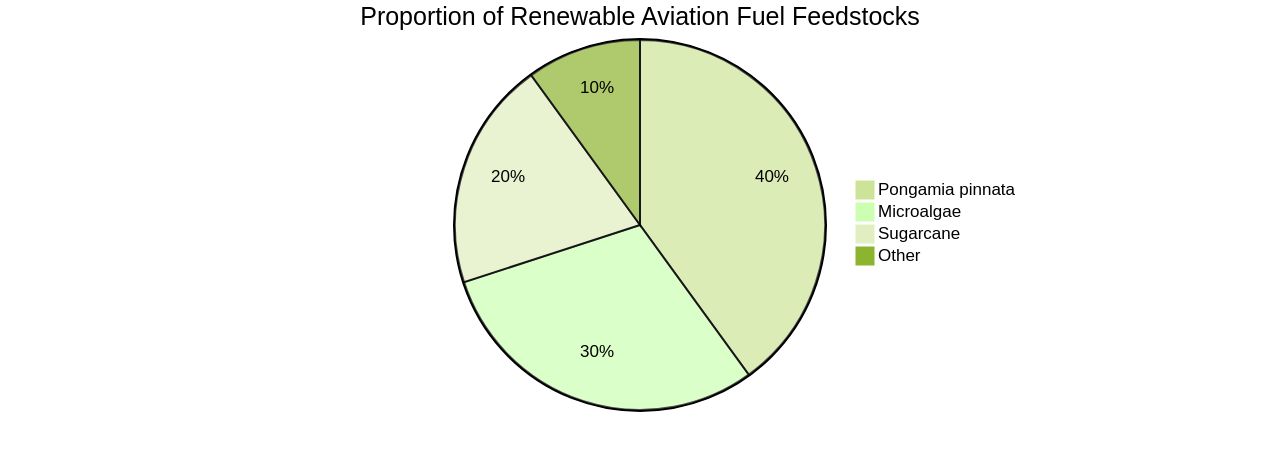

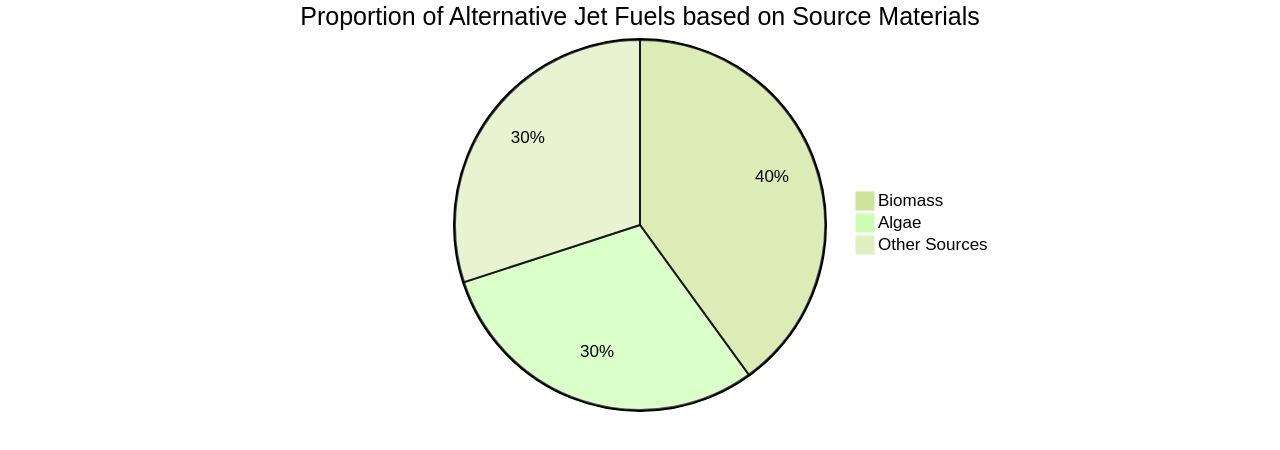

The journey towards sustainable aviation fuel (SAF) has led us to consider algae as a possible biofuel source due to its efficiency in converting sunlight and carbon dioxide into biomass. This biomass can be processed to extract bio-oil, which can then be refined into a renewable jet fuel with significantly lower carbon emissions than conventional jet fuel. However, recent research has cast doubts on this promising prospect.

Despite the significant investments from fossil fuel giants like Exxon and Chevron, biodiesel derived from microalgae may actually emit more carbon during production and usage than petroleum-based diesel, largely due to the energy-intensive manufacturing process. The environmental cost of setting up the infrastructure to cultivate and process the algae, combined with the electricity required to run the operations, may outweigh the environmental benefits of burning the biofuel. Even though phytoplankton, a type of microalgae, are promising candidates due to their capacity to produce up to 30 times more energy than other biofuels, this doesn't necessarily translate into energy efficiency.

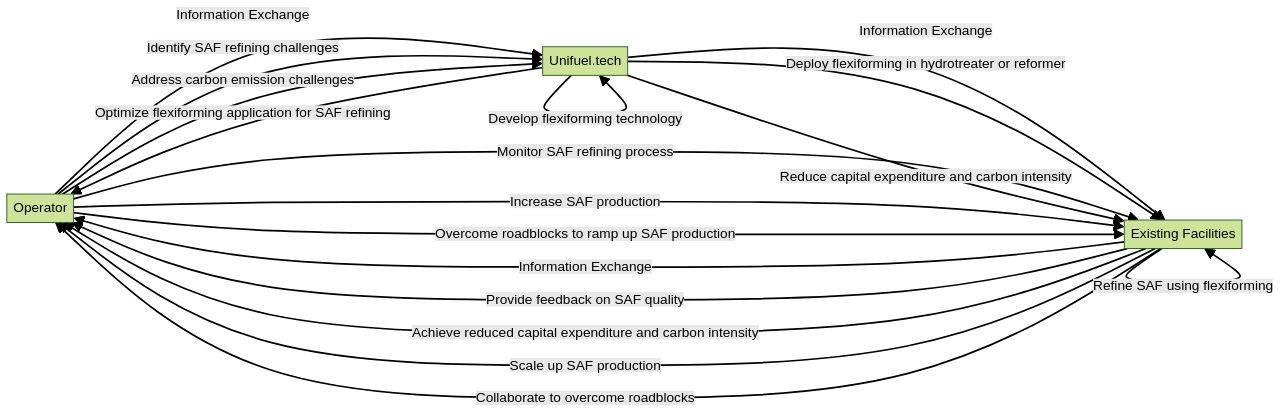

Given that the aviation sector contributes approximately 2% of global carbon emissions, a small but rapidly increasing fraction, the search for greener alternatives to fossil fuel-derived kerosene remains a global priority. While we wait for the mass adoption of new technologies like electric or hydrogen-electric powered flights, the refining processes for SAF need to be optimized. In this regard, the introduction of technologies such as Unifuel.tech's flexiforming could play a critical role.

Flexiforming allows operators to choose their speed of decarbonization and can be deployed in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. By providing information about the operator's feeds, target products, and existing facilities, Unifuel. Tech can find an optimal application for flexiforming, offering a potential solution to the carbon emission challenges posed by current SAF refining processes.

Sustainable Alternative Fuels in Aviation

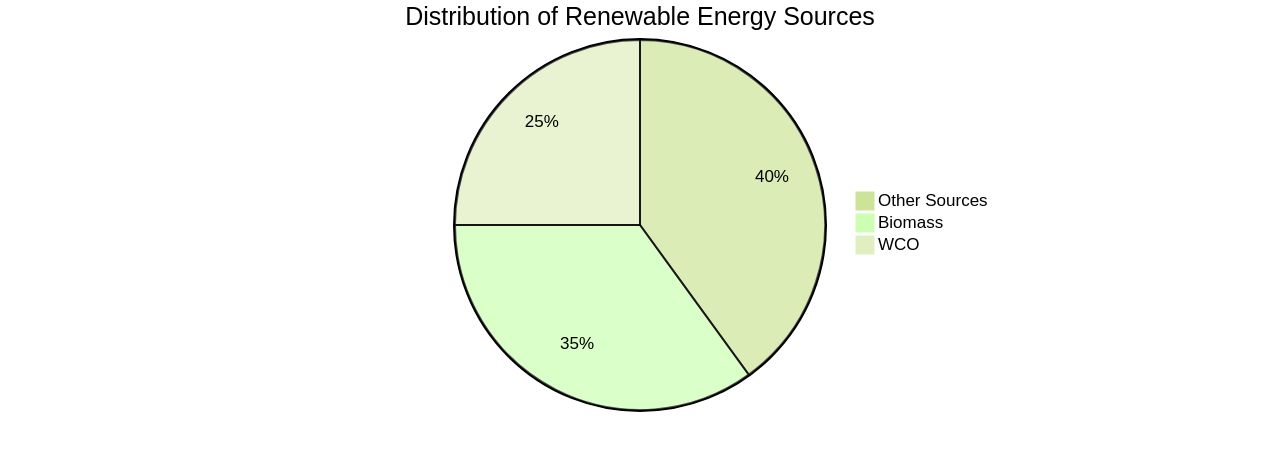

The aviation sector is actively pursuing sustainable fuel alternatives, such as Sustainable Aviation Fuels (SAF), to curb its environmental footprint. These fuels, derived from renewable resources like biomass, algae, and waste oils, offer remarkable potential to reduce greenhouse gas emissions, enhance air quality, and bolster energy security.

However, large-scale availability of SAF remains a challenge, making it 3 to 4 times more expensive than traditional fuels. Despite this, SAF is increasingly recognized as the most effective solution to address CO2 emissions in the aviation industry.

Pioneering companies like Airbus are setting ambitious targets, aiming to make all their aircraft 100% SAF-capable by 2030. Virgin Atlantic, another industry leader, has committed to a Net Zero target by 2050 and is leading an industry consortium to deliver the first 100% SAF flight across the transatlantic in 2023.

This will demonstrate that SAF can be safely used as a drop-in fuel in existing infrastructure, engines, and airframes. SAFs essentially offset their carbon dioxide emissions, depending upon their production process. They can be part of a circular energy economy and are a drop-in solution, requiring minimal adjustment of aircraft and airport infrastructure. However, the real impact of SAF will depend on various factors, including the expansion of supply. The aviation industry's ambitious goal of net-zero carbon dioxide emissions by 2050 is largely dependent on the successful adoption and advancement of SAFs.

Liquid Biofuels Production and Emissions Performance in Gas Turbines: A Review

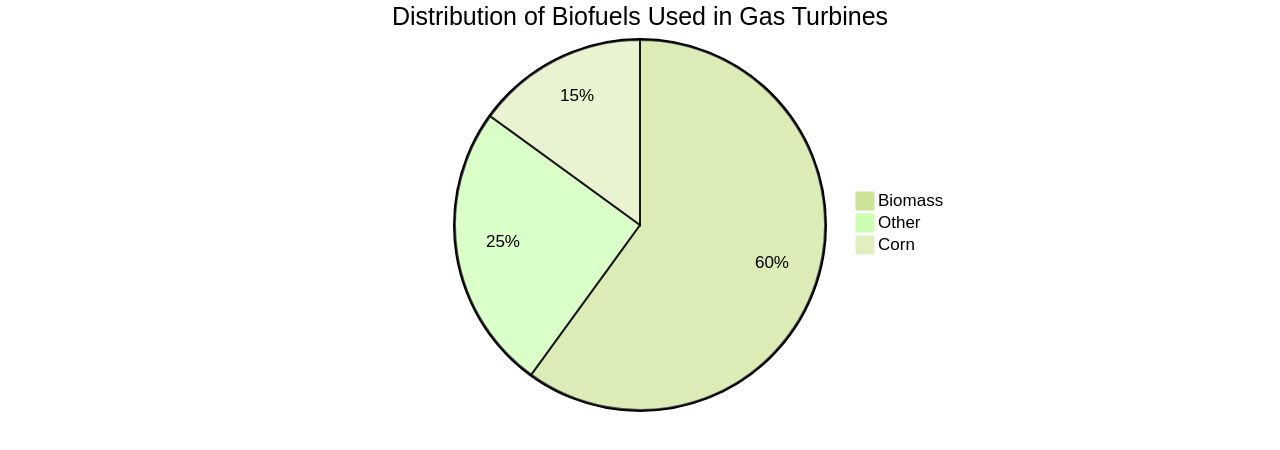

The rising interest in biofuels, especially those originating from biomass, is notable for their potential use in aviation's gas turbines. This section explores the production techniques and emission performance of these biofuels when utilized in gas turbines.

The quest for technical viability, environmental sustainability, and economic feasibility of replacing traditional jet fuel with biofuels is thoroughly examined. Taking a look at gas turbines operating in a combined cycle configuration that produces 3.5GW of electricity, sufficient to power 875,000 homes, the shift of 20 such turbines from liquid fuel to natural gas resulted in a substantial decrease of carbon emissions by 1.7 million tons annually.

Biofuels, like those created from lignocellulosic biomass, provide a cost-effective and carbon-neutral substitute to petroleum-based fuels. The biomass is decomposed into its primary components, including lignin, a complex organic polymer responsible for the structural integrity of plants.

The robust nature of lignin presents a challenge in its extraction and utilization, a barrier that can be surmounted by incorporating a renewable chemical in the pretreatment step, leading to a more efficient and sustainable biofuel production process. Biomass, encompassing materials from living organisms, can be used for carbon sequestration or as a fossil fuel alternative for energy production.

For example, indigenous biogas production in the EU witnessed a 1.7% increase in 2021, reaching 14.9 million tonnes of oil equivalent, lessening the region's dependency on foreign fossil fuels. On the technological front, Unifuel. Tech offers a solution named Flexiforming, a technology that enables operators to control their decarbonization rate, which can be installed in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. Unifuel. Tech guarantees to respond to inquiries within 24 hours, requesting details about feeds, target products, and existing facilities to determine the best application for Flexiforming.

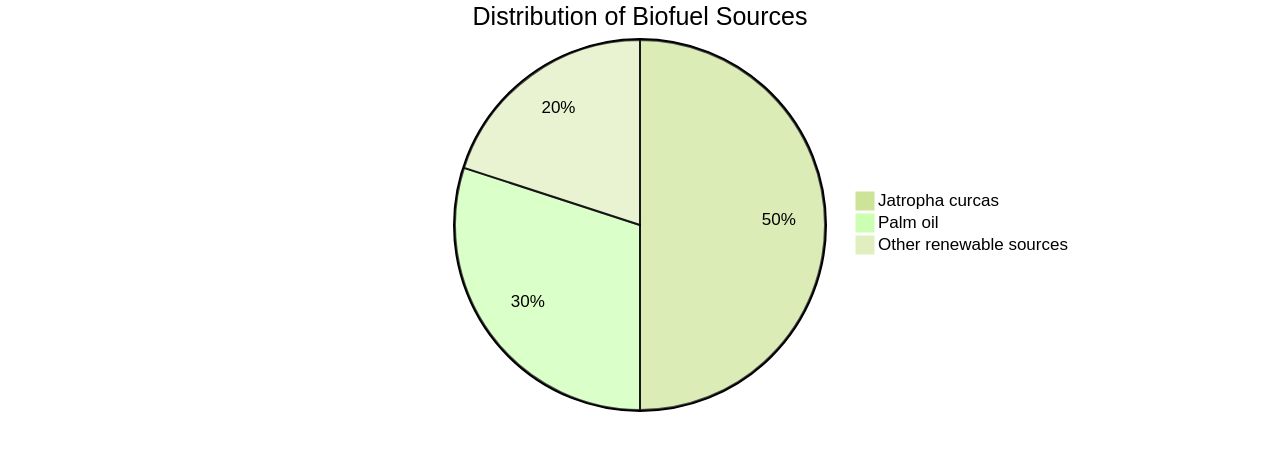

Jatropha curcas as a Feedstock for Jet Biofuel Production

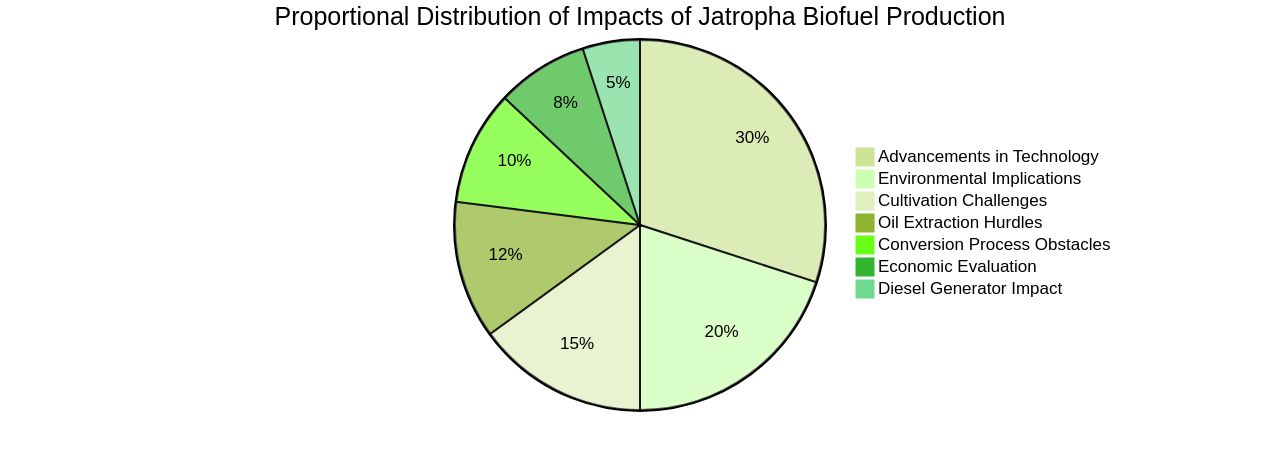

The potential of Jatropha curcas, a non-edible oilseed plant, in jet biofuel production has sparked significant interest. The oil derived from Jatropha curcas exhibits properties that make it suitable for biofuel conversion processes.

However, challenges persist in its cultivation and processing stages. A case study in Colombia demonstrates the potential savings from using a blend of Jatropha biodiesel (JB10) as compared to commercial fuel.

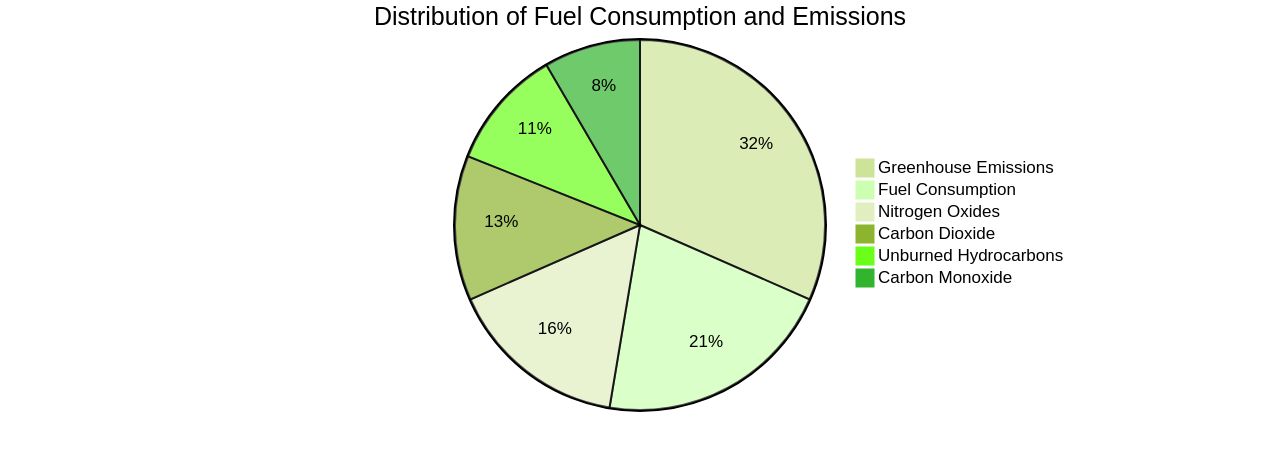

The study also assessed the environmental impact of replacing palm crops with Jatropha curcas, focusing specifically on soil degradation. Despite concerns, the use of biodiesel has shown to reduce unburned hydrocarbons and carbon monoxide by up to 75% of the engine load, which is crucial for communities living near diesel generators.

While the aviation industry is actively seeking alternative fuels to reduce its carbon footprint, the production of Sustainable Aviation Fuel (SAF) from sources like Jatropha curcas poses its own set of challenges. These include the need for biofuel production facilities to adapt their operations and the concerns over deforestation in palm oil production. Nonetheless, the versatility of biofuel as a 'drop-in' fuel, substituting petroleum-derived hydrocarbons without requiring engine or fuel system modifications, presents an exciting prospect for the future of renewable energy and the sustainability of the aviation industry. This shift towards a circular bioeconomy, utilizing waste biomass including non-edible plants like Jatropha curcas, is not only crucial for future energy demands but also potentially beneficial for the economy through job creation and regional development.

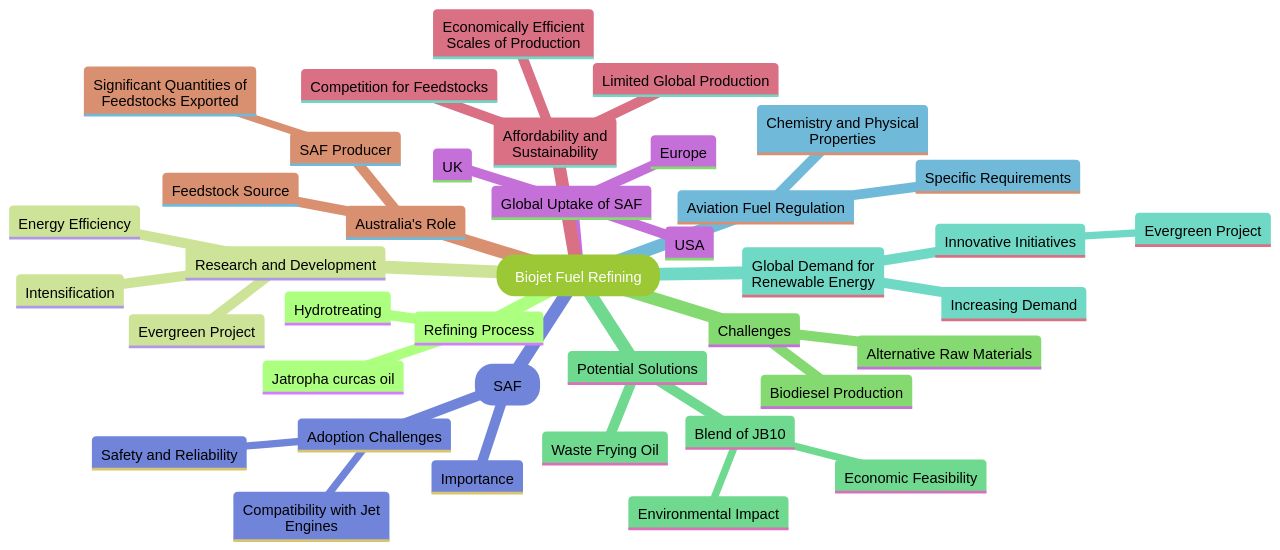

Simultaneous Energy Integration and Intensification of the Hydrotreating Process to Produce Biojet Fuel from Jatropha curcas

The refining process of biojet fuel from Jatropha curcas oil entails a crucial stage known as hydrotreating, which has been the focus of intensive research and development efforts. This process is being examined for its potential to enhance the energy efficiency and intensification, thereby bolstering the sustainability and cost-effectiveness of biojet fuel production.

The importance of this research is underscored by the increasing global demand for renewable energy sources, driven by factors such as the depletion of fossil fuels, escalating oil prices due to geopolitical conflicts, and growing environmental concerns. The Evergreen project exemplifies such innovative initiatives, aiming to produce a sustainable biofuel through acid liquefaction of lignocellulosic feedstocks, which could significantly reduce CO2 emissions.

However, biodiesel production faces challenges, particularly the high cost of raw materials, which necessitates the exploration of alternative, environmentally friendly raw materials that do not compromise food security. The potential of waste frying oil, a common household waste, as a viable raw material is under investigation. Additionally, the economic feasibility and environmental impact of using a blend of JB10 as an alternative to commercial fuel in Colombia have been examined, with a focus on the potential fuel savings and the impact on soil degradation from palm oil and JCL cultivation. These research efforts underscore the potential of technological innovations in refining processes for Sustainable Aviation Fuel (SAF) in meeting the global energy demand in a sustainable and cost-effective manner.

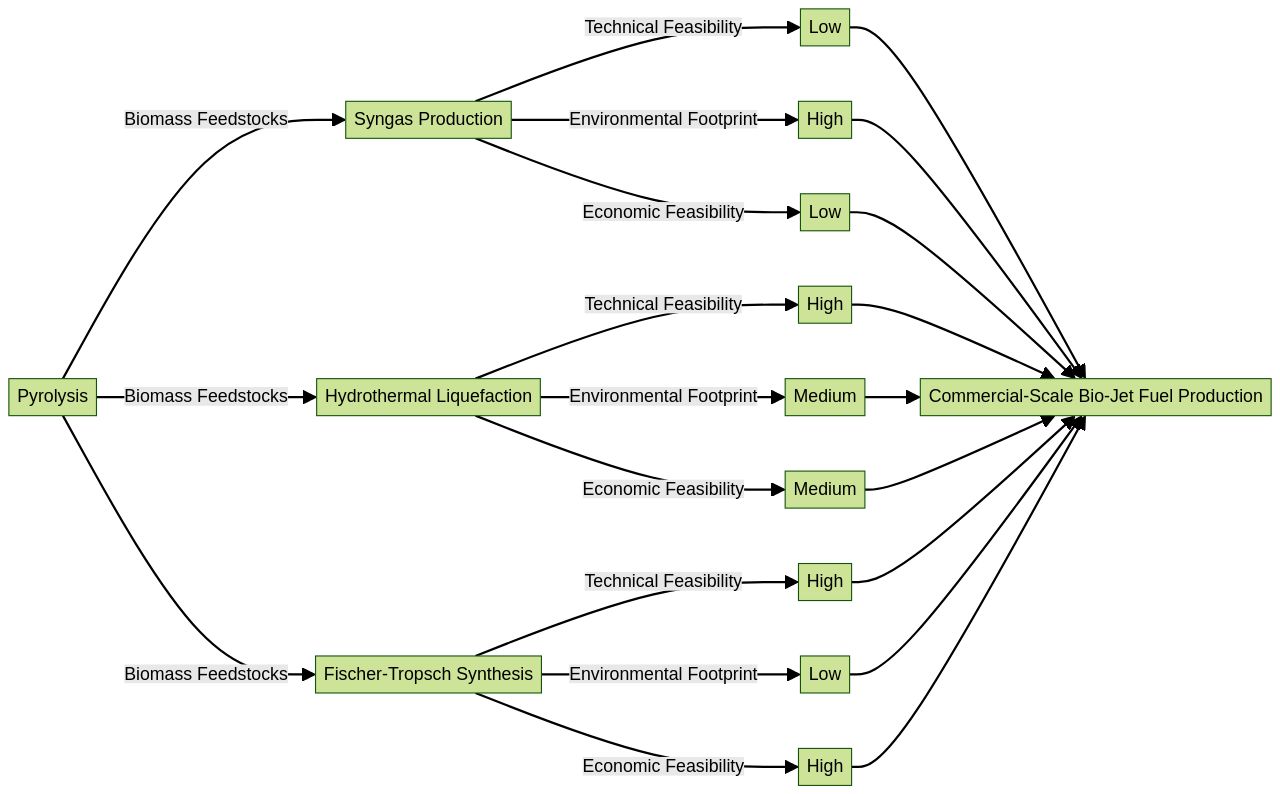

Bio-jet Fuel Conversion Technologies

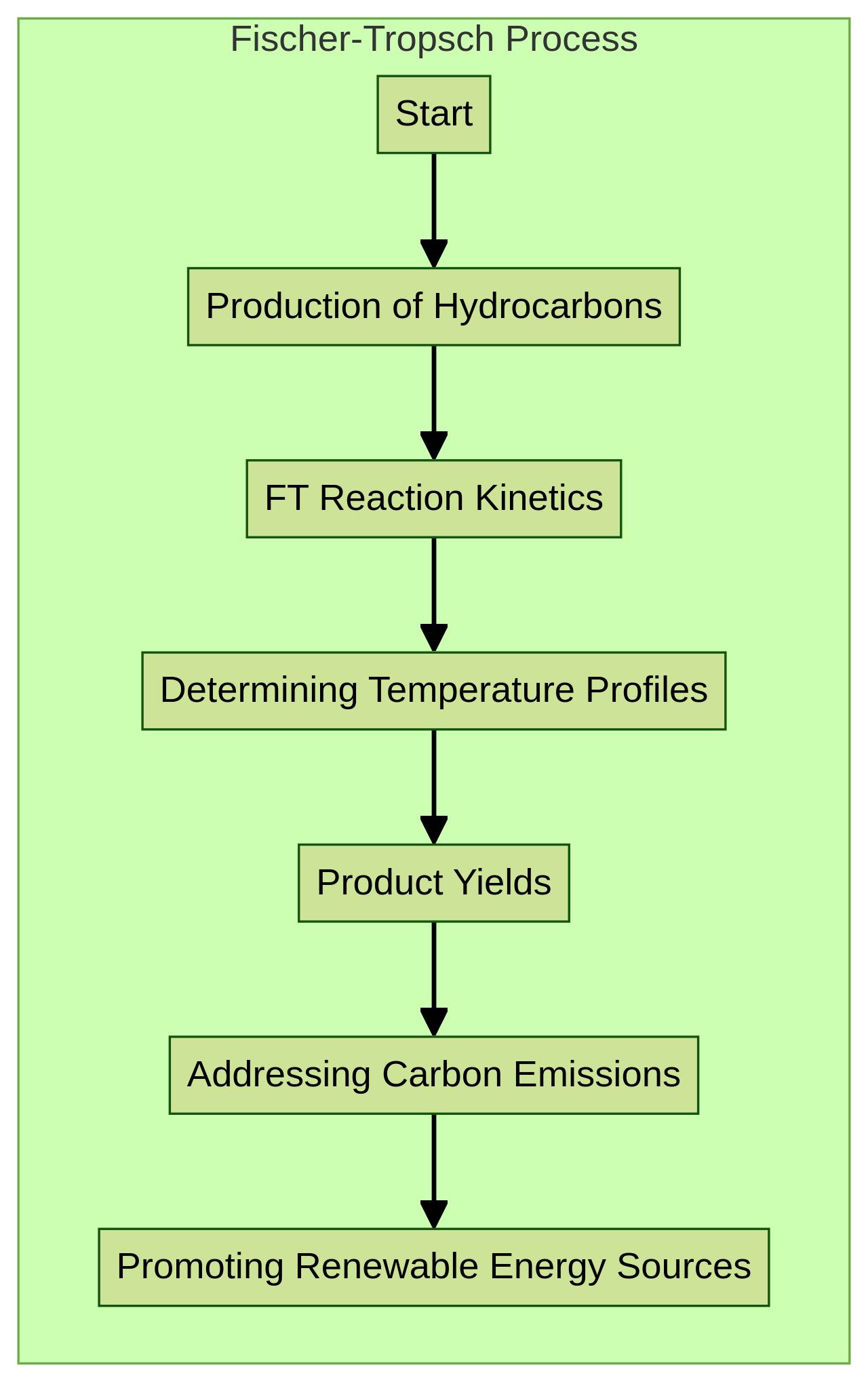

This segment delves into the various bio-jet fuel conversion technologies, emphasizing the potential pathways such as pyrolysis, hydrothermal liquefaction, and Fischer-Tropsch synthesis for transforming biomass feedstocks into jet fuel. The technical feasibility, environmental footprint, and economic feasibility of each conversion technology are scrutinized, underlining their potential for commercial-scale bio-jet fuel production.

A case study of the steel mill in Ghent exemplifies an innovative process developed by LanzaTech, where gases produced during the steel production chemistry are fermented by microbes to produce ethanol. This technique deviates from conventional commercial ethanol production technologies, offering both challenges and opportunities.

The environmental characteristics of this type of fuel are assessed through a life cycle assessment (LCA) based on data from the Ghent plant, offering insights into its environmental performance. This assessment aids in comparing this ethanol with other fuels, understanding its relative advantages and societal benefits.

The aviation industry, contributing around 2% of global carbon emissions, is facing the challenge of reducing carbon footprint. New, greener ways to produce kerosene without using fossil fuels are being explored, as evident from the development of electric planes and the quest for sustainable hydrocarbon fuel for aircraft.

The conversion of carbon dioxide into formate, a liquid or solid material that can power a fuel cell and generate electricity, is another promising development. This process, developed by researchers at MIT and Harvard University, exhibits high carbon efficiency and produces fuels that are safe and easy to handle. The quest for feasible substitutes for fossil oil is intensified due to the growing demand for transportation fuels. Biomass, being the most feasible alternative, can provide alternative transportation fuels via Fischer-Tropsch synthesis. However, the large-scale production of such fuels is not economically feasible in the near future.

Renewable Aviation Fuel by Advanced Hydroprocessing of Biomass: Challenges and Perspective

The exploration of advanced hydroprocessing technologies offers a practical approach to producing renewable aviation fuel from biomass feedstocks. Such technologies have the potential to revolutionize the renewable fuels industry, as the petroleum sector is showing interest in altering their hydrotreating and separation procedures to manufacture renewable diesel and sustainable aviation fuel (SAF). These transitions can be quicker and more cost-efficient than building new renewable fuel production facilities from scratch.

For instance, a production facility near Forsmark on the east coast of Sweden is set to be operational by 2030. The facility aims to satisfy up to 25% of SAS's global SAF demand in the 2030s by using fossil-free electricity, water, and recycled carbon dioxide to produce electrofuel, a type of SAF. Despite the obvious environmental advantages, such as a substantial reduction in carbon dioxide emissions compared to fossil fuel, the exact reduction percentage remains undefined.

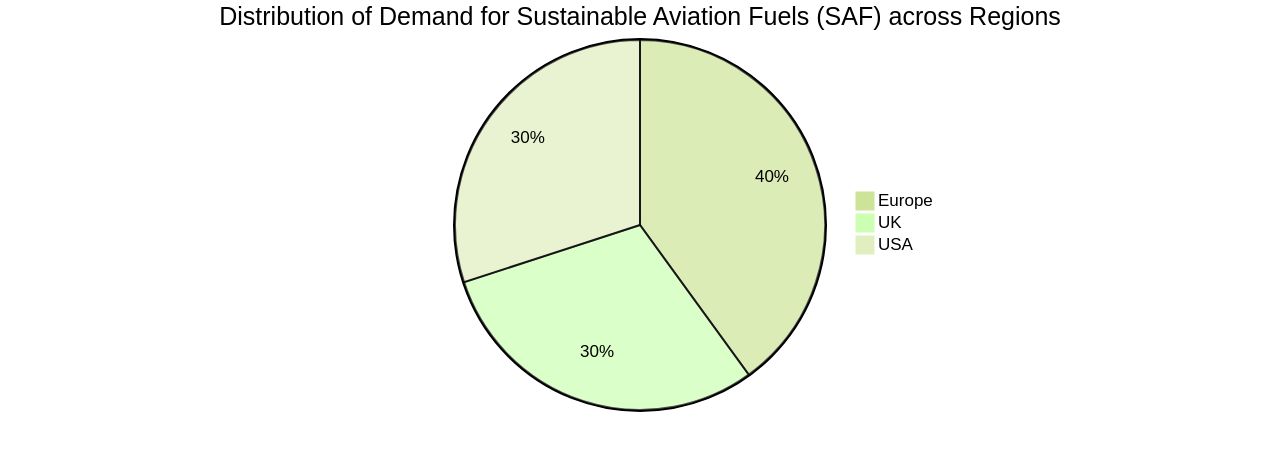

This highlights the complexity of the issue, as the demand for biomass often exceeds its supply in a decarbonizing world. However, with the growing global adoption of SAF, particularly in Europe, the UK, and the USA, the future of aviation fuel production seems optimistic, despite the persistent concerns about affordability, sustainability, and feedstock competition. One solution to speed up decarbonization is Unifuel.tech's flexiforming technology.

This technology can be implemented in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. The company commits to responding to inquiries within 24 hours and requests details about feeds, target products, and existing facilities to determine the best application for flexiforming. This innovative approach could potentially address some of the challenges faced in the production of SAF.

A Review on the Production of Renewable Aviation Fuels from the Gasification of Biomass and Residual Wastes

Gasification, a thermochemical process, transforms biomass and residual wastes into synthesis gas, or syngas, which can be further refined into renewable aviation fuels. This process is not only technically feasible but also environmentally friendly and economically viable.

The production of renewable aviation fuels through gasification has been the subject of extensive research. For instance, studies have examined electrofuel, a type of sustainable aviation fuel (SAF) that uses fossil-free electricity, water, and recycled carbon dioxide.

The carbon dioxide, captured from district heating facilities, is reused in electrofuel production, resulting in a significant reduction in carbon dioxide emissions. Efforts to decarbonize the aviation industry have led to innovative solutions like the use of waste oils and corn oils to produce SAFs.

These solutions mirror the carbon emissions of traditional aviation fuels, but because the original plants capture CO2 while growing, they are considered to be an 80-90% reduction on fossil fuel carbon emissions. Recent developments in bio-based aromatics production have enabled the aviation industry to use greater volumes of SAF, even up to 100%.

This drop-in solution is considered the most practical pathway to decarbonization because it avoids the need for extensive modifications to global aircraft fleets, airports, and fueling infrastructure. Furthermore, advancements in synthesizing methanol, a potential liquid fuel, have opened up new possibilities. Methanol can be produced from syngas, but newer technologies allow for the direct hydrogenation of CO2. Direct electrolysis even enables the production of methanol from water, CO2, and electricity in a single step. The renewable fuels industry's future hinges on these and other technological innovations, all of which aim to optimize SAF production through innovative refining techniques, thus addressing the pressing need to reduce fossil fuel dependence and mitigate climate change.

Techno-economic and Resource Analysis of Hydroprocessed Renewable Jet Fuel

Considering Hydroprocessed Renewable Jet Fuel's (HRJF) potential in the sustainable aviation fuel (SAF) domain, it is becoming a compelling alternative to traditional jet fuel. The provided techno-economic and resource analysis of HRJF production sheds light on the technical feasibility, economic viability, and resource implications of hydroprocessing technologies.

An upcoming production facility in Forsmark, Sweden, scheduled for commissioning in 2030, demonstrates HRJF's potential. The facility's location near the Forsmark nuclear power plant ensures a consistent supply of fossil-free electricity which, along with water and recycled carbon dioxide, will produce electrofuel, a type of SAF.

The adoption of SAF is on the rise, particularly in Europe, the UK, and the USA, with ambitious adoption timelines set. However, the global production limitations may lead to demand exceeding supply, posing questions about affordability, sustainability, and feedstock competition.

There are innovative solutions, such as Unifuel.tech's Flexiforming process. This technology allows operators to determine their decarbonization rate, can be implemented in an idle hydrotreater or reformer, and lowers capital expenditures and carbon intensity.

Unifuel.tech, owned by Universal Fuel Technologies, responds to inquiries within 24 hours and requests details about feeds, target products, and existing facilities to determine the optimal application for Flexiforming. One such innovation is the creation of jet fuel from plants, as demonstrated by a project backed by the United States Department of Energy. This project is developing a catalyst to convert ethanol into butene, which is then refined into aviation fuel identical to the existing crude oil-based variety. These advancements in SAF technology are crucial to meet the aviation industry's commitment to reducing emissions. Hrj f, with its sustainable production and use potential, could play a key role in this transition.

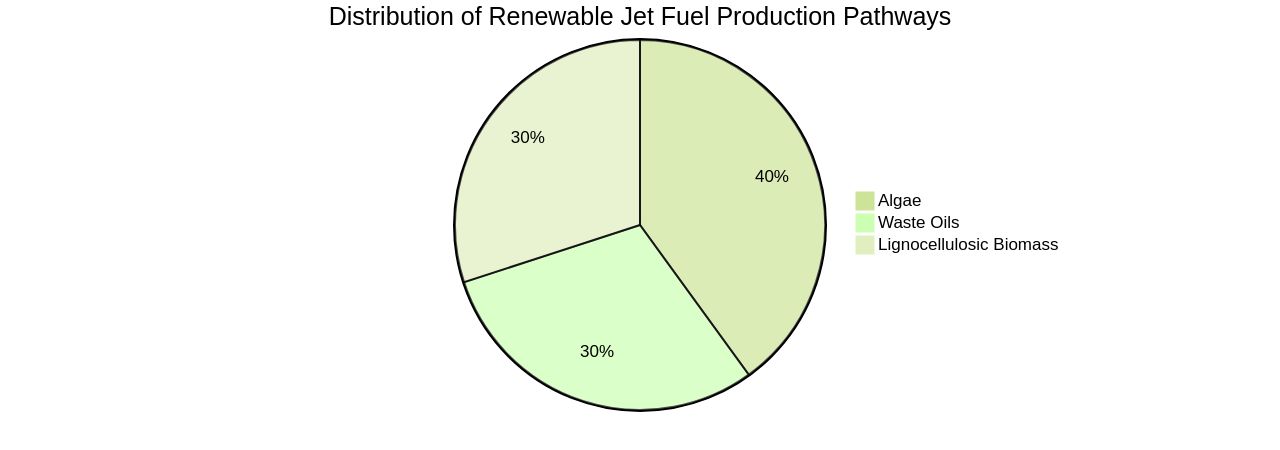

Feasibility of Short-Term Production Strategies for Renewable Jet Fuels: A Techno-economic Comparison

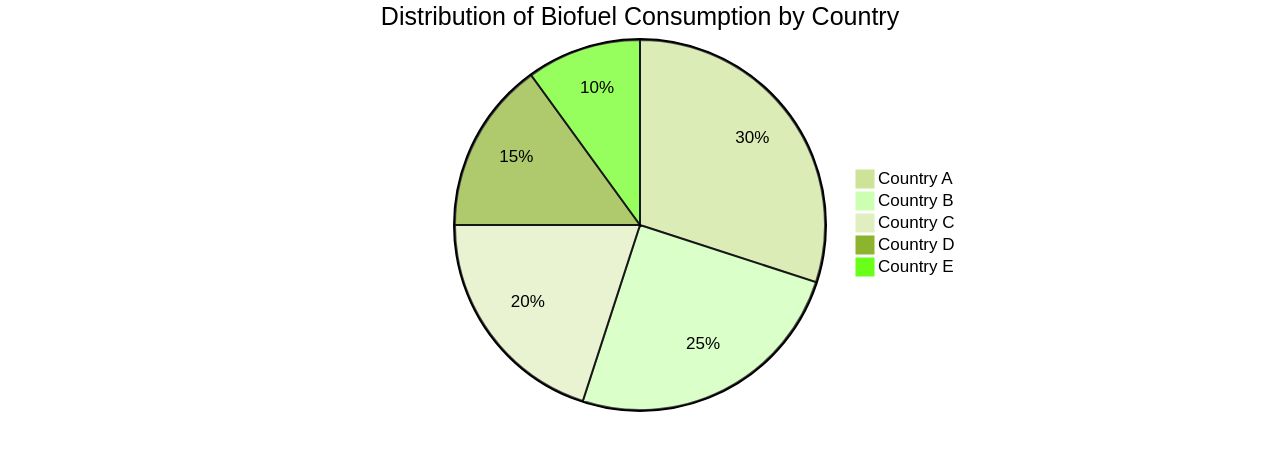

Assessing the techno-economic viability of short-term renewable jet fuel production strategies, this section scrutinizes cost-effectiveness, scalability, and environmental impacts of various pathways - waste oils, algae, and lignocellulosic biomass. For instance, the planned SAF output of 80,000 tons annually in Sweden equates to 5% of the current total jet fuel demand and 20% of the projected SAF requirement in 2030.

These figures demonstrate the potential for significant carbon dioxide emissions reduction when synthetic aviation fuel substitutes fossil fuel. However, the exact reduction percentage remains undefined, indicating a need for more precise data.

Furthermore, with aviation contributing to 2% of global carbon emissions and the demand for jet fuel projected to double by 2050, the search for greener alternatives to fossil fuel-derived kerosene has intensified. Despite the promising emergence of electric planes and hydrogen-electric flights, complete reliance on these new technologies for mass air travel remains years or even decades away.

Moreover, the US aviation sector, being the third-largest source of US transportation emissions, is expected to see a rise in emissions due to the growing demand for air travel and air freight transport. With commercial aircraft operating for an average of 20 to 30 years, the sector's decarbonization would take a significant amount of time if reliant solely on improvements in aircraft design and efficiency or the electrification of aircraft. Lastly, while the global uptake of SAF is increasing, especially in Europe, the UK, and the USA, limited global production means demand will surpass supply. This raises key questions around affordability, sustainability, competition for feedstocks, and economically efficient scales of production. Australia could potentially play a key role as a source of feedstocks and SAF producer, given its significant production of feedstocks for biofuel production.

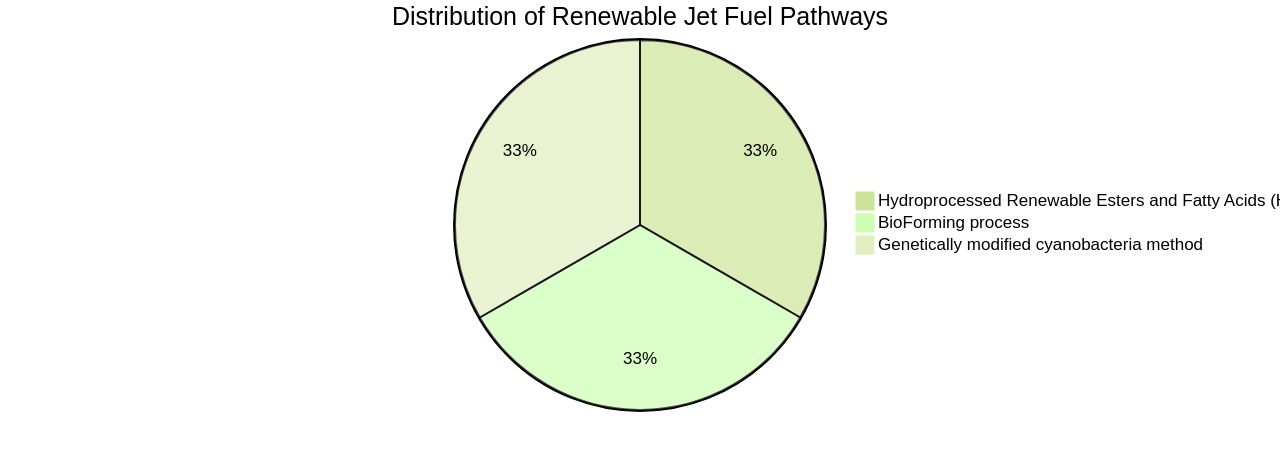

Hydroprocessed Renewable Esters and Fatty Acids for Jet Fuel Production: A Techno-economic Review

The dominant conversion process in the production of renewable jet fuel is identified as the Hydroprocessed Renewable Esters and Fatty Acids (HEFA) pathway. So, what is jet fuel made out of? The production of jet fuel, made possible by what is jet fuel made out of, offers a sustainable solution that is not only technically feasible but also economically viable. A techno-economic analysis of various pathways for SAF production found that HEFA is the most competitive due to its low triglyceride conversion costs and high yield rates. Can you explain what jet fuel is made out of?

In addition, the yearly production of 80,000 tons of Sustainable Aviation Fuel (SAF), which is made out of a combination of renewable sources such as biomass and waste oils, is projected to fulfill around 5% of Sweden's current jet fuel need and 20% of its SAF necessity by 2030. However, for large-scale production, economic feasibility is not imminent due to the high costs associated with the process. Additionally, the production of alternative fuels can be linked to CO2 emissions, either from the energy required for their production or due to their impact on ecosystems that emit carbon.

Despite these challenges, recent breakthroughs like the BioForming process, which converts sugars to aromatics, have paved the way for flights that use 100% SAF, which is what jet fuel is made out of. This process uses a wide range of plant sugars, making it adaptable to different resource availabilities worldwide. A potential approach involves using genetically modified cyanobacteria to produce the hydrocarbon isoprene, which can be converted into larger hydrocarbons similar to existing aviation fuels. What is jet fuel made out of?

This method harnesses sunlight as the energy source for the process. What is jet fuel made out of? In conclusion, while SAFs offer a potential solution for reducing CO2 emissions, their production needs to be optimized to minimize their environmental impact. Furthermore, the development of supply chains and infrastructure for hydrogen-derived liquid fuels will be critical for decarbonizing long-distance transport after 2030.

Progress in Utilization of Waste Cooking Oil for Sustainable Biodiesel and Biojet Fuel Production

Waste cooking oil (WCO) is not just a byproduct, but a valuable resource for producing biodiesel and biojet fuel. The evolution in WCO utilization has led to significant strides in sustainable fuel production.

An illustration of such progress is the use of straight vegetable oil (SVO), extracted from WCO, in maritime transport. In one instance, a 499 GT coastal RoRo vessel operated on a fuel blend consisting of 24% SVO and heavy oil A.

This approach, which bypasses complex methylation or hydrogenation processes, has the potential to curtail CO2 emissions even more than conventional biofuels, while being cost-effective. Moreover, the rising concerns over fossil fuel depletion, escalating oil prices, and the environmental toll of emissions have amplified the urgency to explore renewable energy sources.

Biomass, including biodiesel, is viewed as a viable renewable energy resource, capable of reducing carbon emissions and mitigating climate change. The use of WCO also circumvents non-food land use and potential environmental hazards if improperly disposed of. Additionally, the application of cogeneration systems and the production of biogas from waste, leftovers, and energy crops are emerging as efficient and sustainable bioenergy production systems. These technological advancements are not only economically prudent but also environmentally beneficial, offering a promising future for the sustainable production of biodiesel and biojet fuel from WCO.

Techno-economic Analysis of Renewable Aviation Fuel from Microalgae, Pongamia pinnata, and Sugarcane

What is jet fuel made out of? Microalgae, Pongamia pinnata, and sugarcane are potential feedstocks for the production of renewable aviation fuel. What is the composition of renewable aviation fuel made from these feedstocks analyzed in this section? The case study assesses the technical feasibility, economic viability, and environmental impact of each feedstock to determine what jet fuel is made out of. providing insights into their potential as sustainable sources of aviation fuel.

Techno-economic and Environmental Analysis of Jet Biofuel Production from Jatropha curcas

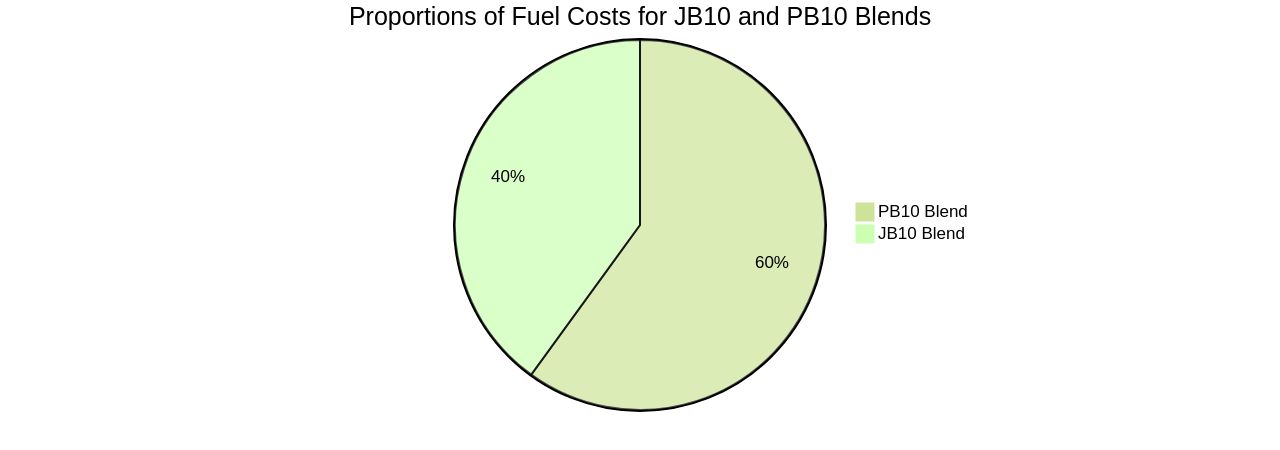

Biofuel derived from Jatropha curcas, a plant species native to tropical regions, presents a promising eco-friendly substitute for conventional jet fuel. The techno-economic and environmental aspects of this alternative are vital to understanding its feasibility. An analysis was conducted on a JB10 blend, a type of jet biofuel from Jatropha, in comparison to a commercial fuel PB10 used in Colombia.

This analysis considered the Brake Specific Fuel Consumption (BSFC), the average cost of diesel, and daily power consumption data from non-interconnected areas in Colombia. The results showed potential fuel savings in these regions. Moreover, the impact of transitioning from palm crops to Jatropha curcas for biofuel production was evaluated, focusing on the effects on soil degradation from the cultivation of both palm oil and Jatropha curcas.

Interestingly, biodiesel blends have shown to reduce greenhouse emissions, but they also led to an increase in fuel consumption and emissions of nitrogen oxides and carbon dioxide. However, they significantly reduced unburned hydrocarbons and carbon monoxide by up to 75% at full engine load, which is crucial given the proximity of combustion ignition-internal combustion engines to residential areas. A recent study has also explored isoprene, a hydrocarbon produced by cyanobacteria, and its potential for sustainable aviation fuel.

The study found that the efficiency of the photochemical reaction depends on the molecular structure of the hydrocarbon. Although the overall yield of isoprene is still low, optimizing the cultivation conditions, such as higher temperatures and violet light, can increase the productivity of cyanobacteria. This research points to a future where fossil fuels in aviation could potentially be replaced with more sustainable alternatives derived from biological sources.

Jatropha-oil Conversion to Liquid Hydrocarbon Fuels Using Mesoporous Titanosilicate Supported Sulfide Catalysts

The green diesel production from palm oil, a leading candidate due to its significant global production, and waste cooking oil, which is about 20% of new cooking oil production, is a promising venture. The catalytic deoxygenation process plays a significant role in this synthesis, with catalyst selection, process conditions, and feedstock type being crucial variables.

The use of nonedible seed oil from plants like Sisymbrium irio L. for biodiesel production is also a noteworthy approach, contributing to the circular bioeconomy of waste biomass. The quality of green diesel produced can be influenced by factors like hydrogen gas, which although increases process cost, reduces CO2 and CO gas side products.

With petroleum fuels causing environmental pollution, the development of these biofuels presents an opportunity for more environmentally friendly energy sources. The Fischer-Tropsch process, which produces a wide range of hydrocarbons, is also a significant alternative fuel production technology.

The process can be tuned to meet various needs, and the product's selectivity can be improved by increasing the electron density of Co active centers. The potential of these processes is further emphasized by recent studies, which show the possibility of producing sustainable aviation fuel from isoprene derived from cyanobacteria using sunlight. This approach could be adapted to biofuel production facilities, with the existing fossil fuel distribution infrastructure being shared by these 'drop-in' fuels. The production of alkenes by enzyme reaction also presents a versatile and adaptable option for use in different sectors. These advancements are a step towards replacing traditional energy sources with more sustainable and environmentally friendly options.

Hydroconversion of Jatropha Oil to Alternative Fuel over Hierarchical ZSM-5

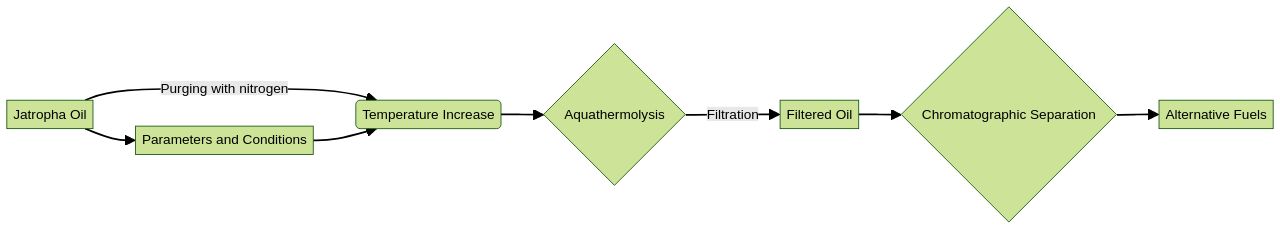

Hydroconversion plays a pivotal role in transforming Jatropha oil into alternative fuels, particularly focusing on the utilization of hierarchical ZSM-5 catalysts. This process is meticulously studied to understand the impact of various parameters, such as catalyst properties, process parameters, and reaction kinetics on the quality and efficiency of the conversion process.

The process is initiated by purging the model system with nitrogen to create an inert atmosphere, followed by an increase in temperature up to 300 °C, maintained for 24 hours. This simulation of extreme conditions mirrors the procedures used in steam-assisted enhanced oil recovery techniques in Russia.

With an oil-to-water mass ratio of 70:30, the process aims to mimic the aquathermolysis in steam-stimulated production techniques. In a different approach, degummed palm oil and deionized water are loaded into an autoclave, followed by purging with 10 bar N2 gas to ensure an inert condition.

The resulting product undergoes filtration to obtain a pure product ready for analysis. Furthermore, the process includes chromatographic separation of crude oil into four primary categories based on polarity. This process uses n-hexane to isolate maltenes from asphaltenes, setting an oil-to-solvent ratio of 1:40. These findings contribute significantly towards the optimization of the hydroconversion process for jet biofuel production, aiding advancements in the renewable fuels industry. With the goal of achieving net-zero emissions by 2050, such innovations are instrumental in ensuring a sustainable energy future.

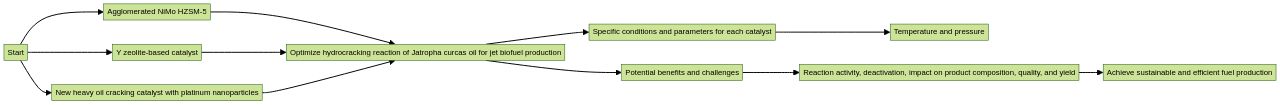

Effect of Agglomerated NiMo HZSM-5 Catalyst for the Hydrocracking Reaction of Jatropha curcas Oil

Optimizing the hydrocracking reaction of Jatropha curcas oil is pivotal to the efficient production of jet biofuel. This process hinges on the performance of agglomerated NiMo HZSM-5 catalysts. Case studies have shown that supercritical water, under specific conditions (375°C and 22.1MPa), can effectively convert bitumen-derived asphaltenes into lighter end products.

This highlights the high reaction activity and potential of using it as an acid/base catalyst. Moreover, agricultural wastes such as date stones are high-value candidates for synthesizing activated carbon, which can support the catalyst. This is particularly beneficial in Mediterranean nations, where these wastes are inexpensive and abundant.

Meanwhile, research has demonstrated the effectiveness of catalytic upgrading of heavy fractions under extreme conditions (400°C and 6 MPa). The Y zeolite-based catalyst, with its well-defined lattice structure, plays a significant role in the process. Despite its susceptibility to rapid deactivation due to sintering, high temperatures, steam, and deposition of carbon and contaminant metals, it can significantly impact the composition, quality, and yield of products.

Recent advancements have introduced a new heavy oil cracking catalyst, which carries platinum nanoparticles to the crude oil surface, promoting dehydrogenation and cracking during in situ combustion. The result is an increased yield of combustion components, maintaining the fire line in the geological formation. These innovations show promise in mitigating some of the challenges faced in the production of jet biofuel, driving us closer to more sustainable and efficient fuel production.

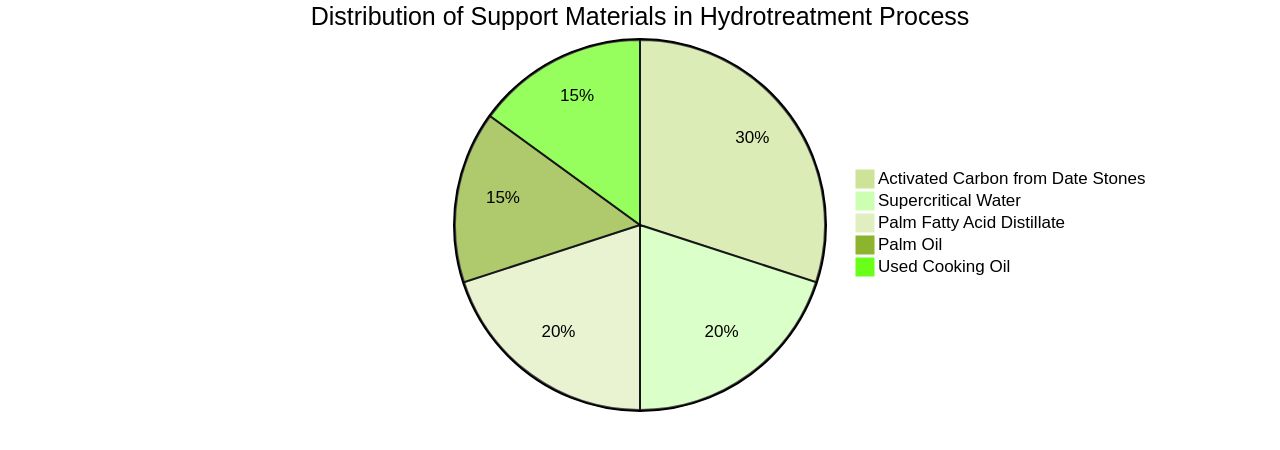

Role of Support in Hydrotreatment of Jatropha Oil over Sulfided NiMo Catalysts

The selection of support materials plays a pivotal role in the hydrotreatment process of Jatropha oil over sulfided NiMo catalysts, determining the quality of jet biofuel produced. This process's efficiency is significantly impacted by the type of support materials used, influencing the NiMo catalysts' catalytic activity and stability.

For instance, activated carbon synthesized from date stones, an abundant agricultural waste in Mediterranean countries, has been identified as a cost-effective and efficient catalyst support. This is substantiated by a study conducted by Galarraga et al., which explored the catalytic upgrading of heavy fractions under extreme conditions.

Furthermore, the use of supercritical water as an acid/base catalyst has shown success in converting bitumen-derived asphaltenes to lighter end products, establishing its potential application in the kinetic reaction of hydrotreatment processes. However, the optimal use of such catalysts depends on selecting the right support materials.

In the pursuit of producing high-quality green diesel, it is crucial to consider the type of raw materials used. Palm oil and its by-product, palm fatty acid distillate, along with used cooking oil, emerge as promising candidates for green diesel production. The production process of green diesel can be maximized by carefully selecting the catalyst, adjusting process conditions, and choosing the appropriate feedstock type. Despite the higher costs involved due to the requirement of hydrogen gas and high-pressure equipment, the hydrotreating process can lead to greener diesel with fewer CO2 and CO gas side products. This provides an opportunity to replace petroleum fuels with more environmentally friendly alternatives, leveraging the abundance of vegetable oil and other raw materials.

Feasibility Study of Jatropha Shell Gasification for Captive Power Generation in Biodiesel Production Process from Whole Dry Fruits

The feasibility of Jatropha shell gasification for captive power generation in biodiesel production is explored here, with a focus on technical, economic, and environmental aspects. By integrating gasification technology, significant changes can be observed in the production process.

Assessments have shown that a blend of JB10, as compared to commercial fuel in Colombia (PB10), can lead to considerable reductions in fuel costs. This is based on the Brake Specific Fuel Consumption (BSFC) reported by Abedin et al and the average cost of diesel referenced internationally.

Furthermore, potential fuel savings were quantified in non-interconnected regions of Colombia, using daily power consumption data from the national government. In terms of environmental impact, the replacement of palm crops with Jatropha Curcas L. (JCL) crops was evaluated.

Emphasis was placed on soil degradation from palm oil and JCL cultivation, as part of the JOB production life cycle. Interestingly, biodiesel blends are pivotal for power generation with internal combustion engines as they help mitigate greenhouse emissions. There was an observed increase in fuel consumption and emissions of nitrogen oxides and carbon dioxide, but a decrease in unburned hydrocarbons and carbon monoxide up to 75% of the engine load was also noted. This reduction is crucial as the presence of Compression Ignition Internal Combustion Engines (CI-ICE) near residential areas could have significant implications on human health.

Jatropha curcas for Jet Biofuel Production: Current Status and Future Prospects

The utilization of Jatropha curcas for jet biofuel production presents both challenges and opportunities. The cultivation of Jatropha curcas, the extraction of its oil, and the conversion process present significant challenges, but these barriers open up opportunities for creative solutions towards a sustainable and low-carbon aviation industry. What is jet fuel made out of? What is jet fuel made out of? The economic evaluation highlighted the potential fuel savings in non-interconnected areas in Colombia achieved by using a blend of JB10 compared to commercial fuel.

However, biodiesel's impact on diesel generators, which make up about 85% of the total capacity, warrants further investigation. What is jet fuel made out of? The reduction in unburned hydrocarbons and carbon monoxide up to 75% of the engine load is significant, especially when considering the health effects of CI-ICE near residential buildings. The substitution of palm crops with JCL crops also has noteworthy environmental implications, particularly on soil degradation and the life cycle of JB production. What is jet fuel made out of?

It's crucial to take into account the wider consequences of such changes, particularly as advancements in technology offer possibilities for more efficient and sustainable fuel production. What is jet fuel made out of? The development of 'drop-in' fuels, for instance, could leverage existing distribution infrastructure, providing a versatile and adaptable solution for various industrial sectors. What is jet fuel made out of? As research continues to evolve in this area, the potential of Jatropha biofuels in achieving a sustainable and low-carbon aviation industry becomes increasingly apparent.

Catalytic Steam Gasification of Biomass: Catalysts, Thermodynamics and Kinetics

The transformation of biomass into syngas via catalytic steam gasification is an emerging technology. This process leverages various catalysts and involves intricate thermodynamics and kinetics. Its potential to produce renewable aviation fuels, specifically Sustainable Aviation Fuel (SAF), is significant.

SAF is produced using fossil-free electricity, water, and recycled carbon dioxide, thereby reducing our reliance on virgin fossil feedstock. Electricity, primarily harnessed to generate hydrogen via electrolysis, plays a pivotal role in the production of ethanol, which is then converted into aviation electrofuel. Moreover, this process capitalizes on carbon capture usage (CCU), where carbon dioxide, instead of being released, is reused for electrofuel production.

A notable example is the use of fossil-free electricity from the Swedish grid and carbon dioxide from Vattenfall’s combined heat and power plant in Uppsala, which recovers approximately 200,000 tons of carbon dioxide annually. This eco-friendly approach keeps fossil raw materials in the ground and minimizes the emission of new fossil carbon dioxide. Researchers at Uppsala University have further enhanced this process by using genetically modified cyanobacteria to produce the hydrocarbon isoprene, which can be converted into larger hydrocarbons that are similar to existing aviation fuels.

This innovative method employs sunlight as the energy source, thereby increasing its potential usability. Moreover, research into the steam gasification of various waste types has shown that the steam-to-biomass ratio significantly impacts the reactivity and performance of the gasification process, with a higher ratio leading to increased hydrogen concentration and yield. Overall, these advancements in catalytic steam gasification of biomass are paving the way for more sustainable and efficient production of renewable aviation fuels.

Fischer Tropsch Synthesis Using Cobalt Based Carbon Catalysts

In the pursuit of sustainable aviation fuels, the Fischer-Tropsch synthesis process and cobalt-based carbon catalysts represent an exciting frontier. This method offers a shift away from the traditional crude oil dependency, which currently fuels over eighty percent of global energy consumption.

The Fischer-Tropsch process utilizes biomass and natural gas to produce a multitude of hydrocarbons, including n-alkanes and linear olefins. A notable study published in ACS Catalysis has highlighted the potential of cobalt phthalocyanine as a catalyst for carbon dioxide conversion into methanol.

This two-step conversion process represents a greener approach to vehicle fuel, reducing greenhouse gas emissions while generating clean energy. The versatility of the Fischer-Tropsch process allows for customization to meet diverse needs, marking it as a robust alternative to conventional fuel production technologies.

The potential for commercial-scale production using cobalt-based carbon catalysts further emphasizes their viability for renewable aviation fuels. Furthermore, the transformation of carbon dioxide into a liquid fuel that is easy to store and transport, a breakthrough achieved by scientists at the U.S. Department of Energy's Brookhaven National Laboratory and the University of North Carolina Chapel Hill, addresses critical challenges related to this potent greenhouse gas. Innovative technologies such as Unifuel.tech's flexiforming technology are also emerging in the energy sector. Flexiforming, which can be utilized in an idle hydrotreater or reformer, allows operators to control their decarbonization speed, reducing both capital expenditure and carbon intensity. The goal to establish a new synthetic fuel production facility by 2030 underscores the growing significance of such innovative processes, which can substantially reduce industrial greenhouse gas emissions while providing economically feasible and environmentally sustainable solutions.

Understanding the Role of Fischer–Tropsch Reaction Kinetics in Techno-economic Analysis for Co-conversion of Natural Gas and Biomass to Liquid Transportation Fuels

The Fischer-Tropsch (FT) process, an increasingly important player in the energy sector, provides an alternative to our over-reliance on crude oil, which accounts for more than 80% of global energy consumption. The FT process, a catalytic process, allows for the production of a wide range of hydrocarbons from biomass, natural gas, and other resources.

This process can be adjusted to meet various needs, and its primary products include n-alkanes and linear olefins, along with ISO-alkanes and cyclic hydrocarbons. A comprehensive understanding of FT reaction kinetics is pivotal in evaluating the technical and economic feasibility of such processes.

For instance, the Energreen project, aimed at producing sustainable biofuel through the acid liquefaction of lignocellulosic feedstocks, demonstrated that reaction kinetics significantly influence production costs, product distribution, and overall process efficiency. The reaction kinetics are also instrumental in determining the temperature profiles and product yields for biomass liquefaction processes. Furthermore, the transformation of CO2 into fuels with high added-value, a strategy employed to address the storage and reutilization of CO2, has been considered a successful approach to reducing carbon emissions and promoting a shift to renewable energy sources. In conclusion, the role of FT reaction kinetics is not only crucial in the techno-economic analysis of alternative fuel production technologies but also in mitigating the impact of global climate changes.

Progress in Biofuel Production from Gasification

The landscape of biofuel production, particularly sustainable aviation fuel (SAF), is evolving due to advancements in technologies such as gasification. This evolution is propelled by the increasing demand for air cargo transport and the use of biofuels in military aircraft.

For instance, the US Department of Energy's Bioenergy Technologies Office (BETO) is spearheading research to alleviate constraints to SAF deployment. Innovative methods such as gas-fermentation are now being used by companies like LanzaTech in Ghent's steel mill to convert industrial waste gases into advanced bio-ethanol.

This process, unique among commercial ethanol production technologies, presents both hurdles and possibilities. An LCA by E4tech provides a detailed examination of this type of ethanol's environmental performance, aiding stakeholders in comprehending its comparative advantages and benefits.

Biogas production, primarily from anaerobic decomposition, represents another renewable fuel development pathway. However, the high methane content in landfill gas raises environmental concerns due to its flammability and greenhouse gas potential.

In 2021, global biofuel consumption reached 1,837 thousand barrels of oil equivalent per day, illustrating biofuels' ability to reduce greenhouse emissions by up to 65% and bolster energy security. The growth of the biofuel industry also signifies potential job creation, contributing to economic and agricultural stability. Government policies worldwide, such as blending mandates and tax credits, are encouraging biofuel use and reducing costs, fueling rapid market growth, particularly in Europe, with France, the UK, Germany, and Poland at the forefront. In this context, companies such as Unifuel.tech are emerging with innovative solutions like flexiforming technology. This technology enables operators to control their decarbonization pace and can be implemented in an idle hydrotreater or reformer, thereby decreasing capital expenditure and carbon intensity. Unifuel.tech, whose rights are held by Universal Fuel Technologies, offers a quick response time of 24 hours for inquiries about feeds, target products, and existing facilities.

Stochastic Techno-economic Analysis of the Production of Aviation Biofuel from Oilseeds

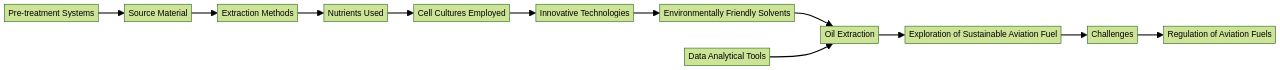

Stochastic techno-economic analysis offers valuable insights into the production of aviation biofuel from oilseeds, considering the uncertainties and risks associated with feedstock availability, market prices, and production costs. This analytical tool, when applied to the production process of biofuels, can help in the optimization of various parameters, including pre-treatment systems, source material, extraction methods, nutrients used, and cell cultures employed.

In the context of oilseed-based aviation biofuel, oil extraction is a critical step that determines the quality and quantity of the oil obtained. The shift in focus from individual operations to the entire production process has led to the adoption of innovative technologies to improve quality and production efficiency.

For instance, the use of environmentally friendly solvents such as ethanol, supercritical CO2, and water enzymatic extraction has emerged as a sustainable alternative to hexane. The production of aviation biofuel from oilseeds also benefits from the application of data analytical tools, which can help in uncovering data about the production procedures, developing predictive models, and understanding the effects of different parameters on the results.

Software tools like MATLAB, Python, and WEKA have been employed for this purpose, contributing to the enhancement of fuel yields. However, the production of aviation biofuel from oilseeds is not without challenges. The high dependency on non-OECD countries for oil reserves, the limited availability of waste oil, and the stringent regulation of aviation fuels are some of the issues that need to be addressed. Despite these challenges, sustainable aviation fuel (SAF) has emerged as a promising solution for emissions abatement in the aviation industry. The production of SAF from biomass crops like Miscanthus, sorghum, and switchgrass, which can be grown without irrigation and can be readily converted into high-performance jet fuel, is being explored.

Kinetics and Mechanistic Study of n-Alkane Hydroisomerization Reaction on Pt-doped γ-alumina Catalyst

The process of hydroisomerization, a key reaction in jet biofuel production, relies heavily on the use of catalysts. Specifically, Pt-doped γ-alumina catalysts have been shown to enhance the selectivity and efficiency of this reaction.

However, the physical properties of these catalysts, including their shape, composition, and the proximity of active sites, can greatly influence their performance. For instance, studies have shown that catalysts with a close proximity between Pt and Beta zeolite resulted in higher conversion and C6 selectivity for the hydroisomerization of n-hexane.

Moreover, the use of binders in catalysts, which aid in shaping and providing mechanical strength, can also affect their catalytic activity. Continued research and development in this area is critical, especially as the demand for alternative and renewable fuels grows.

The aviation industry, in particular, is facing the challenge of transitioning to greener fuels as traditional fossil fuels can't be easily replaced due to their high energy-to-weight ratio. As such, the development and optimization of catalysts for hydroisomerization and other refining processes are of paramount importance.

Furthermore, understanding the influence of different operating parameters on the hydroisomerization process is crucial. This requires the use of Design of Experiments (Doe) to quantify effects and their interactions. In addition, the shift towards more sustainable processes necessitates the exploration of bio-based carbon sources, such as lignin from the paper industry, which is currently underutilized. In conclusion, while significant strides have been made in optimizing the hydroisomerization process for jet biofuel production, there is still much work to be done. Continued research and development in this area will play a vital role in the transition towards more sustainable and efficient fuel production methods.

Techno-economic and Environmental Analysis of Aviation Biofuels

The aviation industry is under immense pressure to reduce emissions and turn to sustainable alternatives. Biofuels, derived from biomass, waste oils, and algae, are being evaluated for their cost-effectiveness, environmental impact, and sustainability. The rising global demand for Sustainable Aviation Fuels (SAF), especially in Europe, the UK, and the USA, outpaces the current production capabilities, raising questions around affordability and sustainability.

Moreover, competition for feedstocks and the need for economically efficient production scales add further complexity to the situation. However, countries like Australia, already a significant producer of biofuel feedstocks, could play a pivotal role in expanding and diversifying feedstock sources. The country's burgeoning hydrogen economy could also potentially provide a clean supply of hydrogen, a crucial component of several fuel production processes.

Despite these promising prospects, the SAF industry faces significant challenges. The necessity for aromatics in aviation fuel currently limits the volume of SAF that can be added. However, recent advancements have enabled the production of bio-based aromatics, facilitating the use of greater volumes of SAF.

Saf's 'drop-in' nature makes it a practical solution for decarbonizing aviation without major infrastructural modifications. Nevertheless, the vast amount of biomass needed to fuel the aviation industry, the fastest-growing sector in terms of emissions, remains a daunting prospect. It is crucial, therefore, to explore more efficient ways of producing biofuels and other 'sustainable fuels, necessitating early innovation and investment in this area.

Energy Return on Investment for Alternative Jet Fuels

The energy return on investment (EROI) is a pivotal metric in determining the efficacy of alternative jet fuels. This section examines the EROI for alternative jet fuels sourced from renewable substrates such as biomass and algae.

By investigating various alternative jet fuel pathways, we highlight energy efficiency, resource needs, and environmental impacts, establishing the EROI's significance in decision-making. A case study of a planned production facility near Forsmark, Sweden, illustrates the potential of electrofuel as a sustainable aviation fuel (SAF).

Here, fossil-free electricity, water, and recycled carbon dioxide are the only inputs, making this a viable alternative to traditional fossil fuels. However, the journey to SAF isn't without challenges.

Despite net-zero plans by organizations like the International Air Transport Association and numerous test flights powered by 100% Safe, alternative fuels made up less than 0.2% of the global jet fuel supply in 2022. Recent research has also cast a shadow on the energy efficiency of some alternatives.

For instance, biodiesel derived from microalgae may emit more carbon during production and use than petroleum-based diesel, due to its energy-intensive manufacturing process. On the other hand, bioenergy from biomass, currently the largest source of renewable energy globally, stands as a near zero-emission fuel with potential uses in hard-to-electrify sectors like aviation and shipping. Moreover, Uppsala University research groups have been exploring a combined photobiological-photochemical method for producing synthetic SAF. The process employs genetically engineered cyanobacteria to manufacture isoprene, a hydrocarbon, using solar energy and carbon dioxide from the air. In conclusion, while SAFs could be the key to meeting the aviation industry's net-zero emissions target by 2050, the actual impact will be dictated by various factors including the specific source material and production method.

Conclusion

In conclusion, renewable aviation fuel production is gaining momentum as the aviation industry aims to reduce greenhouse gas emissions and achieve sustainability goals. Sustainable Aviation Fuel (SAF) offers a shift from petroleum-based kerosene, but challenges remain in procurement due to limited availability and higher costs. Emerging green business models like algae biofuel show promise, but energy-intensive manufacturing processes raise concerns about carbon emissions.

Innovative refining processes like Unifuel.tech's flexiforming offer solutions for optimizing SAF production and reducing capital expenditure and carbon intensity. Sustainable alternative fuels from biomass, algae, and waste oils have potential for reducing emissions, but large-scale availability remains a challenge. Companies like Airbus and Virgin Atlantic are leading the way in SAF adoption.

Techno-economic analysis emphasizes the need to optimize refining processes, address affordability and sustainability challenges, and manage feedstock competition. Advanced hydroprocessing technologies can transform traditional fuel production procedures. Jatropha curcas is a promising feedstock for jet biofuel production, but cultivation and processing challenges exist.

Biofuels as drop-in solutions without engine modifications offer renewable energy possibilities. Gasification of biomass provides a technically feasible and environmentally friendly pathway for renewable aviation fuels. Waste cooking oil utilization also presents opportunities for sustainable biodiesel and biojet fuel production.

Understanding catalysts is crucial for efficient jet biofuel production through hydroprocessing technologies. Catalyst selection and support materials significantly impact catalytic activity and stability. The Fischer-Tropsch synthesis process with cobalt-based carbon catalysts shows promise in producing alternative fuels.

Technological advancements like direct hydrogenation of CO2 contribute to greener fuel sources. Continued research is necessary to optimize refining processes, address feedstock availability and affordability, and ensure sustainable practices. Innovations like Unifuel.tech's flexiforming technology offer potential solutions for more efficient SAF production while reducing costs.