Introduction

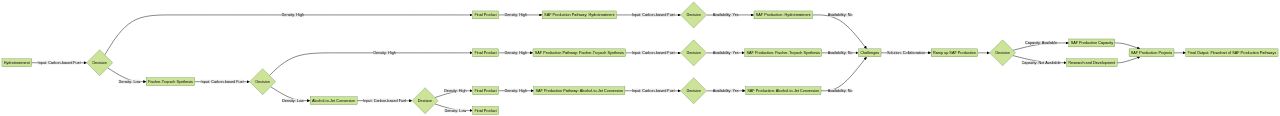

The quest for enhancing sustainable aviation fuel (SAF) density is anchored in a profound understanding of the technologies and pathways integral to its creation. In this article, we will explore the different production pathways and technologies involved in the creation of SAFs, such as hydrotreatment, Fischer-Tropsch synthesis, and alcohol-to-jet conversion.

We will also delve into the challenges faced by the aviation industry in terms of production capacity and demand. Join us as we explore the world of sustainable aviation fuels and the innovative solutions being developed to drive the industry towards a more sustainable and environmentally friendly future.

Understanding Sustainable Aviation Fuels: Pathways and Technologies

The quest for enhancing sustainable aviation fuel (SAF) density is anchored in a profound understanding of the technologies and pathways integral to its creation. SAFs, extracted from diverse feedstocks like waste oils, biomass, and algae, traverse various production pathways. These pathways - hydrotreatment, Fischer-Tropsch synthesis, and alcohol-to-jet conversion - each bestow unique traits that shape the final fuel product's density.

However, despite the critical role of SAFs in the aviation industry's emissions reduction strategy, the current global production, ambitious adoption timelines, and high volume targets are daunting, with demand forecast to outstrip supply. In the wake of energy system instability, the quest for alternative energy production, supply, and security heightens. The aviation sector, devoid of the option for electrification or alternative fuels like green hydrogen for long-haul flights, relies heavily on Safe for emissions reduction.

SAFs, derived from biomass, waste products, natural oils, fats, and other carbon sources, have gained increasing global acceptance, with Europe, the UK, and the USA leading the pack. Nonetheless, affordability, sustainability, feedstock competition, and economically efficient production scales remain as lingering challenges. Addressing these challenges, Unifuel.tech introduces its Flexiforming technology.

This solution offers operators the flexibility to determine their decarbonization pace and can be implemented into an idle hydrotreater or reformer, thereby cutting down capital expenditure and carbon intensity. Unifuel.tech's agile customer service guarantees a response to inquiries within 24 hours, offering customized solutions based on the customer's feed, target products, and existing facilities. This innovative approach offers a promising pathway towards sustainable and cost-effective fuel sourcing for the aviation industry.

Fischer-Tropsch Synthesis: A Promising Method for SAF Production

Sustainable Aviation Fuel (SAF) is produced via the Fischer-Tropsch process, converting carbon-based feedstocks into liquid hydrocarbons. This approach facilitates the generation of high-energy-density SAFs that improve aircraft performance.

Progressive corporations like ORLEN and Yokogawa have pushed this field forward by developing a 'digital twin' of a production system, fine-tuning processes, and identifying the most sustainable synthesis methods. Furthermore, ORLEN is targeting an annual production of 70 thousand tonnes of synthetic fuels by 2030, signifying a major stride towards aviation decarbonization.

In parallel, Uppsala University researchers are exploring the potential use of genetically engineered cyanobacteria for isoprene production, a potential SAF, using solar power and carbon dioxide. The BioForming method has showcased its potential in producing SAF from various plant sugars and has successfully powered 100% SAF trans-Atlantic flights, underlining SAF's viability in achieving net-zero carbon emissions in aviation.

Emerging solutions such as Unifuel.tech's flexiforming technology offer operators the ability to control their decarbonization pace. This technology can be deployed within an idle hydrotreater or reformer, thereby cutting both capital expenditure and carbon intensity. As a subsidiary of Universal Fuel Technologies, Unifuel. Tech symbolizes another step towards environmentally friendly alternatives to traditional jet fuel in the aviation industry. The company also guarantees a response within 24 hours for inquiries related to optimal applications of flexiforming based on the user's feeds, target products, and existing facilities.

Fuels and Fuel-Additives: Properties and Characteristics

Sustainable Aviation Fuels (SAFs) present a compelling strategy for combating greenhouse gas emissions in the aviation sector. They primarily consist of hydrocarbons, particularly elongated carbon atom chains, or 'aliphatic' molecules, forming 75% to 90% of the total composition. The residual 10% to 25% is occupied by 'aromatic' molecules, essential for achieving the requisite physical and combustion characteristics of the aviation fuel mix.

Attributes such as carbon chain length, aromatic content, and the presence of oxygenates in SAFs and their additives considerably influence fuel density optimization. The combustion process entails the disassociation of hydrogen and carbon atoms, forging new bonds with oxygen to produce water (H2O), carbon dioxide (CO2), and significant heat (energy). This energy is harnessed for propulsion, turbine rotation, or piston drive linked to a drivetrain.

Besides environmental gains, SAF production can catalyze economic growth, boost industrial production, and fortify the rural economy. Despite stringent regulations, the aviation industry has made strides in SAF adoption, with airlines like United Airlines and Emirates Airline initiating the use of 100% SAF. The transition to SAFs is not merely environmentally advantageous but also strategic, curtailing reliance on oil imports and alleviating supply risks.

This shift is being expedited by technological breakthroughs such as flexiforming offered by Unifuel.tech. This technology enables operators to dictate their decarbonization rate and augment sustainable aviation fuel density. Flexiforming can be incorporated into an idle hydrotreater or reformer, diminishing capital expenditure and carbon intensity.

Unifuel. Tech assures a response within 24 hours to inquiries about feeds, target products, and existing facilities, to identify an optimal application for flexiforming. This transition to Safe underscores a significant stride towards a sustainable aviation future, with the potential to dramatically lower carbon dioxide emissions.

Conclusion

In conclusion, the production of sustainable aviation fuels (SAFs) requires a deep understanding of different pathways and technologies. Challenges like production capacity and demand hinder widespread adoption in the aviation industry.

However, solutions like Unifuel.tech's Flexiforming technology offer promising pathways for sustainable and cost-effective fuel sourcing. This technology allows operators to control decarbonization pace and reduce capital expenditure and carbon intensity.

Fischer-Tropsch synthesis shows promise in SAF production by converting feedstocks into high-energy-density liquid hydrocarbons. Companies like ORLEN make strides towards aviation decarbonization with synthetic fuel targets.

Transitioning to SAFs brings environmental benefits while reducing reliance on oil imports and mitigating supply risks. Technological breakthroughs like flexiforming accelerate this shift by enabling operators to dictate decarbonization rates while increasing fuel density. Overall, developing sustainable aviation fuels is crucial for a more environmentally friendly future in aviation. With continued advancements and innovative solutions, we can significantly reduce carbon dioxide emissions while promoting economic growth and energy security.

Join Universal Fuel Technologies today and be a part of the sustainable aviation fuel revolution!