Introduction

The imperative to decarbonize the aviation industry is underscored by the fact that air travel contributes approximately 2% to global carbon emissions, a number that is expected to rise sharply. Sustainable Aviation Fuel (SAF) emerges as a pivotal solution, with the potential to reduce emissions by up to 70% compared to conventional jet fuel.

However, the nascent state of SAF technology, coupled with economic challenges, underscores the urgency to optimize production processes for scalability and cost-effectiveness. This article explores the importance of sustainable aviation fuel, methodologies for repurposing existing manufacturing facilities, economic analysis and carbon credits, and a case study of Memphis International Airport's efforts in the sustainable aviation fuel arena. By providing technical insights and analysis, this article aims to deepen the understanding of renewable fuels in the aviation industry.

The Importance of Sustainable Aviation Fuel

The imperative to decarbonize the aviation industry is underscored by the fact that air travel contributes approximately 2% to global carbon emissions, a number that is expected to rise sharply. Sustainable Aviation Fuel (SAF) emerges as a pivotal solution, with the potential to reduce emissions by up to 70% compared to conventional jet fuel.

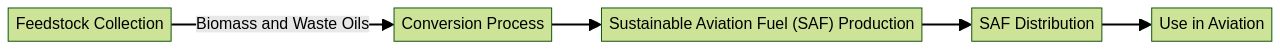

SAF production utilizes diverse feedstocks, including biomass, waste oils, and fats, offering a renewable alternative to fossil fuels. However, the nascent state of SAF technology, coupled with economic challenges, underscores the urgency to optimize production processes for scalability and cost-effectiveness.

Despite a global commitment to reducing emissions, the aviation sector grapples with limited SAF production capabilities, leading to a demand that far outstrips supply. This situation is further complicated by the competition for feedstocks and the need for economically viable production scales.

The International Civil Aviation Organization's ambitious target of achieving net-zero carbon emissions by 2050 amplifies the need for rapid advancement in SAF technology and production. With aviation's indirect emissions, such as contrails, also contributing to its greenhouse gas (GHG) footprint, the transition to SAF is not just a matter of swapping fuels but a comprehensive shift in aviation's approach to its environmental impact.

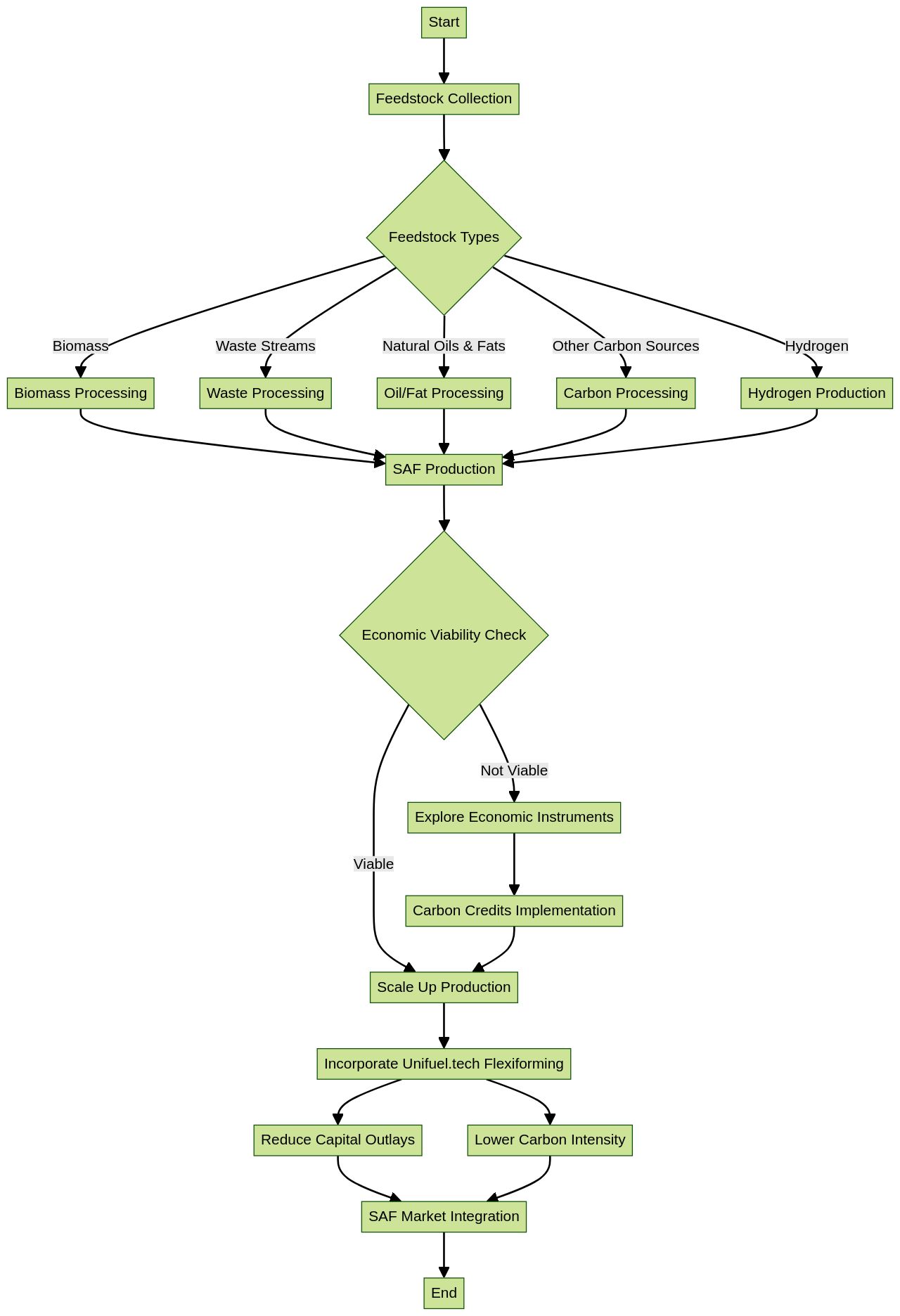

Addressing the economic and technological hurdles, Unifuel. Tech presents Flexiforming, an innovative technology enabling operators to tailor their decarbonization pace. This solution can be integrated into existing idle hydrotreaters or reformers, streamlining the adoption process by leveraging current infrastructure and reducing the capital expenditures typically associated with new technology deployments. By reducing carbon intensity and offering rapid response times to inquiries, Flexiforming stands as a promising catalyst in the scale-up of SAF production. The technology's compatibility with various feeds and target products positions it as a versatile tool in meeting the stringent safety standards and operational requirements of the aviation industry, propelling it towards a greener horizon.

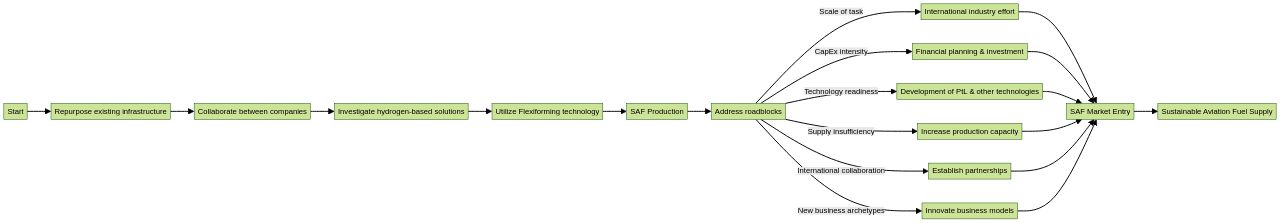

Methodology for Repurposing Existing Manufacturing Facilities

Harnessing the innovative spirit that has characterized the aviation industry's approach to sustainability, repurposing existing manufacturing facilities emerges as a pragmatic strategy for optimizing sustainable aviation fuel (SAF) production. This approach capitalizes on pre-existing infrastructure, thereby curtailing the significant capital expenditure typically required for constructing new plants. In alignment with this strategy, Unifuel.tech's flexiforming technology offers a seamless integration into idle hydrotreaters or reformers, enabling operators to retrofit their facilities for SAF production with reduced capital outlay and diminished carbon intensity.

The agility of flexiforming allows for an adaptable decarbonization pace, meeting the varied needs of operators. With Virgin Atlantic's CEO highlighting the insufficient supply of SAF to meet burgeoning demand, and industry statistics underscoring the shortfall in production, the capacity to swiftly convert existing assets into SAF production units becomes invaluable. The US aviation sector, contributing approximately 7% to the nation's transportation emissions, and the long operational lifespan of commercial aircraft, amplify the need for scalable SAF solutions.

The narrative of Virgin Atlantic's historic Flight 100, powered entirely by SAF, exemplifies the potential of innovation coupled with supportive regulations. Unifuel.tech's commitment to rapid response times, within 24 hours, and their tailored approach to integrating flexiforming based on specific operational parameters, feeds, and target products, positions them as a pivotal player in the industry's transition to SAF. This is crucial as the sector strives to achieve mid-century decarbonization goals.

Economic Analysis and Carbon Credits

In the pursuit to mitigate aviation-related emissions, the industry's focus has shifted to sustainable aviation fuel (SAF) for its dual benefits of environmental responsibility and economic viability. The production of SAF through established pathways, which leverage biomass, waste streams, and varied carbon sources, is under scrutiny for their greenhouse gas reduction potential.

Yet, the economic viability of these pathways remains paramount. A comprehensive economic analysis is vital, considering carbon credits' role in offsetting production costs.

By monetizing the environmental impacts of SAF, producers can bolster its economic appeal. Grasping the diversity of fuel types, carbon footprints, and related expenditures is crucial for judicious investment in SAF.

Economic instruments are instrumental in navigating the hurdles of elevated production costs and scarce supply, facilitating Saf's scalability and its acceptance as a legitimate substitute for traditional jet fuel. Unifuel.tech's flexiforming technology emerges as a strategic solution, presenting operators with the autonomy to tailor their decarbonization trajectory.

Flexiforming, which can be integrated into dormant hydrotreaters or reformers, diminishes both capital outlays and carbon intensity. By gathering specific data about feedstocks, desired products, and existing infrastructure, Unifuel. Tech delineates the most suitable applications of flexiforming. Their commitment to respond to inquiries within a day underscores their dedication to customer service. Information regarding the flexiforming solution and contact details can be found on Unifuel.tech's website, which also delineates the ownership and usage rights by Universal Fuel Technologies.

Case Study: Memphis International Airport

Memphis International Airport has taken a significant step in the sustainable aviation fuel (SAF) arena by repurposing its existing infrastructure to support SAF production, a move that underscores both economic feasibility and the potential for accruing carbon credits. This initiative is part of a wider trend, with regions like the Great Lakes and Rocky Mountains actively conducting studies and forming collaborations to shape the future of environmentally friendly aviation. For instance, the collaboration between Plug Power Inc., Airbus, Hartsfield-Jackson Atlanta International Airport, and Delta Air Lines to investigate a hydrogen-based hub at ATL is indicative of the industry's dedication to decarbonization through cutting-edge energy solutions.

Baker Hughes and Avports have also joined forces to offer a technical and economic blueprint for airports to sustainably meet their energy needs. These efforts are critical in the face of limited SAF supplies and high costs, contributing to the Biden administration's goal of scaling SAF production by 2050. In this context, Unifuel.tech's Flexiforming technology emerges as a transformative solution, enabling operators to retrofit idle hydrotreaters or reformers for SAF production.

This approach offers a tailored speed of decarbonization, minimizing both capital expenditures and carbon intensity. Unifuel.tech, a branch of Universal Fuel Technologies, is committed to swift customer service, promising 24-hour response times to inquiries regarding the integration of Flexiforming, based on specific feedstock, target product profiles, and existing facility parameters. These attributes affirm Unifuel.tech's role in advancing the SAF roadmap and fostering the aviation sector's transition to greener energy sources.

Conclusion

In conclusion, the aviation industry's imperative to decarbonize is driven by the significant contribution of air travel to global carbon emissions. Sustainable Aviation Fuel (SAF) emerges as a pivotal solution, with the potential to reduce emissions by up to 70% compared to conventional jet fuel.

However, the nascent state of SAF technology and economic challenges highlight the need to optimize production processes for scalability and cost-effectiveness. Repurposing existing manufacturing facilities presents a pragmatic strategy for optimizing SAF production.

Unifuel.tech's Flexiforming technology allows operators to retrofit idle hydrotreaters or reformers, reducing capital expenditure and carbon intensity. This adaptable approach aligns with the varied needs of operators and addresses the limited supply of SAF and long lifespan of commercial aircraft.

Economic analysis is crucial in assessing the viability of SAF production pathways, considering carbon credits as a means to offset costs. Unifuel.tech's Flexiforming technology offers operators autonomy in tailoring their decarbonization trajectory, minimizing both capital outlays and carbon intensity.

Their commitment to rapid response times underscores their dedication to customer service. The case study of Memphis International Airport exemplifies the industry's efforts in repurposing existing infrastructure for SAF production. Collaborations and studies across different regions further demonstrate the commitment to decarbonization through innovative energy solutions. Unifuel.tech's Flexiforming technology stands as a transformative solution in retrofitting facilities for SAF production, supporting the industry's transition to greener energy sources. Overall, sustainable aviation fuel is a crucial component in achieving net-zero carbon emissions by 2050. By optimizing production processes, leveraging existing infrastructure, and conducting comprehensive economic analysis, the aviation industry can accelerate its transition towards a more sustainable future.