Introduction

Sustainable Aviation Fuel (SAF) has emerged as a game-changer in the aviation industry's quest for environmental sustainability. With the goal of achieving net-zero carbon emissions by 2050, SAF offers a cleaner alternative to fossil-based jet fuel, potentially reducing aviation emissions by up to 95%.

However, the industry faces significant challenges in terms of technology development and high production costs. In this article, we will explore the role of SAF in reducing emissions, the different types of SAF and their production pathways, as well as the challenges and limitations the industry must overcome. Join us as we delve into the technical insights and analysis of the renewable fuels industry's journey towards a greener future.

What is Sustainable Aviation Fuel (SAF)?

Sustainable Aviation Fuel (SAF) is poised to revolutionize the aviation sector's environmental impact by potentially curbing the 2 to 3% of global CO2 emissions for which the industry is currently accountable. As a cleaner alternative to fossil-based jet fuel, SAF comes from renewable resources and is pivotal for the aviation industry's goal of net-zero carbon emissions by 2050.

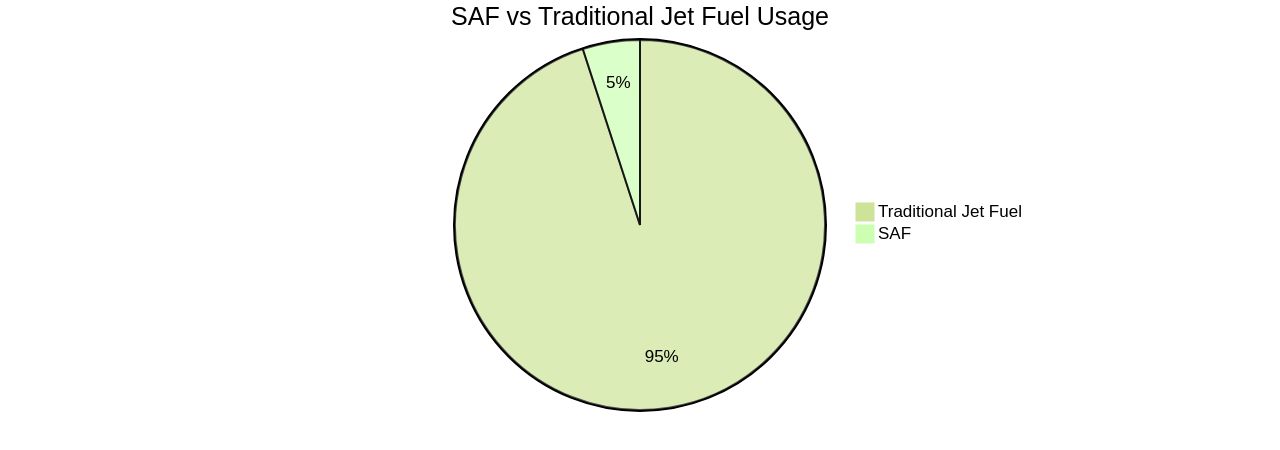

The industry, however, is grappling with the early-stage development of SAF technologies and the steep costs of production and scaling. Presently, Saf's market price is substantially higher than that of conventional jet fuel, and its production volume is minuscule in comparison to the total kerosene consumption of commercial aviation.

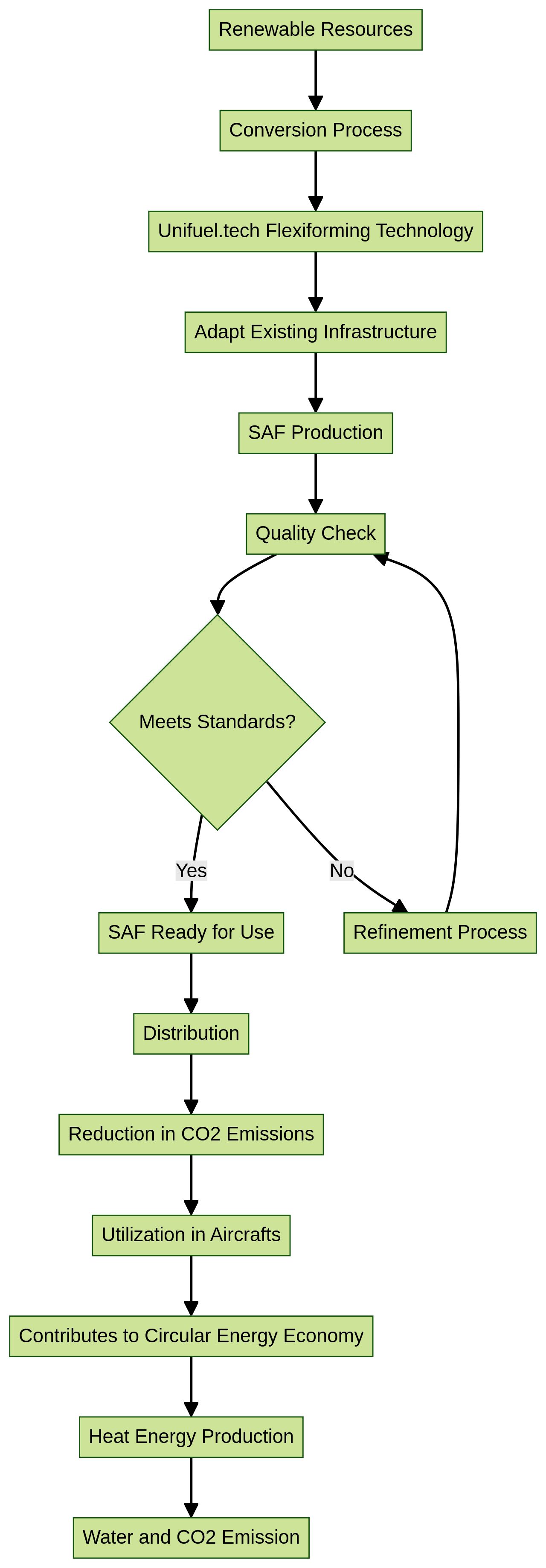

In response to these challenges, innovative solutions such as Unifuel.tech's flexiforming technology are emerging. This method enables the adaptation of existing infrastructure, like dormant hydrotreaters or reformers, for SAF production, thereby minimizing capital investments and carbon intensity.

Unifuel.tech's approach facilitates a tailored decarbonization strategy, taking into account the operator's raw materials, desired outputs, and current facilities. They provide a rapid turnaround, promising feedback within a day upon receiving the relevant details. This responsiveness and adaptability could play a significant role in overcoming the barriers to SAF production scalability. Additionally, global initiatives, like the collaborative SAF Roadmap and Airbus's pledge for SAF-compatible aircraft by 2030, along with Unifuel.tech's flexiforming technology, are accelerating the transition to a sustainable aviation industry. With such advancements, SAF has the potential to reduce aviation emissions by 60 to 100% compared to traditional jet fuels, marking a significant leap towards the sector's decarbonization ambitions.

The Role of SAF in Reducing Emissions

Sustainable Aviation Fuel (SAF) is pivotal in mitigating the environmental footprint of the aviation industry, capable of slashing carbon emissions by up to 95% in comparison to standard jet fuel. Produced from a variety of sources, including used cooking oil, agricultural waste, and even direct air capture of CO2, Saf's production adaptability is crucial for the industry's greener aspirations.

The aviation sector's goal to achieve net-zero emissions by 2050, as set by the International Civil Aviation Organization, is deeply intertwined with the advancement of SAF. Despite its potential, Saf's current use is a mere fraction of total fuel consumption, primarily due to higher costs—nearly quadruple that of traditional kerosene—and its early development stage.

The industry is committed to resolving these challenges, with milestones such as the first transoceanic flight powered entirely by SAF and Airbus's target to ensure its fleet is SAF-ready by 2030 being notable examples. To support the upscaling of SAF and to address the infrastructural and financial hurdles, innovations such as Unifuel.tech's flexiforming technology are emerging.

Flexiforming, a versatile solution by Universal Fuel Technologies, enables operators to tailor their decarbonization trajectory. By integrating into existing idle hydrotreaters or reformers, it offers a pathway to reduce both capital expenditure and carbon intensity. For those seeking to leverage this technology, Unifuel. Tech promises a swift response within 24 hours to inquiries, providing customized solutions that consider the operator's specific feedstocks, desired products, and current facilities. Such technological advancements and partnerships are critical to making SAF a cornerstone of aviation's sustainable transformation, necessitating a unified push to surmount the production and cost barriers that currently impede its widespread adoption.

Types of SAF and Their Production Pathways

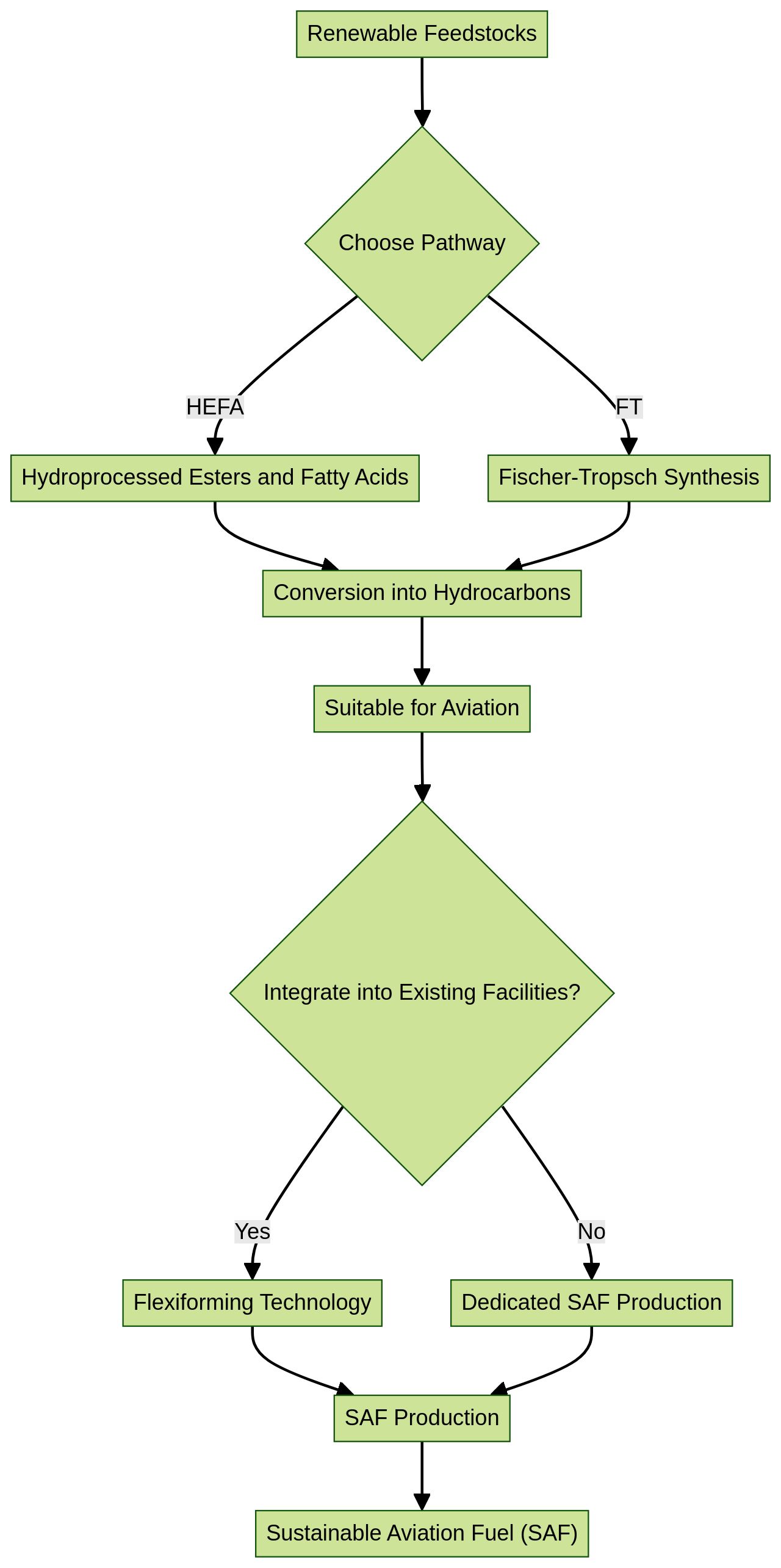

Producing Sustainable Aviation Fuel (SAF) through established pathways like Hydroprocessed Esters and Fatty Acids (HEFA) and Fischer-Tropsch (FT) synthesis is pivotal in transforming the aviation industry towards carbon neutrality. These processes convert renewable feedstocks into hydrocarbons suitable for aviation, aligning with the industry's ambitious goal to achieve net-zero carbon emissions by 2050. The HEFA pathway typically involves the hydroprocessing of fats, oils, and greases to create paraffinic hydrocarbons, while the FT synthesis is a gas-to-liquid process that converts carbon monoxide and hydrogen into liquid hydrocarbons.

A case in point is the SAF+ initiative, which operates a pilot plant in Montreal, showcasing the practicality of e-SAF production. The plant's anticipated output is a testament to the scalability of SAF technologies, with an expected launch in 2028 and a projected reduction in CO2 emissions substantially contributing to the decarbonization efforts. The potential of SAF is further underscored by the PtL process, which can reduce CO2 emissions by 89 to 94%.

However, the technology, while promising, faces challenges in large-scale production. Despite the technological readiness and understanding of the cost structures for most relevant SAF production technologies, the current supply remains insufficient. Overcoming this supply gap is critical, as the annual planned SAF output of 80,000 tons meets only a fraction of current and future demands, illustrating the urgent need for ramp-up in production to meet the sector's targets.

Moreover, the integration of SAF into the current aviation infrastructure offers a seamless transition, with recent innovations enabling 100% SAF flights without engine modifications. This breakthrough aligns with the chemistry of a circular energy economy, where the production of hydrocarbon fuels, such as biofuels or synthetic kerosene, results in the combustion of CO2, water, and energy, without the reliance on fossil-derived feedstocks. Flexiforming technology, offered by Unifuel.tech, represents one such innovation.

It allows operators to integrate SAF production into existing facilities, such as an idle hydrotreater or reformer, enhancing the flexibility and reducing the carbon intensity of fuel production. This approach could significantly address the supply gap by utilizing existing capital more efficiently. Universal Fuel Technologies, holding the rights to Unifuel.tech, provides swift responses to inquiries, aiding operators in identifying the most beneficial application of flexiforming for their specific needs.

Challenges and Limitations of SAF

Sustainable Aviation Fuel (SAF) is at the forefront of emissions reduction strategies in the aviation sector, with the International Civil Aviation Organization targeting net zero carbon emissions by 2050. However, the path to large-scale SAF production is fraught with challenges.

Key among these is the sourcing of feedstocks, which are currently limited and often expensive, as highlighted by Virgin's Weiss, who emphasizes the need for increased investment and regulatory support to scale up production. This is compounded by the fact that SAF currently constitutes less than 0.1% of global aviation fuel, and the agricultural resources needed are at risk due to ecosystem and biodiversity impacts from overuse.

The circular economy concept offers a promising framework for SAF, where CO2 emissions from jet fuel combustion are eventually recycled back into fuel production. However, achieving this requires all processes to be powered by zero-emission energy sources, a goal that is yet to be fully realized.

As companies like Rivian and Doosan Enerbility strive for more sustainable operations, the demand for SAF will likely increase, heightening the competition for biomass and potentially impacting global food supplies, as cautioned by Mortensen. Despite these hurdles, progress is being made.

Unifuel.tech introduces flexiforming technology, which enables operators to retrofit existing infrastructure such as idle hydrotreaters or reformers for SAF production, potentially reducing capital expenditures and carbon intensity. This technology allows for a tailored decarbonization approach, aligning with the operator's existing assets and product goals. Unifuel.tech's rapid response time and proprietary rights under Universal Fuel Technologies indicate an agile and secured approach to SAF production scaling. While Ethanol-based SAF production facilities like LanzaJet's Freedom Pines Fuels facility are nearing commissioning, the integration of flexiforming could accelerate the establishment of commercial SAF facilities. Current estimates of Saf's economic impact and job creation potential, though speculative, are set to be substantiated as these innovative solutions and collaborations materialize, bolstering the SAF value chain globally.

Conclusion

In conclusion, Sustainable Aviation Fuel (SAF) is a game-changer for the aviation industry's environmental sustainability goals. It offers a cleaner alternative to fossil-based jet fuel and has the potential to reduce aviation emissions by up to 95%.

Despite challenges in technology development and high production costs, innovative solutions like Unifuel.tech's flexiforming technology are emerging to overcome these hurdles. Global initiatives and collaborations, such as the SAF Roadmap and Airbus's pledge for SAF-compatible aircraft by 2030, are driving the transition towards a sustainable aviation industry.

SAF plays a pivotal role in reducing emissions, with its ability to slash carbon emissions by up to 95% compared to traditional jet fuels. The integration of SAF into existing aviation infrastructure is seamless, with recent innovations allowing for 100% SAF flights without engine modifications.

This breakthrough aligns with the circular energy economy concept, where hydrocarbon fuel production results in the combustion of CO2, water, and energy without relying on fossil-derived feedstocks. While challenges remain, such as sourcing feedstocks and achieving zero-emission energy sources for all processes, progress is being made. Unifuel.tech's flexiforming technology offers tailored decarbonization strategies based on operators' specific needs and facilities. In conclusion, with continued innovation and investment, SAF has the potential to become a cornerstone of the aviation industry's journey towards a greener future. The advancements in SAF production technologies and collaborations indicate a promising path forward in achieving net-zero carbon emissions by 2050.