Introduction

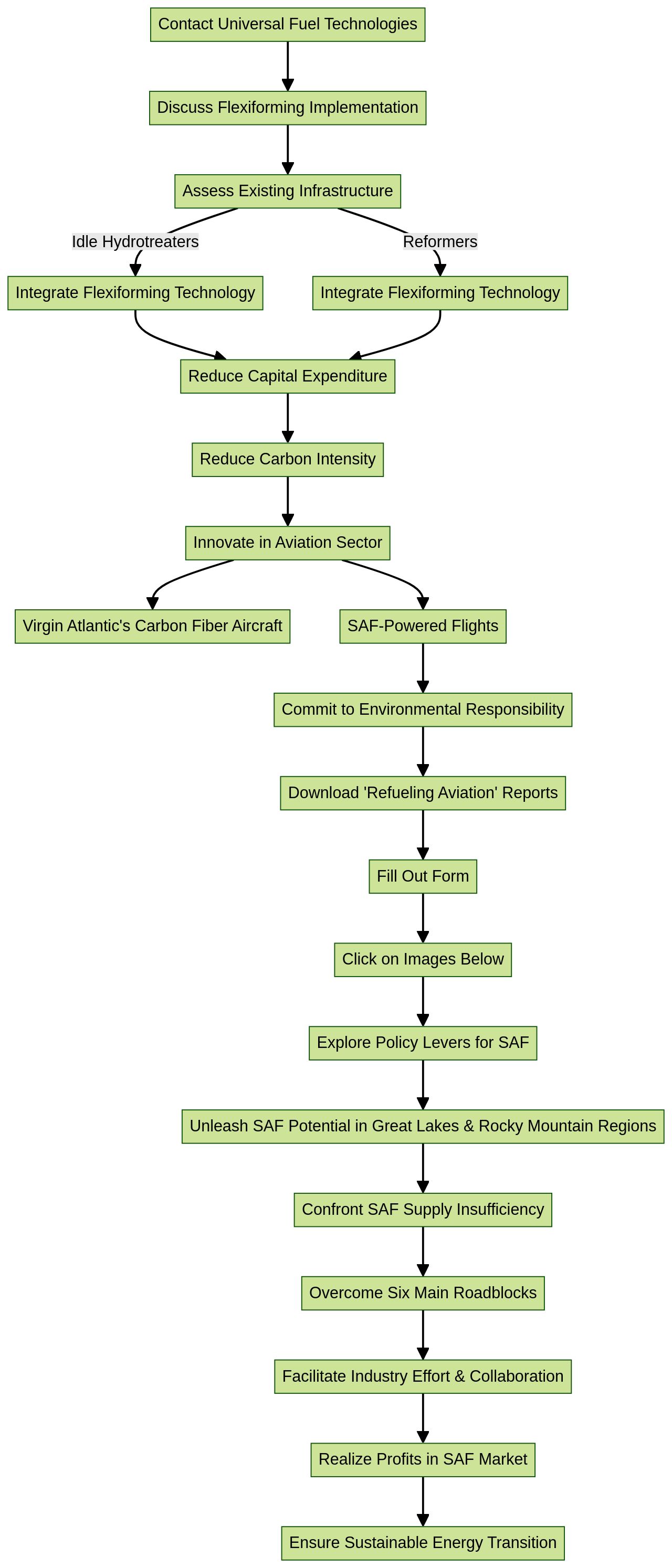

Sustainable aviation fuel (SAF) is an essential component in the aviation industry's quest for environmental sustainability. To meet the International Civil Aviation Organization's goal of achieving net zero carbon emissions by 2050, innovative solutions are needed. Universal Fuel Technologies introduces flexiforming technology, a groundbreaking approach to SAF production that allows operators to tailor their decarbonization trajectory.

By integrating flexiforming into existing infrastructure, such as idle hydrotreaters or reformers, operators can significantly reduce both capital expenditure and carbon intensity. This bespoke solution underscores the industry's commitment to innovation and environmental responsibility, propelling the aviation industry towards a greener and more resilient future. In this article, we will explore the importance of feedstock options for SAF production, the certification and sustainability of feedstocks, and successful case studies highlighting the implementation of sustainable aviation fuel.

The Need for Sustainable Aviation Fuel

Sustainable aviation fuel (SAF) is a pivotal element in the aviation sector's journey towards environmental sustainability, aiming to significantly curtail the carbon emissions associated with air travel. To accelerate the adoption of SAF and meet the International Civil Aviation Organization's net zero carbon emissions goal by 2050, innovative solutions are being sought.

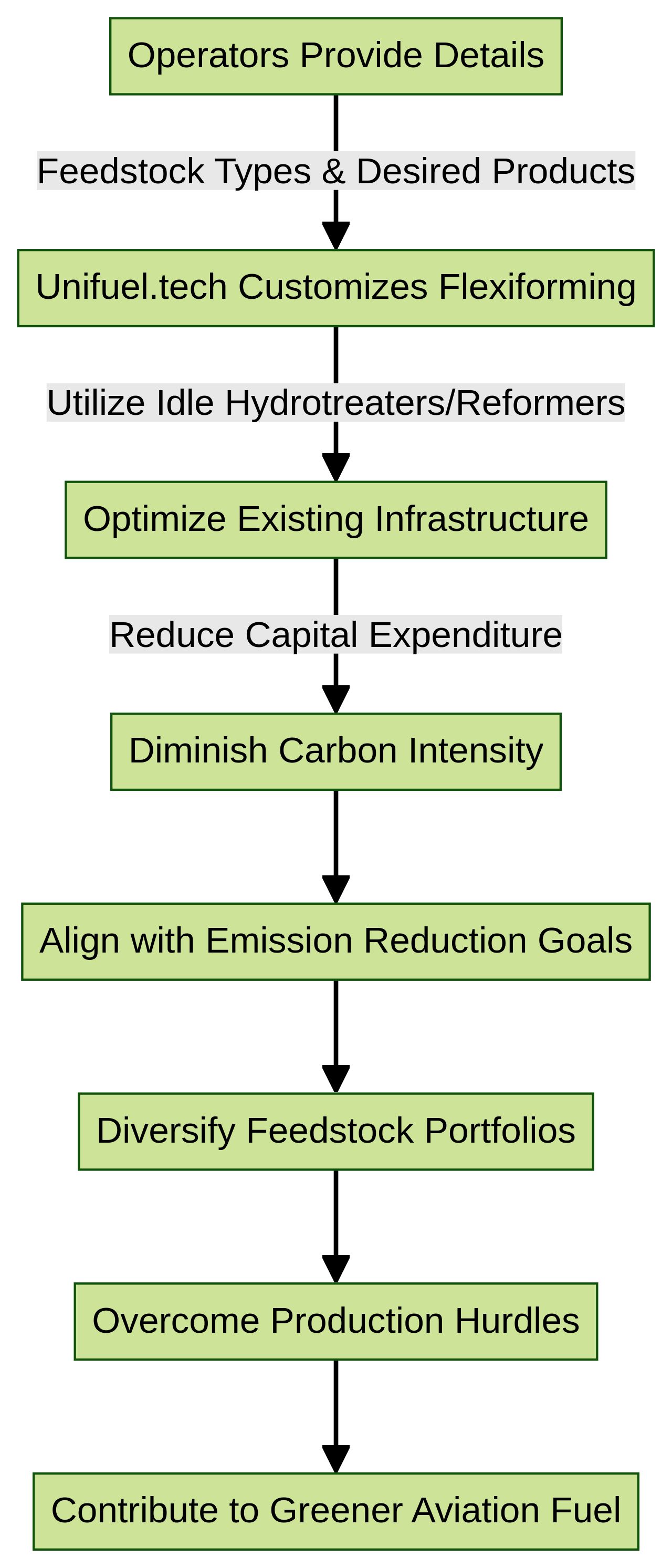

Universal Fuel Technologies presents such an innovation with its flexiforming technology, offered through Unifuel.tech. This adaptable technology enables operators to tailor their decarbonization trajectory by integrating flexiforming into existing infrastructure such as idle hydrotreaters or reformers.

The result is a marked reduction in both capital expenditure and carbon intensity, facilitating a more sustainable and cost-effective transition to SAF. Unifuel.tech's approach involves a thorough analysis of an operator's current feeds, desired products, and facilities to determine the most effective deployment of flexiforming.

This bespoke solution underscores the industry's commitment to innovation and environmental responsibility, as demonstrated by initiatives like Virgin Atlantic's carbon fiber aircraft and SAF-powered flights. With operators seeking to navigate the complexities of feedstock competition and sustainability, technologies like flexiforming are crucial in propelling the aviation industry towards a greener, more resilient future. For those interested in exploring the potential of flexiforming, Unifuel. Tech assures a prompt response within 24 hours to any inquiries, emphasizing their dedication to customer engagement and support in the drive for decarbonization.

Feedstock Options for Sustainable Aviation Fuel

Sustainable aviation fuel (SAF) stands at the forefront of reducing the aviation industry's carbon footprint, with multiple feedstock options playing a pivotal role in SAF production. These include waste and residues, non-food energy crops, and algae. Each feedstock presents unique advantages and challenges, such as the ability to convert waste products into valuable fuel, thus reducing emissions and waste simultaneously.

Non-food energy crops offer a renewable source that doesn't compete with food supply chains. Algae, with its high yield and minimal land use, could revolutionize SAF production if economically scalable methods are developed. As global SAF demand escalates, particularly in Europe, the UK, and the USA, the quest for sustainable, cost-effective, and scalable feedstock sources intensifies.

Australia's significant contribution to feedstock exports and its burgeoning hydrogen economy position it as a potential key player in the SAF market. However, with global production lagging behind demand, challenges such as feedstock competition, affordability, and production scales need to be navigated. The development of bio-based aromatics has enabled higher SAF blending ratios, with successful tests of 100% SAF flights, underscoring Saf's viability as a drop-in fuel and its role in the industry's net-zero ambitions.

With aviation contributing to 2-3% of global CO2 emissions and electrification or alternative fuels like green hydrogen not yet viable for long-haul flights, SAF remains the most practical decarbonization strategy. However, the industry must address supply chain constraints, international standards, and regulations to capitalize on this opportunity. As detailed in reports by Carbon Direct and Apple, understanding the range of fuel types, carbon intensities, and sustainability criteria is crucial for the industry to scale SAF production and significantly reduce greenhouse gas emissions.

Certification and Sustainability of Feedstocks

The integration of Sustainable Aviation Fuel (SAF) into the aviation industry's fuel supply chain represents a significant step toward reducing greenhouse gas emissions. According to a report from Carbon Direct, in collaboration with Apple, SAF has been identified as the primary means of emissions abatement for the sector.

The report provides a comprehensive overview of the diverse fuel types, their associated carbon intensities, and the sustainability criteria they must adhere to. To ensure the environmental integrity of SAF, rigorous certification programs set the benchmark for sustainable feedstock production.

As highlighted in the case studies by Idaho National Laboratory, the shift towards regional feedstocks for bioenergy and converting waste to energy exemplifies the industry's commitment to sustainable practices. The recent technological breakthrough in bio-based aromatics production, as evidenced by Virent's BioForming technology, has facilitated the historic 100% SAF trans-Atlantic crossing by Virgin Atlantic.

This 'drop-in' solution bypasses the need for extensive modifications to aircraft and infrastructure. Moreover, the Inflation Reduction Act of 2022 propels this momentum by offering federal tax credits for SAF that meet a minimum 50% reduction in greenhouse gas emissions, aligning with the U.S. government's ambition to reach a production target of 3 billion gallons per year by 2030. This policy support, together with the innovations in SAF production, underscores the growing belief within the aerospace sector that SAF could match or even surpass crude oil-based fuels in terms of cost and performance. Ultimately, the adoption of SAF, underpinned by sustainable feedstock sourcing and certification, is poised to reshape the aviation industry's fuel landscape and contribute to global environmental goals.

Case Studies: Successful Implementation of Sustainable Aviation Fuel

As the industry grapples with the supply-demand imbalance for sustainable aviation fuel (SAF), innovative solutions such as Unifuel.tech's 'flexiforming' technology offer a promising avenue to enhance production capabilities. Flexiforming enables operators to tailor their decarbonization trajectory by utilizing idle hydrotreaters or reformers, thus optimizing the use of existing infrastructure. This adaptability not only mitigates capital expenditure but also diminishes carbon intensity, aligning with the industry's drive towards emission reduction.

The technology's swift integration into current facilities is facilitated by Unifuel.tech's commitment to rapid response times, promising to address inquiries within a day. Operators are encouraged to provide details about their feedstock types, desired end products, and the specifics of their existing setup, which Unifuel. Tech uses to customize the application of flexiforming to their unique context.

This approach is particularly relevant for countries like Australia, which is poised to expand its role in the SAF market by leveraging local feedstocks and its burgeoning hydrogen economy. With the capacity to select varying feed types and proportions, flexiforming stands out as a strategic tool for diversifying Australia's feedstock portfolio and surmounting production hurdles. As the aviation sector continues to prioritize SAF in its decarbonization efforts, technologies like flexiforming are essential in realizing the ambitious SAF volume targets and advancing towards a greener future in aviation fuel innovation.

Conclusion

In conclusion, Universal Fuel Technologies' flexiforming technology offers an innovative solution for sustainable aviation fuel (SAF) production. By integrating flexiforming into existing infrastructure, operators can reduce capital expenditure and carbon intensity, aligning with the industry's commitment to innovation and environmental responsibility.

The article highlights the importance of feedstock options for SAF production and the need for sustainable and scalable sources. Successful case studies demonstrate the industry's commitment to regional feedstock sourcing and converting waste to energy.

Certification programs ensure the sustainability of feedstocks used in SAF production. Technological breakthroughs like Virent's BioForming technology have facilitated significant milestones in SAF production.

Unifuel.tech's flexiforming technology is a successful implementation of SAF production. By utilizing idle hydrotreaters or reformers, operators can optimize existing infrastructure while reducing costs and carbon emissions. In summary, technologies like flexiforming are essential in propelling the aviation industry towards a greener future. With continued efforts to address supply chain constraints and adhere to international standards, the adoption of sustainable aviation fuel will reshape the industry's fuel landscape and contribute to global environmental goals.