Introduction

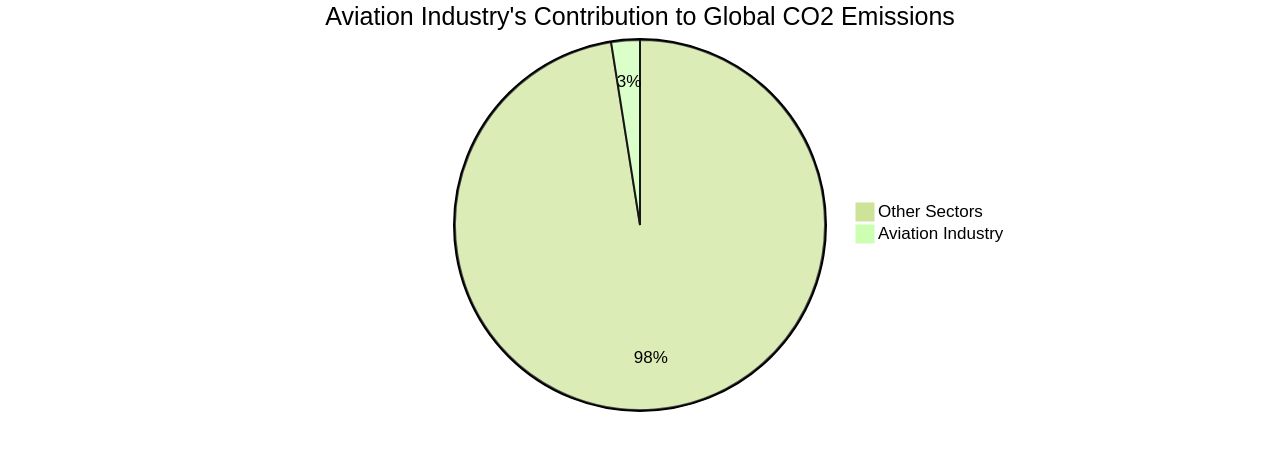

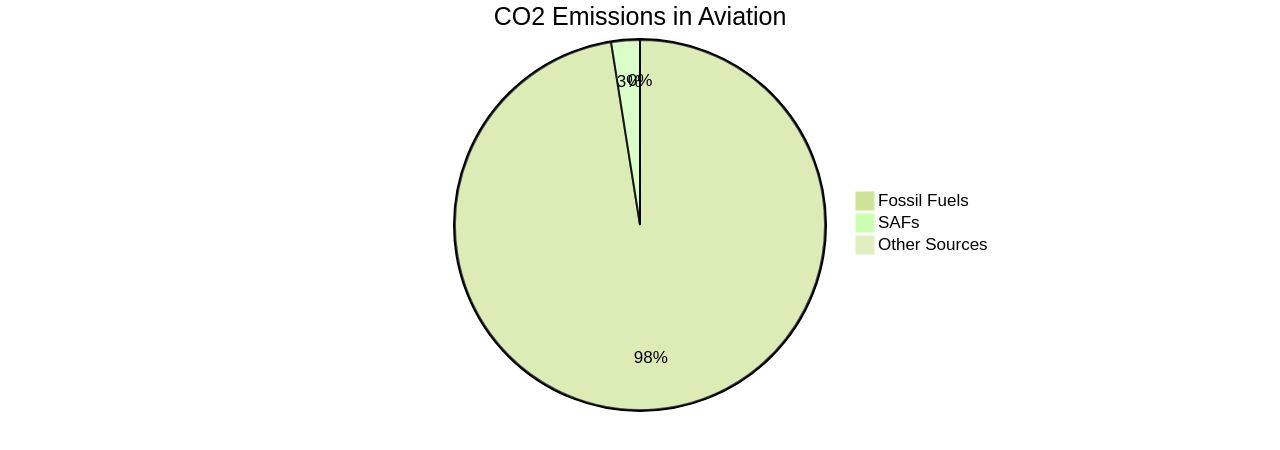

The imperative for the aviation industry to reach net-zero carbon emissions by 2050 is clear, with the sector contributing 2-3% of global CO2 emissions. Sustainable Aviation Fuels (SAFs) are the cornerstone of this decarbonization effort, despite their nascent stage of development.

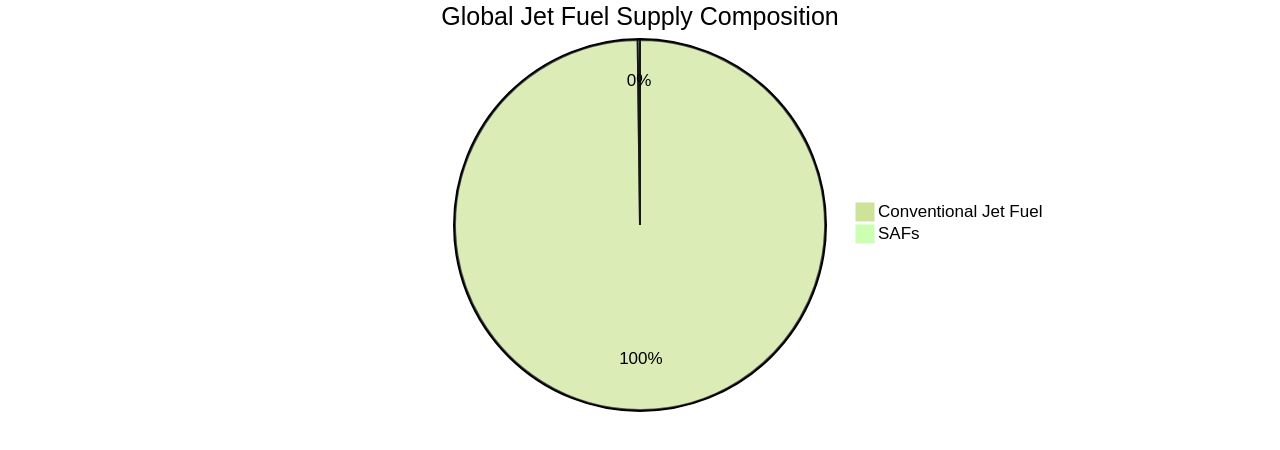

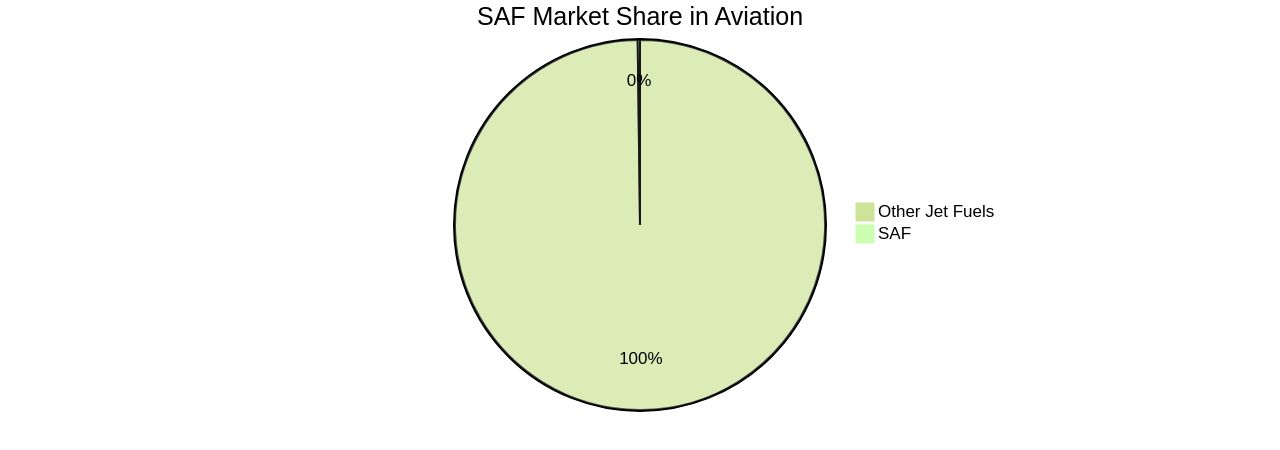

The complexities of scaling SAF production are evident from the fact that they accounted for less than 0.2% of the global jet fuel supply in 2022. This article explores the potential of SAFs to mitigate the environmental impact of flying, the challenges in scaling production, the various feedstocks and their life-cycle carbon emissions, the benefits of using SAFs, and the policy support needed to shift emphasis towards sustainable, low-carbon options. Join us as we delve into the technical insights and analysis of the renewable fuels industry.

The extent of SAF's potential to mitigate the environmental impact of flying

The imperative for the aviation industry to reach net-zero carbon emissions by 2050 is clear, with the sector contributing 2-3% of global CO2 emissions. Sustainable Aviation Fuels (SAFs) are the cornerstone of this decarbonization effort, despite their nascent stage of development.

The Royal Society has outlined the enormity of the challenge, indicating that achieving the necessary SAF volume in the UK alone would require a vast allocation of agricultural land or a doubling of renewable electricity capacity. The complexities of scaling SAF production are evident from the fact that they accounted for less than 0.2% of the global jet fuel supply in 2022.

The current SAF production predominantly relies on fats, oils, and greases, which presents limitations. In Sweden, for example, the projected annual SAF output of 80,000 tons is estimated to fulfill only 5% of the current jet fuel demand and 20% of the SAF need by 2030.

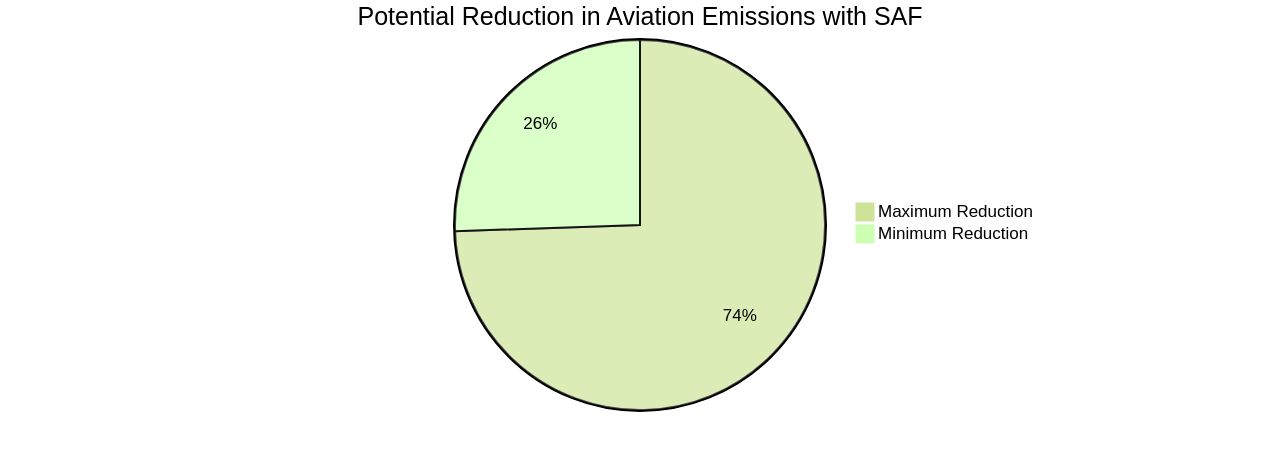

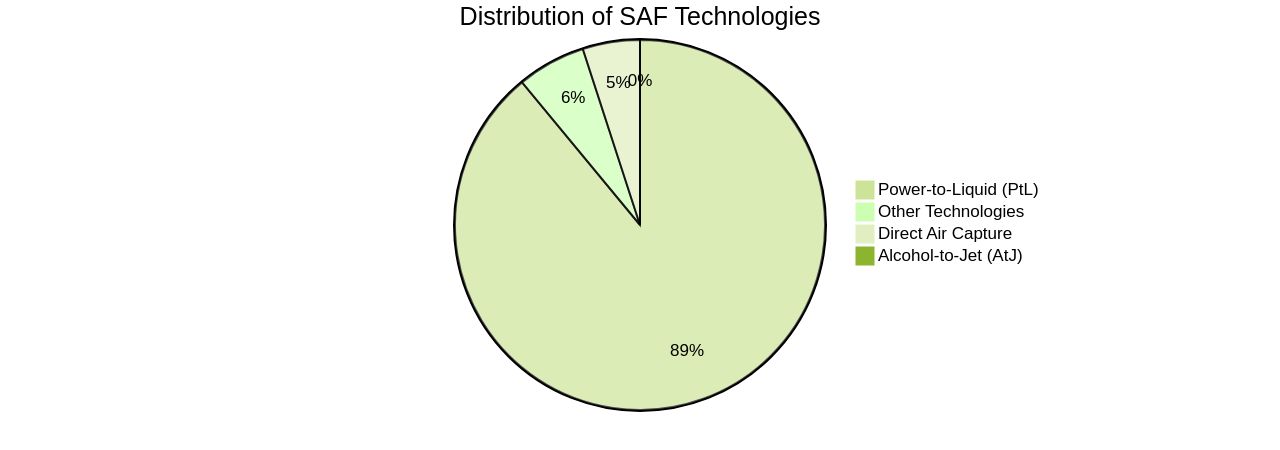

Meanwhile, the cost of SAF is 3 to 4 times higher than conventional jet fuel, due partly to its limited supply and the infancy of the technology involved. Airbus, a leader in SAF research and application, has committed to making its aircraft 100% SAF-capable by 2030 and is actively collaborating to expand the global SAF market. This is in response to the recognition that SAFs, though emitting CO2 when burned, can significantly offset their carbon footprint based on the production pathway. The Power-to-Liquid (PtL) process, for instance, can save up to 94% in CO2 emissions, yet scaling up this technology remains challenging. To overcome these barriers and meet the demand for Safe, a concerted effort across legislative initiatives, industry strategies, and passenger contributions is required, all while ensuring that the sustainability criteria and carbon intensities of SAFs are thoroughly evaluated and managed.

SAF's contribution to the aviation industry's net-zero carbon emissions goal by 2050

As the aviation sector confronts the monumental challenge of decarbonization, Sustainable Aviation Fuels (SAFs) stand at the forefront of this transformation. With the International Civil Aviation Organization's target of net-zero carbon emissions by 2050, SAFs are not merely an option but a necessity for the industry's sustainable future.

Presently, SAFs represent a fraction—only 0.2%—of the global jet fuel supply, highlighting the urgency to scale up production to meet environmental targets. Despite the progress in fuel efficiency, which has improved by 39% from 2005 to 2019, the overall growth in emissions continues to outpace these gains.

This underscores the need for not only short-term measures but a sustained, strategic approach to carbon mitigation. Addressing the substantial cost disparity—Safe are currently 2-5 times more expensive than conventional jet fuel—is critical in this endeavor.

Unifuel.tech's flexiforming technology offers a promising solution by enabling the integration into existing infrastructure, such as dormant hydrotreaters or reformers, reducing both capital expenditure and carbon intensity. The company's commitment to rapid response and tailored applications of flexiforming technology aligns with the industry's imperative for versatility and rapid adaptation in the pursuit of Safe. The collaboration between ORLEN and Yokogawa epitomizes the innovative strides being made in the sector, with their agreement set to catapult synthetic fuel production capacity to 70 thousand tons annually by 2030. Their approach, leveraging a 'digital twin' to fine-tune production processes for economic viability and environmental sustainability, exemplifies the strategic investments necessary to drive the decarbonization of aviation. This partnership not only advances the production of synthetic fuels, which share nearly identical properties to conventional fuels but also presents a significant opportunity to reduce industrial greenhouse gas emissions by utilizing carbon dioxide from various industrial processes.

SAF feedstocks and their life-cycle carbon emissions

The aviation sector, contributing between two and three percent of global CO2 emissions, is actively seeking ways to reduce its carbon footprint. Sustainable Aviation Fuels (SAFs) have emerged as a pivotal solution, particularly for long-haul flights where electrification and alternative fuels like green hydrogen are not yet viable options.

To harness the full potential of Safe and meet aggressive adoption timelines, a deep dive into a diverse portfolio of feedstocks is essential. With a surge in SAF adoption across Europe, the UK, and the USA, the demand for these fuels is expected to exceed the current limited global production capacity.

This underscores the importance of exploring various sources such as biomass, waste oils, natural fats, and renewable hydrogen. In Brazil, biomass is a cornerstone of renewable energy, accounting for almost 70% of the sector's global production.

By converting biomass waste into valuable energy carriers like hydrogen and ammonia, Brazil could significantly reduce greenhouse gas emissions while addressing waste disposal issues. Australia's burgeoning hydrogen economy presents another promising avenue, offering a clean hydrogen supply for several SAF production pathways.

Implementing life cycle assessments for SAF feedstocks is critical for ensuring their sustainability. This approach evaluates the environmental impact from cultivation to processing, considering factors such as land use efficiency, soil carbon sequestration, and the effects of water and fertilizer usage. It is paramount to recognize that not all biofuels offer the same carbon savings; biofuels from food crops or organic waste may cause indirect land-use changes, potentially negating their environmental benefits. The aviation industry's commitment to net-zero emissions by 2050, as set by the International Civil Aviation Organization, hinges on the development of Safe. With Australia positioned to contribute significantly as a feedstock source and SAF producer, and with a planned annual SAF output of 80,000 tons in Sweden, which is about 5% of its current jet fuel demand, the global push for Safe is undeniable. The challenge now lies in scaling production sustainably and affordably while navigating the competition for feedstocks.

Waste streams for SAF production and their environmental benefits

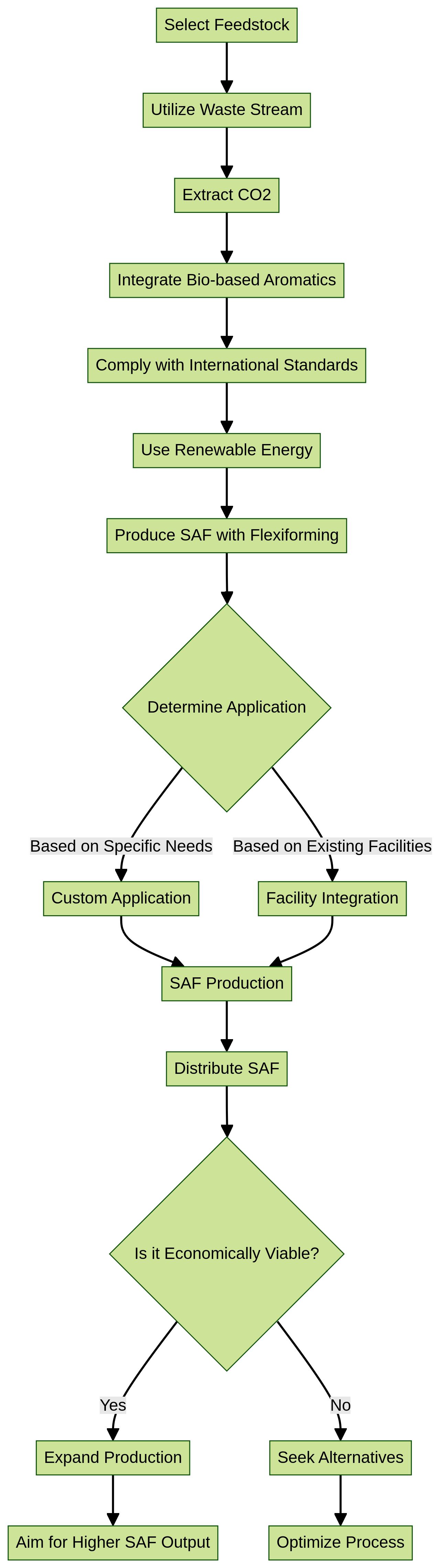

The production of Sustainable Aviation Fuel (SAF) leverages Flexiforming technology, a significant advancement in the utilization of various waste streams, including agricultural residues, municipal solid waste, and industrial by-products. This innovative approach not only diverts waste from landfills but also substantially reduces greenhouse gas emissions. The feedstock crops' ability to sequester carbon and the CO2 extraction during the production process contribute to a dramatic decrease in Saf's lifecycle emissions.

Additionally, the integration of bio-based aromatics into SAF blends enhances environmental benefits, making it possible for aircraft to operate entirely on SAF. While the benefits of SAF are clear and the aviation industry is dedicated to achieving a net-zero carbon future by 2050, current production levels are unable to meet the global demand for jet fuel. Even with ambitious national projects, such as Sweden's, which aims to produce enough SAF to cover 5% of its jet fuel needs annually and 20% by 2030, there is a significant gap in production capacity.

Industry leaders like Airbus are working towards having fleets that are 100% SAF-capable by 2030, which is an essential step in nurturing the SAF market. The full potential of emissions reduction from SAF can only be realized if production facilities are powered by renewable energy sources. For SAF to be certified, it must comply with international standards and pass comprehensive lifecycle greenhouse gas assessments.

Despite the high costs of SAF production, which are currently three to four times that of conventional jet fuel, the CO2 emission savings from technologies such as Power-to-Liquid (PtL) are substantial, with possible reductions of 89 to 94%. The transition to net-zero aviation is a multifaceted challenge that demands collective effort and innovation. Unifuel.tech's Flexiforming technology presents a solution for operators to accelerate their decarbonization process.

By utilizing existing infrastructure such as idle hydrotreaters or reformers, operators can reduce both capital expenditure and carbon intensity. Unifuel. Tech commits to rapid engagement with operators to determine the most beneficial application of Flexiforming, based on their specific needs and existing facilities.

The process of producing ASTM-compliant SAF and its seven approved annexes

Sustainable Aviation Fuel (SAF) represents a pivotal innovation in the aviation sector, with the potential to significantly reduce carbon emissions and contribute to the industry's ambitious net-zero carbon goals by 2050. Saf's compatibility with existing aircraft and airport infrastructure makes it a 'drop-in' solution, allowing for immediate integration into the current fueling systems without the need for extensive modifications, which would entail considerable costs and logistical challenges. The BioForming process, capable of converting sugars into aromatic compounds, has made strides in addressing the aromatic content required by ASTM international standards for jet fuel, without the need to blend with conventional jet fuel.

This advancement has led to historical milestones such as Virgin Atlantic's 100% SAF trans-Atlantic flight, illustrating the feasibility of higher SAF blends in commercial aviation. Despite these technological leaps, the SAF industry faces hurdles, including limited production capacity and high costs, with SAF prices being 3 to 4 times higher than conventional jet fuel. As of now, SAF constitutes only a fraction of the aviation fuel market.

However, with ongoing research and development, including efforts by Airbus and GE Aerospace to increase SAF usage and understand its environmental impacts, the industry is laying the groundwork for broader adoption. The commitment to expanding Saf's role is further underscored by the planned output of 80,000 tons annually in Sweden, which represents a significant step towards meeting the country's SAF needs by 2030. As the industry continues to evolve, the collective efforts of passengers, airlines, and regulatory bodies will be crucial in scaling SAF production and making it a cornerstone of sustainable aviation.

SAF blending with conventional fossil fuels and its impact on carbon footprint

The integration of Sustainable Aviation Fuel (SAF) into the aviation sector is a critical step towards diminishing the industry's carbon emissions. Although SAF is compatible with current fuel systems and offers the potential to significantly reduce the aviation industry's 2-3% share of global CO2 emissions, its adoption is hindered by the nascent stage of production technologies such as Power-to-Liquid (PtL). With Saf's current use being a small fraction of the total jet fuel supply, there is a pressing need for technological advancements to meet the International Civil Aviation Organization's net-zero carbon emissions goal by 2050.

SAF can be produced from various feedstocks, reducing lifecycle greenhouse gas emissions when compared to traditional jet fuels. Nonetheless, the industry must overcome the challenge of SAF blends' lack of necessary aromatic compounds, which restricts blending ratios to 50%. Addressing this, Unifuel.tech's Flexiforming technology emerges as a promising solution, enabling operators to select their decarbonization pace.

This technology can be incorporated into existing idle hydrotreaters or reformers, curtailing both capital expenditure and carbon intensity. Unifuel.tech, a subsidiary of Universal Fuel Technologies, ensures a swift response to inquiries within 24 hours, and provides personalized solutions predicated on the operator's feedstock, target products, and existing facilities. As the industry strives to enhance SAF availability, which is currently at least three times more expensive than conventional kerosene, concerted efforts from various stakeholders, including passengers, are essential to support the shift towards sustainable aviation.

The critical work of SAFs in meeting the aviation industry's GHG emissions reduction targets

Sustainable Aviation Fuels (SAF) are increasingly recognized as a pivotal element in the aviation industry's strategy to curb greenhouse gas (GHG) emissions. Despite being a relatively recent development, SAF offer a concrete pathway toward decarbonization in an industry that contributes 2-3% of global CO2 emissions. The International Civil Aviation Organization's aggressive target of net-zero carbon emissions by 2050 significantly depends on the growth of SAF production and usage.

Projections suggest that SAF could account for a 24% to 70% reduction in aviation emissions, yet this potential relies on various factors, including governmental support, investment, production costs, and the availability of feedstocks. While SAF are critical, the industry's broader efforts, such as enhancing operational efficiency and exploring hydrogen and battery-powered aircraft, also play an essential role. The aviation sector has seen a 39% improvement in fuel efficiency from 2005 to 2019.

Nevertheless, the continued rise in overall emissions underscores the need for effective measures like SAF adoption. In this landscape, Unifuel.tech's Flexiforming technology stands out as a possible turning point. This innovative approach enables operators to modulate their decarbonization efforts and can be integrated into existing hydrotreaters or reformers, thus minimizing both capital expenses and carbon intensity.

Unifuel. Tech ensures a rapid response to inquiries, typically within 24 hours, and tailors solutions based on operators' specific feeds, target products, and existing facilities. With the backing of Universal Fuel Technologies and a commitment to customer-focused service, Flexiforming represents a strategic enhancement to SAF production processes and aligns with the industry's comprehensive approach to achieving substantial emission reductions and fulfilling sustainability objectives.

Three scenarios for SAF deployment to meet climate ambitions

The pursuit of sustainable aviation is advancing with Sustainable Aviation Fuel (SAF) at the forefront, aiming to minimize aviation's 2.5% share in global CO2 emissions. Although Saf's current market share is less than 0.2% of total jet fuel consumption, its ability to integrate with existing aircraft and infrastructure underscores the need for scalable production enhancements.

Unifuel.tech's Flexiforming technology emerges as a significant innovation in the SAF production landscape. This technology facilitates a customizable decarbonization journey, enabling operators to adapt their shift towards a lower carbon footprint seamlessly, capitalizing on dormant refinery assets like idle hydrotreaters or reformers.

This approach is not only capital efficient but also diminishes the carbon intensity of the fuel production process. Unifuel.tech, a subsidiary of Universal Fuel Technologies, provides a swift 24-hour response commitment to inquiries, offering bespoke optimization of Flexiforming technology based on the client's input materials, desired outcomes, and facility attributes.

Despite Saf's premium pricing, which can be quadruple that of standard jet fuel, its gradual market uptake is evident, with initiatives by passengers and airlines bolstering its growth. Sweden's aim to produce 80,000 tons of SAF annually, meeting 5% of their jet fuel demand by the current year and aspiring for 20% by 2030, exemplifies this progress. The airline industry, with leaders like Emirates collaborating with Airbus and Engine Alliance, is working towards a wholly SAF-compatible fleet by 2030. Virgin Atlantic's recent achievement of a trans-Atlantic flight powered entirely by SAF is a testament to the practicality of SAF as a 'drop-in' fuel, setting a precedent for the aviation sector's transition to meet the net-zero emission targets by 2050.

Benefits of using SAF to reduce emissions, including environmental, economic, and social value

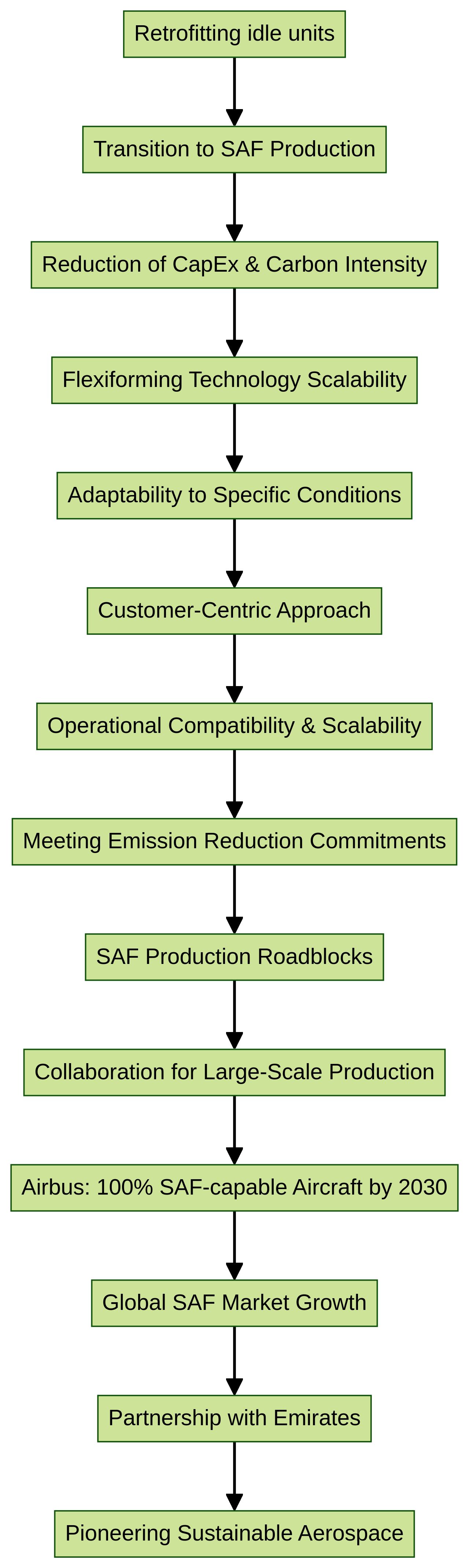

Unifuel.tech's Flexiforming technology represents a significant leap forward in the production of Sustainable Aviation Fuels (SAFs), a cornerstone in the aviation industry's path to decarbonization. By retrofitting existing idle hydrotreatment or reformer units with Flexiforming, operators can efficiently transition to SAF production, reducing both capital expenditure and carbon intensity.

This not only aligns with the International Civil Aviation Organization's net-zero carbon emissions goal for 2050 but also brings about economic and social benefits, including job creation and enhanced energy security. Flexiforming's scalable nature allows for the production of SAFs that meet global jet fuel demand and Jet A fuel specifications, which include the necessary bio-based aromatics.

The technology's adaptability to the operator's specific conditions—such as feedstock availability, product objectives, and existing facility infrastructure—ensures a tailored approach to SAF production. Unifuel.

Tech actively supports operators in implementing Flexiforming by offering consultations based on detailed information regarding their operational needs. This customer-centric approach is bolstered by a commitment to respond to inquiries within 24 hours, demonstrating the company's dedication to facilitating the industry's transition to greener fuel alternatives. As the aviation sector strives for 100% SAF blends and the realization of a more sustainable future, technologies like Flexiforming by Unifuel. Tech are pivotal, enabling the industry to meet its emission reduction commitments while ensuring operational compatibility and scalability.

Risks and challenges to overcome to increase SAF uptake levels, such as lack of commercial facilities and difficulties in monetizing benefits

The quest for net-zero aviation emissions by 2050 is underscored by the pivotal role of Sustainable Aviation Fuels (SAFs). These fuels are essential for the industry's decarbonization efforts, yet their widespread adoption faces significant obstacles.

Commercial production facilities for Safe are scarce, and as a result, options like Alcohol-to-Jet (AtJ) remain unavailable on a commercial scale. Current technology readiness levels indicate that while SAF production is technically feasible, the supply remains critically limited.

This supply shortage is illustrated by the fact that there are no commercial AtJ facilities in operation, with the world's first such facility, LanzaJet's Freedom Pines Fuels, set to begin operations later this year. The complexity of scaling SAF production requires a collective industry effort and the development of new business models along the SAF value chain.

Despite these challenges, innovative solutions are being pursued to enhance SAF uptake. For instance, leveraging unconventional resources and fostering cross-sector collaborations are among the strategies being implemented.

Notably, the use of Flexiforming technology, as offered by Unifuel.Tech, presents an opportunity for the aviation sector to tailor their decarbonization strategies to their specific needs. Flexiforming can be integrated into existing infrastructure, such as idle hydrotreaters or reformers, potentially reducing capital expenditures and carbon intensity.

With Unifuel.Tech's commitment to responding to inquiries within 24 hours and their ability to optimize Flexiforming applications based on individual feeds, target products, and existing facilities, this adaptability may accelerate the adoption of SAFs, contributing significantly to the industry's decarbonization goals. In the broader context, international collaboration and a shared vision are paramount. The aviation industry must navigate the capex-intensive nature of SAF production and the demand-gap, which is projected to persist into the foreseeable future. However, this also presents an opportunity for SAF producers to realize healthy profits when entering the market at the right time. The concerted effort to scale SAF production is further underpinned by a global commitment to renewable energy, as evidenced by companies like Neste, which has expanded its SAF production capacity significantly at its Changi refinery. This expansion not only exemplifies the industry's progress but also reinforces the potential for Safe to substantially reduce greenhouse gas emissions across their lifecycle.

Policy support needed to shift emphasis from carbon-based fuels to sustainable, low-carbon options

The aviation sector, accountable for 2-3% of global CO2 emissions, faces the challenge of decarbonization with Sustainable Aviation Fuels (SAFs) as a pivotal tool. SAFs are instrumental in achieving the International Civil Aviation Organization's goal of net-zero carbon emissions by 2050.

With technology still emerging, the cost and supply of SAFs are critical factors in the transition. Flexiforming technology by Unifuel.

Tech emerges as a significant innovation, offering a practical pathway to SAF production. It integrates seamlessly into existing refinery infrastructure, such as idle hydrotreaters or reformers, enabling operators to tailor their decarbonization strategies to their specific needs, minimizing capital expenditure and carbon intensity.

In regions like the Great Lakes and the Rocky Mountains, policy levers are recognized as key to unlocking the potential of SAFs. These regions are identified as Targeted Opportunity Regions with unique strengths in feedstock availability, infrastructure, transport, and demand.

The promise of Safe in these areas is not only a testament to their environmental benefits but also to the revitalization of local industries. The recent CAAF/3 summit outlined strategic directions to enhance global SAF supply and adoption, targeting a 5% reduction in aviation fuel carbon intensity by 2030 compared to current fossil fuel benchmarks. Airbus's commitment to making all aircraft 100% SAF-capable by 2030 and the partnership with Emirates underscore the industry's collaborative efforts. The historic flight operated by Virgin Atlantic from London to New York, powered by SAF and supported by government funding, further demonstrates the viability of a greener aviation future, despite the current supply challenges. As the industry propels towards sustainability, it is clear that innovation, collaboration, and responsive solutions like Flexiforming will be crucial in navigating the complexities of this transition.

Special consideration for SAF's role in combating climate change, creating rural jobs, securing energy supply, and reducing waste impact

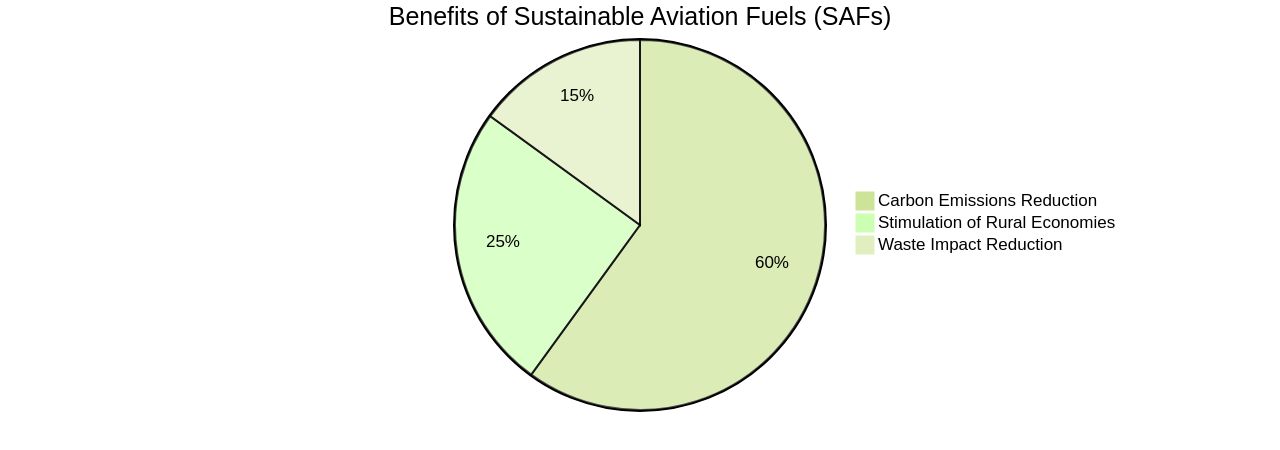

Sustainable Aviation Fuels (SAFs) are increasingly recognized as pivotal in the aviation industry's quest to align with the International Civil Aviation Organization's 2050 net-zero carbon emissions goal. They not only offer a substantial reduction in carbon emissions but also promise to stimulate rural economies and reduce waste impact.

Technologies such as Flexiforming provide a strategic advantage, enabling operators to decarbonize at their chosen pace, utilizing existing infrastructure to minimize capital expenditures. Unifuel.tech's Flexiforming, in particular, allows for seamless integration with idle hydrotreaters or reformers, thereby enhancing economic and environmental efficiency.

The company is known for its responsive approach, addressing inquiries within 24 hours and customizing solutions based on operators' feeds, target products, and existing facilities to optimize the application of Flexiforming technology. The synthetic fuel production landscape is evolving, with initiatives like ORLEN's collaboration with Yokogawa to create a 'digital twin' of a production facility by 2030, demonstrating the industry's forward momentum.

This advancement is set to improve production processes, ensuring they are economically viable and environmentally sustainable. Synthetic fuels, amalgamating hydrogen from renewable-powered electrolysis with carbon dioxide from industrial processes, offer a cleaner alternative to traditional jet fuels, compatible with current aircraft engines without the need for modifications. Despite the high costs and limited supply associated with the infancy of SAF technology, regional initiatives like Canada's collaborative platform for the SAF value chain are instrumental in fostering innovation and scaling up usage. These efforts are key to harnessing the full potential of SAFs in transforming local industries and adhering to environmental directives. With strategic policy support, regions such as the Great Lakes and Rocky Mountain could become leading contributors to a cleaner aviation industry, as detailed in recent reports that discuss Saf's promising future and are available for download.

Conclusion

In conclusion, Sustainable Aviation Fuels (SAFs) are key to achieving the aviation industry's net-zero carbon emissions goal by 2050. Despite challenges in scaling production and limited feedstock availability, technologies like Flexiforming offer practical solutions for integrating SAF production into existing infrastructure. Collaboration between stakeholders is crucial for driving innovation and increasing SAF uptake.

With collective efforts, we can make SAFs a cornerstone of sustainable aviation, reducing greenhouse gas emissions and creating economic opportunities. Policy support is needed to shift towards low-carbon options and ensure the sustainability of SAFs. By working together, we can make a significant impact on the decarbonization of the aviation industry and achieve a greener future.