Introduction

The aviation industry is actively pursuing sustainable aviation fuel (SAF) integration to reduce carbon emissions and achieve net-zero emissions by 2050. However, SAF adoption faces challenges such as high production costs and limited availability of raw materials.

In response to these challenges, Unifuel.tech introduces Flexiforming technology, which allows for the integration of SAF production within existing fuel processing infrastructures. This innovative solution provides a scalable and cost-effective approach to decarbonization, supporting the aviation sector's environmental goals. With a deep understanding of the renewable fuels industry, this article explores the background, development, production processes, promotion, economic considerations, logistics, and best practices of sustainable aviation fuel.

Background and Context of Sustainable Aviation Fuel

Sustainable Aviation Fuel (SAF) is a critical innovation for reducing aviation carbon emissions, offering a pathway to net-zero emissions by 2050. SAF is produced from renewable resources, such as agricultural residues and waste oils, and can significantly lower lifecycle greenhouse gas emissions compared to conventional jet fuels.

Despite its environmental benefits, SAF adoption faces challenges, including high production costs and limited availability of raw materials, which could affect ecosystems and biodiversity. Moreover, Saf's production capacity must grow to meet aviation fuel demands, exemplified by Sweden's efforts to increase SAF output to fulfill a larger percentage of its fuel needs by 2030.

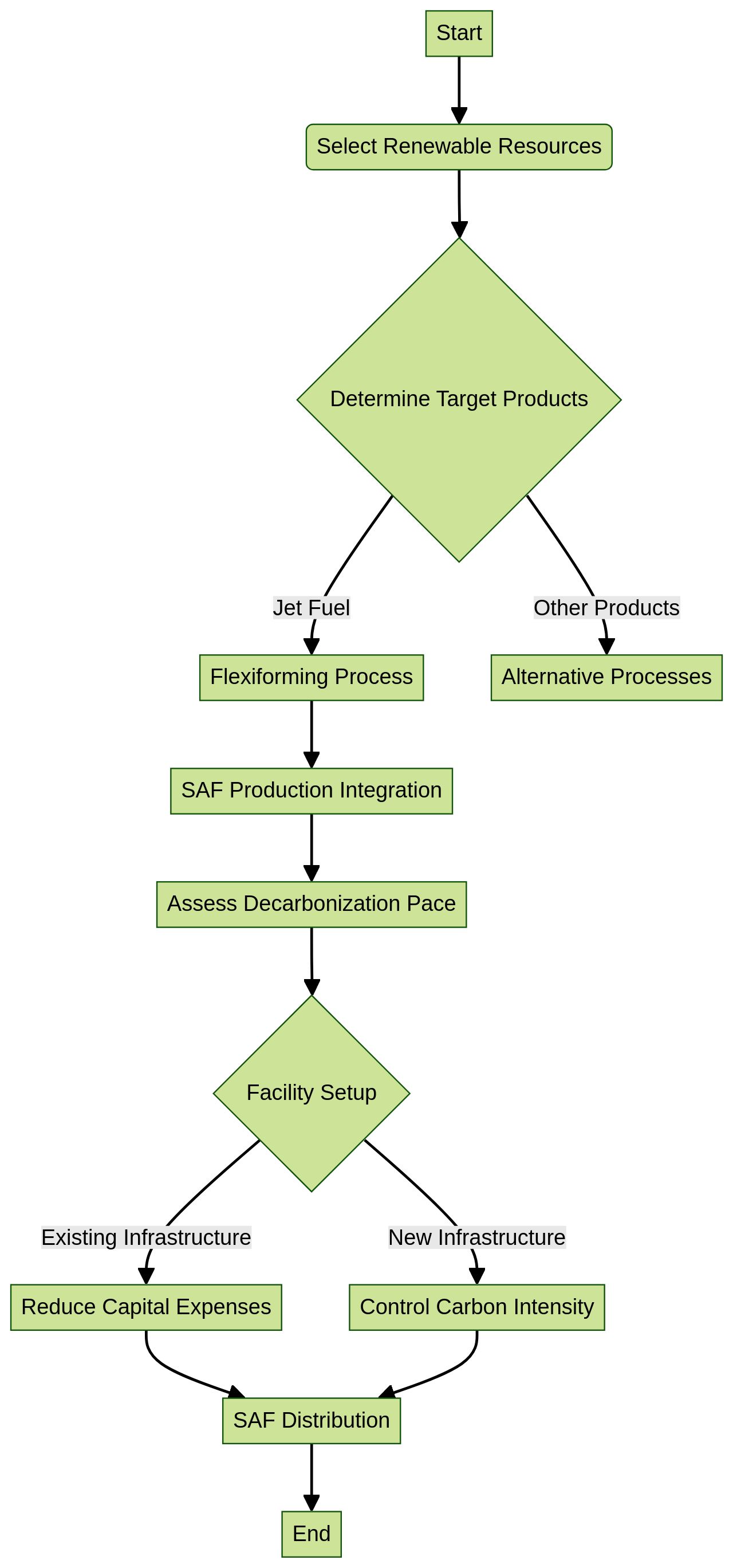

The aviation industry is actively pursuing SAF integration, with companies like Airbus aiming for SAF-capable fleets by 2030 and exploring higher blend ratios with traditional fuels. In response to these challenges, Unifuel.tech, a subsidiary of Universal Fuel Technologies, introduces Flexiforming technology.

This innovation allows for the integration of SAF production within existing fuel processing infrastructures, such as idle hydrotreaters or reformers. Flexiforming provides a scalable solution for operators to control their decarbonization pace, potentially reducing capital expenses and carbon intensity. Unifuel.tech's approach prioritizes rapid engagement with customers, pledging to respond to inquiries within 24 hours and collaboratively determining the most effective application of Flexi forming based on the operator's specific feeds, target products, and facility setup. This technological advancement is poised to support the aviation sector's environmental goals by facilitating more sustainable and economically viable SAF production.

Sustainable Aviation Fuel Development and Case Studies

The aviation industry's commitment to sustainability is exemplified by the adoption of Sustainable Aviation Fuel (SAF), which is instrumental in the sector's pursuit of net-zero emissions by 2050. Saf's production, deriving from sources such as biomass, waste products, and natural oils and fats, has already demonstrated its potential in significantly reducing carbon emissions.

This was evident in Virgin Atlantic's landmark flight, which achieved a 70% reduction in carbon emissions, utilizing SAF produced from waste cooking oils and animal fat. Airbus is also on board with its goal to make all its aircraft SAF-ready by 2030, supporting its vision for a sustainable aerospace future.

While SAF faces hurdles related to cost, sustainability, and production scale, the industry is unwavering in its goal to integrate SAF comprehensively. Addressing the carbon footprint of Saf's production and sourcing, Unifuel.tech's Flexiforming technology emerges as a game-changer.

It empowers operators to tailor their decarbonization pace and can be integrated into idle hydrotreaters or reformers, which curtails both capital expenditure and carbon intensity. The adaptability of Flexiforming technology ensures that operators can leverage existing infrastructure to streamline their transition to SAF, thus expediting the adoption process. As the aviation sector anticipates a 5% annual growth, strategic deployment of solutions like Flexiforming by Unifuel. Tech is crucial to overcoming the imminent sustainability challenges and achieving a greener flight path.

Sustainable Aviation Fuel Production Processes

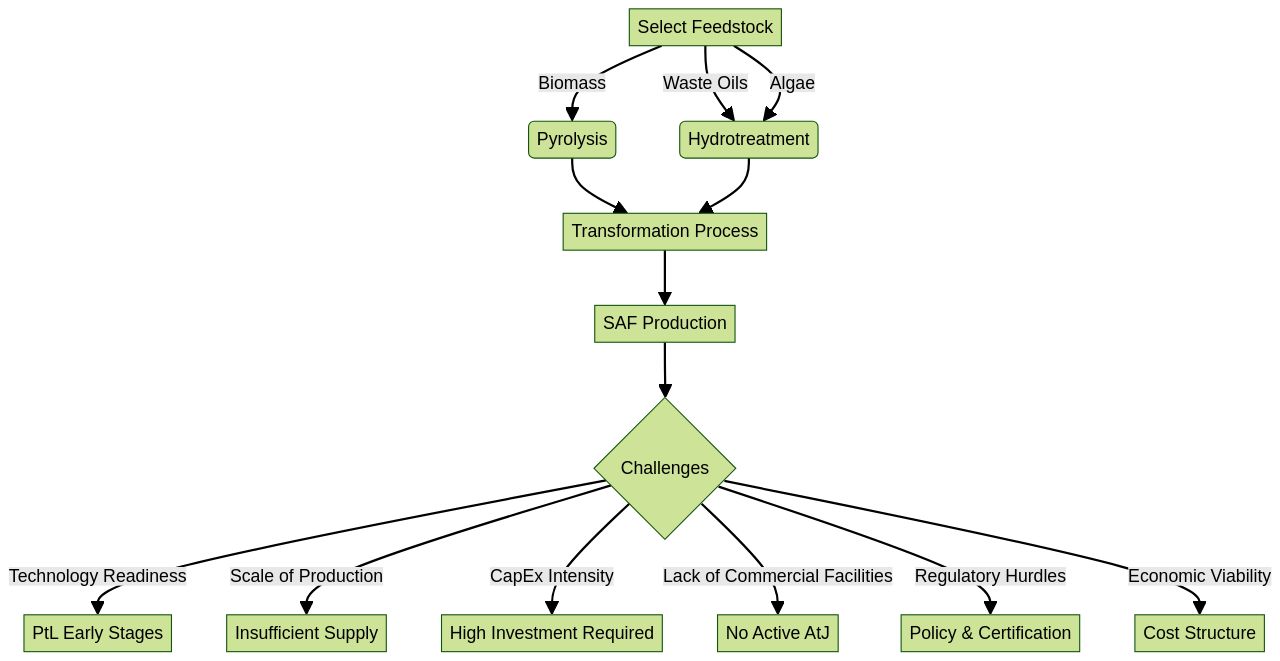

The quest for a greener aviation industry is accelerating, with the spotlight firmly on Sustainable Aviation Fuel (SAF) as the primary tool for reducing the sector's carbon footprint. Saf's production hinges on the careful selection of feedstocks, which include biomass, waste oils, and even algae, and their transformation through processes like pyrolysis and hydrotreatment. The result is a fuel that not only aligns with stringent aviation standards but also supports the industry's commitment to curtail its 2% contribution to global carbon emissions.

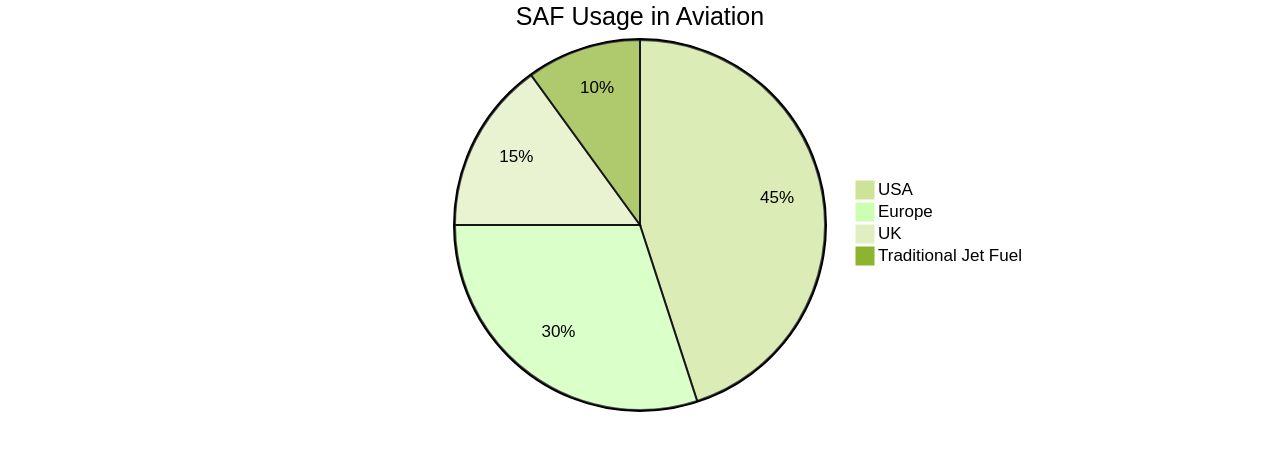

Despite the promise of SAF, the industry faces a significant supply challenge. As demand for SAF rises in regions like Europe, the UK, and the USA, production lags behind, raising crucial questions about affordability and the sustainable sourcing of feedstocks. Amidst these challenges, Unifuel.tech's Flexiforming technology emerges as a beacon of innovation.

It offers aviation operators the flexibility to pace their decarbonization efforts by retrofitting existing infrastructure, such as idle hydrotreaters or reformers, thus minimizing capital outlays and reducing carbon intensity. Flexiforming's integration into the SAF supply chain represents a strategic move towards a more sustainable aviation future. It addresses the pressing need for a reliable and cost-effective SAF supply, one that stands up to the competition for feedstocks while pushing the boundaries of economic efficiency.

The technology, a brainchild of Universal Fuel Technologies' subsidiary Unifuel.tech, is poised to play a critical role in meeting the aviation industry's net-zero emissions target by 2050, as endorsed by the International Civil Aviation Organization (ICAO). Operators seeking to integrate Flexiforming can contact Unifuel. Tech for a tailored solution, with the assurance of a swift response, typically within 24 hours, to discuss the specifics of their feeds, target products, and existing facilities.

Promoting the Use of Sustainable Aviation Fuel

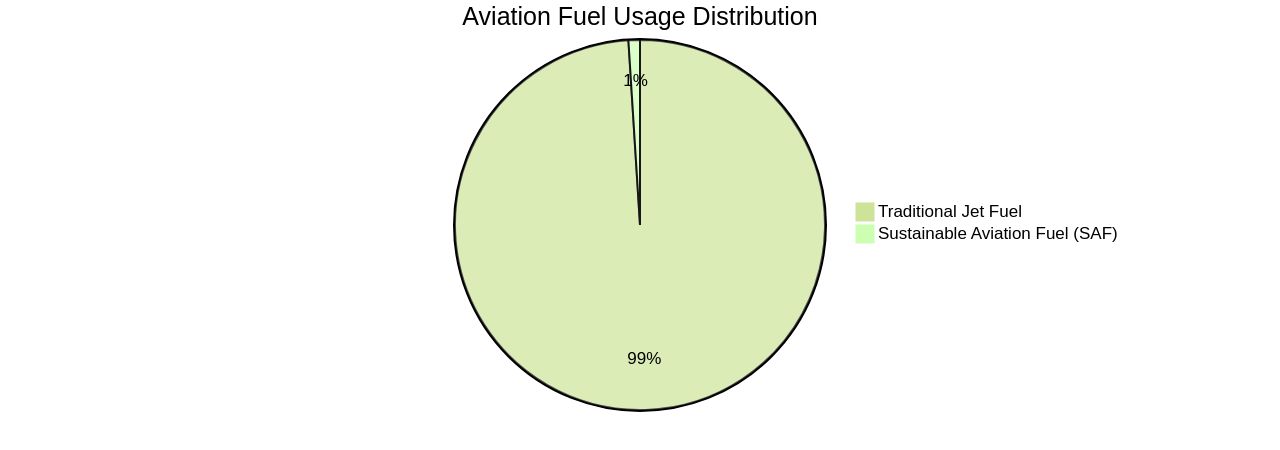

The aviation industry's commitment to the International Civil Aviation Organization's net-zero carbon emissions target by 2050 has made Sustainable Aviation Fuel (SAF) a critical factor in this endeavor. The sector, responsible for up to three percent of global CO2 emissions, recognizes SAF as an essential component for decarbonization, highlighted by the recent Virgin Atlantic flight from London to New York using SAF. Despite SAF currently accounting for only 0.1% of aviation fuel and its production costs being significantly higher than traditional jet fuel, investments in clean energy are on the rise.

A notable $2.8 trillion was invested last year, surpassing fossil fuel investments. The EU's RefuelEU regulation, which mandates increasing SAF quotas, reflects the concerted effort to shift towards sustainable aviation. Additionally, the current geopolitical climate, influenced by events like Russia's war in Ukraine, is prompting a realignment of investments from oil to solar energy.

This is particularly pertinent for the aviation sector, which aims to reduce hard-to-abate in-flight emissions by up to 95% with SAF. To facilitate this transition, Unifuel. Tech introduces flexiforming technology, enabling a customizable decarbonization pace.

It can be integrated into existing infrastructure such as an idle hydrotreater or reformer, offering a cost-effective solution to reduce carbon intensity. The company engages with operators within 24 hours to discuss their specific needs, including feedstock, desired products, and facility details, to tailor the flexiforming application. This approach underscores the importance of strategic collaboration and technological innovation in achieving the aviation industry's ambitious sustainability goals.

Economic Considerations and Supporting Measures

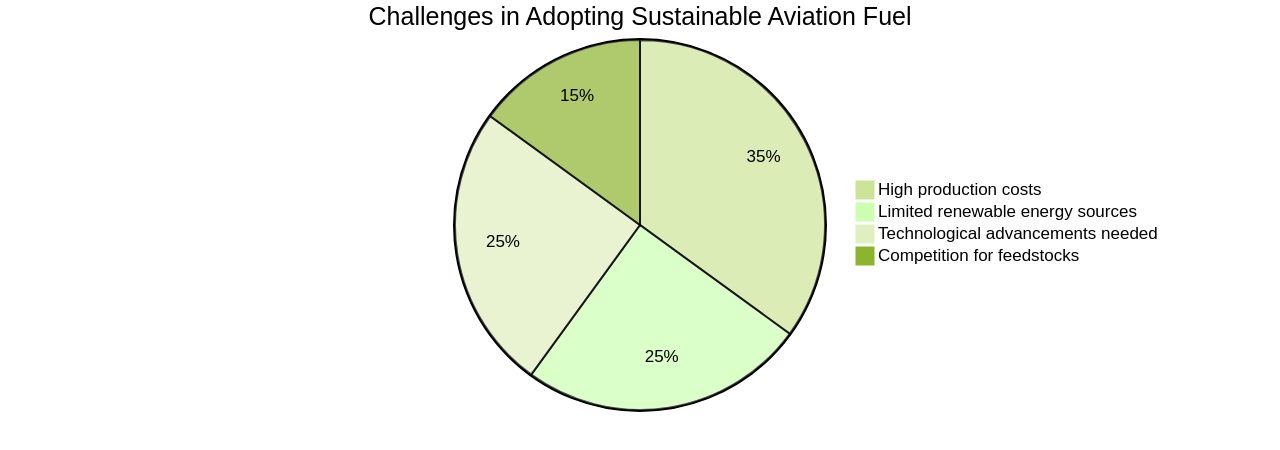

Sustainable Aviation Fuel (SAF) stands at the forefront of the aviation industry's efforts to reduce its carbon footprint, with a potential to substantially lower greenhouse gas emissions. Yet, the journey towards widespread adoption of SAF is fraught with economic and technical challenges.

The cost of SAF production remains high, primarily due to the nascent stage of technologies involved, the scarcity of feedstocks, and the complexities of scaling up production to meet increasing demand. The Power-to-Liquids (PtL) process, a cornerstone in SAF production, promises up to 94% CO2 emission savings, yet it is still evolving.

The success of this process is contingent on the availability of renewable energy sources, such as solar and wind power, which are currently limited. Moreover, the competition for biofuel feedstocks from various industries further constrains SAF supply.

Technological advancements like Unifuel.tech's Flexiforming and React™ are paving the way for more efficient and versatile production methods. Flexiforming, for instance, can be retrofitted into existing infrastructure, offering a more cost-effective pathway to decarbonization.

This technology allows operators to tailor the pace of their green transition by utilizing idle hydrotreaters or reformers, thus optimizing capital expenditure and reducing carbon intensity. For those considering Flexiforming, Unifuel.tech provides personalized assistance and ensures a response within 24 hours to inquiries, aiding in finding the optimal application of the technology based on specific operational parameters.

Despite the challenges, there is optimism for the future. With the aviation industry aiming for net-zero carbon emissions by 2050, SAF is critical, especially for long-haul flights where alternatives like electrification are not yet viable. The integration of carbon capture usage (CCU) in electrofuel production and the anticipated commissioning of novel facilities like the one near Forsmark, Sweden, exemplify the innovative strides being taken. The industry's commitment to SAF is evident, with initiatives like the HyFlexPower project showcasing real-world applications of renewable energy for industrial decarbonization. As the world's first commercial AtJ facility by LanzaJet nears operation, it marks a significant milestone towards making SAF more accessible. However, with Saf's current price being 3 to 4 times higher than traditional jet fuel, there is a pressing need for collective efforts, including government policies and incentives, to bridge the gap and accelerate the transition to a more sustainable aviation sector.

Logistics and Quality Certification of Sustainable Aviation Fuel

Sustainable aviation fuel (SAF) is at the forefront of the aviation industry's efforts to reduce its carbon footprint, with a goal set by the International Civil Aviation Organization to achieve net-zero emissions by 2050. The logistics of SAF, including its transportation and storage, require stringent infrastructure and handling protocols to maintain fuel integrity and quality. Certification schemes like the Sustainable Aviation Fuel Certification Scheme are crucial in validating the fuel's sustainability credentials, carbon reduction potential, and feedstock traceability, ensuring compliance with industry standards.

As the aviation sector aims to diminish its environmental impact, the uptake of SAF is growing, particularly in Europe, the UK, and the USA, signifying a collective endeavor to reach net-zero emissions. Airbus' ambition to ensure all its aircraft are SAF-compatible by 2030, alongside efforts to enlarge the SAF market, exemplifies industry-wide support for such initiatives. Despite being a practical solution, alternative fuels like SAF still represent a minor fraction of the global jet fuel supply, calling for significant advancements.

The trailblazing Flight 100 by Virgin Atlantic, powered solely by SAF, showcases the potential of these fuels to supplant traditional jet fuel. However, Saf's current scarcity underscores the urgent need for increased investment, regulatory certainty, and pricing support to bolster its production and adoption. The aviation industry's innovative drive is propelling the transition towards a more sustainable future, powered by SAF, though the journey is just beginning.

Developing a National Sustainable Aviation Fuel Programme

The Sustainable Aviation Fuel (SAF) market is experiencing a surge in demand, with the US aviation sector, accounting for a notable share of transportation emissions, being a significant player in this growth. The industry's shift towards SAF is underpinned by the need for high energy density fuels that can be adopted by current aircraft without extensive infrastructure overhauls.

Innovations such as flexiforming technology, pioneered by Unifuel.tech, demonstrate the sector's commitment to integrating scalable solutions that support carbon neutrality goals. Flexiforming enables the conversion of idle hydroprocessing units, like hydrotreaters or reformers, into SAF production sites.

This adaptability allows for a tailored decarbonization pace, minimizing capital investments and carbon intensity, which is paramount for the industry's shift towards a circular energy economy. Unifuel.tech's approach is designed to align with the aviation sector's existing infrastructure and the Biden administration's ambitions for enhancing SAF production. The company ensures prompt communication, promising a response within 24 hours to inquiries, and seeks specific details about feeds, target products, and facilities to ascertain the most effective application of flexiforming technology. Unifuel.tech, a branch of Universal Fuel Technologies, upholds all rights under their terms of use, emphasizing their commitment to providing a transitional solution for the aviation industry's sustainable evolution.

Case Studies and Best Practices

Amidst the push for decarbonization, the aviation industry is exploring sustainable aviation fuel (SAF) to reduce its carbon footprint. Notably, Saf's adoption is challenged by technological infancy and the need for considerable investments. However, innovative solutions like Flexiforming, offered by Universal Fuel Technologies through their Unifuel.

Tech platform, are on the rise, offering a pathway to integrate SAF production while managing costs and carbon intensity. Flexiforming can be retrofitted into existing infrastructure, such as idle hydrotreaters or reformers, allowing for a more pragmatic approach to decarbonization and enabling operators to tailor the pace of their green transition. The aviation sector's CO2 emissions, currently at 2.5% of global fossil CO2 emissions, are a critical target for reduction efforts.

With emissions quadrupling since the 1960s, proactive measures are essential. SAF projects are proliferating, with over 130 announced, aiming to boost annual production to 18 billion gallons by 2028. These efforts are crucial as the industry strives to meet the net-zero emissions goal by 2050.

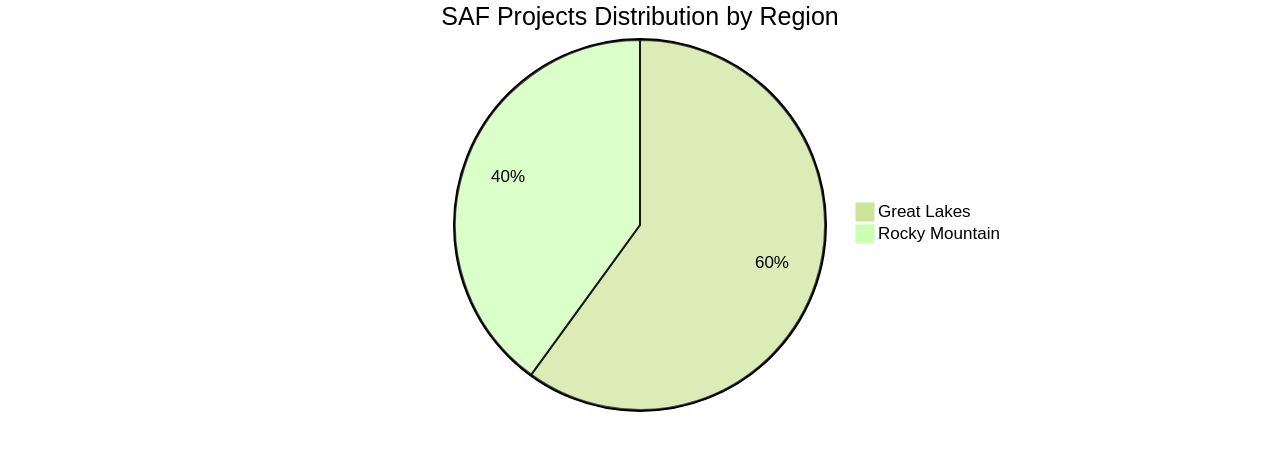

While SAF currently constitutes a minuscule fraction of global aviation fuel, its potential is recognized. For instance, Ørsted has transformed its business model to prioritize renewable energy, and ENGIE's HyFlexPower project demonstrates the viability of green hydrogen for industrial decarbonization. The promise of SAF is particularly strong in regions with abundant feedstock, infrastructure, and policy support, such as the Great Lakes and Rocky Mountain regions.

As Virgin Atlantic's CEO emphasizes, achieving scale in SAF production necessitates regulatory certainty and price support mechanisms. The industry remains optimistic, with Airbus targeting 100% SAF-capability by 2030. The journey towards a greener aviation sector, powered by SAF and technologies like Flexiforming from Universal Fuel Technologies, is underway, with the hope of significantly reducing greenhouse gas emissions and advancing towards a sustainable future.

Conclusion

In conclusion, Sustainable Aviation Fuel (SAF) is a renewable alternative to conventional jet fuel, holding promise in reducing carbon emissions. Despite challenges like high costs and limited availability, SAF has shown transformative potential through successful case studies and partnerships.

Collaborative efforts among airlines, fuel suppliers, and governments are crucial in promoting SAF adoption. Financial incentives stimulate private investment, while logistics and quality certification ensure safe transport and storage.

Developing a national SAF program is essential for long-term growth. Technological advancements like Unifuel.tech's Flexiforming offer solutions to reduce costs and carbon intensity.

However, economic considerations and supporting measures must be addressed to achieve widespread adoption. The aviation industry's commitment to decarbonization remains strong. With continued collaboration and supportive policies, SAF holds significant potential for a greener aviation future. The pioneering spirit within the industry will continue driving progress towards sustainable aviation fueled by renewable alternatives.