Introduction

The decarbonization problem in the aviation industry is a pressing issue that requires immediate attention. Despite the sector's efforts to improve fuel efficiency, the absolute growth of emissions continues to overshadow these gains. Sustainable Aviation Fuel (SAF) is seen as a key solution in the industry's decarbonization efforts, but its adoption is hindered by cost and scale challenges.

This article explores the role of SAF in reducing carbon emissions, the feedstocks and production process involved, and the environmental, economic, and social benefits of using SAF. Additionally, it highlights the innovative flexiforming technology developed by Unifuel.tech, which offers a cost-effective and tailored approach to SAF production. With the urgency to achieve net-zero emissions by 2050, it is crucial for the aviation industry to intensify its efforts in scaling up SAF and other decarbonization measures.

The Decarbonization Problem in Aviation and the Role of SAF

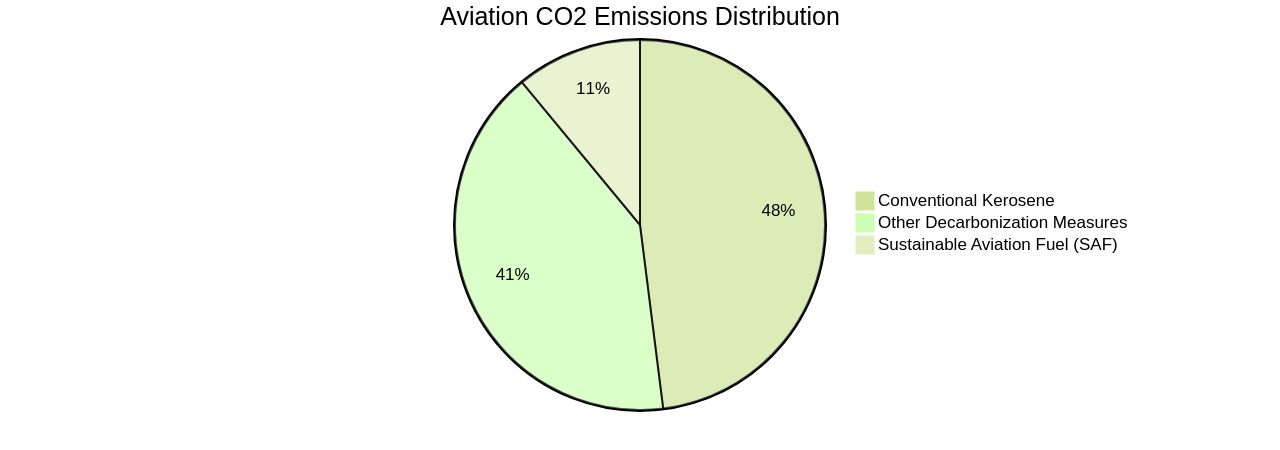

While the aviation sector has made strides in fuel efficiency, increasing by approximately 39% from 2005 to 2019, the absolute growth of emissions overshadows these gains. Aviation's share of global CO2 emissions, at 2.5%, is projected to increase significantly.

Sustainable Aviation Fuel (SAF) stands as a key element in the industry's decarbonization, yet its adoption is hindered by cost and scale. SAF is currently three to four times more costly than conventional kerosene, contributing to a minute fraction of the fuel mix.

Even with passenger contributions to purchase additional SAF at airports like Amsterdam's Schiphol, the logistical complexity prevents direct application to specific flights. Canada, recognizing the need for collaborative innovation, has established a platform to accelerate the SAF value chain.

This initiative aims to bridge the gap between stakeholders and catalyze the production and usage of SAF, not just domestically but globally. Meanwhile, GE Aerospace's comprehensive tests on 100% SAF demonstrate the industry's readiness to support a transition, evaluating factors from engine performance to environmental impact.

Despite these advancements and a collective call for oil companies to prioritize SAF supply, the technology remains nascent. With the International Civil Aviation Organization targeting net-zero emissions by 2050, and the European Union's GHG emissions data highlighting the urgency, the sector must intensify efforts to scale SAF and other decarbonization measures. In this context, Unifuel.tech's flexiforming technology emerges as a pivotal innovation. By allowing operators to retrofit idle hydrotreaters or reformers, flexiforming presents a cost-effective path to producing SAF, thereby reducing both capital expenditure and carbon intensity. This adaptability facilitates a phased approach to decarbonization, aligning with operators' varying capacities and targets. Unifuel.tech's commitment to rapid response and tailored solutions underscores their role as a catalyst in the SAF production landscape, potentially easing the transition towards a more sustainable aviation industry.

Sustainable Aviation Fuels: Definition, Feedstocks, and Production Process

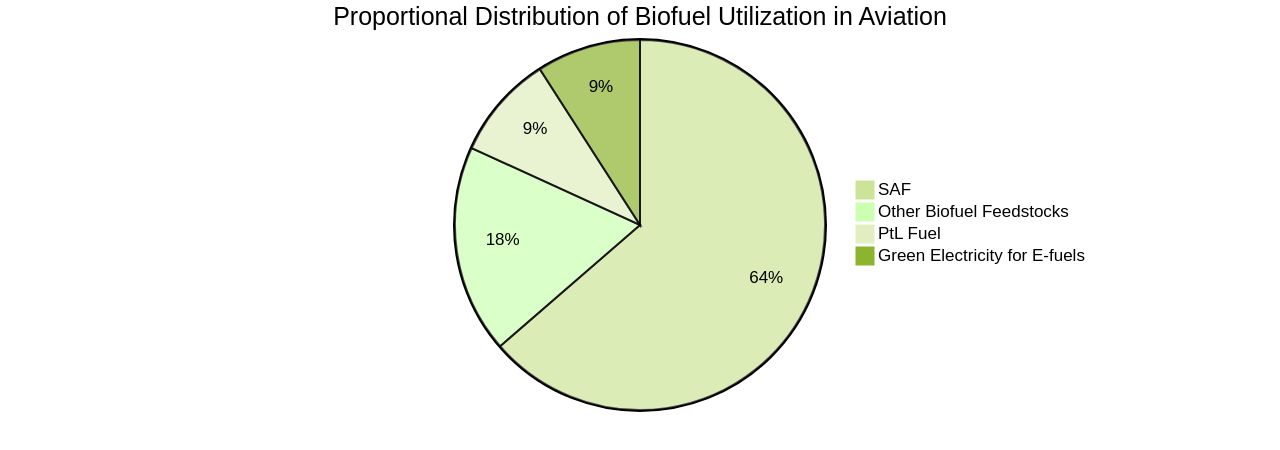

Sustainable Aviation Fuel (SAF) represents a pivotal shift in the aviation industry's approach to reducing its environmental footprint. Derived from a spectrum of renewable resources, including used cooking oil, municipal waste, and agricultural residues, SAF is not only a viable alternative to traditional jet fuel but also an essential component in the quest for carbon-neutral aviation.

The potential for SAF is underscored by its versatility, with production possible from renewable electricity and atmospheric carbon dioxide capture. Currently, used cooking oil is a primary source for SAF creation, highlighting the innovative repurposing of waste materials.

The transformative impact of SAF is evidenced by Virgin Atlantic's historic transatlantic flight powered entirely by alternative fuels, signaling a tangible step towards greener aviation. However, scaling up production remains a critical challenge, as demand is projected to outpace supply, raising questions about affordability, sustainability, and the efficient utilization of feedstocks.

Australia's burgeoning hydrogen economy and significant feedstock production position it as a potential key player in SAF production, offering a diversified portfolio of sources. The complexity of jet fuel specifications necessitates precise quality and composition, underscoring SAF as a 'drop-in' solution that avoids extensive modifications to aircraft and infrastructure. The production of bio-based aromatics now enables aircraft to utilize higher volumes of SAF, with successful tests of 100% SAF flights by major airlines. This advancement, coupled with the urgent need to address the 2% contribution of global carbon emissions from aviation, propels SAF to the forefront of sustainable energy solutions for a sector facing one of its most daunting challenges - decarbonization.

The Environmental Benefits of SAF: Reducing CO2 Emissions and Other Pollutants

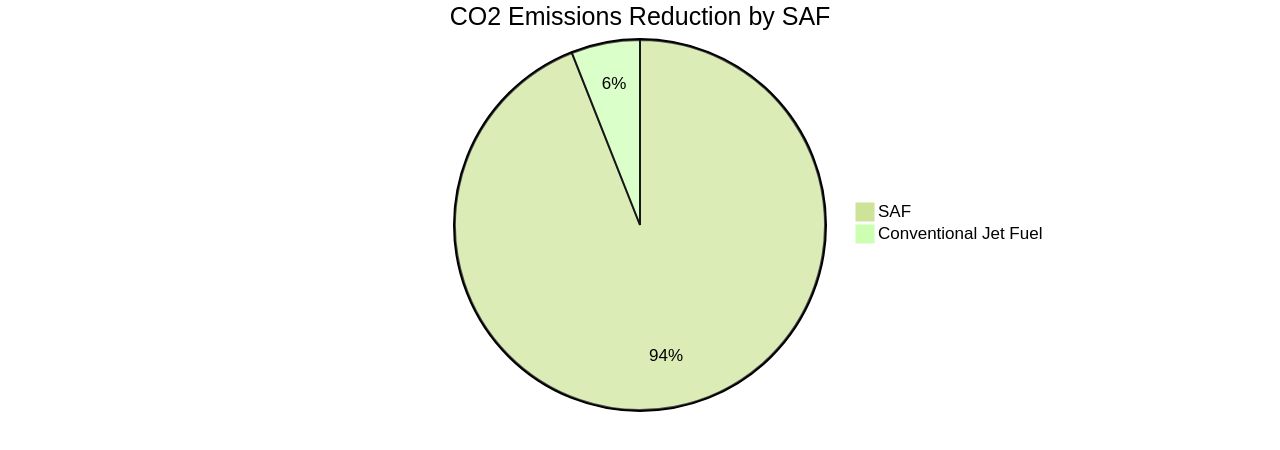

Sustainable Aviation Fuel (SAF) is an essential element in the aviation industry's strategy to reduce its environmental footprint. It's noteworthy that SAF can slash CO2 emissions by up to 80% in comparison to conventional jet fuels.

This is a significant leap forward, given that the aviation sector accounts for 2-3% of the world's CO2 emissions. The environmental benefits of SAF go beyond carbon reduction, as it also lowers the emission of other harmful pollutants, such as sulfur oxides (SOx) and nitrogen oxides (NOx), which contribute to air quality deterioration.

A pivotal study at Copenhagen Airport, conducted by SAS, shed light on Saf's positive impact on air quality in a practical airport environment, adding to its known CO2 emission reduction capabilities. These advancements are vital for the industry's goal to achieve net zero carbon emissions by 2050, as set by the International Civil Aviation Organization.

The shift to SAF is not only environmentally imperative but also carries economic advantages, including job creation, industrial growth, and rural economic development. Although challenges like high costs and limited production capacity exist, the future looks promising for SAF in fostering a more sustainable and carbon-neutral aviation industry.

Unifuel.tech introduces a pioneering approach with flexiforming technology, enabling a tailored pace of decarbonization for operators. This innovative solution can revitalize dormant hydrotreaters or reformers, offering a cost-effective and less carbon-intensive alternative. Unifuel.tech's readiness to provide a 24-hour response and devise an optimal flexiforming strategy based on an operator's specific feedstock, desired products, and existing infrastructure, represents a significant advancement in the production of SAF. Ownership of Unifuel. Tech by Universal Fuel Technologies further solidifies its position in the market as a go-to solution for operators seeking to reduce their environmental impact.

Benefits of Using Sustainable Aviation Fuels: Environmental, Economic, and Social Value

Sustainable Aviation Fuel (SAF) is not only pivotal for environmental stewardship in aviation but also instrumental in catalyzing socio-economic progress. The bioeconomy's expansion, driven by SAF production, can bolster employment significantly. With biofuel utilization capable of reducing greenhouse gas emissions by up to 65%, the agricultural sector is poised to benefit from the heightened demand for biofuel crops.

This, in turn, strengthens the economy's foundation. Furthermore, proactive government policies, such as blending mandates and tax incentives, have spurred biofuel demand while mitigating costs, as reflected in the consumption of 1,837 thousand barrels of oil equivalent per day in 2021. The aviation industry's commitment to achieving net-zero carbon emissions by 2050, as outlined by the International Civil Aviation Organization, aligns with broader climate objectives, including the European Green Deal's target of a 55% emissions reduction by 2030.

Andy Cronin, CEO of Avalon, emphasizes the economic potential of the green economy, heralding SAF as a harbinger of new business ventures and job creation. Saf's promise extends to enhancing energy security, reducing fossil fuel reliance, and fostering global collaboration, as evidenced by Canada's initiative to create a platform for SAF stakeholders. The nexus of SAF development with economic growth and social benefits positions it as a cornerstone in the aviation sector's sustainable transformation.

Innovations in this field, such as Unifuel.tech's flexiforming technology, are set to further revolutionize SAF production. Flexiforming allows for a tailored approach to decarbonization, utilizing existing infrastructure like idle hydrotreaters or reformers to produce SAF, thus curtailing capital expenditure and carbon intensity. This adaptability underscores the potential for SAF to not only meet environmental targets but also to adapt swiftly to market demands and existing assets, driving forward the [sustainable transformation of the aviation sector](https://www.aircargoweek.com/potential-for-e2-55-billion-sustainable-aviation-fuel-saf-industry-in-ireland-by-2050/).

Conclusion

In conclusion, Sustainable Aviation Fuel (SAF) is a pivotal solution in the aviation industry's decarbonization efforts. Despite challenges related to cost and scale, SAF offers significant environmental, economic, and social benefits. SAF, derived from renewable resources like used cooking oil and agricultural residues, has the potential to reduce CO2 emissions by up to 80% compared to conventional jet fuels.

This makes it essential for achieving net-zero emissions by 2050. Unifuel.tech's flexiforming technology revolutionizes SAF production by retrofitting idle hydrotreaters or reformers. This cost-effective approach reduces capital expenditure and carbon intensity, making it a catalyst in the SAF production landscape.

To intensify decarbonization efforts, the aviation industry must scale up SAF production alongside other measures. The urgency to achieve net-zero emissions by 2050 requires collective action and innovation. In summary, SAF plays a crucial role in reducing carbon emissions in aviation while addressing other environmental pollutants.

Its economic and social benefits further solidify its importance. Innovations like Unifuel.tech's flexiforming technology offer practical solutions for scaling up SAF production. The aviation industry must prioritize the adoption of SAF to achieve a sustainable and carbon-neutral future.