Introduction

The task of refueling commercial aircraft is a complex process that requires careful coordination and adherence to specific standards. From the arrival of the fuel truck to the transfer of fuel into the aircraft's tanks, there are numerous factors to consider.

However, this process is not without its challenges, including the modification of global aircraft fleets and fueling infrastructure. In this article, we will explore the intricacies of the fueling process in commercial aircraft, comparing fueling times for different types of aircraft, examining factors that affect fueling efficiency, and discussing how technology is being used to streamline aircraft refueling. Join us as we delve into the technical and analytical aspects of the renewable fuels industry.

Fueling Process in Commercial Aircraft

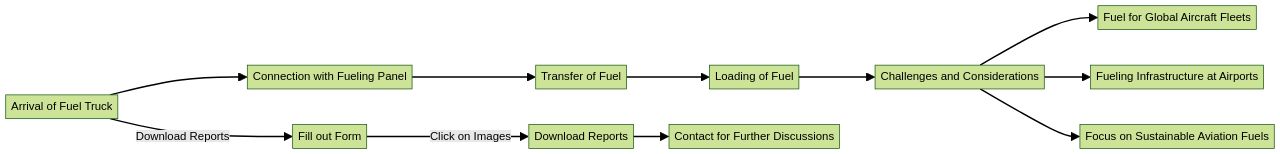

The task of refueling commercial aircraft is multifaceted, requiring a series of steps to ensure a secure and efficient process. The journey commences with the arrival of the fuel truck, which is laden with jet fuel for the aircraft.

The fuel truck then establishes a connection with the aircraft's fueling panel, setting the stage for the fuel operator to initiate the transfer process. The fuel is transported from the truck into the aircraft's fuel tanks via fueling hoses and nozzles.

This process is sustained until the required amount of fuel is loaded, which is dictated by factors such as the aircraft's fuel capacity and the planned flight distance. However, the process is not as straightforward as it seems.

The modification of global aircraft fleets, airports, and fueling infrastructure, a significant portion of which is underground, poses a grand challenge in terms of cost, time, logistics, and disruption to air travel. The jet fuel has specific quality and composition requirements, and air transportation is heavily dependent on the availability of this global network.

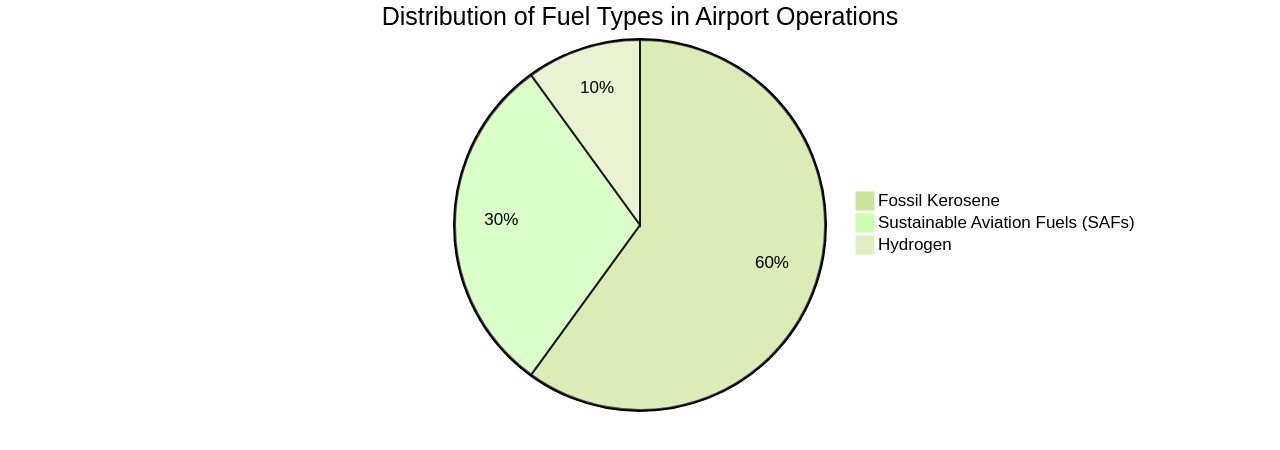

The term SAF (Sustainable Aviation Fuels) has become a banner for various blends of SAF with traditional jet fuels. If a fuel blend can reduce emissions by a certain percentage, it can be referred to as SAF.

The path to sustainable fuel is the reverse of combustion, where energy is harnessed to convert the ingredients of water and CO2 back into fuel, returning oxygen back into the air. This process, though complex, is increasingly supported by the world's leading airlines as the most effective way to address CO2 emissions in the aviation industry today. Airbus, for instance, is striving to make all its aircraft 100% SAF-capable by 2030, working with partners to expand the global SAF market. The company's purpose is to pioneer sustainable aerospace for a safe and united world. Through its partnership with Emirates, ambition is matched with action. This drive towards sustainable fuels is a testament to the pioneering spirit of the aviation industry, which continues to challenge the status quo and push boundaries.

Comparing Fueling Times: Wide-Body vs. Narrow-Body Aircraft

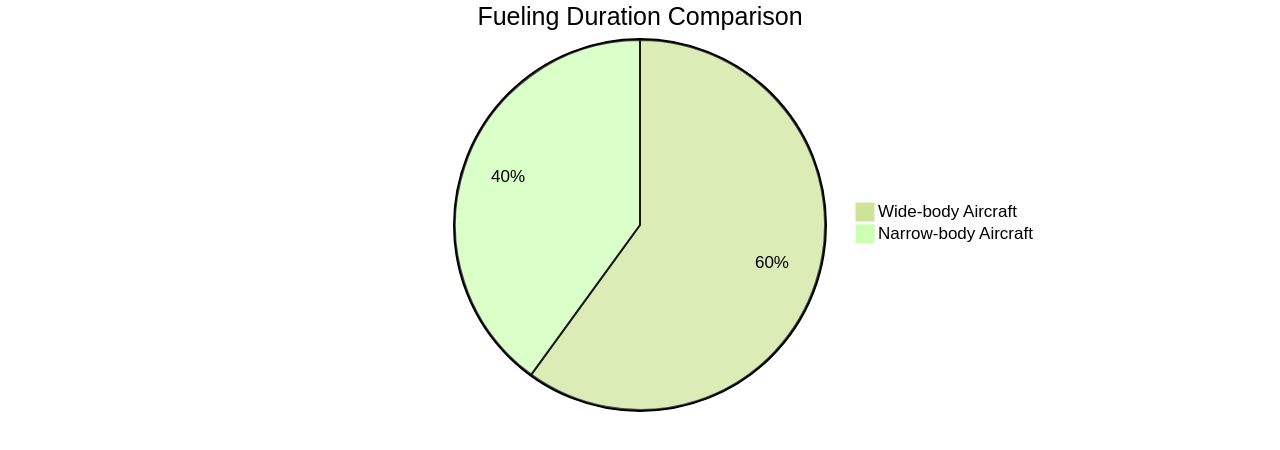

The fueling duration for aircraft is contingent on numerous variables, including the aircraft's type and size. Wide-body aircraft, such as the Airbus A350 and Boeing 787, commonly referred to as 'composite' widebody aircraft, have a larger fuel capacity compared to narrow-body aircraft, such as the Boeing 737 or Airbus A320.

This larger capacity often results in a lengthier fueling process. Factors such as the fueling equipment utilized, the efficiency of the fueling process, and the availability of fueling personnel also influence the fueling duration.

Moreover, the operational dynamics of the aircraft also play a critical role. Pilots can manipulate flight controls to convert between kinetic and potential energy, optimizing the aircraft's performance and maneuverability.

This energy management strategy is crucial when dealing with situations such as loss of power. In the context of fuel efficiency, recent developments in the aviation industry have seen General Electric (GE) working with CFM Rise to develop a 'propfan' engine. This engine promises a 20% fuel saving over conventional turbojet engines, a significant advancement in the drive for net zero and fuel price anxiety. As the aviation industry continues to grow, the narrowbody market is now more significant than ever. Despite issues with the Pratt & Whitney GTF, the narrowbody market is expected to continue growing, opening up new markets and enhancing the capabilities of the latest generation narrow body aircraft.

Factors Affecting Fueling Efficiency

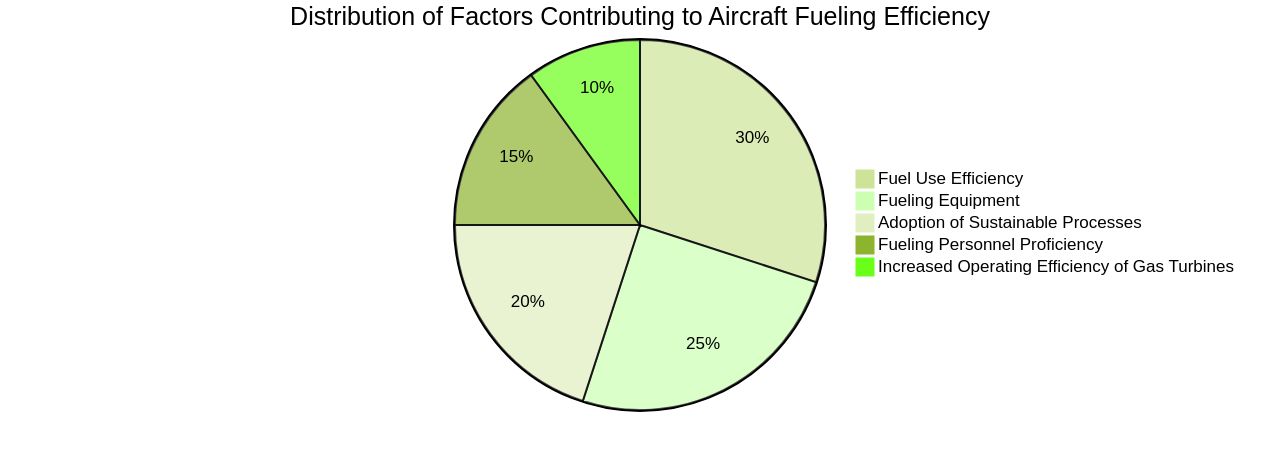

How long does it take to fuel a plane, considering various elements, among which the fueling equipment stands out? When incorporating state-of-the-art fueling systems, such as those equipped with high-flow rate pumps and automated fueling controls, it is important to consider how long it takes to fuel a plane, as this can result in a significant reduction in fueling times.

In addition, it is important to consider how long it takes to fuel a plane, taking into account the proficiency and expertise of the fueling personnel. Proficient fueling operators can minimize any potential delays or errors by performing quick and precise fueling tasks. How long does it take to fuel a plane?

How long does it take to fuel a plane in order to amplify the efficiency of fuel use and conserve fuel? For instance, the Suzuki SJ410, an off-road vehicle equipped with an F10A type engine, is renowned for its fuel efficiency and durability.

It still utilizes a carburetor system, which functions to mix fuel with air, creating a homogeneous mixture at the required ratio. Moreover, the drive for sustainability is compelling companies like Rivian, an electric vehicle manufacturer, to adopt more sustainable processes, including a net-zero emissions goal by 2040.

Similarly, the aviation industry is exploring sustainable aviation fuels, with Airbus committing to making all its aircraft 100% SAF-capable by 2030. Additionally, Can you explain how long it takes to fuel a plane during the transformation from hydraulic and pneumatic systems to electrical ones to achieve optimal engine efficiency? Do you know how long it takes to fuel a plane? This is because the engine provides power to the critical systems in electrical form through shaft-driven generators, resulting in lower fuel consumption. Lastly, it's worth noting that the capacity factor of combined-cycle gas turbines increased to 57 percent in 2022, up from 40 percent in 2008. This increase in operating efficiency could be attributed to the rising usage of these turbines and the lower price of gas in 2022.

Streamlining Aircraft Refueling with Technology

In the quest to enhance efficiency and safety in aircraft refueling, technological advancements are being adopted. Real-time monitoring and data analysis in fueling systems are providing invaluable insights into fuel consumption, flow rates, and potential areas for efficiency upgrades.

This has been exemplified by Hydrogen Airport, an engineering firm committed to aiding airports transition to hydrogen. They offer bespoke feasibility studies, including hydrogen needs assessment and cost estimates, to airports, each with its unique challenges and opportunities.

Moreover, the push towards automation is gaining momentum with technologies such as robotic fueling arms being tested to mitigate human error and expedite the refueling process. The International Civil Aviation Organization's 193 member states' unanimous vote for a 'net-zero CO2' target for 2050 illustrates the growing urgency to decarbonize air transport, which currently accounts for approximately 2% of global CO2 emissions.

Sustainable Aviation Fuels (SAFs) and hydrogen are emerging as viable alternatives to fossil kerosene. LH2, with its high energy density, provides a promising solution to reducing greenhouse gas emissions and fossil fuel dependency in airport operations. However, this requires a comprehensive understanding of the operational, regulatory, economic, and safety impacts, as well as the capacity and performance of technologies. In the words of Karine Guenan, Vice President of ZEROe Ecosystem, Airbus, hydrogen will be an instrumental fuel for the future of short-haul aviation. As the aviation industry continues to evolve, the integration of advanced technologies into aircraft refueling operations remains a key priority for ensuring efficiency, safety, and sustainability.

Conclusion

In conclusion, the fueling process in commercial aircraft is a complex operation that requires coordination and adherence to specific standards. Challenges such as modifying global fleets and fueling infrastructure can pose obstacles.

The industry is embracing sustainable aviation fuels (SAFs) to address CO2 emissions, with Airbus aiming for SAF-capable aircraft by 2030. Efficiency in fueling times can be enhanced through advanced equipment and skilled personnel.

Technology plays a key role in streamlining operations, including real-time monitoring and automation. The industry is focused on decarbonizing air transport with SAFs and hydrogen as alternatives to fossil kerosene.

The integration of advanced technology remains a priority for efficiency, safety, and sustainability in refueling operations. Collaboration within the industry is crucial for successful implementation. In conclusion, the aviation industry is committed to pioneering sustainable aerospace for a safe and united world. By addressing challenges, embracing technology, and collaborating, the industry can achieve efficient and sustainable aircraft refueling processes.