Introduction

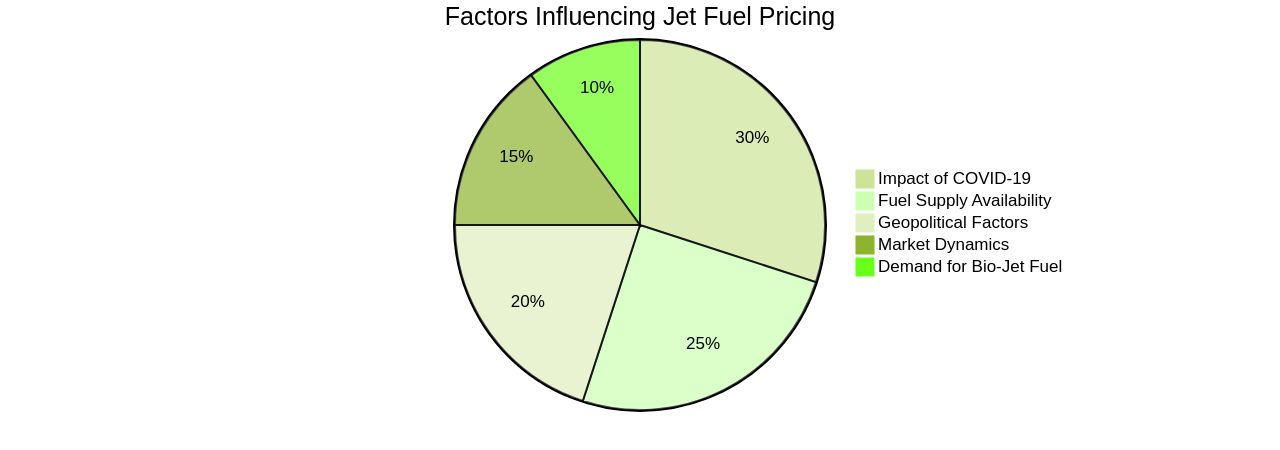

The complex interplay of factors determining jet fuel pricing, such as fuel supply availability, market dynamics, and geopolitical influences, has a significant impact on the operational costs of airlines. In this article, we will explore the intricate landscape of jet fuel prices and the challenges they pose to the aviation industry.

Additionally, we will examine the demand for bio-jet fuel and its potential to promote sustainable air travel. Furthermore, we will delve into the comparative analysis of jet fuel versus other fuels and the implications for fuel procurement strategies. Finally, we will introduce Flexiforming technology offered by Unifuel.tech as a promising solution to optimize plant operations, reduce costs, and address environmental concerns in the renewable fuels industry.

Section 1: Understanding Jet Fuel Prices

The complex interplay of factors determining jet fuel pricing, a critical operational cost for airlines, is multifaceted. A key determinant of prices is the availability of fuel supplies, with scarcity leading to cost escalation, sometimes even reaching two to five times the cost of conventional jet fuel.

To mitigate costs, airlines often have to adjust their strategies, which subsequently impacts emissions and climate change. Conservation measures can reduce emissions significantly.

Market dynamics and geopolitical factors also exert influence on jet fuel prices. For instance, oil prices witnessed a 25% surge in the first half of a year due to production cuts announced by Saudi Arabia and Russia, triggering a corresponding increase in jet fuel prices.

The demand for bio-jet fuel, aimed at decreasing pollution and promoting sustainable air travel, is another crucial factor. However, the high costs associated with aircraft fuels can impede market progress.

The COVID-19 pandemic, marked by travel and mining restrictions, led to supply shortages and fuel price instability. Regional factors also play a role in the aviation fuel market.

The Asia Pacific, with its numerous developing countries and relaxed transport and travel regulations, is expected to lead the aviation fuel market. In contrast, North America is likely to see increased product demand due to growing air traffic. In this complex landscape, solutions like Flexiforming offered by Unifuel. Tech provide a viable option. Flexiforming allows operators to choose their decarbonization speed, which can be deployed in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. The technology is responsive, with inquiries addressed within 24 hours, and requires information about feeds, target products, and existing facilities to tailor the optimal application. Universal Fuel Technologies holds the rights to Unifuel.tech and their services.

Section 2: Historical Perspective on Jet Fuel Prices

The aviation fuel market's complexity is a result of the interplay of economic, geopolitical, and environmental factors. A recent 23% surge in jet fuel prices, as reported by the International Air Transport Association (IATA) and S&P Global Commodity Insights, is primarily credited to the recovery of the Asia Pacific air travel market.

The global air traffic in June 2023 saw a 31.0% increase compared to the previous year, thanks to a substantial 6.9% increase in domestic seats in the Asia Pacific region. However, How much is gas for a plane is a significant challenge due to the cost of aircraft fuels and price fluctuations caused by supply constraints.

This was particularly evident during the COVID-19 pandemic. These high costs impact not only airlines but also society due to the climate change implications.

Airlines are thus employing cost-minimizing strategies to conserve fuel and potentially lower emissions. Do you know how much gas for a plane costs? The future market growth is expected to be driven by the increasing demand for bio-jet fuel, a sustainable alternative that aims to lower pollution levels. How much is gas for a plane in terms of cost?

The Asia Pacific region, with numerous developing countries, leads the aviation fuel market share, contributing to a market size of USD 63.94 billion in 2021. In North America, a surge in air traffic has increased product demand.

Despite the benefit of lower fuel costs in the first half of the year, the increase in oil prices by 25% since the end of June has resulted in a surge in prices for jet fuel. How much is gas for a plane? This is partly due to production cuts announced by Saudi Arabia and Russia, along with OPEC+ reductions. In light of these dynamics, it is crucial to determine how much is gas for a plane in order to comprehend market trends. In this context, Universal Fuel Technologies offers a solution named 'flexiforming' that can be deployed in an idle hydrotreater or reformer. This technology optimizes plant operations, reducing capital expenditure and carbon intensity while providing a cost-effective supply chain solution. The flexiforming technology allows operators to choose their speed of decarbonization, making it a promising solution for aviation fuel challenges.

Section 3: Jet Fuel vs. Other Fuels: A Comparative Analysis

Fuel procurement strategies are significantly dictated by the types of fuel, their cost fluctuations, and market dynamics. A comprehensive understanding of fuel price trends can be gleaned from annual evaluation of Energy Information Administration (EIA) data.

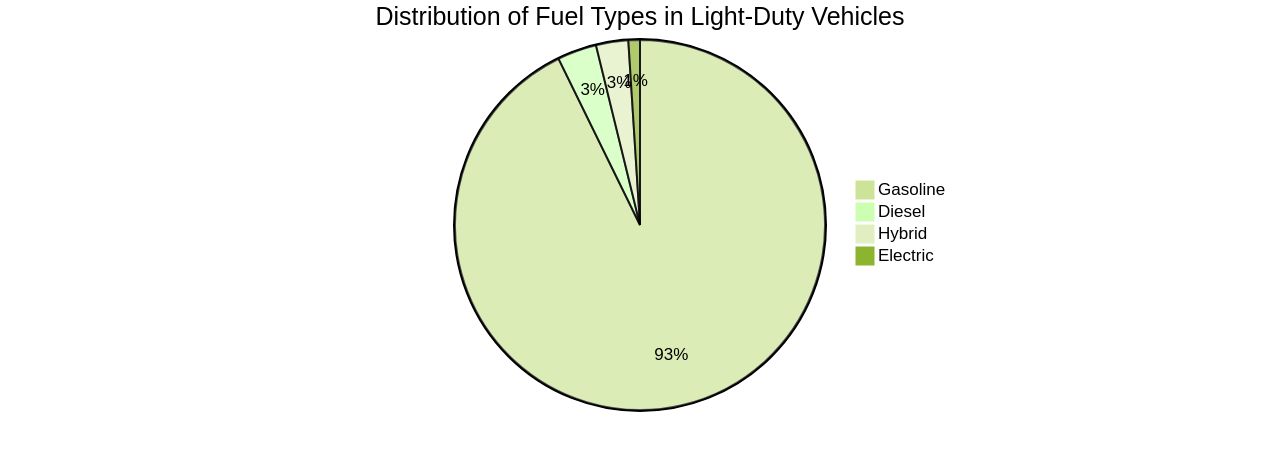

This is notably beneficial for assessing seasonal diesel demand. Prior to 2005, gasoline held a slight premium over diesel, but diesel has consistently traded at a higher premium since then, coinciding with the U.S. introduction of ultra-low-sulfur diesel (ULSD) in 2006 to cut down sulfur dioxide emissions.

The choice of transportation fuel is largely influenced by factors such as energy density, fuel cost, weight, and storage size. Despite the presence of cheaper fuels, gasoline and diesel continue to dominate due to their superior energy density and convenient onboard storage.

As of 2012, gasoline (containing up to 10% ethanol) made up 99% of light-duty vehicle fuel consumption, with diesel making up over half of the remaining 1%. When comparing fuels, the impact of supply and demand dynamics on fuel prices is a crucial consideration.

For example, in the U.S., gasoline prices are on the rise as demand starts to recover. In addition, operational issues in California's refineries can lead to significant price increases due to the state's high gasoline demand.

Finally, while the aviation fuel market has been slowed by high costs and travel restrictions during the COVID-19 pandemic, the demand for bio-jet fuel is expected to increase, opening new opportunities for market growth. In an effort to address these challenges, Unifuel. Tech offers flexiforming technology, allowing operators to choose their speed of decarbonization. This technology can be deployed in idle hydrotreaters or reformers, thereby reducing capital expenditure and carbon intensity. Unifuel. Tech invites potential users to provide information about their feeds, target products, and existing facilities to find the best application for flexiforming.

Section 4: Optimizing Plant Operations with Flexiforming

Flexiforming, a technology offered by Unifuel.tech, is an innovative approach in the production of sustainable aviation fuel (SAF). It provides plant operators the flexibility to adjust feed types and proportions, mirroring market fluctuations.

A key feature is the development of a 'digital twin' of the production facility - a virtual model that allows in-depth simulations and precision-tuning of production processes, targeted towards the most economically and environmentally sustainable synthesis methods. The technology enables the production of sustainable synthetic fuels which closely resemble traditional petroleum-derived products, but are created by merging hydrogen and carbon dioxide molecules sourced from various industrial processes.

This method notably curtails industrial greenhouse gas emissions. These synthetic fuels, due to their similarity to petroleum-derived products, can be incorporated into existing combustion engine vehicles without any technical modifications.

The compatibility extends to current infrastructure for petroleum fuel storage, transport, and distribution, ensuring a smooth transition to synthetic fuels. Companies such as ORLEN, Yokogawa, and Unifuel.tech are at the forefront of this transformation, aiming for a production capacity of 70 thousand tons of such fuels annually by 2030. This initiative significantly contributes towards effective decarbonization of the aviation industry. Unifuel.tech's Flexiforming technology can be deployed in an idle hydrotreater or reformer, allowing plant operators to choose their pace of decarbonization, thereby reducing capital expenditure and carbon intensity. Unifuel.tech guarantees a response to inquiries within 24 hours, ensuring optimal application of Flexiforming based on the operator's feeds, target products, and existing facilities.

Section 5: Balancing Cost and Environmental Concerns

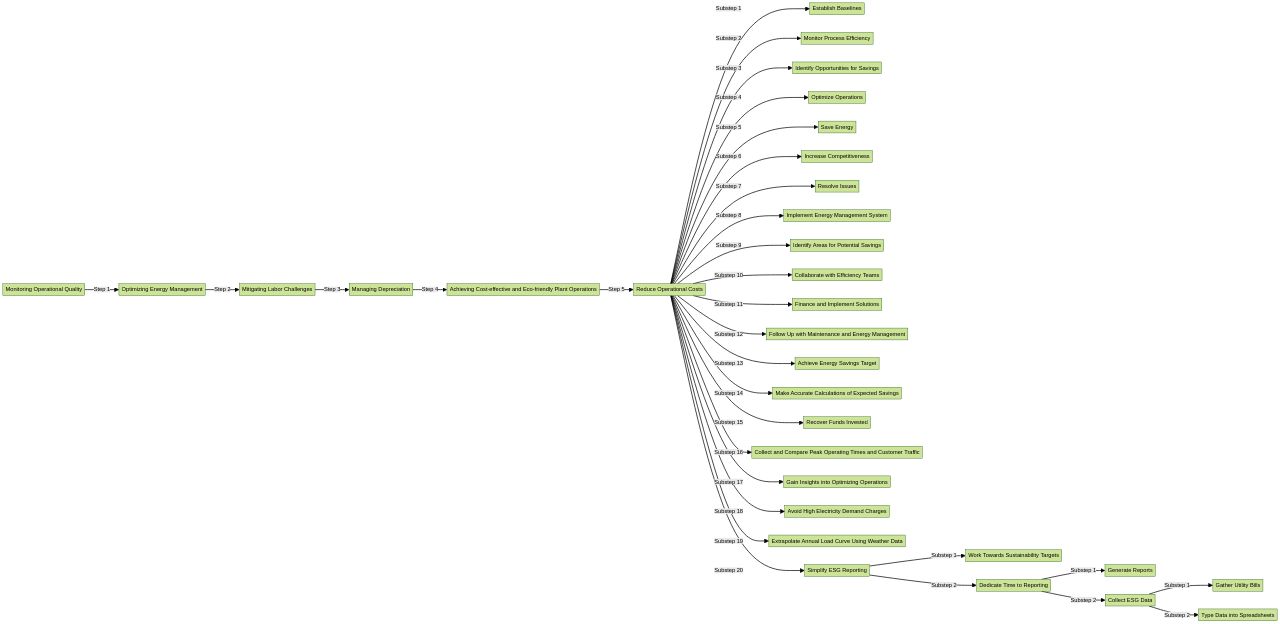

Plant operations present a complex challenge of balancing financial expenditure against sustainable practices. Unifuel.tech's innovative solution, Flexiforming technology, addresses this by targeting the three key cost areas: energy, labor, and facility management. Envision a facility equipped with a cutting-edge chip system designed to monitor operational quality, track speed, and enhance scalability and production efficiency.

This system can significantly reduce errors, as demonstrated at Flex's Hungarian site where thousands of printed circuit board assemblies are produced monthly. The importance of reliable monitoring systems is underscored when considering the potential for failure if machine cycle times are not appropriately balanced. Energy management is another area where Flexiforming technology shines.

For example, in a malting plant, the efficient operation of electric fans, a significant electricity cost driver, could be optimized with this technology. Labor challenges, such as a shortage of skilled workers, can also be mitigated by Flexiforming. The technology fosters operational knowledge, ensures consistent results, and streamlines facility management.

Additionally, depreciation, often an overlooked operational factor, can be efficiently managed through time-dependent operating costs distributed over a set depreciation period. Flexiforming technology from Unifuel.tech not only optimizes machine performance but also gives operators the autonomy to choose their decarbonization pace. It can be implemented in an idle hydrotreater or reformer, leading to reduced capital expenditure and carbon intensity.

Unifuel. Tech is committed to rapid customer service, responding to inquiries within 24 hours, and customizes solutions based on the client's feeds, target products, and existing facilities. Ultimately, Flexiforming technology facilitates more cost-effective and eco-friendly plant operations.

Conclusion

In conclusion, jet fuel pricing in the aviation industry is influenced by various factors such as fuel supply availability, market dynamics, and geopolitical influences. The demand for bio-jet fuel and its potential to promote sustainable air travel are significant considerations. Unifuel.tech's Flexiforming technology offers a promising solution to optimize plant operations, reduce costs, and address environmental concerns.

It allows operators to choose their decarbonization speed and can be deployed in idle hydrotreaters or reformers, reducing capital expenditure and carbon intensity. By incorporating Flexiforming technology, operators can achieve more cost-effective and eco-friendly production processes. The technology enables the production of sustainable synthetic fuels that closely resemble traditional petroleum-derived products while curbing greenhouse gas emissions.

With solutions like Flexiforming technology, we can work towards a more sustainable future for air travel while balancing financial considerations with environmental concerns. Embracing innovative approaches and technologies is crucial for effective decarbonization of the aviation industry. In summary, understanding the complex landscape of jet fuel prices is essential for airlines to mitigate costs.

The demand for bio-jet fuel presents opportunities for sustainable air travel. Unifuel.tech's Flexiforming technology offers a viable solution to optimize plant operations and address environmental concerns. By adopting these solutions, we can contribute to a more sustainable future in the aviation industry.