Introduction

The refining process of jet fuel has undergone revolutionary advancements, particularly with the introduction of catalysts like Ni, Mo, Co, Pt, Ru, and Pd. These catalysts have significantly enhanced the conversion of crude oil into superior jet fuel, resulting in higher efficiency and reduced energy consumption.

Researchers at the Whiting School of Engineering have even developed a catalyst that can convert ethanol into a precursor for aviation fuel, known as Sustainable Aviation Fuel (SAF), which could help combat CO2 emissions. However, despite these innovations, the transition towards SAF faces challenges such as limited supply and higher costs compared to traditional jet fuel. This article explores the technological advancements and innovative solutions in the refining processes of renewable fuels, with a focus on the renewable fuels industry's technical insights and analysis.

Enhanced Refining Techniques: Achieving Higher Efficiency

Revolutionary techniques have transformed the refining process of jet fuel, including the introduction of catalysts like Ni, Mo, Co, Pt, Ru, and Pd. These catalysts enhance the conversion of crude oil into superior jet fuel and decrease energy consumption.

Catalysts are typically deposited on different supports such as zeolites, metal oxides, and various carbon types. Zeolites are commonly utilized due to their inherent acidity, large surface area, and porosity.

The work of researchers at the Whiting School of Engineering exemplifies these advancements, with the development of a catalyst to convert ethanol into butene, a precursor for aviation fuel. This Sustainable Aviation Fuel (SAF) could help counteract harmful CO2 emissions as it is derived from CO2-absorbing plants.

Nevertheless, the transition towards SAF is fraught with challenges, such as the limited supply and higher cost of alternative fuels compared to traditional jet fuel. Despite SAF currently accounting for less than 0.1 percent of the total jet fuel used by major U.S. airlines, the U.S. government aims to produce 3 billion gallons of SAF per year by 2030, a nearly 30-fold increase from current levels.

This goal underscores the significance and urgency of technological innovations in SAF refining processes. Moreover, the aviation industry's future is looking brighter with the emergence of solar fuels, like those developed by Synhelion, which convert water and carbon dioxide into synthetic liquid fuels using solar energy. This process is particularly significant for its potential to produce carbon-neutral fuels. However, the challenge remains in procuring SAF in the first place, as supplies are limited and can cost up to five times more than conventional jet fuel. The need for technological advancements and innovative solutions in SAF refining processes has never been more critical.

Hydroprocessing: Reducing Environmental Impact

The evolution of Sustainable Aviation Fuel (SAF) refining technologies has been marked by a growing emphasis on hydroprocessing methodologies. This method, which employs hydrogen to remove impurities and transform heavier hydrocarbons into lighter, more valuable fractions, not only improves the quality of jet fuel but also lessens environmental impact by reducing sulfur and aromatic content. The result is a cleaner, more sustainable jet fuel, thanks in part to hydroprocessing.

In a stride towards expanding this trend, a unique production facility is in planning stages in Forsmark, on Sweden's east coast. The facility will produce electrofuel, a category of SAF, using fossil-free electricity to generate hydrogen through electrolysis. This hydrogen, combined with carbon dioxide, will be synthesized into ethanol before being converted into aviation electrofuel.

However, the journey to SAF is not without its challenges. Issues such as limited supplies and high costs are still prevalent. The task of retrofitting global aircraft fleets, airports, and fueling infrastructure to accommodate SAF is massive and complex, involving considerable cost, time, logistics, and potential disruption to air travel.

Despite these hurdles, the refining industry has demonstrated that expanding the capacity of existing refineries can be more economical than constructing new ones. This strategy has led to a gradual shutdown of less competitive refineries in the United States, with their owners contemplating conversion to renewable fuels production. Innovative solutions, like the flexiforming offered by Unifuel.tech, present a promising path forward.

This technology allows operators to control their decarbonization pace and can be implemented in an idle hydrotreater or reformer, thereby reducing both capital expenditure and carbon intensity. While SAF alone cannot achieve decarbonization, it forms an integral part of a blended solution that reduces emissions. As such, the future of jet fuel lies in innovative refining techniques that foster more sustainable alternatives.

Alternative Feedstocks: Expanding the Raw Material Pool

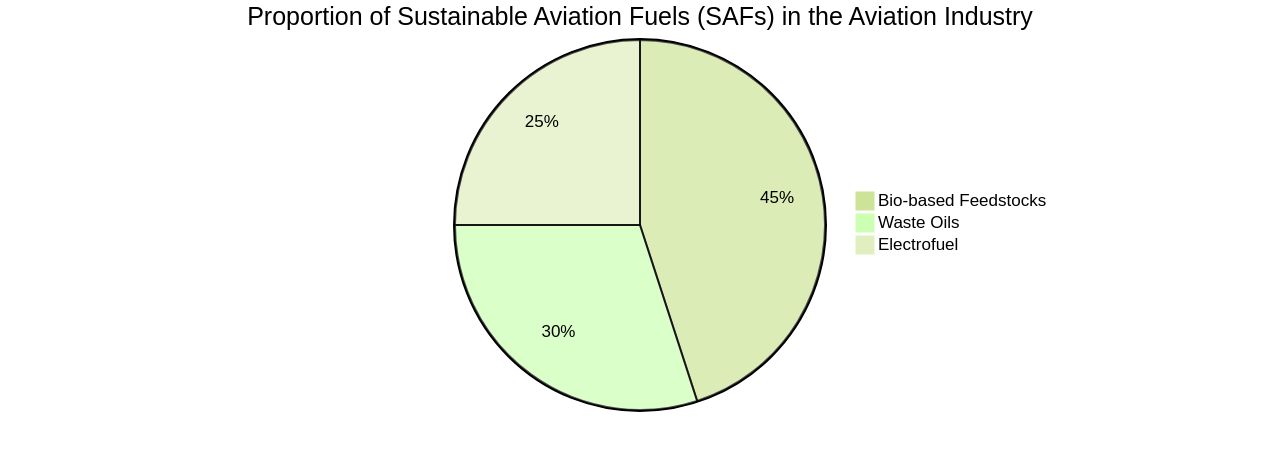

Technological advancements have opened up the possibility to explore sustainable alternatives to petroleum-based jet fuel. These alternatives include bio-based feedstocks and waste oils, which are instrumental in mitigating the aviation industry's reliance on fossil fuels, thereby promoting a sustainable fuel supply chain.

These sustainable aviation fuels (SAFs) can be blended with, or fully replace, petroleum-based kerosene in existing jet engines. However, their supply is still in nascent stages, and they can cost two to five times more than conventional jet fuel.

Notably, their production process often involves carbon dioxide emissions due to the energy required to manufacture them or their impact on ecosystems that emit carbon. A promising solution to reduce emissions in the aviation industry is the electrofuel, which is categorized as a SAF as it uses fossil-free electricity, water, and recycled carbon dioxide.

A production facility for this alternative fuel is planned to be commissioned around 2030 near Forsmark on Sweden's east coast. The facility will be located adjacent to the Forsmark nuclear power plant to leverage fossil-free electricity from the Swedish electricity mix.

The recycled carbon dioxide is captured from a district heating facility and used for electrofuel production, a process known as carbon capture usage (CCU). The global demand for SAFs is increasing, especially in Europe, the UK, and the USA. Despite the commitment to high SAF volume targets and aggressive adoption timelines, the limited global production means demand will surpass supply. Key challenges remain around affordability and sustainability, as well as competition for feedstocks and economically efficient scales of production. However, countries like Australia, which already produces significant quantities of feedstocks exported for biofuel production, could play a key role in meeting this demand.

Biojet Fuel: A Promising Solution

The journey of aviation fuel has welcomed the introduction of biojet fuel, a green alternative derived from renewable resources like agricultural waste, algae, and municipal waste. These resources, transformed through hydroprocessing and fermentation techniques, provide a sustainable substitute for traditional jet fuel.

This advanced fuel technology is linked with significant environmental benefits, such as reduced greenhouse gas emissions and particulate matter. A key advancement is electrofuel, a type of Sustainable Aviation Fuel (SAF), which utilizes fossil-free electricity, water, and recycled carbon dioxide.

The recycled carbon dioxide, sourced from a district heating facility, plays a critical role in the electrofuel production process, forming a carbon capture and usage (CCU) cycle. This process has demonstrated a significant reduction in carbon dioxide emissions from aircraft compared to fossil fuels.

In addition, the potential of genetically modified photosynthetic microorganisms, cyanobacteria, is under scrutiny for fuel production. These cyanobacteria are manipulated to produce isoprene, which can be transformed into larger hydrocarbons akin to existing aviation fuels.

Moreover, the exploration of waste biomass like forest residues is underway. These are cost-effective and immune to shortages.

This biomass is transformed into synthesis gas (syngas), a gas rich in carbon monoxide and hydrogen, through gasification and Fischer-Tropsch processes. The syngas is then synthesized into paraffins, mirroring the process of biojet fuel creation.

Despite the advantages, these alternative fuels encounter challenges related to limited supply and high costs, which can be two to five times higher than traditional jet fuel. Nevertheless, advancements in biofuel technology are acknowledged as a crucial stride towards aviation decarbonization.

Innovative solutions like Unifuel.tech's Flexiforming technology address these challenges. Flexiforming allows operators to control their decarbonization speed and can be installed in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. Unifuel. Tech ensures responsive customer service, aiming to reply within a 24-hour timeframe. To optimize the application of Flexiforming, Unifuel. Tech requires information about the operator's feeds, target products, and existing facilities. It's worth noting that Unifuel. Tech is a division of Universal Fuel Technologies, with all rights reserved and terms of use applied.

Conclusion

In conclusion, the refining process of jet fuel has seen revolutionary advancements with catalysts like Ni, Mo, Co, Pt, Ru, and Pd. These catalysts have improved efficiency and reduced energy consumption in converting crude oil into superior jet fuel.

The development of a catalyst to convert ethanol into Sustainable Aviation Fuel (SAF) holds promise for reducing CO2 emissions. However, challenges such as limited supply and higher costs compared to traditional jet fuel hinder the transition towards SAF.

The goal to produce 3 billion gallons of SAF per year by 2030 underscores the need for technological advancements in refining processes. Hydroprocessing methodologies have played a crucial role in reducing the environmental impact of SAF refining by improving fuel quality and reducing sulfur and aromatic content.

The emergence of solar fuels and electrofuels offers potential for carbon-neutral aviation. Alternative feedstocks like bio-based materials and waste oils provide sustainable alternatives to petroleum-based jet fuel.

Although supply is still in early stages, these can be blended with or replace traditional kerosene. However, cost remains a challenge.

Biojet fuel derived from renewable resources like agricultural waste and algae shows promise for reducing greenhouse gas emissions. Electrofuel technology utilizing fossil-free electricity and recycled carbon dioxide has demonstrated significant CO2 emission reductions from aircraft. Despite challenges related to limited supply and high costs, ongoing technological advancements drive the industry forward. Innovative solutions like Unifuel.tech's Flexiforming technology offer opportunities to control decarbonization speed while reducing expenditure and carbon intensity. In conclusion, the future of aviation fuel lies in innovative refining techniques that foster sustainable alternatives. With continued research efforts, it is possible to overcome challenges and achieve a greener aviation industry that reduces environmental impact while ensuring reliable fuel supplies.