Introduction

With the aviation sector contributing to a significant portion of global CO2 emissions, the need for sustainable solutions in the industry is more pressing than ever. In this article, we will explore the advancements and innovations in the production of Sustainable Aviation Fuel (SAF) and its role in decarbonizing air travel.

From the use of alternative low-carbon feedstocks to advanced HEFA technologies, we will delve into the science behind carbon jet fuel production and the potential for substantial reductions in emissions. Join us as we examine the efforts of companies like Carbon Direct and Unifuel.tech in driving the transition towards a more sustainable future for aviation.

The Need for Carbon Reduction in Aviation

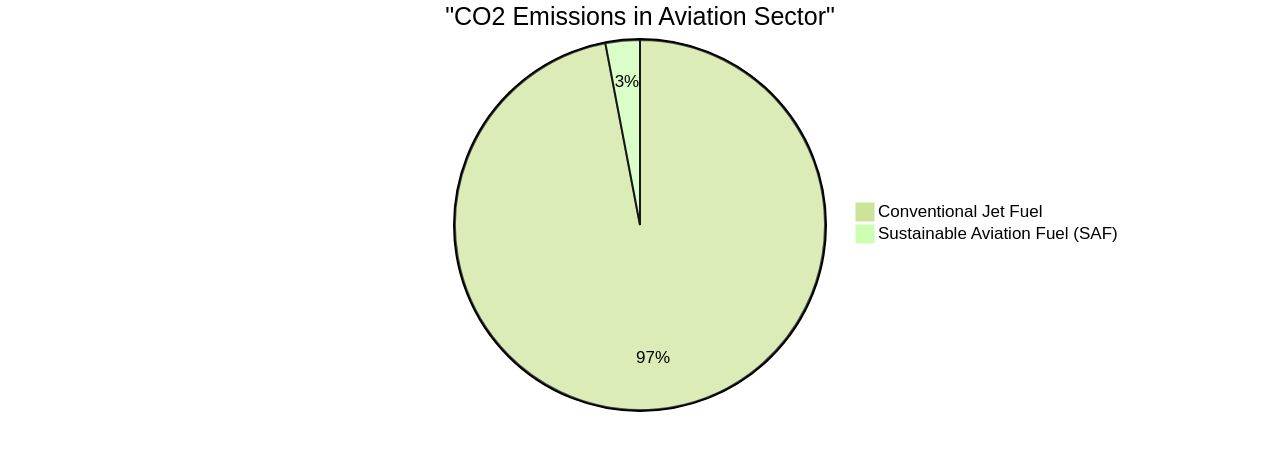

With the aviation sector contributing to 2-3% of global CO2 emissions, the push for Sustainable Aviation Fuel (SAF) has become critical in the industry's journey towards decarbonization. Despite the infancy of SAF technology and the associated costs—being 3 to 4 times more expensive than conventional jet fuel—its integration into the aviation fuel supply system is a significant step forward.

One compelling example is the initiative at Amsterdam Airport Schiphol, where contributions from passengers are utilized to purchase additional SAF, which is then added to the airport's fuel system, demonstrating a collaborative approach to addressing aviation emissions. Moreover, with the Swedish aviation sector's ambition to replace 5% of its total jet fuel demand with SAF by today and 20% by 2030, it is evident that such efforts can lead to substantial reductions in carbon emissions.

However, precise data on the reduction percentages when using electrofuels, a type of synthetic aviation fuel, is still under development. The International Civil Aviation Organization's target to achieve net-zero carbon emissions by 2050 underscores the urgency and the potential of SAF in creating a more sustainable future for air travel.

Innovations such as Unifuel.tech's flexiforming technology are emerging to address the cost and technology barriers associated with SAF. Flexiforming allows for the deployment of decarbonizing solutions at a pace that aligns with an operator's specific needs and existing infrastructure, potentially reducing the carbon intensity and capital expenditures. This technology can be integrated into idle hydrotreaters or reformers, supporting the scalability of SAF production. With a commitment to rapid response and a tailored approach to each operator's requirements, Unifuel.tech, a subsidiary of Universal Fuel Technologies, is contributing to the enhancement of fuel supply chain security and the acceleration of the aviation industry's decarbonization efforts.

Carbon Direct's Role in SAF Development

The pursuit of decarbonizing the aviation industry has gained a formidable ally in the form of advanced HEFA technologies for SAF production. Companies like Carbon Direct are at the forefront of this revolution, tapping into the potential of sustainable feedstocks to craft carbon-neutral jet fuel.

Their efforts are particularly significant in light of recent findings that forecast an 80,000-ton annual SAF output could meet 5% of Sweden's current jet fuel demand and 20% by 2030. This shift in fuel sourcing is anchored in the production of electrofuel, which, when utilized in aircraft, promises a substantial reduction in CO2 emissions compared to conventional fossil fuels, though specific percentages are still under investigation.

Innovative processes have enabled the aviation sector to contemplate a reality where 100% SAF usage is not just a possibility but a practical solution. This is evidenced by the successful trans-Atlantic flight by Virgin Atlantic, powered entirely by SAF, marking a transformative moment for the industry.

The integration of bio-based aromatics through the BioForming process has been crucial, allowing for the creation of SAF that meets ASTM international standards without blending with traditional fuels. This breakthrough is not dependent on a single feedstock, thus providing flexibility in the choice of sustainable resources. The urgency of these advancements cannot be overstated, as even with a 39% improvement in fuel efficiency since 2005, the aviation industry's emissions continue to outpace gains. The adoption of SAF is recognized as the most viable emissions reduction lever, with the potential to cut emissions by 60% by 2040. Carbon Direct's partnership with Apple to produce a comprehensive SAF report underscores the technical and economic aspects of various SAF production pathways, reaffirming the significance of HEFA technology in achieving net-zero emissions for the aviation sector.

The Science Behind Carbon Jet Fuel Production

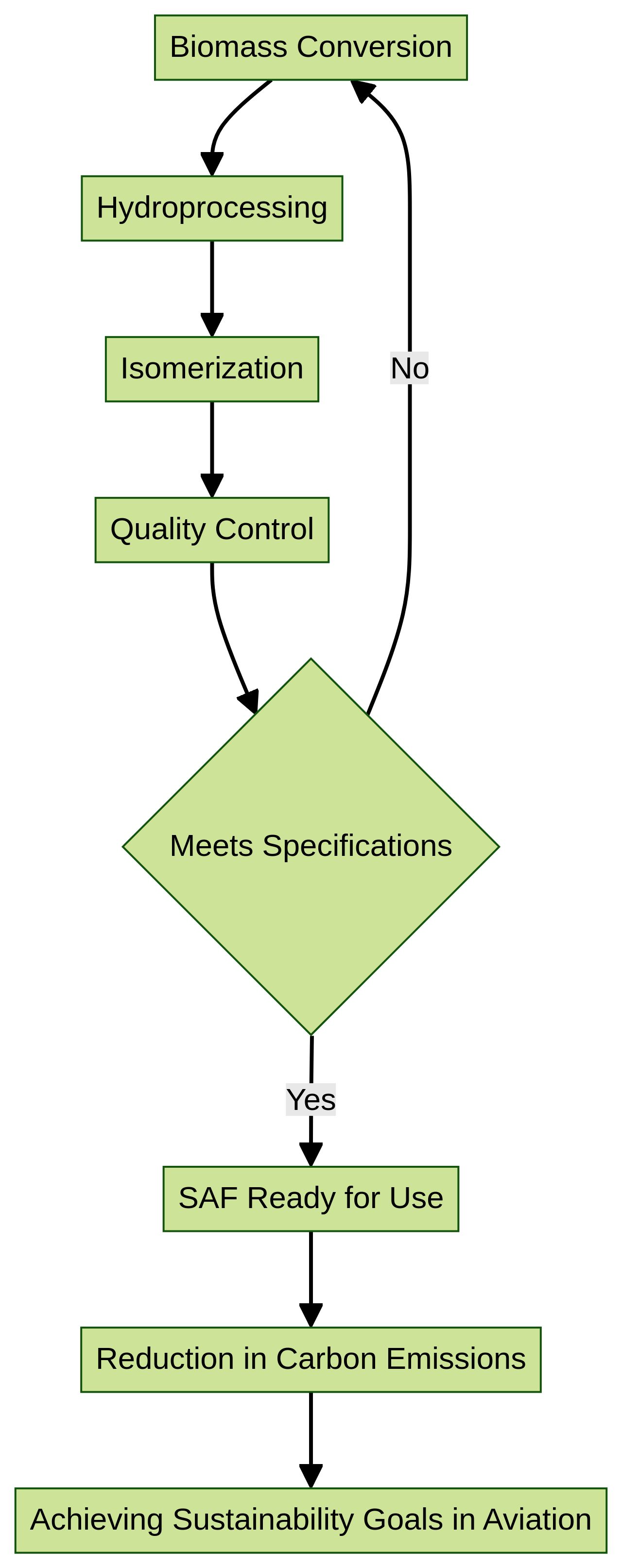

The evolution of Sustainable Aviation Fuel (SAF) production through Hydroprocessed Esters and Fatty Acids (HEFA) technology is pivotal for the aviation sector's sustainability goals. By converting renewable biomass, such as vegetable oils and animal fats, into jet fuel hydrocarbons, HEFA technology not only serves as a renewable substitute but also plays a significant role in diminishing aviation carbon emissions.

Although research is ongoing, the reduction in carbon dioxide emissions is expected to be substantial when HEFA-produced electrofuels are compared with traditional fossil fuels. The complex procedures involved in SAF creation, including hydroprocessing and isomerization, are critical to fulfill the strict quality requirements of aviation fuel.

The commitment to HEFA technology is evident with industry giants like easyJet and Rolls-Royce investing in solutions geared towards achieving net-zero carbon emissions. The anticipated SAF production is set to meet a considerable portion of Sweden's jet fuel needs by 2030, showcasing HEFA's potential in aiding the decarbonization of carbon-intensive sectors such as the steel industry.

The innovative capture and reuse of carbon from industrial activities for SAF production mark a significant advancement towards meeting aviation emission goals, propelled by initiatives like the Iverson Ammonia Project and the European Union's Horizon 2020 program support. In line with these advancements, Universal Fuel Technologies, operating under the name Unifuel.tech, introduces Flexiforming—a versatile decarbonization technology.

Flexiforming allows operators to dictate their decarbonization pace, integrating seamlessly into existing idle hydrotreaters or reformers, which can lead to lower capital investments and carbon intensity. Unifuel. Tech ensures swift interaction, promising to respond within a day to queries. To tailor the Flexiforming technology to an operator's specific needs, they require details about the operator's feedstock, desired products, and current infrastructure. This approach reflects their commitment to providing optimized decarbonization solutions that align with the operator's unique operational framework.

Sustainable Sources for Carbon Jet Fuel

In the quest for reducing the aviation industry's carbon footprint, Carbon Direct has strategically pivoted towards utilizing alternative low-carbon feedstocks for the production of carbon jet fuel. These feedstocks, primarily derived from waste materials such as used cooking oil, animal fats, and non-food crop oils, demonstrate a commitment to sustainability without compromising the energy density required for aviation fuel.

The innovative use of these waste-derived resources aligns with the wider industry's objective to transition towards more sustainable aviation fuels (SAF), which are essential for curbing emissions in the sector. According to a Sustainable Aviation Fuel Roadmap, SAF, derived from a variety of feedstocks including waste products, holds the potential to significantly diminish aviation emissions, especially given the limitations of electrification in the sector.

Moreover, advancing technologies in the production of SAF, such as the 'bio-crude' developed by Firefly Green Fuels, are showing promise for net-zero emissions fuel alternatives. This aligns with recent reports highlighting the importance of SAF in achieving carbon neutrality in aviation, amidst growing concerns over the availability and sustainability of animal-derived fuels. Although the exact reduction percentage in carbon dioxide emissions when using synthetic aviation fuel as opposed to fossil fuel remains undetermined, the industry consensus points to a substantial decrease, reinforcing the value of Carbon Direct's approach to feedstock sourcing for carbon jet fuel production.

Conclusion

In conclusion, the aviation industry is actively working towards decarbonization through Sustainable Aviation Fuel (SAF) production. Collaborative initiatives and ambitious targets demonstrate the potential for significant reductions in carbon emissions.

Companies like Carbon Direct and Unifuel.tech are leading the way with advanced technologies and innovative processes to produce carbon-neutral jet fuel from alternative low-carbon feedstocks. HEFA technology plays a crucial role in achieving sustainability goals by converting renewable biomass into jet fuel hydrocarbons.

This reduces aviation carbon emissions substantially. The commitment to HEFA technology is evident as industry giants invest in solutions for net-zero carbon emissions.

Carbon Direct's focus on alternative low-carbon feedstocks, such as waste materials, aligns with the industry's transition towards more sustainable aviation fuels. These strategies prioritize sustainability without compromising energy density requirements.

Advancements in SAF production, such as flexiforming, offer promising solutions to accelerate decarbonization efforts. With continued research and collaboration, substantial reductions in carbon dioxide emissions can be achieved, creating a greener future for air travel. In summary, SAF production is essential for reducing the aviation industry's carbon footprint. Advanced technologies, innovative processes, and alternative low-carbon feedstocks pave the way for a more sustainable aviation sector. By prioritizing collaboration and investment in SAF development, we can work towards significant emission reductions and a greener future for air travel.