Introduction

The aviation industry is under increasing pressure to decarbonize and reduce its carbon footprint. Sustainable aviation fuels (SAFs) have emerged as a key solution in achieving this goal.

In this article, we will explore two case studies that highlight the leadership and innovative approaches of companies such as Neste and Gevo in SAF production. We will also delve into the advantages of SAF in aviation, including its potential to curb CO2 emissions, enhance local air quality, and lessen contrail impact. Join us as we delve into the renewable fuels industry and analyze the technical insights and advancements shaping the future of aviation.

Case Study: Neste's Leadership in SAF Production

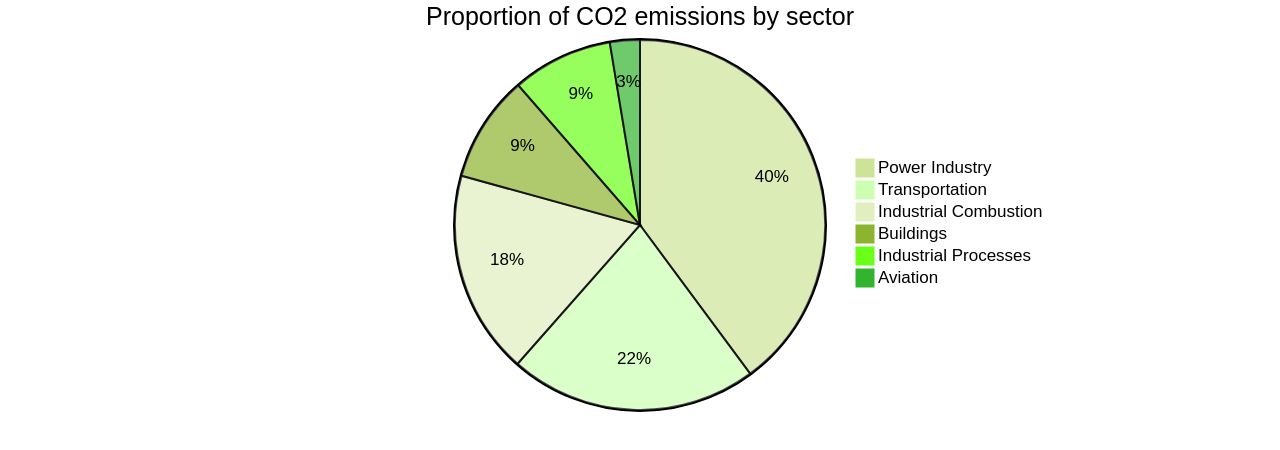

The aviation industry, contributing to about 2-3% of global CO2 emissions, is striving to decarbonize, with sustainable aviation fuels (SAFs) being a primary tool for achieving this goal. Amidst this, Neste, a Finnish renewable fuel company, has positioned itself as a trailblazer in SAF production.

The company's dedication to innovation and responsibility has led to substantial investments in research and development, allowing it to produce SAF from a variety of feedstocks, notably waste, and residues. Notably, SAFs have proven their potential by reducing the carbon footprint by an average of 80% compared to conventional fuel.

Neste's commitment to this cause is further exemplified by the certification and adoption of its SAF by several airlines. However, the company's ambitious project in Singapore, aimed at increasing fuel capacity, has experienced setbacks, delaying the production of renewable diesel and SAF. Despite these challenges, Neste remains unwavering in its mission, echoing the sentiments of industry leaders who stress the importance of sustainability and social responsibility in business decisions. With the International Civil Aviation Organization setting a target of net-zero carbon emissions for the industry by 2050, Neste's role in shaping the future of biofuels in aviation is pivotal.

Case Study: Gevo's Innovative Approach to SAF Production

As the quest for sustainable aviation fuel (SAF) gains momentum, companies like Gevo are leading the race through innovative production methods. Leveraging renewable feedstocks such as corn, Gevo employs a unique fermentation process to produce SAF.

The company's SAF has not only been thoroughly tested but has also been employed in commercial flights, underscoring its potential as a viable alternative to traditional jet fuels. The use of synthesized sugar as a raw material in biomanufacturing, as demonstrated by Gevo, is a game-changer in the industry.

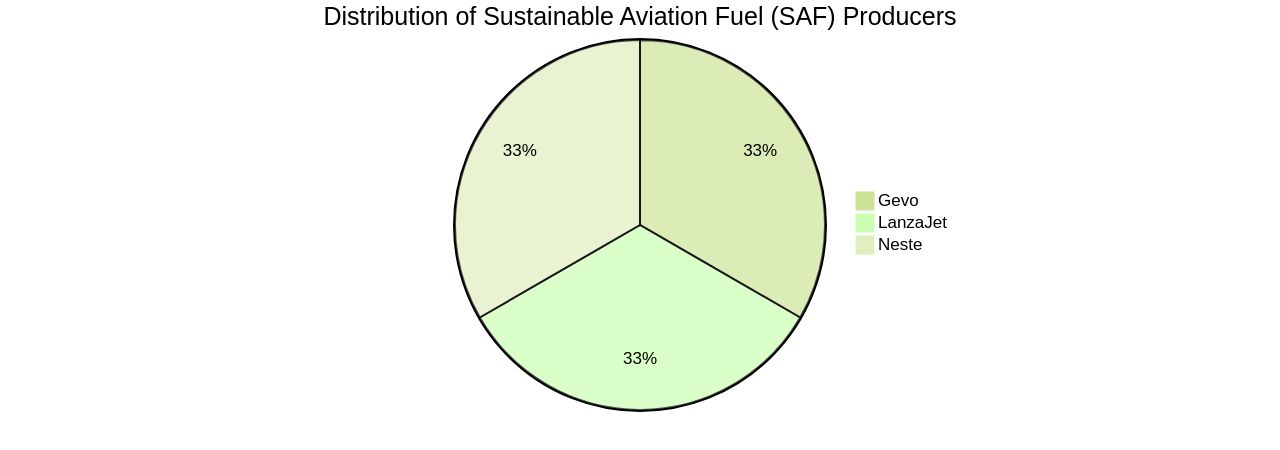

This approach ensures a sustainable supply of raw sugar that doesn't compete with food supplies, addressing one of the key challenges in biomass procurement. Gevo's efforts are complemented by other industry players such as LanzaJet and Neste, the latter being the world's largest SAF producer.

Both are working towards increasing the compatibility of their SAF with commercial aircraft, aiming for 100% unblended SAF compatibility by the end of this decade. However, the journey towards sustainable aviation is not without challenges. High costs and limited supply remain significant hurdles, and the industry's infancy means that SAF remains an expensive option for many airlines. Yet, with ongoing advancements in technology and increased investment in renewable energy sources, the future of SAF looks promising. In conclusion, Gevo's commitment to sustainability and continuous efforts to enhance SAF production efficiency have not only cemented its position as a key industry player but are also paving the way for a more sustainable future in aviation.

Research Insights: The Advantages of SAF in Aviation

Sustainable Aviation Fuel (SAF) emerges as a formidable weapon in the fight against carbon emissions, especially in the aviation sector, which has a significant carbon footprint. The technology remains in its nascent stage, yet SAF is considered a pivotal tool for meeting the International Civil Aviation Organization's ambitious goal of achieving net-zero carbon emissions by 2050.

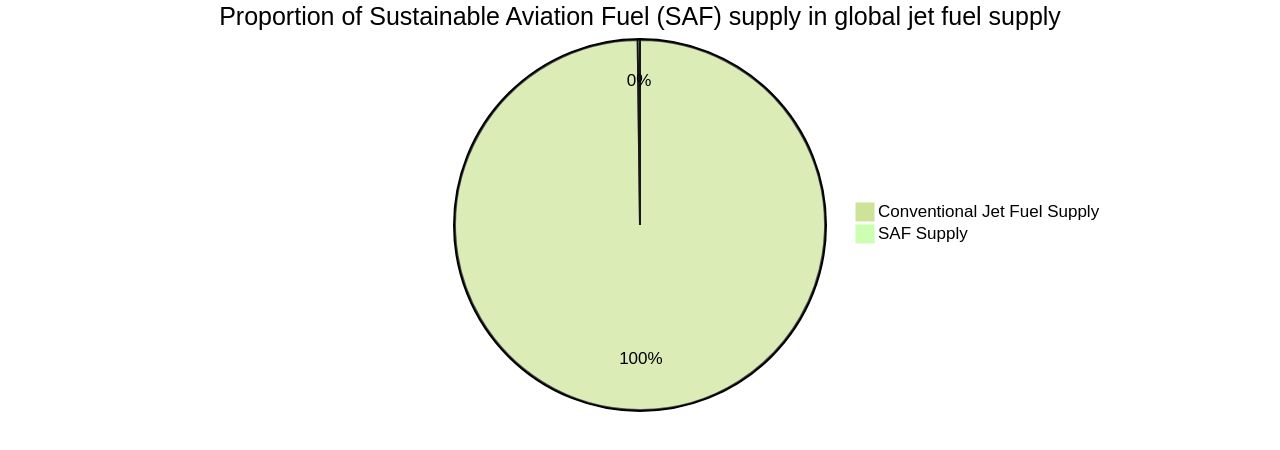

However, the SAF supply as of 2022 accounts for a mere 0.2% of the total global jet fuel supply. The challenge, therefore, is to amplify the supply without compromising on the sustainability of the resources used.

An intriguing experiment at Copenhagen Airport revealed that SAF not only curbs CO2 emissions but also lessens contrail impact and enhances local air quality. This underlines another key advantage of transitioning to sustainable fuels in aviation.

Despite Saf's higher cost, the emission savings range from 89 to 94%, highlighting its substantial environmental benefits. The path to widespread SAF production is riddled with obstacles, but the environmental payoffs and the potential to steer the aviation industry toward greener alternatives make it a compelling proposition. Universal Fuel Technologies has proposed a solution in the form of 'flexiforming', a technology that allows operators to control their decarbonization pace. This technology can be integrated into an idle hydrotreater or reformer, which can decrease both capital expenditure and carbon intensity. This solution could potentially pave the way for a more sustainable and cost-effective SAF production.

Conclusion

In conclusion, the case studies of Neste and Gevo highlight their leadership and innovative approaches in sustainable aviation fuel (SAF) production. Neste's commitment to research and development has allowed them to produce SAF from various feedstocks, significantly reducing the carbon footprint compared to conventional fuel.

Despite setbacks, Neste remains dedicated to shaping the future of biofuels in aviation. Gevo showcases an innovative approach to SAF production by leveraging renewable feedstocks and employing a unique fermentation process.

Their SAF has been successfully tested and used in commercial flights, demonstrating its potential as a viable alternative to traditional jet fuels. Gevo's commitment to sustainability and continuous efforts in enhancing production efficiency position them as a key player in the industry.

The advantages of SAF in aviation are significant. It curbs CO2 emissions, lessens contrail impact, and enhances local air quality.

Despite its higher cost, the emission savings range from 89% to 94%, highlighting its substantial environmental benefits. The path to widespread SAF production faces challenges such as limited supply and high costs, but ongoing advancements in technology and increased investment in renewable energy sources offer a promising future for SAF. Overall, these case studies and research insights emphasize the importance of sustainable aviation fuels in achieving decarbonization goals. The aviation industry must continue to prioritize sustainability and social responsibility in business decisions to meet the target of net-zero carbon emissions by 2050 set by the International Civil Aviation Organization. By embracing renewable fuels like SAF, we can pave the way for a greener future in aviation.