Introduction

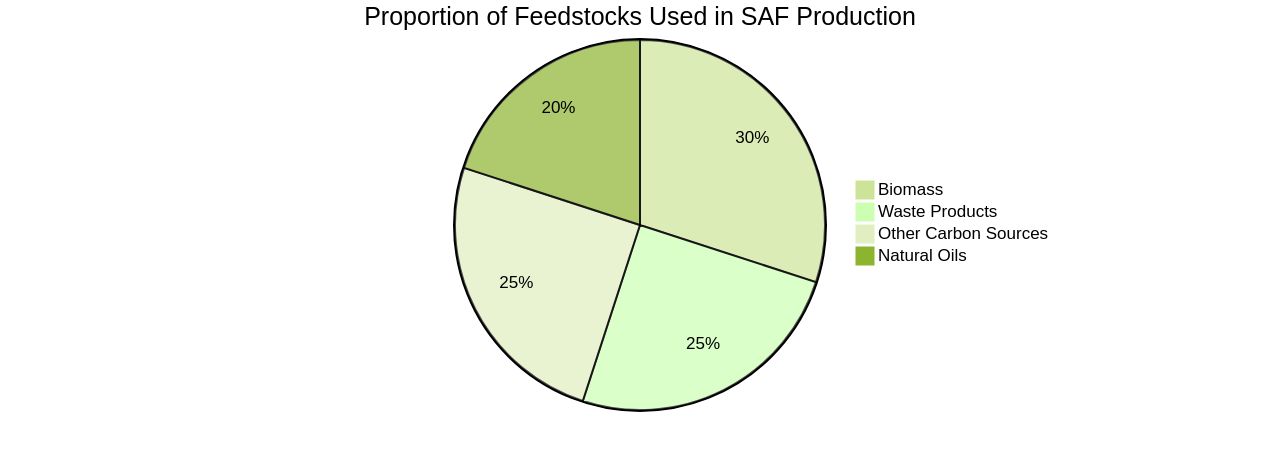

The aviation industry is facing increasing pressure to reduce its carbon dioxide emissions and mitigate its impact on climate change. In response, Sustainable Aviation Fuels (SAF) have emerged as a crucial tool in decarbonizing the industry. These fuels, derived from diverse feedstocks such as biomass and waste products, offer a viable alternative to traditional jet fuels.

Despite challenges in affordability, sustainability, and feedstock competition, the global demand for SAF is growing rapidly. This article will explore the different types of biobased SAF, the production process and emissions, the challenges in establishing SAF supply chains, the environmental assessment of SAF, and the comparison of greenhouse gas emissions for different supply chains. With a deep understanding of the renewable fuels industry, this article will provide technical insights and analysis for readers familiar with this sector.

Background of Sustainable Aviation Fuels (SAF)

The aviation industry, a significant contributor to global carbon dioxide emissions, is striving to reduce its environmental footprint amid escalating concerns about climate change. Sustainable Aviation Fuels (SAF) have emerged as a pivotal tool in this endeavor, offering a viable alternative to traditional jet fuels.

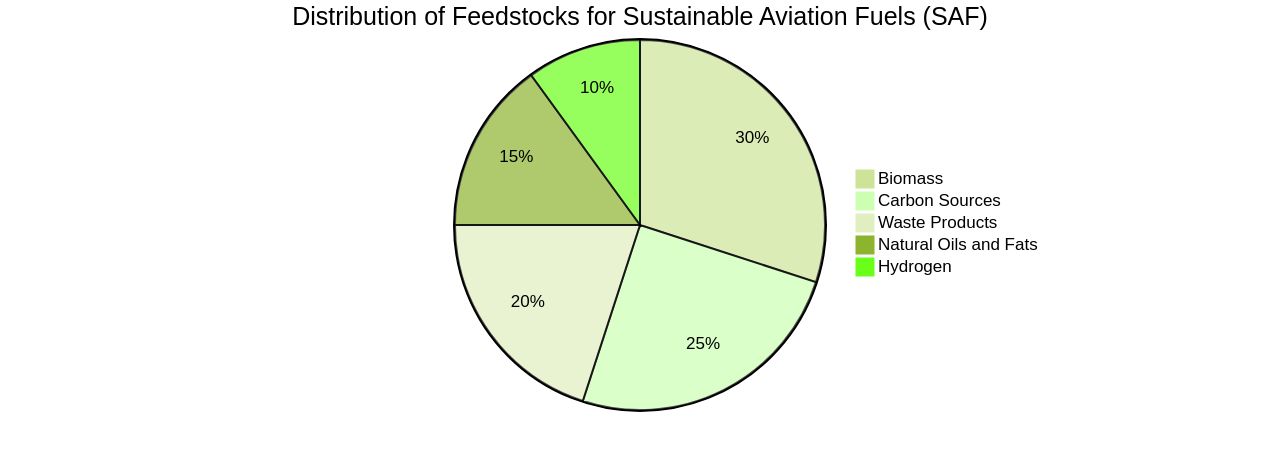

These fuels are derived from diverse feedstocks such as biomass, waste products, natural oils and fats, and other carbon sources, including hydrogen. The global uptake of SAF, particularly across Europe, the UK, and the USA, has seen a significant surge, despite the challenges of affordability, sustainability, and competition for feedstocks.

The growth in demand is outpacing the limited global production, signaling a potential opportunity for countries like Australia, known for its substantial biofuel feedstock production. One of the pioneers in SAF production is Marquis, a leading renewable energy company.

The trajectory towards a multi-fuel future will necessitate substantial innovation, strategic shifts in the aviation industry, and well-thought-out policies. There is an optimistic outlook that a mix of bio-SAF and synthetic kerosene could meet 86% of the overall aviation fuel demand by 2050. Despite the challenges, SAF offers the most practical solution for aviation decarbonization due to its compatibility as a 'drop-in' solution, negating the need for extensive modifications to aircraft fleets, airports, and fueling infrastructure. However, Saf's large-scale availability remains a challenge, with current prices being 3 to 4 times higher than traditional fuels. The goal is to achieve net-zero carbon emissions in the aviation industry by 2050, a target set by the International Civil Aviation Organization, with SAF playing a crucial role in this mission.

Types of Biobased SAF: ATJ, HEFA, and SIP

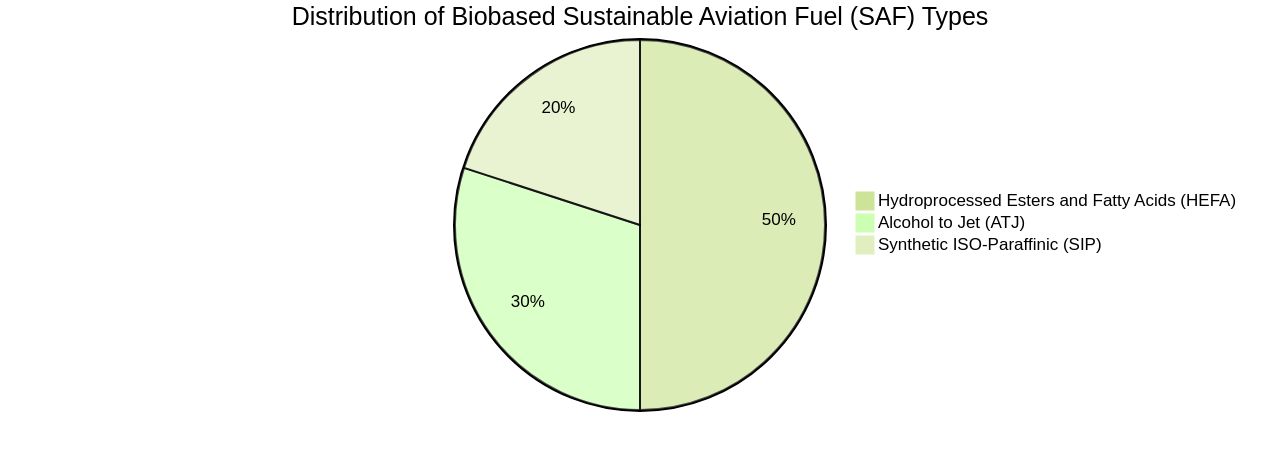

Biobased Sustainable Aviation Fuel (SAF) comes in several forms, including Alcohol to Jet (ATJ), Hydroprocessed Esters and Fatty Acids (HEFA), and Synthetic ISO-Paraffinic (SIP) fuels. Each of these fuels is produced through a unique process and has distinctive characteristics; however, they all contribute to reducing carbon emissions. A significant example of this is the planned SAF output of 80,000 tons annually in Sweden, which will meet 5% of the country's current total jet fuel demand and 20% of its SAF needs by 2030.

This shift is expected to drastically reduce carbon dioxide emissions. In terms of economic viability, HEFA proves to be the most competitive technology for SAF production because of its low conversion costs and high product yield. Although the production of SAF is still in its infancy, the technology required for its production is at an advanced stage, and the cost structure is well-understood.

Despite the current insufficient supply of SAF, the demand gap is expected to persist, providing producers with the opportunity for profitable market entry. Moreover, the partnership between ORLEN and Yokogawa is developing an integrated management solution for synthetic fuel production. This solution will enable the simulation and optimization of production processes to select the most economically viable and environmentally sustainable synthesis method.

The production of synthetic fuels, which share near-identical properties with conventional petroleum-derived products, can significantly curb industrial greenhouse gas emissions. Finally, to ensure that SAF meets international standards, certification processes including lifecycle greenhouse gas assessments will need to be developed. This will ensure that SAF produced in Australia, for instance, can be sold in global markets and labelled as SAF.

Production Process and Emissions of ATJ, HEFA, and SIP

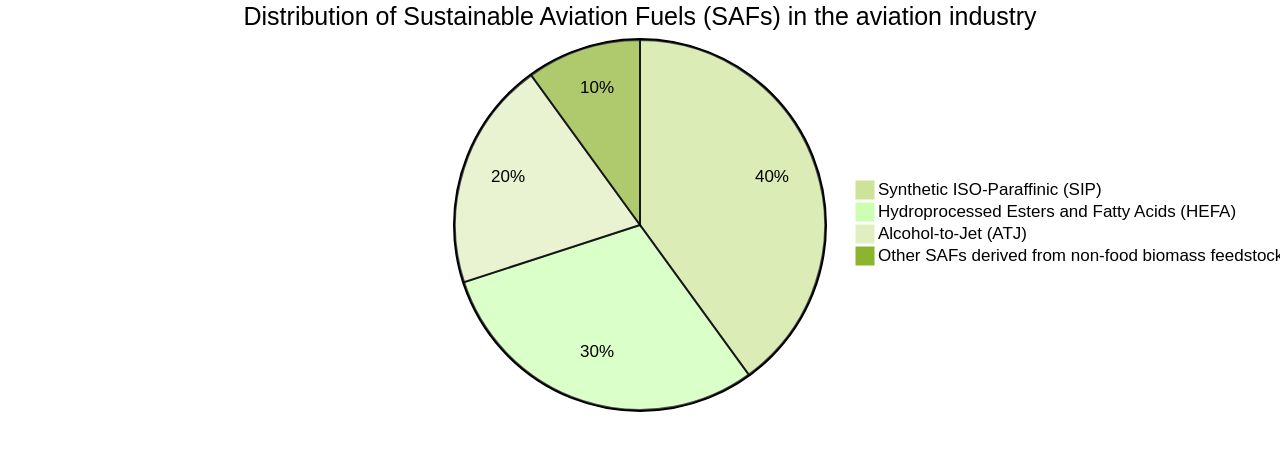

Sustainable Aviation Fuels (SAFs) such as Alcohol-to-Jet (ATJ), Hydroprocessed Esters and Fatty Acids (HEFA), and Synthetic ISO-Paraffinic (SIP) fuels are transforming the aviation industry. Each of these fuels is derived from different feedstocks and processes.

ATJ fuels, for instance, are created through the conversion of sugars or cellulosic biomass into alcohols, subsequently processed into jet fuel. HEFA fuels, on the other hand, are produced by hydroprocessing lipids from vegetable oils or animal fats.

SIP fuels are synthesized from non-food biomass feedstocks. In addition to these, a novel approach to SAF production is underway near Forsmark on Sweden's east coast.

This facility aims to produce electrofuel, a type of SAF, using fossil-free electricity, water, and recycled carbon dioxide. This process is known as carbon capture usage (CCU), where carbon dioxide is captured from a district heating facility and reused for electrofuel production.

The carbon dioxide is then released into the atmosphere when the electrofuel is combusted by aircraft engines, effectively using the carbon dioxide twice. The aviation industry is not the only sector benefiting from low-emission liquid fuels.

By 2030, these fuels are projected to meet 10% of the energy needs in road transport, 10% in aviation, and 6% in shipping. Biofuels are expected to dominate low-emission liquid fuel demand by 2030, with a share of 92%. However, the development of supply chains and infrastructure for hydrogen-derived liquid fuels, like ammonia and synthetic kerosene, will be critical for decarbonizing long-distance transport after 2030. The production of SAFs is not without challenges. Despite the promise of carbon offsetting, the process of making these alternative fuels can be linked to carbon dioxide emissions. This is due to the energy required for their production or the impact on ecosystems that result in carbon emissions. Therefore, achieving a truly sustainable aviation fuel requires careful consideration of the entire life cycle of the fuel from production to point of use.

SAF to Airport Supply Chains

Sustainable Aviation Fuel (SAF) has emerged as a vital instrument for decarbonizing the aviation sector, which contributes to 2-3% of global CO2 emissions. However, the nascent technology and its expense pose significant challenges.

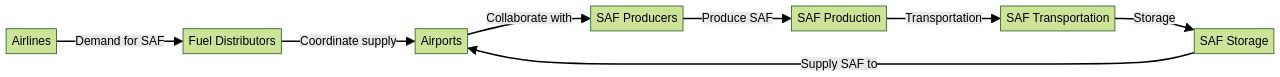

Despite these hurdles, the aviation industry, under the guidance of the International Civil Aviation Organization, is striving to achieve net-zero carbon emissions by 2050. In this context, Marquis has been instrumental in developing strategic alliances with airlines, fuel distributors, and airports to create a robust and efficient SAF supply chain.

This involves meticulous coordination of SAF production, transportation, and storage, thereby ensuring its constant availability at airports. This initiative by Marquis is in line with the industry's aim to reduce the carbon footprint by an average of 80%, as SAF has the potential to achieve this.

Notably, airlines like Korean Air are already cooperating with governments and oil refinery companies to expedite the use of SAF and develop an efficient domestic SAF infrastructure. However, the current supply of SAF is insufficient, and large-scale availability is yet to be achieved, making SAF 3-4 times more expensive than kerosene. Therefore, the concerted efforts of stakeholders in overcoming these roadblocks are imperative for the successful implementation of SAF in the aviation industry. These efforts, coupled with the growing demand for SAF, present a lucrative opportunity for SAF producers to enter the market and reap substantial profits.

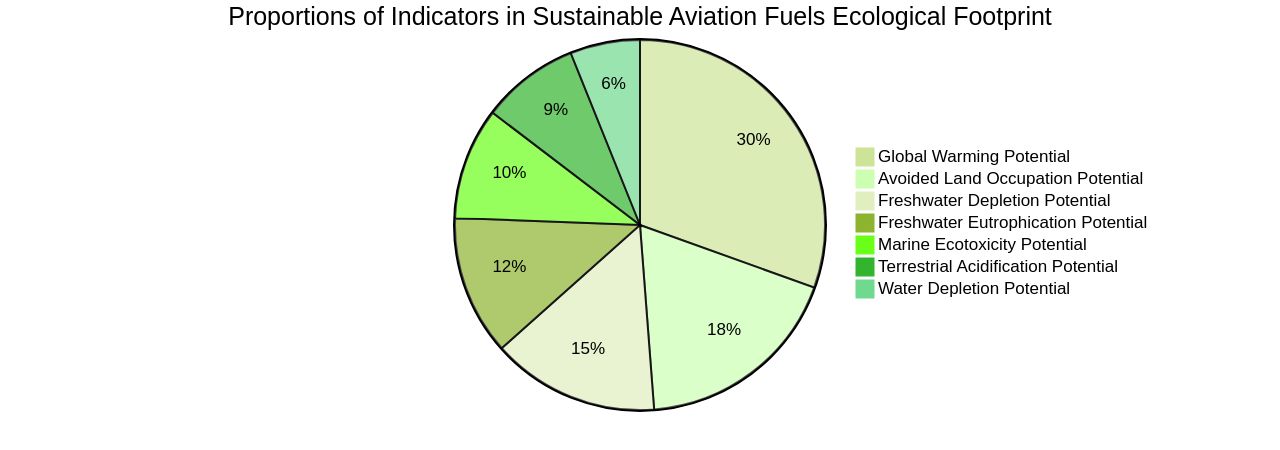

Environmental Assessment of SAF: GWP 100, ALOP, FDP, FEP, METPinf, TAP, and WDP

Saf's ecological footprint is gauged through various indicators, such as Global Warming Potential over a century (GWP 100), Avoided Land Occupation Potential (ALOP), Freshwater Depletion Potential (FDP), Freshwater Eutrophication Potential (FEP), Marine Ecotoxicity Potential infinite (METPinf), Terrestrial Acidification Potential (TAP), and Water Depletion Potential (WDP). These evaluations yield valuable insights into the sustainability and environmental advantages of SAF usage.

Aviation contributes to approximately 2-3% of global CO2 emissions, making it one of the most challenging sectors to decarbonize. SAFs are considered a primary tool for decarbonizing the aviation industry, despite their cost and nascent technology.

The International Civil Aviation Organization has set a goal for the industry to achieve net zero carbon emissions by 2050. SAF can serve as a safe, drop-in replacement for fossil-based jet fuel, as demonstrated by Flight100.

However, there is a clear need for more significant investment to scale up SAF production. The ReFuelEU Aviation initiative, part of the ‘Fit for 55’ package, aims to enable the EU to reduce its net greenhouse gas emissions by at least 55% by 2030 compared to 1990 levels and to achieve climate neutrality in 2050. This initiative will also incentivize the use of different types of waste to produce fuel, such as sawdust and bark from forests, to address global issues such as deforestation, biodiversity, and competition with food production. The role of SAF varies from 24%-70% (with a median value of 53%). This wide range reflects the uncertainties regarding potential supportive government action, the level of investments, cost of production, and profit potential, as well as access to feedstocks.

LCA of SAF and GHG Emissions of Multiblend JET A-1

Life Cycle Assessment (LCA) studies provide a comprehensive analysis of the environmental impacts of Sustainable Aviation Fuel (SAF) production, encompassing everything from feedstock procurement to fuel combustion. Recent findings underscore Saf's potential in substantially curtailing greenhouse gas (GHG) emissions, compared to traditional jet fuels like JET A-1. Such studies are instrumental in identifying and mitigating environmental changes, thereby enhancing the efficiency of SAF production systems.

These assessments include a thorough inventory of data, aided by software like SimaPro and databases like Ecoinvent 3.6, to offer a meticulous understanding of the environmental footprint of SAF and its plant-based alternatives. However, the aspiration for a carbon-neutral aviation industry by 2050, as set by the International Civil Aviation Organization, is hampered by the nascent stage of SAF technology and the challenges of large-scale production. Despite the promising emission savings of 89 to 94% offered by the Power to Liquid (PtL) process, the supply of SAF remains insufficient.

As of 2022, alternative fuels, including SAF, constitute less than 0.2% of the global jet fuel supply, despite numerous test flights powered by 100% Safe. This underlines the need for extensive progress in providing climate-friendly alternative fuels. The expansion of SAF supply is one of the main challenges to getting Safe into the skies.

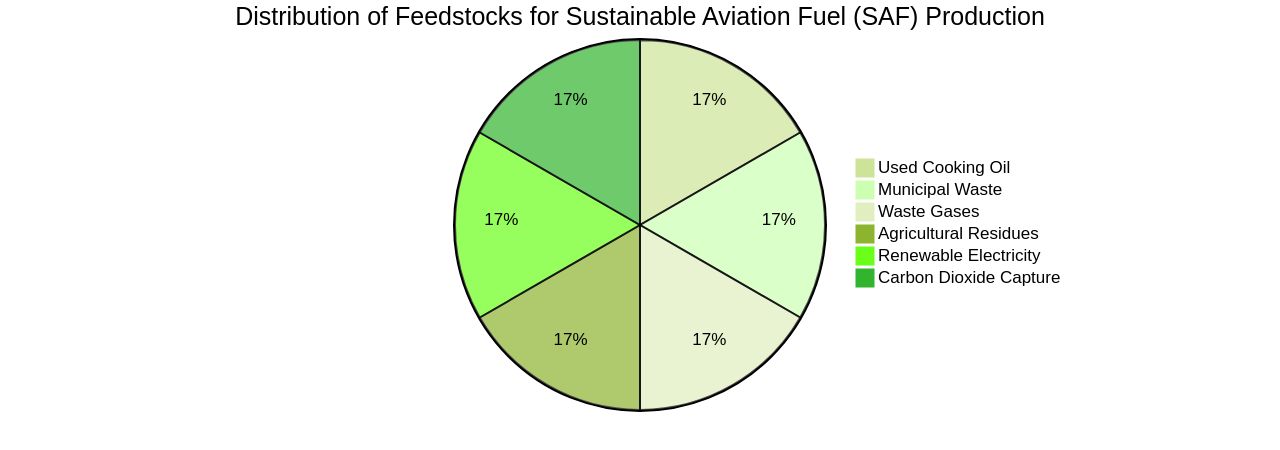

Feedstocks for SAF production include used cooking oil, municipal waste, waste gases, and agricultural residues, and even renewable electricity, and carbon dioxide captured from the atmosphere. However, the current feedstock sources like used cooking oil are not sufficient to meet the global jet fuel demand alone. Therefore, research is crucial to identify and resolve bottlenecks in maintaining a consistent feedstock supply and optimizing resource allocation amid competition for feedstock and biorefinery capacity between renewable diesel and SAF.

Comparison of GHG Emissions of Multiblends for Different Supply Chains

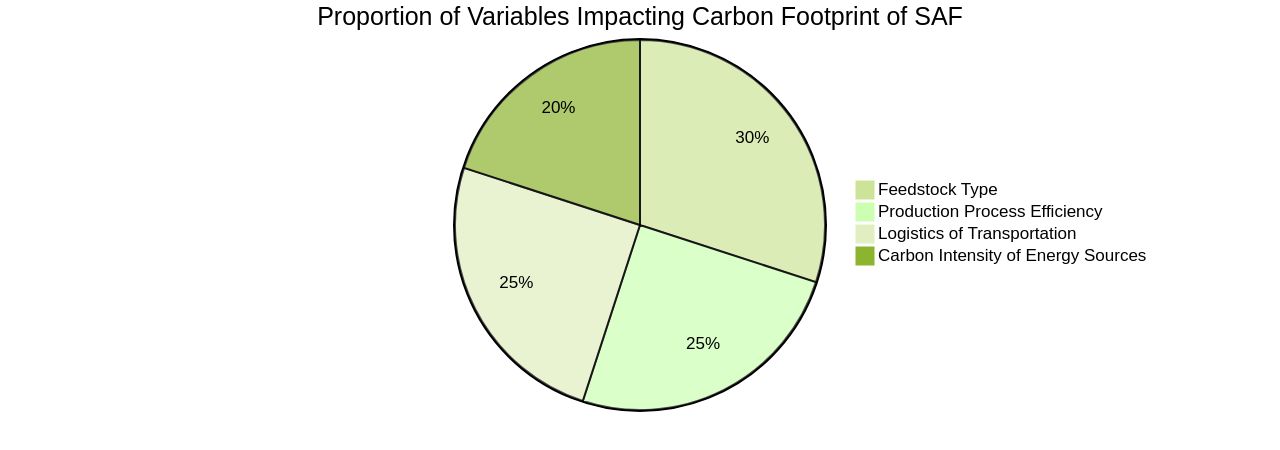

The multifaceted nature of Sustainable Aviation Fuel (SAF) supply chains results in distinct levels of greenhouse gas (GHG) emissions. Factors such as the type of feedstock, production methodology, and logistics play a significant role in these variations.

For instance, Power-to-Liquids (PtL) process, though still in its nascent stages, can yield substantial CO2 emissions savings between 89 to 94%. However, the SAF supply is currently lagging, partly due to the technology's readiness level and the understanding of its cost structure.

Marquis's comparative studies have been instrumental in identifying efficient SAF supply chains. These studies have shed light on the fact that without policy alterations, SAF supply could be restricted to 135 million metric tons by 2050, which is approximately 35% of the predicted global jet fuel demand.

This limitation is primarily due to the economic viability of different SAF feedstocks and competition from other industries for biofuel feedstock. Additionally, the aviation industry, contributing to between 2 to 3% of global CO2 emissions, is striving to achieve net-zero carbon emissions by 2050. SAFs are considered the primary tool for this purpose. However, the technology is still in its early stages, and SAF made up less than 0.2% of the global jet fuel supply in 2022. Therefore, a concerted industry-wide effort is needed to overcome these challenges and ramp up SAF production, as the task ahead cannot be accomplished by a single entity due to the industry's international and CapEx-intensive nature.

Discussion: Factors Affecting GHG Emissions of SAF

The carbon footprint of Sustainable Aviation Fuel (SAF), a key solution for the aviation industry's emissions problem, is impacted by several variables. These include the type of feedstock used, the production process's efficiency, the carbon intensity of the energy sources utilized, and the logistics of transportation.

Companies like Marquis are committed to refining these factors in order to lower the carbon emissions of SAF, thereby making aviation more sustainable. Feedstock selection, which can vary from used cooking oil to agricultural residues, is a critical element in SAF's generation.

Used cooking oil, for example, is frequently used as a primary feedstock source for SAF. Likewise, the efficiency of the production process significantly impacts Saf's environmental footprint.

The Power-to-Liquid (PtL) process, although still in its early stages, can achieve CO2 emissions savings of 89 to 94%. The carbon intensity of the energy sources used in the production process can also greatly influence Saf's overall carbon footprint.

Strategies such as using renewable electricity and capturing carbon dioxide from the atmosphere have shown promise. Moreover, the logistics of transporting SAF from production plants to airports can contribute to its overall greenhouse gas emissions.

However, SAF's widespread adoption faces obstacles like the lack of large-scale production due to high costs, which make SAF 3 to 4 times more expensive than typical jet fuel. Yet, with concerted efforts from stakeholders and ambitious sustainability commitments, the industry is gradually overcoming these challenges. Innovative technologies like Unifuel.tech's Flexiforming offer potential solutions. Flexiforming allows operators to control their decarbonization pace and can be deployed in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. Unifuel.tech provides prompt responses to inquiries and customizes Flexiforming applications based on the operator's feeds, target products, and existing facilities. As the aviation industry confronts increasing CO2 emissions, such advancements are paving the way for a greener future.

References

Emerging as the primary means for emissions abatement, Sustainable Aviation Fuel (SAF) is the aviation industry's response to the pressing need for climate action. SAF is derived from a diverse range of feedstocks, including biomass, waste products, natural oils, and other carbon sources, thereby offering a greener alternative to traditional jet fuel. The global urgency for climate action has sparked aggressive adoption timelines and high volume targets for SAF, particularly in Europe, the UK, and the USA.

However, the limited global production of SAF presents a significant challenge, as demand is set to surpass supply. Furthermore, the affordability and sustainability of SAF production, as well as competition for feedstocks and economically efficient scales of production, are key areas of concern. Despite these challenges, SAF holds immense promise in reducing greenhouse gas emissions.

Notably, the Carbon Direct report, in partnership with Apple, provides a comprehensive review of the diversity of fuel types, their carbon intensities, sustainability criteria, and costs associated with SAF. Additionally, the report explores promising production pathways and opportunities for scaling SAF, thereby leading to reduced greenhouse gas emissions. While the aviation industry's commitment to emissions reduction is commendable, the actual impact of SAF will depend on a variety of factors, including the successful resolution of bottlenecks in maintaining a consistent feedstock supply and optimizing resource allocation.

Conclusion

In conclusion, Sustainable Aviation Fuels (SAF) are crucial for decarbonizing the aviation industry. Despite challenges in affordability and feedstock competition, global demand for SAF is rapidly growing.

Different types of biobased SAF, such as ATJ, HEFA, and SIP fuels, offer viable alternatives to traditional jet fuels and reduce carbon emissions. Efforts to establish efficient SAF supply chains are underway.

However, large-scale availability remains a challenge due to limited supply and higher costs. Environmental assessments consider indicators like GWP 100 and ALOP, providing insights into the sustainability of SAF usage.

Life Cycle Assessment studies show that SAF can significantly reduce greenhouse gas emissions compared to traditional jet fuels. Scaling up production and ensuring consistent feedstock supply are necessary for wider adoption of SAF. Despite challenges, SAFs offer a practical solution for decarbonization. With continued innovation and collaboration, achieving net-zero carbon emissions by 2050 is within reach.