Introduction

The Role of SAF in Decarbonizing the Aviation Industry

The aviation industry is actively pursuing decarbonization strategies to combat its significant contribution to global CO2 emissions. One critical tool in this effort is Sustainable Aviation Fuel (SAF). SAF is derived from renewable resources like biomass, waste oils, and agricultural residues, and can reduce lifecycle carbon emissions by up to 80%.

However, the technology is still in its early stages and currently more expensive than conventional jet fuel, limiting its usage in the aviation sector. In this article, we will explore the role of SAF in decarbonizing the aviation industry and the challenges it faces in terms of cost and adoption. We will also discuss innovative technologies and solutions, such as Unifuel.tech's Flexiforming technology, that aim to overcome these challenges and pave the way for a cleaner and more sustainable aviation future.

The Role of SAF in Decarbonizing the Aviation Industry

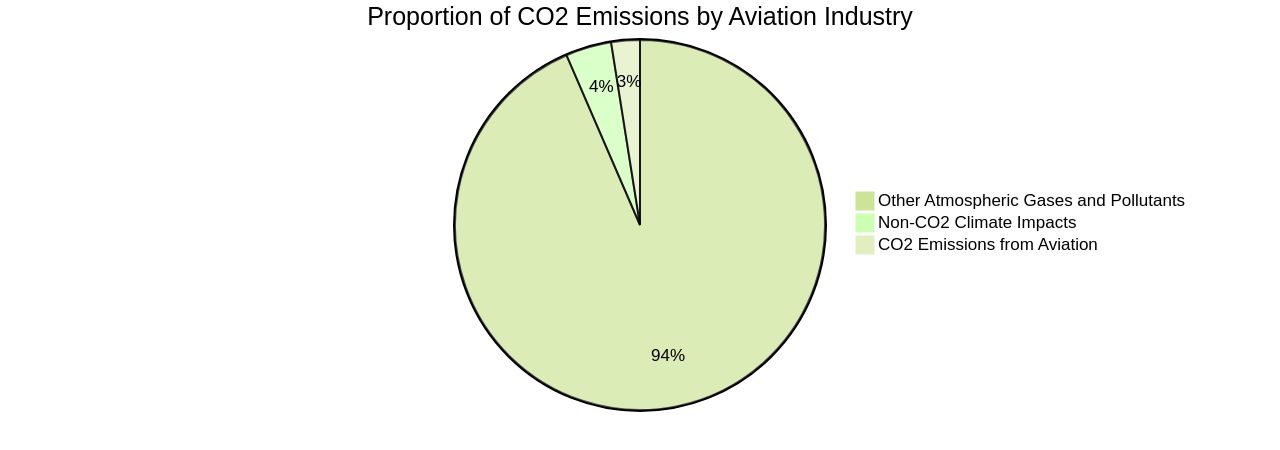

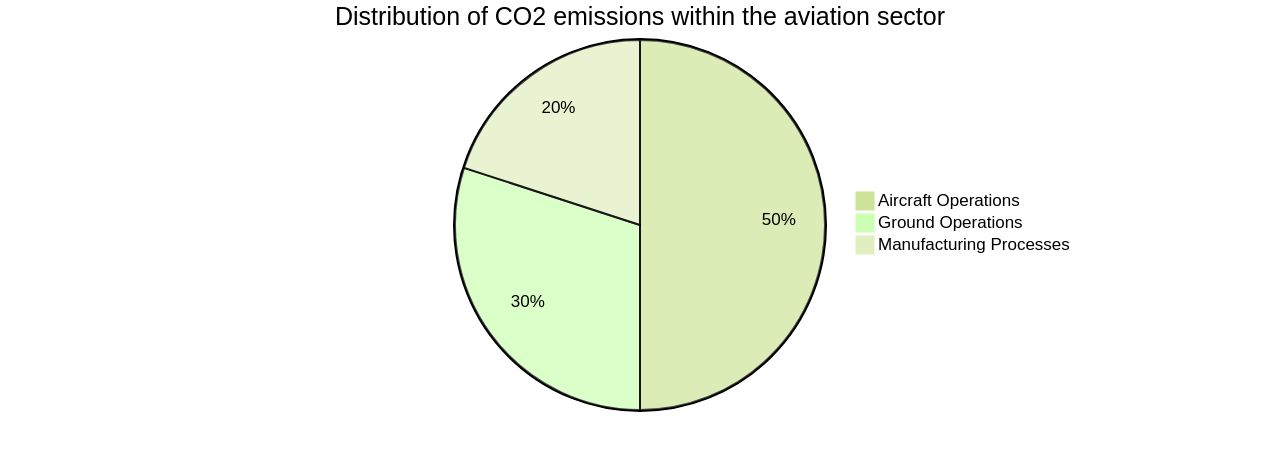

The aviation industry, which contributes to 2-3% of global CO2 emissions, is actively pursuing decarbonization strategies. A critical tool in this effort is Sustainable Aviation Fuel (SAF), derived from renewable resources like biomass, waste oils, and agricultural residues.

Through advanced refining processes and sustainable feedstocks, SAF can reduce lifecycle carbon emissions by up to 80%. However, the technology is still in its infancy and is currently 3 to 4 times more expensive than conventional jet fuel, leading to its limited usage in the aviation sector.

The International Civil Aviation Organization has set an ambitious goal to halve aviation sector CO2 emissions by 2050, emphasizing the pivotal role of SAF. SAF's properties closely resemble traditional jet fuel, making it a viable alternative.

It can be produced from renewable biomass, waste materials, or captured CO2 and green hydrogen, significantly reducing lifecycle greenhouse gas emissions. One of the main challenges facing SAF adoption is its lack of aromatics, which are crucial components in conventional jet fuels.

This limitation restricts SAF's blend with traditional jet fuel to 50%. However, the inclusion of bio-based aromatics in the SAF blend could enable 100% SAF-powered flights, enhancing its environmental benefits.

Unifuel.tech proactively addresses these challenges with their innovative Flexiforming technology. This solution allows operators to regulate their decarbonization speed and can be implemented in an idle hydrotreater or reformer, which lowers capital expenditure and carbon intensity. By providing information about the feeds, target products, and existing facilities, Unifuel. Tech can pinpoint an optimal application for Flexiforming. Moving towards the aviation industry's goal of achieving net-zero carbon emissions by 2050, the role of SAF is undeniably significant. Despite the challenges, the promise of a cleaner, more sustainable aviation future makes the effort worthwhile.

SAF Feedstocks and their Environmental Implications

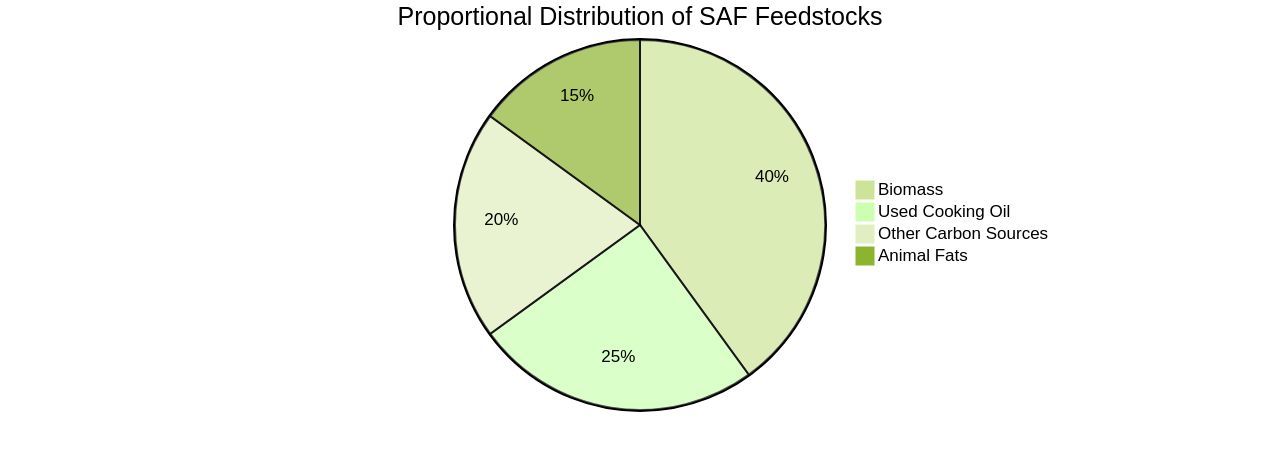

Sustainable Aviation Fuel (SAF) is a critical tool for achieving the International Civil Aviation Organization's net-zero carbon emissions goal by 2050. The complexity of selecting feedstocks for SAF production lies in the delicate balance of environmental, social, and economic factors.

Standard feedstocks include used cooking oil, animal fats, biomass, and other carbon sources. However, their environmental impacts need to be assessed for sustainability, ensuring they don't interfere with food production, contribute to deforestation, or have negative social implications.

The Power-to-Liquid (PtL) process can realize CO2 emission savings of 89 to 94%, but the technology is still nascent. The cost of SAFs, three to four times higher than conventional jet fuel, coupled with technological development stages, raises questions of affordability and sustainability in SAF production.

Despite these challenges, there is a global surge in SAF uptake, particularly in Europe, the UK, and the USA. But, the current supply of SAF is insufficient, with demand poised to outpace supply.

Australia is becoming a key player in this sector, producing a significant amount of biofuel feedstocks and potentially playing an instrumental role in SAF production. Furthermore, the country's burgeoning hydrogen economy could supply the clean hydrogen needed by several fuel production processes. To further SAF adoption and reach the decarbonization goal, it's vital to keep exploring and developing sustainable feedstocks and production methods. The solution offered by Unifuel.tech, known as flexiforming, empowers operators to choose their decarbonization speed. Flexiforming can be implemented in an idle hydrotreater or reformer, minimizing capital expenditure and carbon intensity. Universal Fuel Technologies, the company behind Unifuel.tech, guarantees a response within 24 hours when approached with information about feeds, target products, and existing facilities, thus providing a viable solution to the challenges in the SAF sector.

Waste Streams for SAF Production and their Benefits

The aviation industry, responsible for 2-3% of global CO2 emissions, is under increasing pressure to decarbonize. Sustainable Aviation Fuel (SAF) offers a promising solution. This innovative fuel can be created from renewable biomass, waste resources, or captured carbon dioxide and green hydrogen, providing a drastic reduction in lifecycle greenhouse gas emissions compared to traditional jet fuels.

The production of SAF has the potential to transform waste streams into valuable resources, offering a significant environmental and economic benefit. This is exemplified by companies such as Neste, which is refining used cooking oil collected from restaurants into fuel. This process not only reduces CO2 emissions but also creates a new revenue stream for waste management facilities.

However, the pursuit of SAF is not without challenges. The technology, still in its early stages, is energy-intensive and costly, hindering widespread adoption. Currently, regulations restrict SAF use to a 50% blend with traditional jet fuel, although this is expected to change with further testing and adjustments.

Despite these hurdles, the aviation industry is making strides towards its net-zero carbon emissions goal by 2050. Companies such as Firefly have ambitious plans to establish SAF production plants and roll out this technology globally. It's clear that with increased collaboration, continued innovation, and supportive policy measures, SAF could play a pivotal role in the decarbonization of the aviation industry.

The Process of Producing ASTM-Compliant SAF and its Challenges

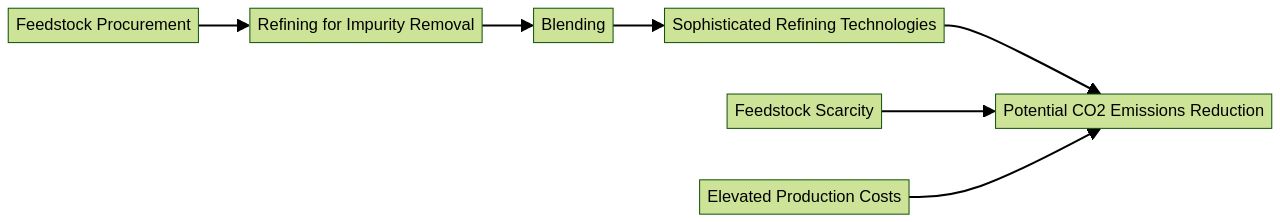

SAF production, compliant with ASTM standards, involves several processes such as feedstock procurement, refining for impurity removal, and blending. With potential CO2 lifecycle emissions reduction up to 70%, SAF stands as a credible substitute for traditional jet fuel. Nevertheless, hurdles like feedstock scarcity, elevated production costs, and the requirement for sophisticated refining technologies can hamper large-scale SAF production.

As stated by Shai Weiss, CEO of Virgin Atlantic, although SAF is a promising substitute for fossil-derived jet fuel, substantial investment is vital for mass production. Over 130 SAF projects are currently underway, with an objective to raise the yearly production to roughly 18 billion gallons by 2028. In the context of a circular economy, SAFs are central as they consist of hydrocarbons that generate water, CO2, and significant heat upon burning.

Despite these challenges, SAFs remain the sole scalable solution to aviation decarbonization in the foreseeable future. Unifuel. Tech brings forward Flex forming, a solution allowing operators to modulate their decarbonization rate.

This technology can be integrated into an idle hydrotreater or reformer, thereby diminishing capital expenditure and carbon intensity. Unifuel.tech ensures responses to queries within a 24-hour window and provides optimal Flexiforming applications depending on the operator's feeds, target products, and existing facilities. The terms of use set by Universal Fuel Technologies, the parent company of Unifuel.tech, are applicable to these services.

SAF Blending and its Potential for Reducing Carbon Footprint

The aviation sector, responsible for 2-3% of global CO2 emissions, is actively working towards decarbonization. The integration of Sustainable Aviation Fuel (SAF) into the conventional jet fuel mix is a key part of this strategy.

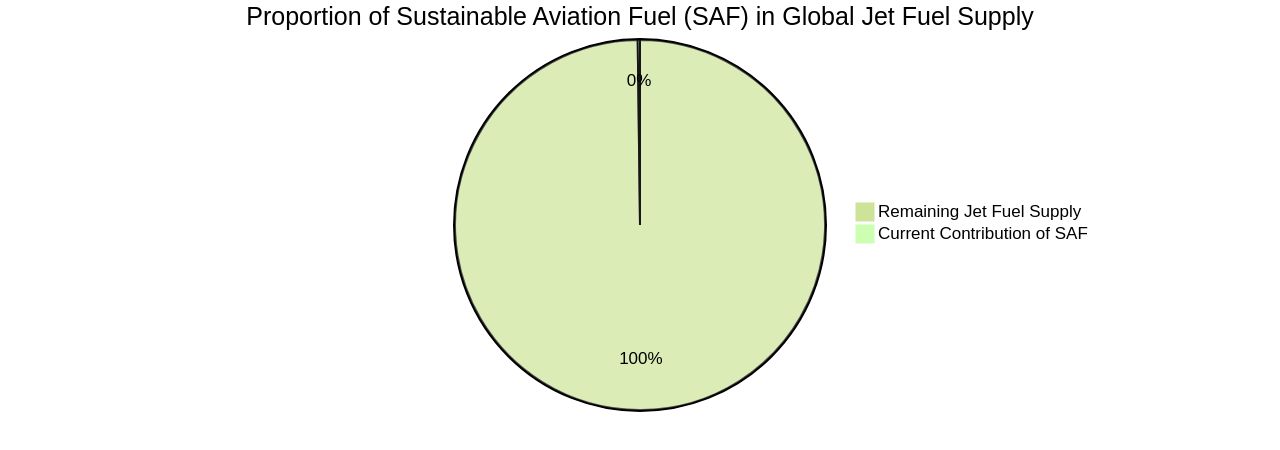

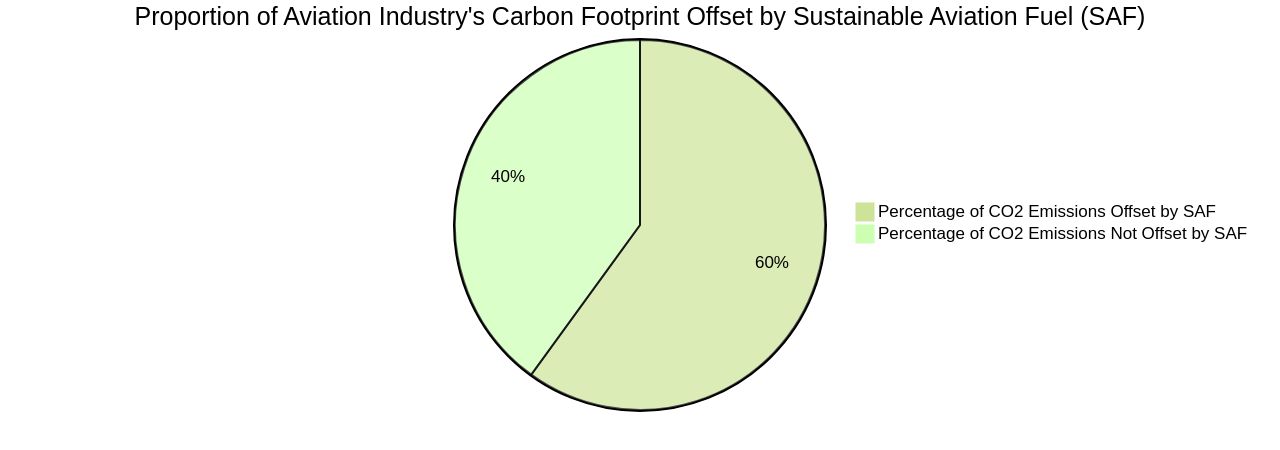

SAF, derived from renewable biomass, waste resources, or captured carbon dioxide and green hydrogen, can significantly reduce lifecycle greenhouse gas emissions. Yet, the current contribution of SAF to the global jet fuel supply remains less than 0.2% due to cost and technology concerns.

SAF's blend with traditional jet fuel is restricted to 50% because of the absence of aromatics in SAF. These ring-shaped molecules in jet fuels are critical for interacting with the aircraft's fuel system seals to prevent leakage.

By adding bio-based aromatics to the SAF blend, it becomes possible to use 100% SAF in airplane fuel without requiring major changes to the aircraft or airport infrastructure. However, large-scale availability of SAF is still a challenge.

Its high cost, three to four times that of the millions of tons of kerosene used by airlines, is a hurdle. Additionally, the supply of fats, oils, and greases, the basis for most commercially available SAFs, is insufficient to meet global jet fuel demand. In the face of these challenges, Unifuel.tech's Flexiforming technology presents a promising solution. This technology can be implemented in an idle hydrotreater or reformer, leading to reduced capital expenditure and carbon intensity. Unifuel.tech's responsive customer service, which guarantees a reply within 24 hours, and its customized solutions based on operators' feeds, target products, and existing facilities, make it a viable option for expanding SAF supply. This will contribute to significant emission reductions and help the industry meet its 2050 targets.

ICF Report on SAF Contributions to Net-Zero Carbon Emissions

The aviation sector, responsible for 2-3% of global CO2 emissions, is striving to reach net-zero emissions by 2050, as defined by the International Civil Aviation Organization. Sustainable Aviation Fuel (SAF) is a viable approach for decarbonization.

Yet, the existing SAF supply, less than 0.2% of the worldwide jet fuel supply, is inadequate to fulfill the growing demand. The high cost of SAF, three to four times that of conventional jet fuel, and the need for substantial investment for mass production are significant barriers to scaling SAF supply.

In response to these challenges, innovative technologies like 'flexiforming,' offered by Unifuel.tech, a subsidiary of Universal Fuel Technologies, are making headway. Flexiforming enables operators to determine their pace of decarbonization and can be utilized in an idle hydrotreater or reformer.

This results in reduced capital expenditure and carbon intensity. The company promises a quick response, typically within 24 hours, to inquiries and requests for information about feeds, target products, and existing facilities to find an optimal application for flexiforming.

Despite these advancements, the transition to SAF is still at an early stage, with many hurdles yet to be overcome. Airbus is taking steps to make its aircraft 100% SAF-capable by 2030 and is working with partners to enlarge the global SAF market. Concurrently, initiatives are underway to establish a platform for the SAF value chain to collaborate, innovate, and increase the scale and usage of SAF. However, the aviation industry's total emissions growth is outpacing its fuel efficiency improvements, which have improved by nearly 39% from 2005 to 2019. This underscores the urgent necessity for broader SAF adoption to meet the industry's net-zero emissions target by 2050.

Benefits of Using SAF to Reduce Emissions

The aviation industry is progressively leveraging Sustainable Aviation Fuel (SAF) to offset its carbon footprint, responsible for 2-3% of global CO2 emissions. Saf's superior energy density and minimal sulfur content not only boost fuel efficiency and flight range but also promote air quality and public health. SAF can expedite the International Civil Aviation Organization's goal of attaining net-zero carbon emissions by 2050, especially considering the intricacy of decarbonizing the aviation sector.

Moreover, SAF bolsters energy security and promotes a sustainable bioeconomy. Traditionally, a blend of up to 50% SAF with conventional jet fuel has been accepted due to Saf's absence of aromatics, vital for reducing freeze points, decreasing viscosity, and averting leakage in jet fuel systems. However, recent studies and tests suggest that incorporating bio-based aromatics could potentially pave the way for 100% SAF usage in the future.

Despite SAF currently being 3 to 4 times costlier than conventional jet fuel, the aviation industry's interest in SAF is on the rise. As the SAF industry evolves and scales up, costs are expected to reduce, further solidifying SAF's role in a greener aviation future. A notable contributor to this evolution is Unifuel.tech, a company offering flexiforming technology for decarbonization.

This technology grants operators the liberty to dictate their decarbonization rate and can be incorporated into existing hydrotreaters or reformers, thereby diminishing capital expenditure and carbon intensity. Unifuel. Tech is committed to identifying optimal flexiforming applications based on operators' feedstocks, target products, and existing facilities, assuring responses to inquiries within 24 hours.

Risks and Challenges in Increasing SAF Uptake Levels

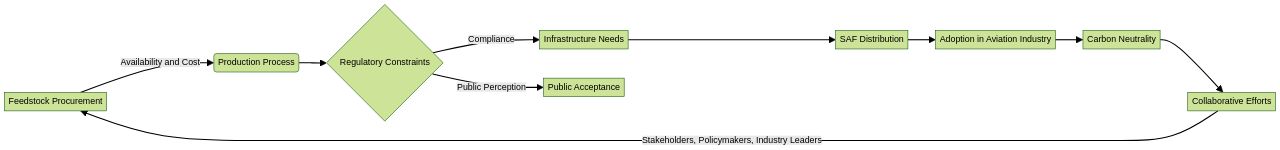

The aviation industry's quest for carbon neutrality has identified Sustainable Aviation Fuel (SAF) as a significant player. The complexities of realizing this potential encompass various issues from feedstock procurement, cost implications, regulatory constraints, infrastructure needs, to public perception. The looming threat of tripling CO2 emissions by 2050 has created a pressing need for the industry to adopt sustainable practices.

While commitments for achieving net-zero emissions by 2050 have been made, they are heavily dependent on public policy support. The International Civil Aviation Organization has set forth a goal to decrease the carbon intensity of aviation fuel by 5% by 2030. However, the pace of deploying green technologies, such as next-gen green aircraft, is lagging behind the schedule needed to meet the 2050 target.

Hence, it is critical for stakeholders, policymakers, and industry leaders to work together in building a conducive framework for SAF production, distribution, and adoption. SAFs, despite their challenges, are identified as the primary tool for decarbonising the aviation sector. The current SAF supply is insufficient, contributing less than 0.2% of the global jet fuel supply in 2022.

The cost of SAFs is 3 to 4 times higher than conventional jet fuel, a result of the absence of large-scale production. Despite these obstacles, Safe are recognized as the most feasible solution for reducing aviation emissions without necessitating significant aircraft or engine modifications. SAFs can be produced from a variety of feedstocks including used cooking oil, municipal waste, waste gases, and agricultural residues.

The procurement of these feedstocks carries its unique set of challenges. For instance, the overuse of agricultural land for biomass production has had negative impacts on ecosystems and biodiversity. Therefore, exploring sustainable feedstock options that do not sacrifice environmental integrity is crucial.

Innovative solutions like Unifuel.tech's flexiforming technology are paving the way for a more sustainable future. This technology allows operators to determine their decarbonization pace and can be implemented in an idle hydrotreater or reformer, cutting down capital expenditure and carbon intensity. The path towards aviation decarbonization is filled with challenges, but with collaborative efforts and breakthrough solutions, the goal of net-zero emissions by 2050 is achievable.

Policy Support for Shifting to SAF and its Importance

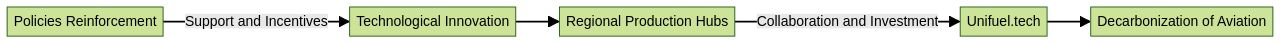

The progression towards Sustainable Aviation Fuel (SAF) is a multifaceted task that demands strategic foresight, policy reinforcement, and inventive strategies. SAF is perceived as the key to decarbonizing aviation, a sector responsible for 2-3% of worldwide CO2 emissions. Despite the technology being nascent and its associated high costs, the International Civil Aviation Organization is committed to realizing net-zero carbon emissions in the aviation sector by 2050.

Consequently, substantial efforts have been initiated, such as the Section 9003 Loan Guarantee Program in the U.S., which offers loan guarantees up to $250 million to encourage the commercialization of advanced biofuel biorefineries. In Europe, the 'Fit for 55' package includes the ReFuelEU Aviation initiative, targeting a minimum 55% reduction in greenhouse gas emissions by 2030 compared to 1990 levels, and a climate-neutral status by 2050. These initiatives not only fortify the SAF industry but also create opportunities for rural communities to engage in this nascent market.

Regions like the Great Lakes and the Rocky Mountain areas are potential SAF production hubs due to their unique advantages in feedstock availability, infrastructure, transport, and demand. Strategically implemented policies could unlock the potential of SAF in these regions, transforming local industries while achieving environmental objectives. In this rapidly changing landscape, technological innovation is crucial.

A case in point is Flexiforming technology from Unifuel.tech, a subsidiary of Universal Fuel Technologies. This technology, deployable in idle hydrotreaters or reformers, empowers operators to determine their decarbonization rate, thus enabling reductions in capital expenditure and carbon intensity. Unifuel.tech, with its commitment to providing the best Flexiforming applications based on operators' feed, target products, and existing facilities, is spearheading a promising future in SAF integration.

Case Study: Large-Scale Swedish Sustainable Aviation Fuels

The green aviation revolution is underway in Sweden, powered by the ambitious goal of creating a large-scale sustainable aviation fuel (SAF) production facility. This innovative project, spearheaded by Swedavia, a global pioneer in the development of eco-friendly airports, is centered around the utilization of forestry residues, a renewable resource abundant in Sweden.

The process of SAF production begins with the capture of carbon dioxide from a district heating plant. This captured carbon dioxide is then combined with hydrogen, generated through electrolysis using fossil-free electricity, to form ethanol.

The ethanol is then converted into aviation electrofuel, effectively recycling carbon dioxide that would have otherwise been released into the atmosphere. The facility, slated to be operational by 2030, will be located near Forsmark on Sweden's east coast, adjacent to the Forsmark nuclear power plant.

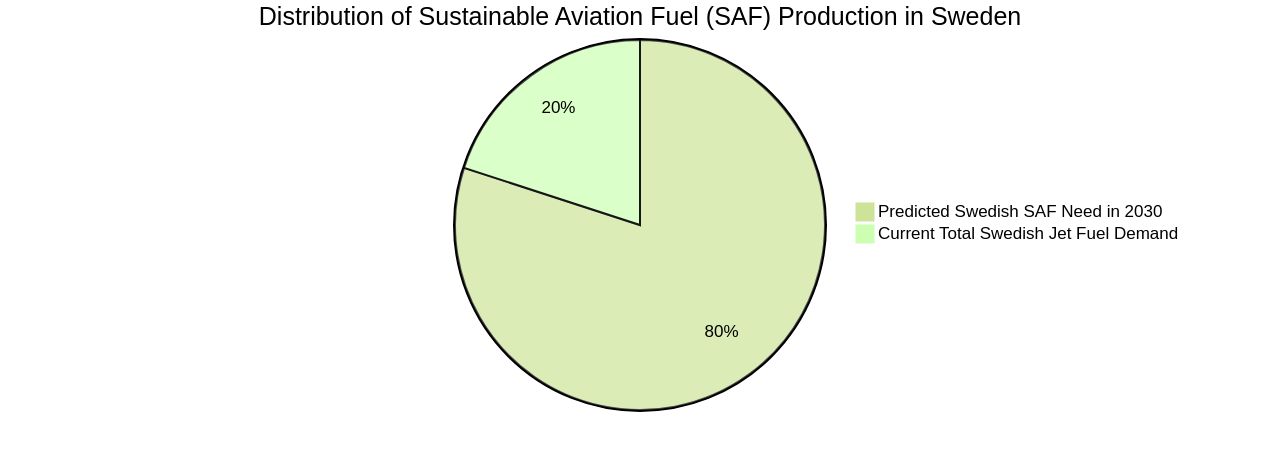

This strategic location guarantees a steady supply of fossil-free electricity from the Swedish energy mix. The aviation industry, which contributes between 2-3% of global CO2 emissions, is set to benefit significantly from this project. The International Civil Aviation Organization's goal of achieving net-zero carbon emissions by 2050 could be within reach with the help of SAF production. The Swedish venture aims to produce 80,000 tons of SAF annually, meeting approximately 5% of the current total Swedish jet fuel demand and 20% of the predicted Swedish SAF need in 2030. This initiative showcases the potential of SAF production and serves as a catalyst for similar global initiatives.

Conclusion

In conclusion, Sustainable Aviation Fuel (SAF) is a critical tool in decarbonizing the aviation industry. It can reduce carbon emissions by up to 80% and is key to achieving the industry's net-zero carbon emissions goal by 2050. Despite challenges like high cost and limited adoption, innovative technologies like Unifuel.tech's Flexiforming offer solutions that regulate decarbonization speed and reduce costs.

Policy support is crucial for driving the shift towards SAF, with initiatives like loan guarantee programs and 'Fit for 55' packages creating opportunities for growth. While SAF currently faces limitations in terms of aromatics, incorporating bio-based aromatics could enable 100% SAF-powered flights. The aviation industry is actively working towards increasing SAF uptake, with companies establishing production plants and regions like Australia playing a key role.

Despite being more expensive than conventional fuel, collaboration, innovation, and policy support are expected to drive down costs as the SAF industry evolves. In summary, SAF is the most feasible solution for reducing aviation emissions without major modifications. With technological advancements and policy support, SAF can pave the way for a cleaner and more sustainable aviation future.