Introduction

The aviation industry is increasingly focused on reducing its environmental impact, particularly in terms of carbon emissions. Sustainable Aviation Fuels (SAFs) have emerged as a crucial component in achieving this goal.

However, the adoption of SAFs is still limited, primarily due to high costs and limited production capacity. In this article, we will explore the advancements in SAF technologies and their potential to revolutionize the industry.

We will delve into the properties and advantages of one such fuel, Hydroprocessed Esters and Fatty Acids (HEFA), and analyze its economic feasibility. Additionally, we will examine the selection criteria for oil feedstocks in HEFA production and evaluate the geographic distribution and production levels of these sources. Finally, we will discuss the impact of oil yield, prices, and chemical composition on the process economics of HEFA fuel production. Join us as we delve into the technical and analytical aspects of the renewable fuels industry, providing insights into the future of sustainable aviation.

Background: Aviation Fuel and the Need for Renewable Alternatives

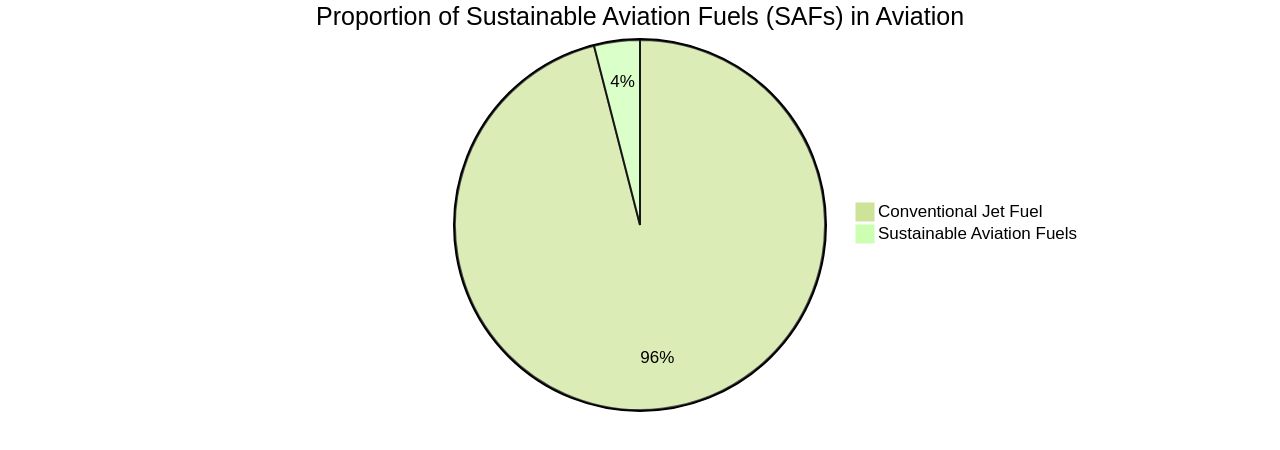

As the aviation industry grapples with its environmental impact, Sustainable Aviation Fuels (SAFs) have emerged as a cornerstone in the strategy to mitigate carbon emissions. The push towards net-zero by 2050, as emphasized by the International Civil Aviation Organization, hinges on the expanded use and production FAFSA.

Despite their critical role, SAFs currently represent a fraction of the fuel used, underscoring the need for increased production capacity and wider adoption. High costs remain an obstacle for SAFs, with prices significantly exceeding those of conventional jet fuel.

This can be attributed to the emerging state of SAF technologies and limited production facilities. Yet, the industry is witnessing advancements that promise to lower these barriers.

Unifuel.tech's Flexiforming technology is a case in point, offering a pathway to decarbonization that aligns with operators' varying capacities and goals. This technology can be integrated into existing infrastructure, such as idle hydrotreaters or reformers, presenting a cost-effective approach to SAF production by minimizing capital expenditures and carbon intensity. The rapid response to inquiries and the tailored application of Flexiforming based on specific operational parameters underscore Unifuel.tech's commitment to customer service and technological adaptability. This innovation is part of a broader, collaborative effort to enhance the viability of Safe, bridging the supply-demand gap and leading the aviation sector towards a sustainable future. The industry's move towards sustainability, as demonstrated by Virgin Atlantic's initiative for SAF-powered flights, is further bolstered by such technological advancements, which are crucial for the commercialization and scalability of SAFs.

HEFA Fuel: Properties and Advantages

The aviation industry, in its bid to decarbonize, is turning to Hydroprocessed Esters and Fatty Acids (HEFA) as a sustainable jet fuel alternative. Derived from feedstocks like vegetable oils and animal fats, HEFA fuel aligns with existing aircraft engines and infrastructure, offering a reduced carbon footprint. A pioneering example was Virgin Atlantic's Flight100, which, using 100% SAF, achieved a 70% reduction in carbon emissions over traditional jet fuel.

This feat was accomplished with a standard Dreamliner aircraft, demonstrating HEFA fuel's seamless integration into current aviation technology. The significance of SAF in the decarbonization journey is echoed by Virgin Atlantic's leadership, emphasizing the technology's readiness and the necessity for substantial investment and regulatory support to scale production. According to the International Energy Agency (IEA), the demand for hydrogen, a component of low-carbon fuels like HEFA, is projected to increase from 95 million tons to 430 million tons by 2050, reinforcing the importance of investments in low-carbon hydrogen production.

Despite the progress, SAF is not the sole solution for decarbonization. It represents a spectrum of fuel blends that can reduce emissions to varying extents. A more comprehensive approach includes energy-efficient design and operations and the development of renewable energy sources such as biomass and geothermal energy.

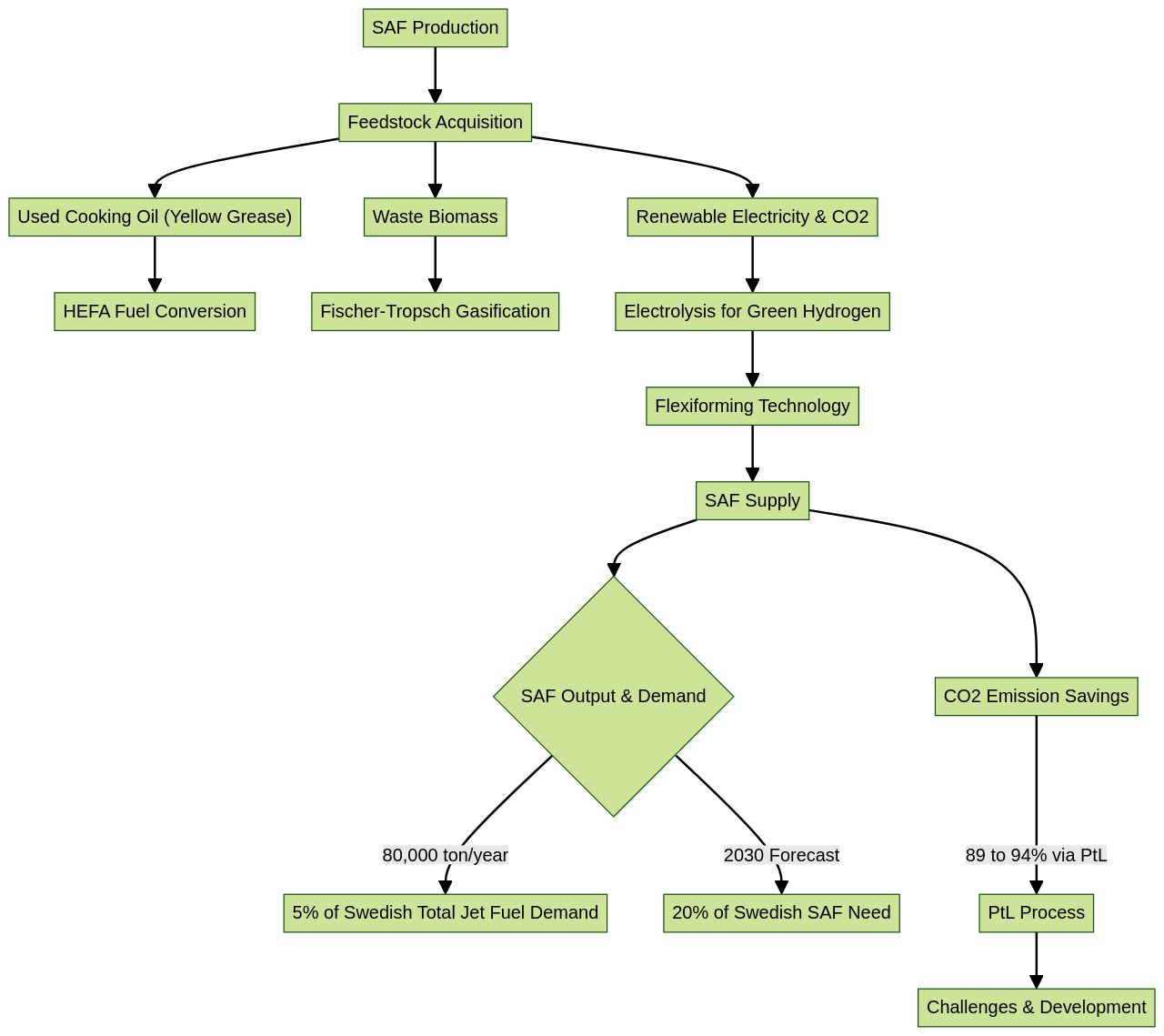

The holistic strategy is further supported by the PtL process, which can achieve CO2 emission savings of up to 94%. Yet, challenges remain, including the insufficient supply of SAF and the need for international collaboration to address the six identified roadblocks to ramp up production. The urgency of addressing climate change demands immediate, collective action to realize the potential of SAF within a critical time scale.

Economic Analyses of HEFA Fuel

The economic landscape of producing Hydroprocessed Esters and Fatty Acids (HEFA) fuels is multifaceted, with a focus on the cost-effectiveness in comparison to conventional jet fuels. A critical variable in this equation is the cost of feedstock, where waste biomass, including forest residues, offers an economical source priced around $60 per ton. These materials can be transformed into fuel through gasification and Fischer-Tropsch synthesis, as demonstrated by industry leaders such as Velocys.

The demand for hydrogen, a key component in low-carbon fuel production, is expected to rise sharply, as indicated by the International Energy Agency (IEA), from the current 95 million tons to a projected 430 million tons annually by 2050. This underscores the necessity for efficient and economical strategies for hydrogen production. Countries like Brazil, Colombia, and Australia present ideal conditions for importing green ammonia, methanol, and kerosene, due to their lower capital costs.

These conditions are conducive to forming bilateral agreements for Power-to-X products and integrating into the burgeoning global hydrogen market. Despite these favorable conditions, the widespread adoption of processes like Alcohol-to-Jet (AtJ) synthesis faces challenges, with the first commercial facility by LanzaJet set to commence operations later in the year. The theoretical underpinnings for cost-effective HEFA fuel production are established, yet the transition to practical, large-scale production remains an impending challenge.

Resource Analysis of Oil Feedstocks for HEFA Production

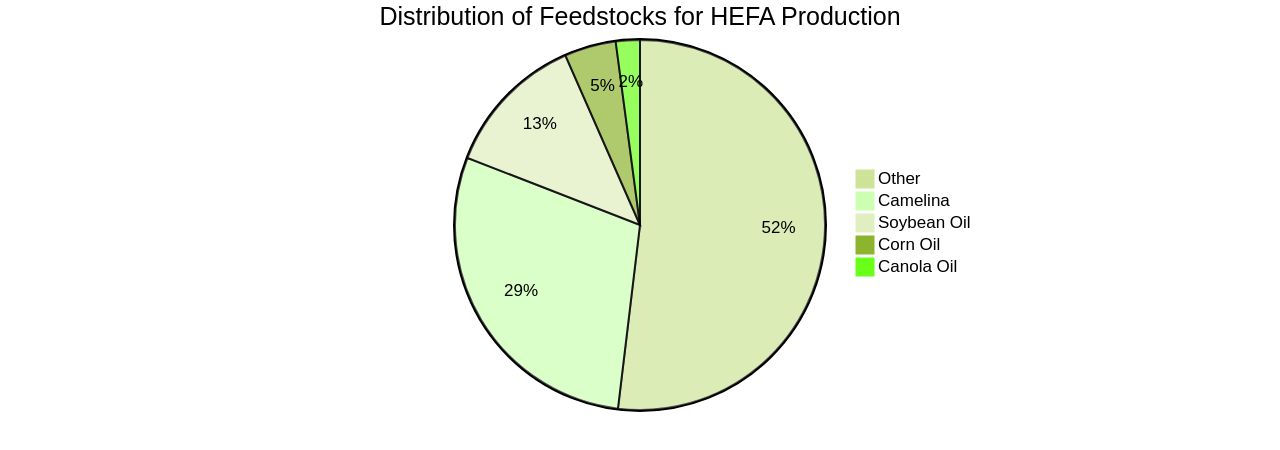

Sustainable aviation fuel (SAF) production is at the forefront of the aviation industry's efforts to reduce its carbon footprint. With the HEFA (Hydroprocessed Esters and Fatty Acids) pathway recognized as a competitive technology, it's crucial to ensure the sustainability and efficiency of its production.

Selecting oil feedstocks for HEFA fuel production requires evaluating their yield potential, availability, and the environmental implications of their use. The quality of these raw materials is paramount, as they must remain uncompromised throughout transport, storage, and processing to produce high-quality fuels efficiently.

Innovations in hydrocracking technology have enabled the conversion of heavy hydrocarbons into lighter, high-value products. This process, which involves a high-temperature and high-pressure reaction facilitated by a catalyst, yields a variety of fuels, including SAF.

Among these innovations, Unifuel.tech's Flexiforming technology provides a versatile approach, allowing operators to retrofit existing hydrotreaters or reformers, thus optimizing capital expenditure and reducing carbon intensity. Their rapid response to inquiries ensures that operators can quickly determine the most effective application of Flexiforming based on their specific feeds, target products, and facility infrastructure.

In the context of heavy residues, gasification can convert these by-products into syngas, a hydrogen source that can potentially replace natural gas in industrial processes without fundamental changes. This aligns with the broader industry shift towards renewable solutions, as evidenced by Shell's commitment to achieving net-zero emissions by 2050 and investments in renewable hydrogen and biomethane plants. Despite the economic challenges of large-scale SAF production, the HEFA pathway's low conversion costs and high product yield make it a frontrunner in SAF technologies. The decarbonization of industries, such as the iron and steel sector, which accounts for about 7% of global CO2 emissions, is essential in meeting climate targets and ensuring responsible use of natural resources. With SAF being a key player in emissions abatement, the latest report from Carbon Direct, in partnership with Apple, offers insights into the promising production pathways and opportunities to scale SAF for reduced greenhouse gas emissions.

Geographic Distribution and Production Levels of Oil Sources

The pursuit of sustainable aviation fuel (SAF) through Hydroprocessed Esters and Fatty Acids (HEFA) pathways necessitates a comprehensive understanding of global oil feedstock sources. The process hinges on a high-temperature, high-pressure reaction between hydrocarbons and hydrogen in the presence of a catalyst, such as those obtained from Group III base oils produced by hydrocracking technology. These base oils are integral to the expanding market for high-quality lubricants and fluids.

Shell's transformational investments in renewable hydrogen and biomethane production at its Energy and Chemicals Park Rheinland underscore the industry's shift towards sustainable practices. The park processes a substantial volume of crude oil annually, reflecting the scale required for economic viability in the oil industry. In terms of geographic distribution, the strategic use of natural gasoline as a diluent for Canada's heavy crude oil illustrates the intricate logistics of oil supply chains.

This substance, derived from pentanes plus, is also blended into motor gasoline and used as a denaturant for fuel ethanol in the United States. As OPEC countries, predominantly located in the Middle East and Africa, contribute significantly to global oil reserves, understanding regional production capacities is imperative. The Middle East accounts for about a third of the world's oil production, with proven oil reserves in South and Central America having doubled from 2008 to 2011.

However, the oil industry is not impervious to challenges, as evidenced by the 26% decline in North American oil imports in 2019 compared to a decade prior. The shift towards SAF is a critical response to the environmental impact of oil-based fuels, especially considering that transport fuels are major contributors to CO2 emissions. As the market responds to these challenges, the transition to SAF offers a path to reduce the environmental footprint of aviation, aligning with global decarbonization goals.

Oil Yield, Prices, and Impact on Process Economics

As the aviation industry seeks to reduce its carbon footprint, the production of sustainable aviation fuels (SAF) through Flexiforming technology remains a focal point. Flexiforming, a process that can convert a range of renewable oils into high-quality fuels, is critical in producing hydroprocessed esters and fatty acids (HEFA) fuel. The economic viability of this technology hinges on the yield and cost of oil feedstocks, making it essential to thoroughly examine these aspects to gauge the affordability of various feedstocks.

Notably, the yield of oil feedstocks is a determinant of price sensitivity and potential volatility in the economics of the HEFA fuel process. The U.S. oil production landscape serves as a barometer for such assessments. Despite a 69% decline in active rigs since 2014, U.S. crude oil production has surged, driven by technological advancements and efficiency gains.

This decoupling of rig count from production underscores the importance of innovation in maintaining economic viability in the face of challenges such as the COVID-19 pandemic, which prompted a nearly 40% reduction in new wells in 2020. Cardinal Energy's ability to increase production to approximately 22,000 barrels per day, despite distributing most of its cash flow as dividends, exemplifies resilience in the sector. While the U.S. ascended to the global lead in crude oil production in 2018, surpassing Russia and Saudi Arabia, projections indicate a potential decline through 2024, influenced by the economic disruptions of the pandemic.

Inflation, geopolitical tensions, OPEC+ compliance, world oil consumption, and economic growth continue to shape oil prices, with crude oil prices accounting for over 50% of U.S. retail gasoline prices. The costs of producing oil and gas have seen a significant increase since COVID-19, rising by over 30 percent, and in 2022, as high as 18 percent above typical levels. These trends in the oil market are critical for stakeholders in the SAF production value chain to monitor and navigate.

Chemical Composition of Oil Feedstock: Free Fatty Acid (FFA) Profile

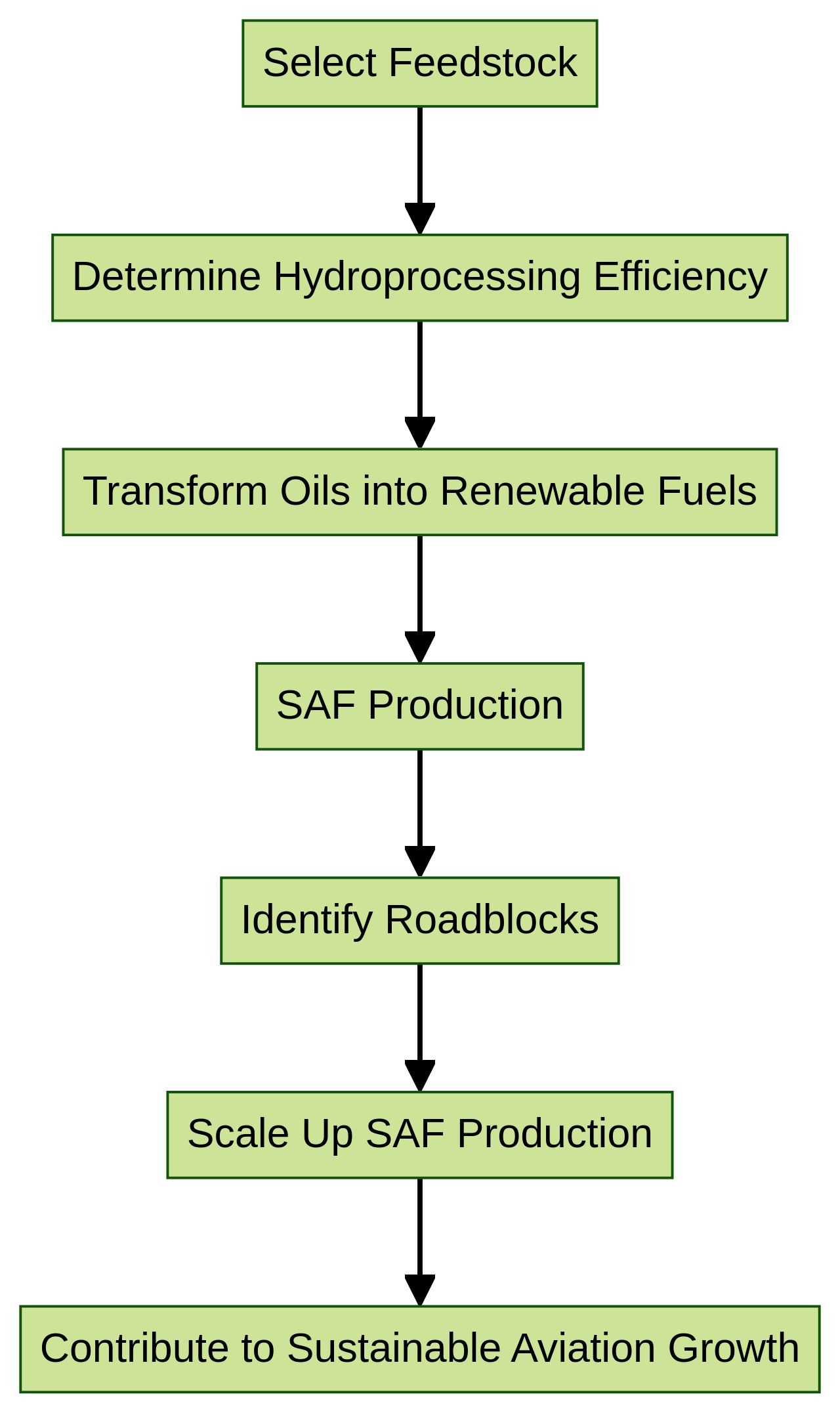

The production of sustainable aviation fuel (SAF) through the Hydroprocessed Esters and Fatty Acids (HEFA) pathway is intricately linked to the feedstock's Free Fatty Acid (FFA) profiles. These profiles are pivotal in determining the hydroprocessing efficiency, which is essential for transforming oils into renewable fuels.

Notably, biodiesel, derived from biological material, contributes to reducing CO2 and CO emissions by 8-41%, thereby advancing the quest for a smaller carbon footprint. Geographical and agricultural factors influence the source of biodiesel feedstock, which is vital for the HEFA process, known for its cost-effectiveness and high yield rates.

As the industry gravitates towards renewable energy, biomass emerges as a significant player in the energy landscape, capable of mitigating climate change effects. Meanwhile, heavy residues from crude oil processing, with their dense viscosity and hydrocarbon structures, are conventionally used for maritime fuel or power generation.

Yet, innovative approaches like gasification are being investigated to convert these residues into valuable syngas. Additionally, the utilization of natural gasoline for denaturing fuel ethanol and diluting heavy crude oil exemplifies the versatility of feedstock applications to meet regulatory and logistical challenges. In this evolving context, Unifuel.tech's Flexiforming technology emerges as a strategic solution, offering operators the ability to scale their decarbonization efforts. This technology can be integrated into existing hydrotreaters or reformers, which minimizes capital expenditure while also reducing carbon intensity. Universal Fuel Technologies, holding the rights to Unifuel.tech, emphasizes prompt communication, responding within 24 hours to inquiries regarding potential applications of Flexiforming, requiring details about the operator's feeds, desired products, and current facilities to tailor an optimal application strategy.

Techno-Economic Analysis (TEA) of Select Oil Feedstocks

Conducting a Techno-Economic Analysis (TEA) is crucial for evaluating oil feedstocks' suitability in Hydroprocessed Esters and Fatty Acids (HEFA) fuel production. This analysis thoroughly investigates capital and operational costs, conversion efficiency, and environmental impact to pinpoint promising feedstocks for large-scale HEFA fuel production.

Heavy residues (Hrs), a byproduct of crude oil refining, are noteworthy for their composition of complex hydrocarbons and heavy metals, and their high viscosity presents a challenge for traditional upgrading processes. However, gasification offers a path for valorizing these by-products, transforming them into valuable syngas, a hydrogen source.

The imperative for alternative energy sources is heightened by predictions of petroleum oil reserves running out within fifty years at current consumption rates. Tecpetrol's 2021 Sustainability Report highlights the necessity for resilience and efficiency in gas production in response to the shifting energy landscape.

The International Energy Agency's 2023 medium-term market report anticipates a 6% rise in global oil demand by 2028, with petrochemical and aviation sectors as primary drivers, though the growth rate is expected to slow, indicating a shift towards cleaner energy alternatives. In line with the push for sustainable solutions, Unifuel.tech presents flexiforming technology, enabling operators to tailor their decarbonization pace.

Flexiforming can be integrated into existing idle hydrotreaters or reformers, thus reducing capital expenditure and carbon intensity. By providing rapid response to inquiries and requiring specific information on feedstock, target products, and existing facilities, Unifuel. Tech can identify an optimal flexiforming application. This approach to oilseed processing concentrates on enhancing quality and efficiency across the entire production chain, with an emphasis on using green solvents and maintaining raw material integrity. A TEA incorporating flexiforming technology offers invaluable insights into the potential of oil feedstocks for sustainable HEFA production.

Selection Criteria for Oil Feedstocks in TEA

The production of Hydroprocessed Esters and Fatty Acids (HEFA) fuels from oil feedstocks necessitates a rigorous Techno-Economic Analysis (TEA) to ensure their viability. This process scrutinizes a variety of elements, such as feedstock sustainability, conversion rates, infrastructure compatibility, and economic feasibility.

Heavy Residues (Hrs), as by-products of crude oil refinement, are evaluated for their potential as feedstocks due to their complex hydrocarbon structures, which include heteroatoms, and their substantial volume of heavy metals. Despite their challenging viscosity and upgradeability, innovative methods like gasification can transform these low-value by-products into valuable syngas, a source of hydrogen.

The burgeoning demand for high-quality engine oils, such as Group III base oils produced by hydrocracking, has prompted companies like Shell to innovate. Shell's Energy and Chemicals Park Rheinland is set to inaugurate a new base oil plant, anticipating the future landscape of engine oil production.

In the context of oilseed-based vegetable oils, advancements have been made not only in oil extraction but across the entire production process, highlighting the interdependence of each step. This holistic approach has facilitated the integration of state-of-the-art technologies that enhance quality and efficiency while addressing environmental concerns, such as the move away from hexane towards greener extraction solvents. The TEA process is indispensable in pinpointing promising oil feedstocks by marrying technical and economic considerations, with an eye on the mounting demand for alternatives to fossil fuels and the environmental imperative. The life cycle assessments of various biomass sources, such as sugarcane and seaweed, for biofuel production have underscored their potential to significantly reduce atmospheric CO2. These assessments serve as decision-making tools for sustainable energy management, reinforcing the role of TEA in navigating the complex landscape of HEFA fuel production.

Camelina: Non-Food Feedstock with High Oil Content

The integration of Camelina in the production of Hydroprocessed Esters and Fatty Acids (HEFA) offers a promising avenue for sustainable aviation fuel (SAF) generation. Boasting a high oil yield and the ability to thrive on marginal lands, Camelina sidesteps the land-use conflict typically associated with food crops, thereby providing a more sustainable option for HEFA production.

A pioneering industrial initiative in Europe recently showcased Camelina's viability in biofuel production, with a remarkable output of 1,000 tons of HEFA from waste cooking oil, underlining the EU's commitment to research in this realm. Additionally, Camelina's role in soil regeneration has come to light; a rotational farming method with barley has demonstrated potential benefits for soil health, suggesting that biofuel production need not be at odds with agricultural food production.

The environmental impact of Camelina-based biofuels is also noteworthy, as they contribute to the reduction of life cycle greenhouse gas emissions, aligning with global decarbonization efforts. The Flexiforming technology by Unifuel.

Tech complements this by enabling operators to tailor their decarbonization pace effectively. Deployable in existing infrastructures like an idle hydrotreater or reformer, Flexiforming presents a cost-efficient solution to reduce capital expenditure and carbon intensity. Unifuel.tech's commitment to swift communication and tailored solutions, with responses to inquiries within 24 hours, further enhances the accessibility and practicality of integrating Flexiforming technology into existing facilities. In parallel, the transformation of Morocco's Laayoune Thermal Power Plant to hydrogen power underscores the burgeoning interest in alternative, low-carbon fuel sources. This project exemplifies the potential for alternative fuels like Camelina-derived biofuels and flexi forming technology to play a significant role in the transition to a more sustainable energy landscape.

Pennycress: Potential for Summer/Winter Rotational Cycle

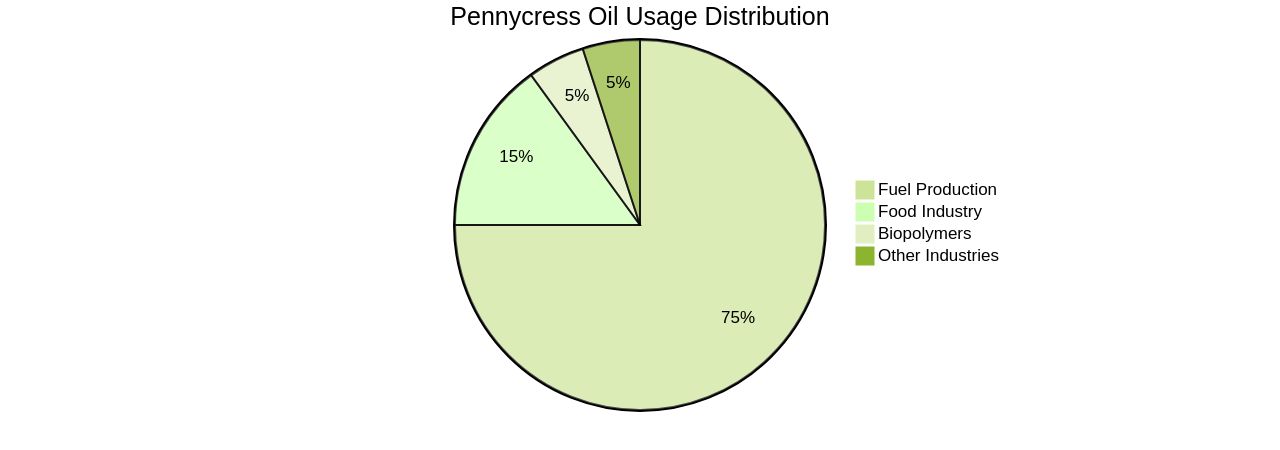

Pennycress, an unconventional oilseed crop, is gaining traction in the Hydroprocessed Esters and Fatty Acids (HEFA) fuel production arena, largely due to its ability to thrive in diverse growing seasons. This versatility makes it an excellent addition to crop rotations, enhancing land use efficiency and promoting sustainable farming practices. When processed, the seed oil from pennycress and winter camelina emerges as a potential substitute for traditional jet fuel and diesel, offering a viable solution for sectors where electrification is challenging.

By growing these crops during off-seasons and benefiting from their minimal input needs, the carbon footprint of the oil produced is substantially lowered. The escalating demand for Sustainable Aviation Fuel (SAF) is driving the search for low-carbon alternatives to conventional diesel. Utilizing pennycress for fuel production could slash emissions by over 60 percent compared to standard jet fuel or diesel, marking a significant stride in climate change mitigation.

Pennycress oil's utility extends beyond fuel, finding uses in food, biopolymers, and other industries, while the residual meal provides high-protein animal feed, illustrating the crop's comprehensive value in HEFA fuel production. Moreover, embracing crops like pennycress supports the ethos of continuous living cover agriculture, promising to reduce nitrogen runoff and soil erosion, and reinforcing the environmental benefits of incorporating such crops into agricultural frameworks. In the context of these developments, technologies like Flexiforming from Unifuel.

Tech play a pivotal role by offering customizable decarbonization rates. This innovative approach can rejuvenate idle hydrotreaters or reformers, optimizing capital outlays and diminishing carbon intensity. Unifuel.tech's commitment to rapid response and tailored solutions presents an opportunity for stakeholders to integrate Flexiforming seamlessly, ensuring an efficient transition to lower-carbon operations.

Jatropha: Multipurpose Plant with Uncertainties in Cultivation

Jatropha-based biofuels, including Hydroprocessed Esters and Fatty Acids (HEFA) for Sustainable Aviation Fuel (SAF) production, are of growing interest due to their potential to reduce greenhouse emissions and reliance on fossil fuels. However, the complex challenges associated with Jatropha cultivation and its economic viability require careful consideration. An economic analysis conducted in Colombia, using a blend of Jatropha-based biofuel (JB10), highlighted possible fuel savings in non-interconnected regions.

Despite this, the study also noted an increase in fuel consumption and emissions of nitrogen oxides and carbon dioxide, contrasting with reductions of up to 75% in unburned hydrocarbons and carbon monoxide at certain engine loads, which are significant for human health in residential areas. The analysis further emphasized environmental concerns, particularly soil degradation from the replacement of palm oil plantations with Jatropha. The global demand for energy, coupled with the urgency to find sustainable alternatives to palm oil and other ecologically intensive crops, underscores the importance of exploring novel agricultural practices.

For example, a European research program has suggested the use of crop rotation systems with compost and biochar to improve soil quality, potentially allowing the cultivation of energy crops like Jatropha on marginal lands. Additionally, incorporating waste biomass such as forest residues could offer a cost-effective feedstock for large-scale SAF production. With the world's petroleum reserves depleting and environmental pollution from fossil fuel combustion on the rise, the quest for alternative energy sources like Jatropha presents a compelling case for innovation in renewable energy technologies and sustainable agricultural methods.

Yellow Grease: Readily Available and Relatively Inexpensive Feedstock

The conversion of yellow grease into HEFA fuel is an integral part of a sustainable aviation fuel (SAF) supply chain, which is vital for reducing reliance on fossil fuels. Projects like those funded by the European Union's Horizon 2020 program, which focus on recycling carbon emissions from industrial sectors, are instrumental in producing high-grade biofuels without competing with food crops for land resources. Such initiatives are essential for minimizing the carbon footprint of the transportation sector.

In addition to these efforts, the utilization of waste biomass, such as forest residues, in the Fischer-Tropsch gasification process is a noteworthy approach. Companies like Velocys are applying this technology to create syngas, essential for the production of sustainable fuels. The subsequent synthesis of paraffins through this process is a significant step towards delivering clean and efficient energy solutions.

Furthermore, the production of green hydrogen via renewable energy-driven electrolysis is gaining traction as a critical component of zero-emission fuel strategies. Expertise from organizations like E4tech is crucial, as they conduct Life Cycle Assessments (LCAs) to determine the environmental impact of these fuels. LCAs are vital for stakeholders to understand the true benefits of alternative fuels over traditional ones.

Complementing these developments, Unifuel.tech introduces flexiforming technology, a versatile solution that empowers operators to tailor their decarbonization trajectory. This innovative technology can be implemented in existing infrastructure such as idle hydrotreaters or reformers, offering a cost-effective and lower carbon intensity pathway to SAF production. Unifuel.tech's quick response time and detailed analysis of feedstock, target products, and facility capabilities ensure a tailored application of flexiforming, aligning with the industry's move towards a decarbonized future.

Castor Bean: High Oil Yield and Suitability on Marginal Lands

The advent of sustainable aviation fuel (SAF) has provided an innovative avenue for reducing the aviation industry's carbon footprint. A notable example is the utilization of castor bean oil, which is particularly suitable for the Hydroprocessed Esters and Fatty Acids (HEFA) pathway, due to its high oil content and adaptability to arid conditions. This promotes economic development in regions with limited agricultural potential and contributes to ecological restoration.

Additionally, the transformation of biodiesel from plant sources like castor bean into SAF is associated with a substantial decrease in environmental pollution, up to 300%, showcasing the environmental advantages of plant-based fuels. Alternatives such as Miscanthus, sorghum, and switchgrass are also being explored for SAF production across the United States. These crops require minimal irrigation and offer potential for high-performance jet fuel conversion.

Moreover, innovative research is harnessing photosynthetic microorganisms, such as cyanobacteria, to generate isoprene, a precursor for photochemical reactions, using enzymes from the Eucalyptus tree. The overarching goal remains to accentuate carbon sequestration in soils and optimize land use, while curtailing the ecological impacts from fertilizers and water use. The recent progress in biofuel technology, as revealed by a University of California, Riverside study, presents a breakthrough in economical and carbon-neutral biofuel production.

This advancement is pivotal in bettering the use of lignin, a robust plant component that poses challenges in biomass processing. Furthermore, the development of bio-based aromatics is revolutionizing the SAF market, enabling the potential for 100% SAF usage in aviation, as demonstrated by airlines like United and Virgin Atlantic. This underscores the significance of SAF as a practical 'drop-in' solution for decarbonizing aviation, negating the need for extensive modifications to existing infrastructure.

Conclusion

In conclusion, the aviation industry is actively pursuing Sustainable Aviation Fuels (SAFs) to reduce its environmental impact. Advancements in SAF technologies, such as Unifuel.tech's Flexiforming, offer a cost-effective solution by integrating into existing infrastructure.

Hydroprocessed Esters and Fatty Acids (HEFA) fuel shows promise in reducing carbon emissions while aligning with current aviation technology. Economic feasibility is crucial for HEFA fuel production, with the cost of feedstock and hydrogen demand being key factors.

The geographic distribution of oil feedstock sources, including countries like Brazil, Colombia, and Australia, plays a role in the global supply chain. The yield potential and chemical composition of oil feedstocks are important considerations.

Innovations in hydrocracking technology and Unifuel.tech's Flexiforming optimize production efficiency and reduce carbon intensity. Techno-Economic Analysis (TEA) evaluates oil feedstock suitability based on costs, efficiency, and environmental impact. Specific feedstocks like Camelina, Pennycress, Jatropha, Yellow Grease, and Castor Bean offer advantages in HEFA fuel production. Advancements in SAF technologies and the selection of suitable feedstocks have the potential to revolutionize the aviation industry's sustainability efforts. By adopting renewable alternatives on a larger scale and integrating innovative technologies like Flexiforming, the industry can significantly reduce its carbon footprint and contribute to global decarbonization goals.