Introduction

As the aviation industry strives to reduce its carbon emissions, the integration of Sustainable Aviation Fuels (SAF) has become crucial. With the goal of achieving net-zero carbon emissions by 2050, SAF is not just an option but a necessity. Created from renewable sources like biomass and waste oils, SAF can significantly reduce carbon emissions compared to traditional jet fuels.

However, the industry faces challenges such as stringent fuel regulations and the need to scale up production. In this article, we will explore the need for sustainable aviation fuels, the challenges in implementing them, and potential solutions, including Unifuel.tech's flexiforming technology. Join us as we delve into the technical insights and analysis of the renewable fuels industry.

The Need for Sustainable Aviation Fuels

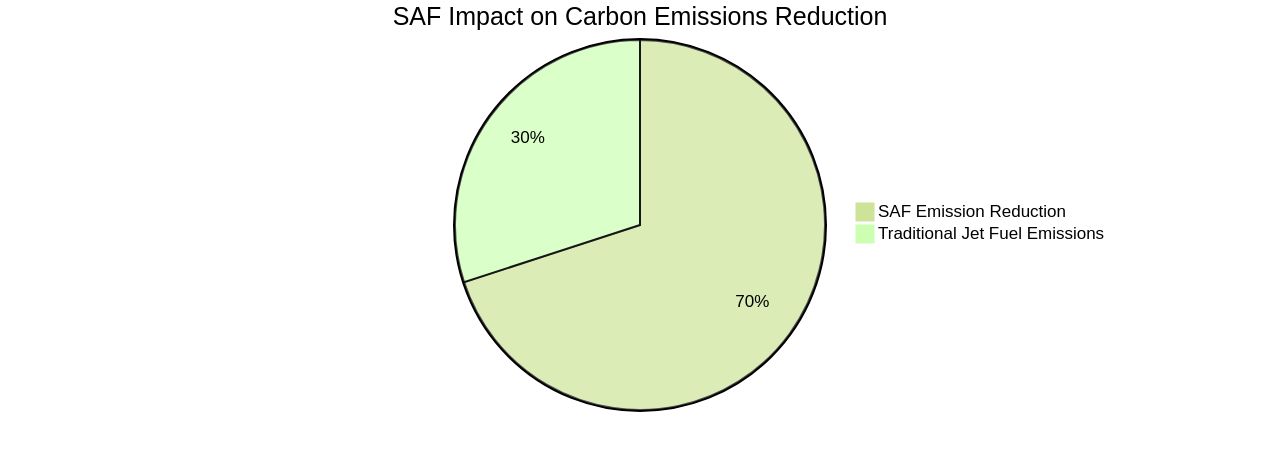

As the aviation industry propels forward with initiatives to reduce its carbon emissions, the integration of Sustainable Aviation Fuels (SAF) has become pivotal. With the objective of achieving net-zero carbon emissions by 2050 set by the International Civil Aviation Organization, SAF is not just an option but a necessity. Created from various renewable sources like biomass, waste oils, and algae, SAF can diminish carbon emissions by as much as 70% over their lifecycle when juxtaposed with traditional jet fuels.

Companies like Airbus, with goals to make their fleets 100% SAF-ready by 2030, and Virgin Atlantic, with its entirely SAF-powered demonstration flight, highlight the sector's dedication to pioneering and eco-friendly practices. Despite the innovation, the industry faces stringent fuel regulations and the challenge to scale up production adequately, considering aviation's 2-3% contribution to global CO2 emissions. The advancement of SAF technology and the associated costs remain high, calling for a unified effort to achieve a greener future.

Here, Unifuel. Tech introduces flexiforming, a technology that enables operators to tailor their decarbonization journey. This solution can be implemented in dormant hydrotreaters or reformers, thereby lowering both capital expenditure and carbon intensity.

Unifuel.tech, a branch of Universal Fuel Technologies, offers detailed consultations regarding feedstocks, desired products, and compatibility with current facilities to optimize the application of flexiforming. Their commitment to swift communication guarantees a response to queries within a day, ensuring that the transition to SAF is as seamless as possible. Their approach reflects the necessity for technological innovation and collaboration in surmounting the hurdles that lie on the path to widespread SAF adoption.

Challenges in Implementing Sustainable Aviation Fuels

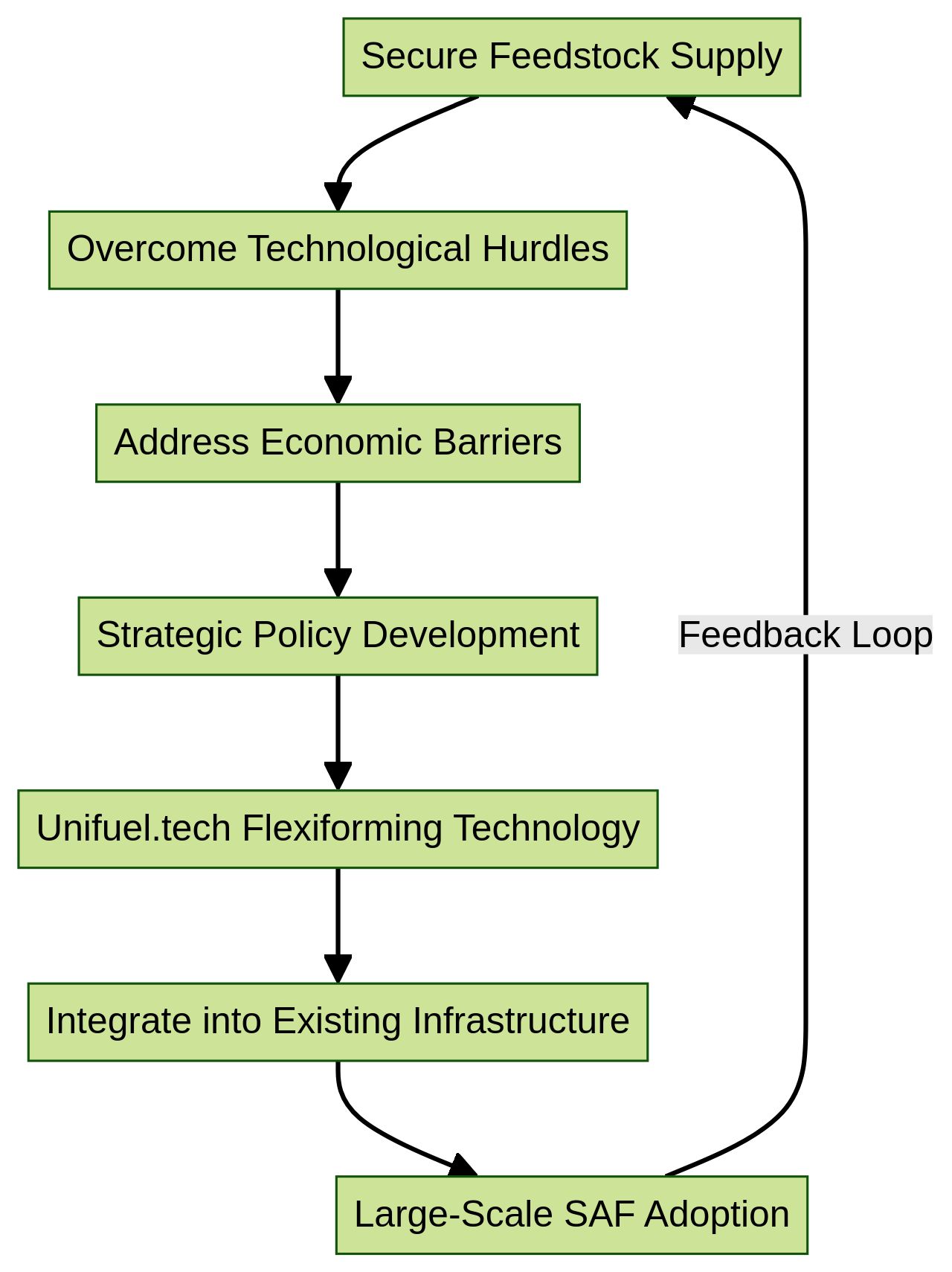

Sustainable aviation fuel (SAF) represents a pivotal shift towards reducing the environmental impact of flying. Despite its promise, the path to large-scale adoption is fraught with challenges.

The foremost issue lies in securing a consistent and plentiful supply of feedstocks necessary for SAF production. This is not merely a matter of logistics but a complex puzzle involving technology, economics, and environmental considerations.

Technological hurdles persist in the development and commercialization of processes such as the PtL (Power-to-Liquid), which, though promising with CO2 emission savings of up to 94%, is still nascent. Economic barriers also loom large, with SAF production costs currently outpacing conventional jet fuel, largely due to the scale of production and nascent technology.

The stakes are high, as the aviation industry's commitment to achieving carbon-neutral status by 2050 hinges on the successful integration of SAF. Yet, as of now, only 0.1% of flights operate on this greener fuel, underscoring the urgency for innovation and strategic policy development to accelerate SAF availability.

Reports, such as those focusing on the Great Lakes and Rocky Mountain regions, offer valuable insights into the potential of SAF within the United States, highlighting the need for concerted efforts in policy, research, and industry collaboration to overcome these barriers. As we stand at the cusp of a cleaner aviation future, the industry must navigate these challenges to make sustainable aviation not just a concept but a widespread reality.

One potential solution to these challenges comes from Unifuel.tech, which provides an innovative technology known as flexiforming. This process can be seamlessly integrated into existing infrastructure, such as idle hydrotreaters or reformers, thereby reducing both capital expenditure and the carbon intensity of fuel production. The adaptability of flexiforming allows aviation operators to dictate their own pace of decarbonization. With a commitment to rapid responsiveness, Unifuel. Tech engages with inquiries within 24 hours, ensuring that potential clients receive prompt assistance in assessing how flexiforming can be optimized for their specific feedstocks, target products, and current facilities. This approach may pave the way for more cost-effective and scalable SAF production, contributing to the acceleration of the aviation industry's carbon-neutral goals.

Case Study: Trinidad and Tobago's Feasibility Study on Sustainable Aviation Fuels

Trinidad and Tobago's exploration into sustainable aviation fuel (SAF) production has been a significant stride towards a greener aviation sector. In the face of global urgency to reduce emissions and the limitations of current alternatives like electrification, the nation's study is particularly timely.

Engaging government bodies, aviation professionals, and renewable fuel experts, the study comprehensively assessed the potential for SAF production, examining local feedstock sources and necessary technology. Additionally, it evaluated market demand in Trinidad and Tobago, leveraging the country's extensive oil and gas expertise.

This initiative is synchronous with the escalating global interest in SAF, despite challenges such as constrained production capabilities, competition for feedstock, and the necessity of cost-effective production scales. A promising solution to these challenges is Unifuel.tech's flexiforming technology, which enables operators to tailor their decarbonization trajectory.

By utilizing existing infrastructure, such as idle hydrotreaters or reformers, flexiforming can reduce both capital expenditure and the carbon footprint. With a commitment to rapid response and tailored solutions based on specific operational needs, Unifuel. Tech stands as an agile partner in the transition to bioenergy. The insights gained from Trinidad and Tobago's study, coupled with innovative approaches like flexiforming, offer valuable guidance for policy-makers in fostering the environmental and economic benefits of SAF, while navigating the uncertainties of a new energy landscape.

Future Opportunities for Sustainable Aviation Fuels in Trinidad and Tobago

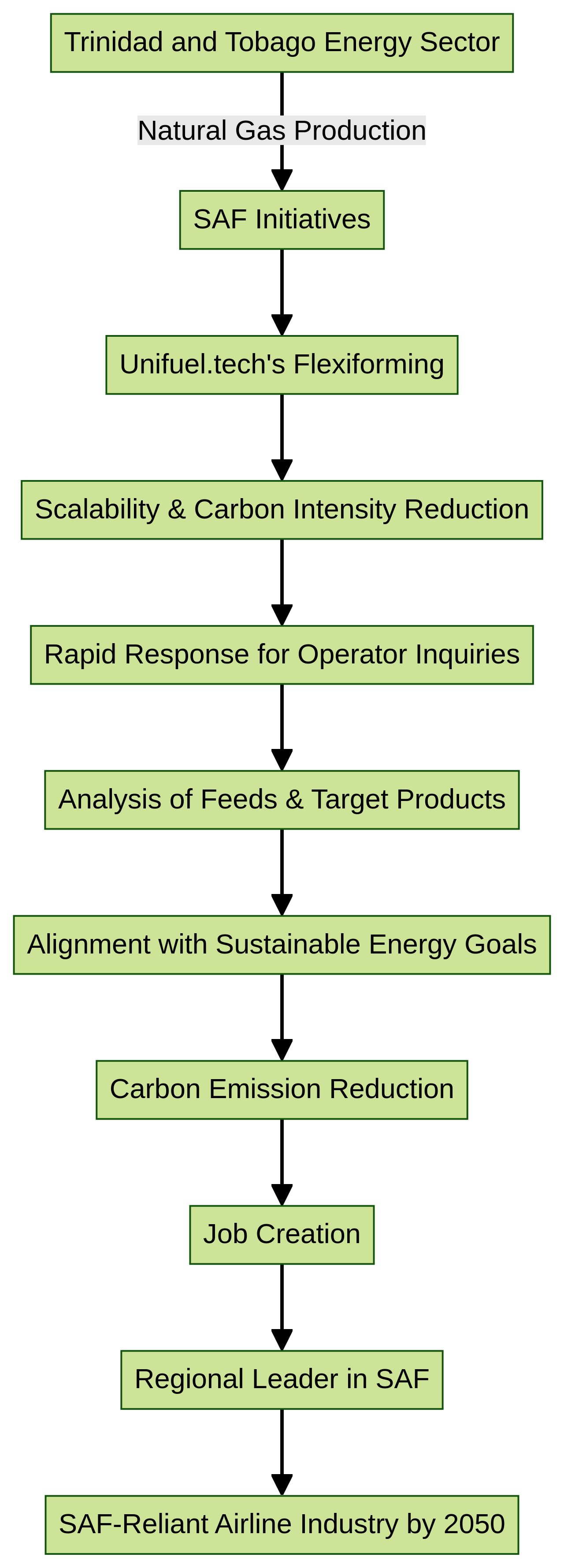

Trinidad and Tobago's energy sector, a powerhouse with significant natural gas production, is well-positioned to spearhead the Caribbean's sustainable aviation fuel (SAF) initiatives. The country's prowess in natural gas and petrochemicals, which together dominate its export profile, lays a robust foundation for SAF production diversification.

The integration of Unifuel.tech's Flexiforming technology into Trinidad and Tobago's energy infrastructure signifies a strategic leap forward. This innovative solution, which can be integrated into existing idle hydrotreaters or reformers, allows for a scalable approach to decarbonization, thereby reducing both capital expenditure and carbon intensity in SAF production.

The rapid response time of 24 hours for operator inquiries and the detailed analysis of feeds, target products, and existing facilities ensure a tailored application of Flexiforming, aligning with the nation's sustainable energy goals. The feasibility study's findings on carbon emission reduction and job creation potential are further enhanced by this technology, positioning Trinidad and Tobago as a forerunner in SAF and aligning with international objectives, such as the Biden administration's aspiration for a SAF-reliant airline industry by 2050. The strategic integration of Unifuel.tech's proprietary technology, held by Universal Fuel Technologies, underscores the nation's commitment to a lower carbon future and its potential to become a regional leader in SAF.

Conclusion

In conclusion, the aviation industry's pursuit of carbon neutrality by 2050 necessitates the integration of Sustainable Aviation Fuels (SAF). SAF, derived from renewable sources like biomass and waste oils, can significantly reduce carbon emissions compared to traditional jet fuels.

However, the industry faces challenges in terms of stringent fuel regulations and the need to scale up production. These challenges include securing a consistent supply of feedstocks, technological hurdles, and high production costs.

One potential solution to these challenges is Unifuel.tech's flexiforming technology. This innovative process can be seamlessly integrated into existing infrastructure, reducing both capital expenditure and the carbon intensity of fuel production.

Flexiforming allows aviation operators to dictate their own pace of decarbonization, offering a tailored approach to SAF adoption. Trinidad and Tobago's feasibility study on sustainable aviation fuels highlights the country's commitment to a greener aviation sector.

With its expertise in natural gas production and petrochemicals, Trinidad and Tobago is well-positioned to lead the Caribbean's SAF initiatives. The integration of Unifuel.tech's Flexiforming technology into the country's energy infrastructure further strengthens its potential as a regional leader in SAF production. Overall, the adoption of sustainable aviation fuels is crucial for achieving carbon neutrality in the aviation industry. Innovative technologies like flexiforming offer promising solutions to overcome the challenges faced in scaling up SAF production. By embracing these opportunities, the industry can pave the way for a greener and more sustainable future in aviation.