Introduction

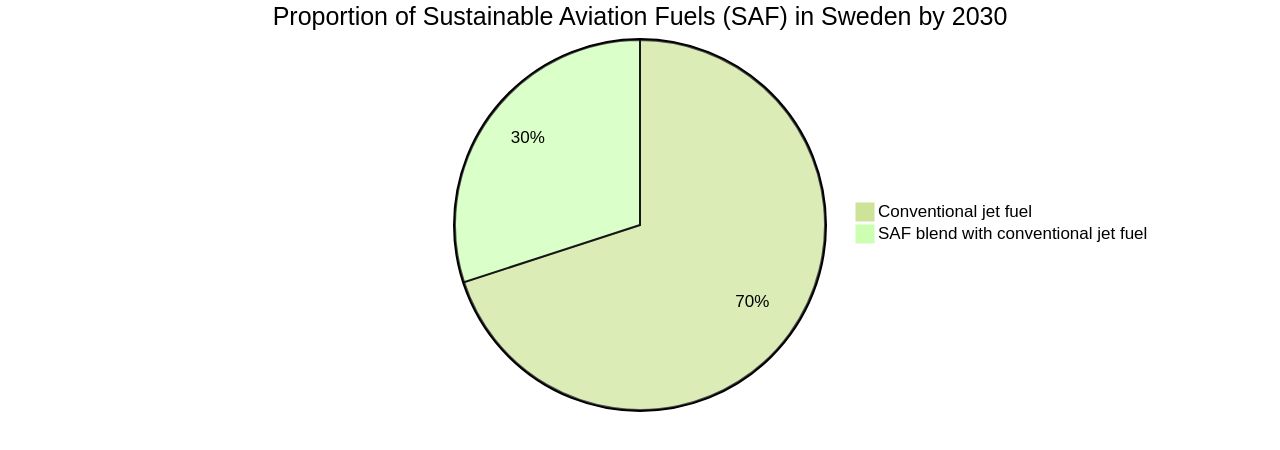

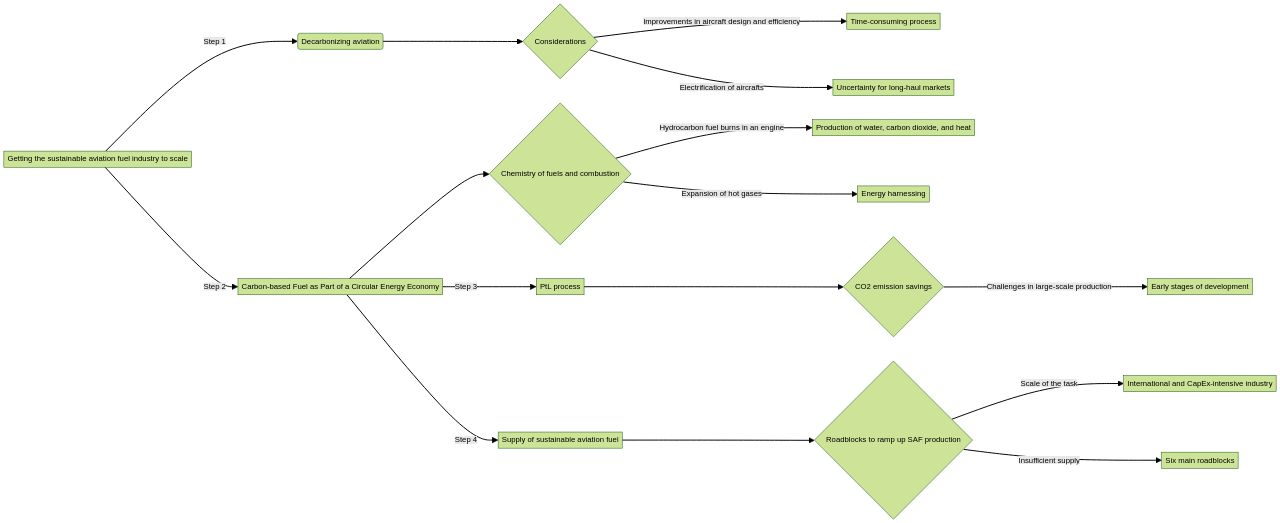

In line with Sweden's ambitious target of achieving a 30% blend of Sustainable Aviation Fuels (SAF) by 2030, the renewable fuels industry is facing formidable challenges in scaling up production and adoption. Currently, the cost of SAF is significantly higher than conventional jet fuel, hindering its widespread use.

However, innovative technologies like Flexiforming, offered by Unifuel.tech, are offering promising solutions to overcome these obstacles. This article explores the potential of Flexiforming technology in achieving Sweden's blending target and highlights the importance of partnerships and innovations in driving the adoption of SAF in the aviation industry. With a focus on technical insights and analysis, this article provides a comprehensive overview of SAF technology pathways, environmental impact assessments, and policy implications to steer the world towards a more sustainable future in aviation.

Background: Sustainable Aviation Fuels (SAF) and Sweden's 30% Volume Blending Target by 2030

In line with its robust climate change mitigation strategy, Sweden is ambitiously targeting a 30% blend of Sustainable Aviation Fuels (SAF) by 2030. Recognized as a pivotal solution to decrease the environmental footprint of aviation, SAF holds the promise of significantly reducing greenhouse gas emissions compared to conventional jet fuel. Industry leaders, including Airbus, are striving to make their aircraft 100% SAF-compatible by 2030, reinforcing Saf's instrumental role in achieving net-zero emissions by 2050.

However, the transition to large-scale SAF production and usage presents formidable challenges. Currently, the cost of SAF is 3 to 4 times higher than standard jet fuel, impeding its extensive adoption. Plus, scaling up production necessitates substantial investment, regulatory backing, and pricing support mechanisms.

Despite these obstacles, companies like Virgin Atlantic are demonstrating that SAF can seamlessly replace fossil-derived jet fuel, as evidenced by their 'Flight100' initiative. The predicted SAF output in Sweden is set to hit 80,000 tons annually by 2030, covering 20% of the nation's SAF needs. One of the promising solutions to these challenges is Flexiforming technology offered by Unifuel.tech.

This technology, which can be installed in an idle hydrotreater or reformer, allows operators to choose their decarbonization pace while reducing capital expenditure and carbon intensity. Through this technology, Unifuel.tech is playing a critical role in the transition towards a sustainable aviation industry. The right partnerships and innovations can propel SAF to the forefront of aviation decarbonization, steering the world towards a more sustainable future.

SAF Technology Pathways and Selection Methodology

As the aviation industry strives to achieve a 30% blending target, it necessitates the adoption of innovative technologies capable of producing Sustainable Aviation Fuel (SAF) at a large scale. One such potential solution is Flex forming, a technology that enables the transformation of biomass feedstocks into SAF.

This technology, offered by Unifuel.tech, a subsidiary of Universal Fuel Technologies, provides operators the flexibility to choose their speed of decarbonization. Moreover, it can be deployed in an idle hydrotreater or reformer, thus reducing capital expenditure and carbon intensity.

Despite being in its early stages with a limited supply and relatively high costs, Saf's environmental performance, scalability, and economic feasibility make Flexiforming a promising candidate. Airbus, a global leader in alternative fuel research, is mitigating these challenges through various initiatives.

One of their recent projects focuses on reducing the environmental footprint of ferry flights, which consume substantial fuel, by using SAF. Airbus's commitment to making all their aircraft 100% SAF-capable by 2030 and expanding the global SAF market in collaboration with partners is a testament to the growing industry trend. Other stakeholders are also fostering SAF innovation, production, and use, with projections indicating that SAF output will meet approximately 20% of Sweden's jet fuel demand by 2030. Despite current challenges, SAF, with its potential as a 'drop-in' solution, is perceived as the most effective means to address CO2 emissions in today's aviation industry, without necessitating significant modifications to global aircraft fleets, airports, and fueling infrastructure.

Projection of Background Systems

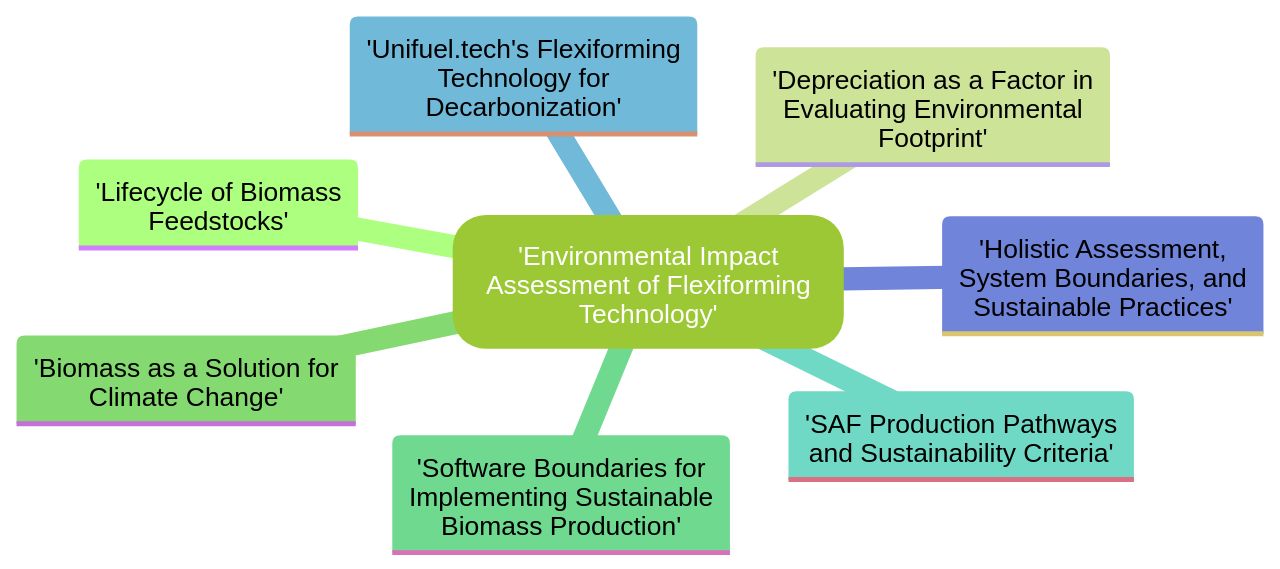

Incorporating Flexiforming technology necessitates a comprehensive examination of its environmental impact. This includes the lifecycle of biomass feedstocks, from cultivation and harvesting to transportation, and the production and distribution of necessary inputs.

By understanding the environmental impact of these systems, areas of concern can be identified and the sustainability of the process can be enhanced. Consider the case of a Spirulina biorefinery.

Here, depreciation, which accounts for equipment wear and obsolescence over a predefined period, forms a significant part of the operational expenditure (OPEX). This time-dependent cost is a crucial factor in evaluating the environmental footprint of the system.

Biomass, derived from living organisms, can help combat climate change. It can sequester carbon from the atmosphere or serve as an alternative to fossil fuels, providing a cleaner energy source.

Corn stover, a byproduct of corn production, is an example of sustainable biomass production. However, the implementation of such a system requires a thorough understanding of factors such as energy efficiency, hardware efficiency, and carbon awareness.

These elements establish software boundaries, that is, the components included in the system, and the quantification method, which can be either telemetry-based real-world measurements or model-based laboratory measurements. In the realm of aviation, sustainable aviation fuel (SAF) offers a viable solution for reducing emissions.

According to a report by Carbon Direct and Apple, SAF production pathways are associated with various fuel types, carbon intensities, sustainability criteria, and costs. This necessitates well-rounded strategies to reduce CO2 emissions, enhance operational efficiency, and maintain passenger satisfaction. Unifuel.tech offers Flexiforming technology, allowing operators to control their decarbonization speed. This technology can be implemented in an idle hydrotreater or reformer, leading to a reduction in capital expenditure and carbon intensity. Unifuel.tech offers bespoke solutions based on the operator's feeds, target products, and current facilities. This ensures the optimal application of Flexiforming for each customer. In summary, effective implementation of Flexiforming technology requires a holistic assessment of environmental impacts, careful consideration of system boundaries, and the adoption of sustainable practices.

Upscaling of Foreground Systems

The refinement of the Flexiforming process, offered by Unifuel.tech, is fundamental for enhancing Sustainable Aviation Fuel (SAF) production. This includes optimizing parameters like temperature, pressure, and catalysts to promote energy efficiency and minimize waste.

The objective is to devise a scalable, efficient system poised to meet targeted blending volumes. A crucial aspect of this process is the development of a 'digital twin', a virtual model of the production facility that enables simulation and optimization of production processes.

This forward-thinking strategy is centered on choosing the most economically feasible and environmentally friendly synthesis methods. Synthetic fuels, created by merging hydrogen and carbon dioxide derived from diverse industrial processes, present a hopeful answer to curbing greenhouse gas emissions.

These fuels closely resemble traditional petroleum-based fuels, which means current combustion engines and infrastructures can be used without any alterations. As the aviation industry strives for carbon neutrality, synthetic fuel production is anticipated to play a crucial role. However, challenges persist, including stringent regulations and the necessity for precise fuel formulations to ensure safety and reliability in aircraft engines. Despite these obstacles, progress is being made in the production of sustainable fuels, particularly SAF blends, through advancements in technology and strategic partnerships. Unifuel.tech's Flexiforming technology, a product of Universal Fuel Technologies, allows operators to control their decarbonization rate and can be integrated into an idle hydrotreater or reformer, leading to reduced capital expenditure and carbon intensity.

Scope of LCA Model

The evaluation of the environmental footprint of the entire production chain is performed using a Life Cycle Assessment (LCA) model. This model takes into account all crucial stages, from the cultivation of biomass feedstocks to the distribution of the final Sustainable Aviation Fuel.

A range of impact categories are considered within this assessment, such as greenhouse gas emissions, energy consumption, and water usage, to provide a comprehensive understanding of the sustainability performance. The LCA model includes detailed Life Cycle Inventory (LCI) modeling for each technology, energy consumption, and emissions related to airframe manufacturing.

The model provides insight into the full range of fuel types, carbon intensities, sustainability criteria, and costs associated with this landscape of options, highlighting the potential of Low Carbon Fuel Standard (LCFS) policies to drive the deployment of SAFs in the aviation sector. However, challenges exist around large-scale production of SAF, as the supply is currently insufficient. The LCA model underscores the role of policy design in shaping the effectiveness of LCFS policies in promoting safe.

Data Inventory and Environmental Impact Assessment

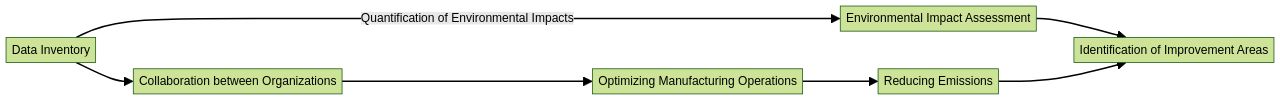

The process of creating a Life Cycle Assessment (LCA) model involves an in-depth data inventory, which collects information on energy inputs, material flows, and emissions at each production stage. This data enables the quantification of environmental impacts and the evaluation of the production system's sustainability performance. It provides significant insights into potential environmental hotspots and improvement areas.

For instance, the collaboration between the Swiss Data Science Center and the Bühler Group is leveraging innovative techniques to optimize manufacturing operations and reduce industry emissions. In another example, the production of Feta cheese involves collecting data to create a Life Cycle Inventory (LCI) that reflects the current situation and evaluates future environmental impacts of innovations. Furthermore, the environmental impact of plant-based alternatives to dairy products is being understood better through Life Cycle Inventories and Life Cycle Impact Assessments.

This approach is critical in industries such as aviation, where sustainable aviation fuel (SAF) has become the main means of reducing emissions. The process of scaling up SAF production, however, faces numerous challenges, including supply chain constraints, international standards, and regulation. Therefore, comprehensive data collection and analysis are vital to uncover opportunities and address these challenges, ultimately reducing greenhouse gas emissions and contributing to a sustainable future.

Life Cycle Environmental Impact Comparison: 30% SAF, 100% SAF, and Jet Fuel

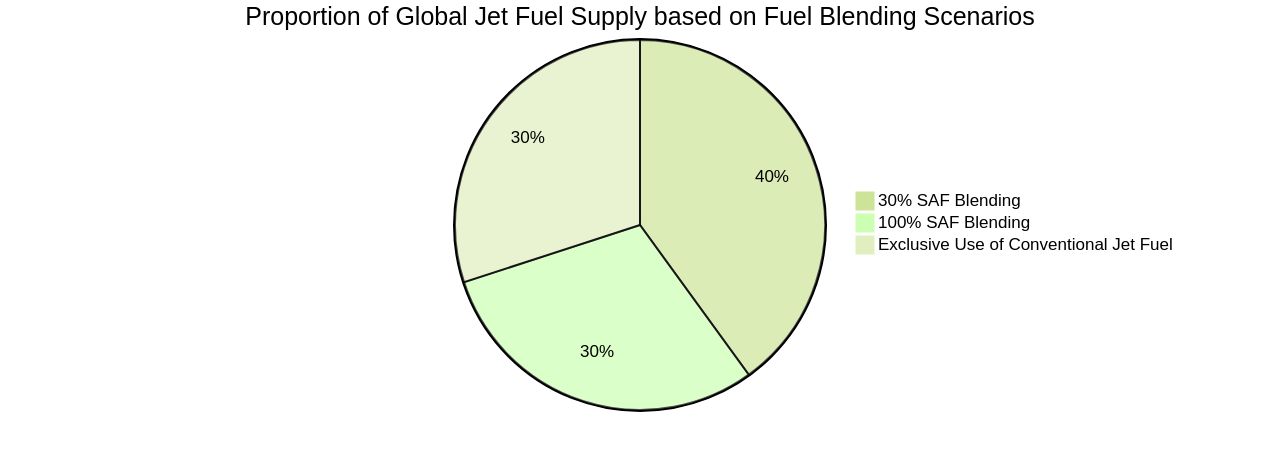

The Life Cycle Analysis (LCA) model is an effective tool in evaluating the environmental impact of various fuel blending scenarios, such as 30% SAF blending, 100% SAF blending, and exclusive use of conventional jet fuel. This analytical tool provides essential insights into the potential benefits and trade-offs of increasing the SAF blending volume.

However, the current SAF supply is insufficient to meet demand, with less than 0.2% of the global jet fuel supply in 2022 being alternative fuels. The high cost of SAF, currently three to four times more expensive than conventional fuel, and the logistical complexities of its distribution, further hinder its widespread adoption.

The Power-to-Liquid (PtL) process, which can yield CO2 emission savings of 89 to 94%, is a promising solution. However, PtL technology is still in its infancy and presents challenges in large-scale production.

Moreover, SAF production technologies, barring Direct Air Capture, are at a high level of readiness, but the actual supply remains inadequate. The recent breakthrough in producing bio-based aromatics has opened the possibility of using greater volumes of SAF, even up to 100%, without requiring modifications to existing aircraft engines or fueling infrastructure. This development can significantly contribute to decarbonizing the aviation sector. However, it is crucial to act collaboratively and promptly to unlock the potential of SAF and meet the industry's climate goals.

Hotspots in SAF Life Cycles

Sustainable Aviation Fuels (SAFs) have emerged as the key solution to reducing the aviation industry's environmental footprint. However, the production and adoption of SAFs present unique challenges that must be addressed to ensure their viability.

Life Cycle Analysis (LCA) has identified areas of concern, or 'hotspots', within the life cycles of SAFs, which can vary based on the technologies and feedstocks employed. Addressing these hotspots is vital to enhancing the overall sustainability of SAF production.

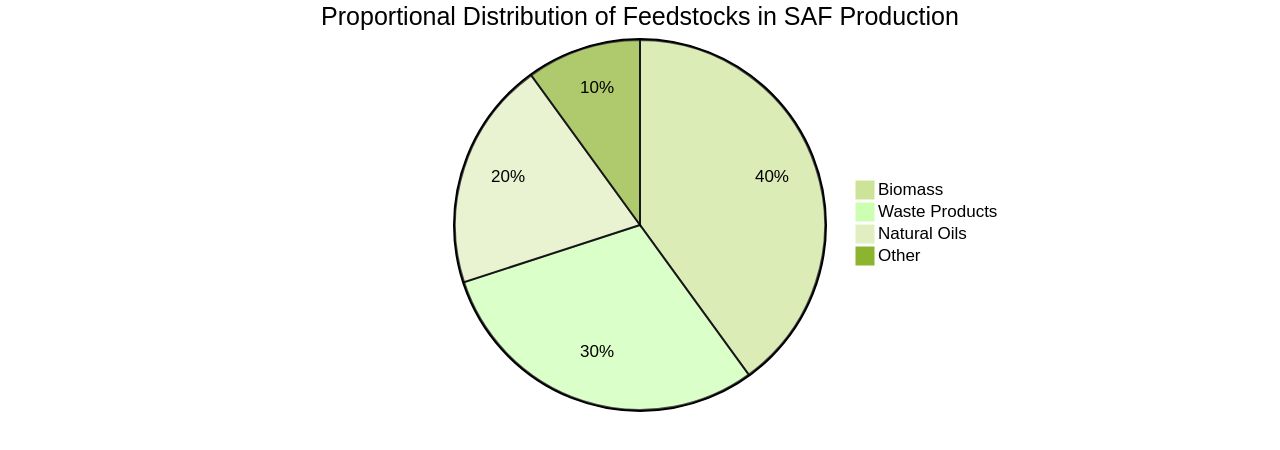

By focusing on areas with the highest environmental impacts, it's possible to introduce targeted mitigation strategies and enhance resource efficiency. The production of SAFs involves various feedstocks such as biomass, waste products, and natural oils.

However, the demand for these feedstocks is set to surpass their supply due to increased global SAF uptake, especially in Europe, the UK, and the USA. This raises questions about the affordability and sustainability of SAFs, and the competition for feedstocks.

Moreover, current engines are certified to operate at peak performance with a 50% SAF blend, which limits the potential CO₂ reduction to -40%. Therefore, advancements in engine technology and fuel production processes are critical to increasing this percentage and making SAFs a more viable alternative to traditional jet fuel. The aviation industry's commitment to reducing emissions has led to historic milestones such as the first transatlantic commercial flight powered entirely by SAFs, a testament to the potential of these fuels. However, SAFs currently account for less than 0.1% of all fuel used, with a production cost 2-5 times higher than conventional fuel. As the aviation industry moves towards achieving its Net-Zero 2050 goal, the focus needs to be on increasing the production and adoption of Safe while addressing the identified hotspots to ensure a cleaner and more sustainable future.

Policy and Investment Decision-Making Implications

The potential of Flexiforming technology in producing Sustainable Aviation Fuel (SAF) has been explored in a notable case study, shedding light on its implications for policy development and investment strategies. The study emphasizes not just achieving Sweden's 30% volume blending target but also underscores the need for a comprehensive perspective of the production process to sustain the aviation fuel sector. The study, backed by substantial evidence, highlights the pioneering efforts of Virgin Atlantic in exploring sustainable fuels, as well as the recent historic flight powered entirely by SAF.

These instances underline the feasibility of SAF as a reliable, direct substitute for fossil-derived jet fuel and its critical role in decarbonizing long-haul aviation. The global aviation sector is currently in a transformative phase, driven by decarbonization. The potential of eSAF to make aviation climate-neutral by the mid-21st century is significant, as evidenced by Germany's initiative to establish potential production capacities for eSAF.

Moreover, the report from Carbon Direct, in collaboration with Apple, provides a thorough overview of different types of fuel, their carbon intensities, sustainability criteria, and associated costs. This primer on SAF production pathways and opportunities highlights the importance of scaling up to minimize greenhouse gas emissions. Unifuel.tech, part of Universal Fuel Technologies, offers a solution that could help navigate these challenges.

Their flexiforming technology allows operators to choose their decarbonization speed and can be deployed in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. This could be a significant step towards achieving the International Civil Aviation Organization's goal of net-zero carbon emissions by 2050. The case study on Flexiforming offers valuable insights for a cleaner, greener aviation industry, and Unifuel.tech's technology could be a part of this transformation.

Conclusion

In conclusion, Sweden's target of achieving a 30% blend of Sustainable Aviation Fuels (SAF) by 2030 presents challenges due to the higher cost of SAF compared to conventional jet fuel. However, innovative technologies like Flexiforming offered by Unifuel.tech show promise in overcoming these obstacles.

Flexiforming technology allows operators to control their decarbonization pace while reducing capital expenditure and carbon intensity. Partnerships and innovations are crucial for driving the adoption of SAF in the aviation industry.

Companies like Virgin Atlantic are already demonstrating the successful replacement of fossil-derived jet fuel with SAF. The projected SAF output in Sweden is expected to cover 20% of the nation's needs by 2030.

Flexiforming technology, offered by Unifuel.tech, offers a scalable solution for SAF production and can be integrated into existing infrastructure. Comprehensive environmental impact assessments and data collection play a vital role in ensuring sustainable practices in SAF production.

Advancements in technology, such as synthetic fuels and the development of a 'digital twin', contribute to optimizing production processes and reducing greenhouse gas emissions. The Life Cycle Assessment (LCA) model is instrumental in evaluating the environmental impact of different fuel blending scenarios. It identifies areas of concern or 'hotspots' within SAF life cycles that require attention for improved sustainability. In summary, with the right partnerships, innovations, and policy support, SAF can play a significant role in decarbonizing the aviation industry. Unifuel.tech's Flexiforming technology offers a viable solution towards achieving Sweden's blending target and contributes to a more sustainable future for aviation.