Introduction

Sustainable Aviation Fuel (SAF) is revolutionizing the aviation industry's approach to reducing greenhouse gas emissions. Derived from various sustainable sources, such as waste oils and agricultural residues, SAFs are a crucial component in achieving the sector's ambitious net-zero carbon emissions target by 2050.

With their ability to mimic conventional jet fuel, SAFs offer a seamless transition to greener skies without requiring modifications to existing aircraft engines. Despite challenges such as high production costs and limited supply, the industry is making significant strides towards incorporating SAF as a standard fuel option.

This article explores the definition, types, emissions savings, production state, future potential, feedstock markets, and case studies of SAF projects from around the world. It also delves into the future of sustainable aviation, highlighting the importance of balancing demand, supply, and environmental impact. Join us as we delve into the technical insights and analysis of the renewable fuels industry.

Understanding SAFs: Definition, Types, and Emissions Savings

Sustainable Aviation Fuel (SAF) represents a paradigm shift in the aviation industry's approach to reducing greenhouse gas emissions. These eco-friendly fuels, derived from varied sustainable sources such as waste oils and agricultural residues, are crucial for the sector's ambitious net-zero carbon emissions target by 2050. With their ability to mimic conventional jet fuel, SAFs such as HEFA and SPK are compatible with current aircraft engines, offering a seamless transition to greener skies.

The partnership between ORLEN and Yokogawa exemplifies the innovative strides being made in SAF production. Their collaboration centers on developing a 'digital twin' for a synthetic fuels production facility, which will utilize green hydrogen and captured CO2 to produce synthetic aviation fuels. These synthetic fuels boast nearly identical properties to traditional jet fuel, allowing for significant emission reductions without altering existing infrastructure.

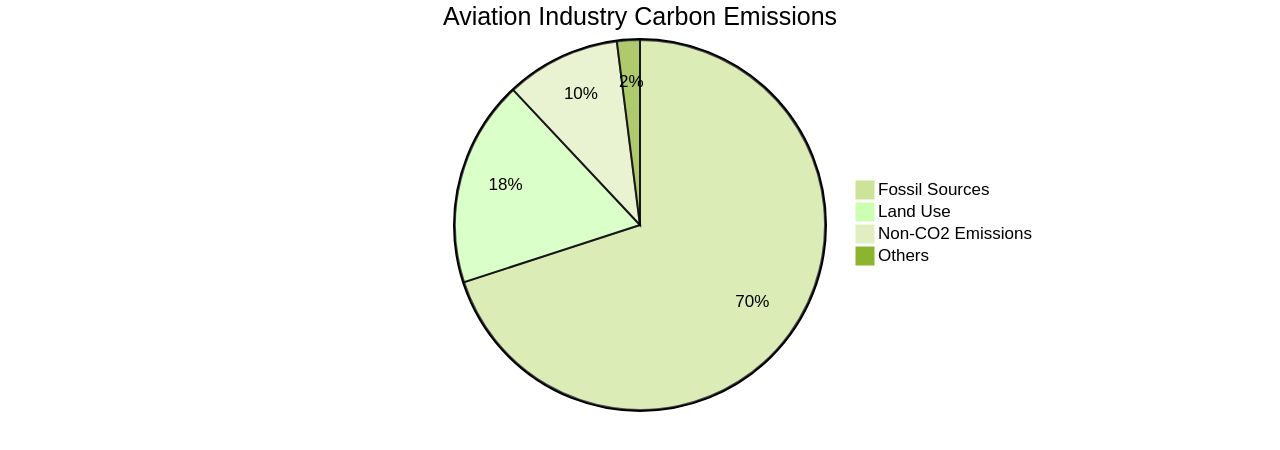

With the aviation sector accounting for 2-3% of global CO2 emissions, the incorporation of SAF is not only an environmental imperative but also a technical one. The recent memorandum signed by ORLEN aims to establish a production capacity of 70,000 tons of synthetic fuels by 2030, marking a significant step towards decarbonizing aviation. Despite SAF's potential, the current global supply is less than 0.2%, hindered by high production costs and nascent technology.

However, the industry is responding with initiatives such as United Airlines' and Virgin Atlantic's successful use of 100% SAF in commercial flights, signaling a future where SAF could be a standard fuel option. The commitment to SAF is echoed by industry leaders like Airbus, which aims to make its aircraft 100% SAF-capable by 2030. To realize the full potential of SAF, overcoming key challenges such as the need for bio-based aromatics in aviation fuel, which limits SAF blending levels, is essential.

United Airlines' 100% SAF flight demonstrates the feasibility of overcoming this barrier. As the technology matures and production scales up, SAF could become a cornerstone in aviation's journey to a carbon-neutral future. In tandem with these efforts, Unifuel.tech's flexiforming technology emerges as a pivotal solution for the production of SAF.

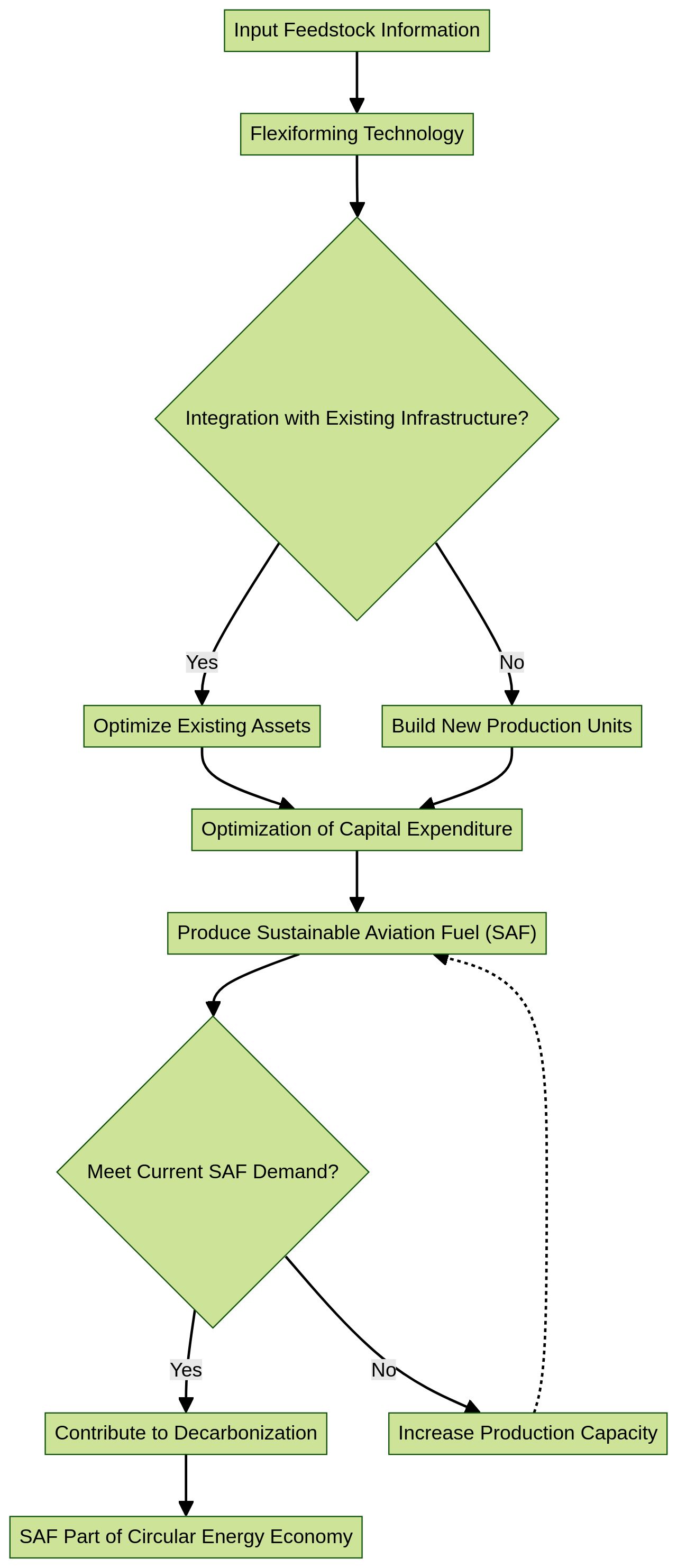

Flexiforming can be implemented within existing infrastructure, such as an idle hydrotreater or reformer, which significantly reduces both capital expenditure and carbon intensity. This innovative approach empowers operators with the flexibility to calibrate their decarbonization trajectory. Unifuel.tech's commitment to rapid response and customized solutions underscores the adaptability of flexiforming technology to a variety of operational contexts, ensuring that operators can efficiently meet their specific fuel production and sustainability goals.

SAF Production: Current State and Future Potential

Flexiforming technology represents a transformative approach to the production of Sustainable Aviation Fuel (SAF), capable of converting a diverse array of sustainable feedstocks into high-grade aviation fuel. This innovative process stands to address the growing demand for SAF, which is poised to become a linchpin in the aviation industry's shift toward carbon neutrality.

With the International Civil Aviation Organization targeting net-zero carbon emissions by 2050, the deployment of flexible and efficient production methodologies like flexiforming is critical. A noteworthy implementation of this technology is Unifuel.tech's Flexiforming solution, designed to integrate with existing refinery infrastructure, such as idle hydrotreaters or reformers.

This integration facilitates a reduction in both capital expenditure and carbon intensity, enabling operators to effectively manage their decarbonization trajectory. Unifuel.

Tech commits to responding to inquiries within 24 hours, working closely with operators to assess their feedstock profiles, target products, and facility capabilities, ensuring a tailored application of their technology to optimize SAF production. The production of synthetic fuels, which combines hydrogen from renewable energy electrolysis with carbon dioxide sourced from industrial processes, is set to significantly reduce industrial greenhouse gas emissions.

Unifuel.tech's approach aligns with this strategy, as their flexiforming technology can generate SAF with properties nearly identical to conventional petroleum-derived fuels, allowing their use in current aviation engines without modifications. Moreover, the existing infrastructure for petroleum fuel logistics can be leveraged for the distribution of SAF, highlighting the versatility and adaptability of this technology. As the industry navigates the hurdles of limited supply and high costs, continuous innovation in flexiforming technology is essential. Embracing the digital twin concept to simulate and refine production processes, as seen in strategic collaborations like ORLEN and Yokogawa's, will further enhance the economic viability and environmental sustainability of SAF manufacturing. With the potential to produce 70 thousand tons of synthetic fuels annually by 2030, such partnerships are paving the way for large-scale SAF production and a significant reduction in aviation's environmental footprint.

SAF Feedstock Markets: Opportunities and Challenges

The aviation sector's quest to diminish its carbon footprint has brought sustainable aviation fuels (SAF) to the forefront of its decarbonization efforts. While traditional SAF production predominantly relies on fats, oils, and greases, the scarcity of these resources necessitates an expansion in feedstock variety.

This expansion is crucial as the industry endeavors to meet the International Civil Aviation Organization's ambitious net-zero carbon emissions target by 2050. The transition to a more sustainable future is not without its challenges, including the need for significant advancements in technology and collaboration across the SAF value chain.

A notable development in this field is the introduction of flexiforming technology by Unifuel.tech, an innovation that provides a flexible approach to decarbonization. This technology can transform underutilized assets such as idle hydrotreaters or reformers into productive units, thereby optimizing capital expenditure and reducing carbon intensity.

Flexiforming facilitates the creation of SAF by allowing operators to input specific information about their feedstock, desired end products, and existing infrastructure, ensuring an efficient and tailored deployment. The potential of flexiforming to integrate with current systems and accelerate the production of SAF could play a crucial role in closing the supply-demand gap. Unifuel.tech's commitment to rapid communication, with a response time of within 24 hours, exemplifies their dedication to fostering partnerships and advancing the use of SAF. As regions like Europe, the UK, the USA, and Australia focus on expanding their SAF capabilities, the integration of such innovative technologies will be paramount in scaling up production and achieving sustainability targets.

SAF Projects and Developments: Case Studies from Around the World

Emerging sustainable aviation fuel (SAF) initiatives around the world are showcasing the potential for significant emissions reduction in the aviation sector. For instance, a European collaboration between a prominent airline and a biofuel company is leveraging used cooking oil to produce SAF, achieving an impressive 80% reduction in emissions. In a similar vein, a partnership in the United States between an airline and an energy company is utilizing agricultural residues as a feedstock for SAF production.

These efforts underscore the innovative spirit of the industry and its commitment to environmental stewardship. SAF has the capability to be produced from a variety of feedstocks, including used cooking oil, municipal waste, waste gases, and agricultural residues, as well as renewable electricity and carbon dioxide captured from the atmosphere. The versatility of feedstock options paves the way for a more sustainable aviation industry, and it is imperative for the sector to embrace SAF to meet the ambitious net-zero emissions target by 2050 set by the International Civil Aviation Organization.

The pioneering Flight 100 by Virgin Atlantic exemplifies the viability of SAF as a replacement for fossil fuels, showcasing the airline's longstanding commitment to the development of SAF and its willingness to share insights for the broader benefit of the industry. Despite the promising trajectory of SAF initiatives, the current scale of production and high costs present challenges. SAF is still in its early development stages and is estimated to be at least three to four times more expensive than conventional jet fuel.

With only a few producers globally, the industry faces a bottleneck in supply. However, the potential of SAF is recognized by industry giants like Airbus, which is working towards making all its aircraft 100% SAF-capable by 2030 and fostering the growth of the global SAF market. This commitment is a testament to the industry's collective ambition to pioneer sustainable aerospace solutions.

The Future of Sustainable Aviation: Balancing Demand, Supply, and Environmental Impact

Sustainable aviation fuel (SAF) has rapidly become the aviation industry's focal point in its mission to reduce carbon emissions, which currently account for about 2.5% of global CO2 emissions from fossil sources and land use. With the aviation sector's overall impact on climate change estimated at approximately 4% due to non-CO2 emissions, the urgency for SAF deployment is palpable.

The transition to SAF is challenging due to its limited production and the resulting supply-demand imbalance, which raises concerns about affordability and the competition for feedstocks. Despite these challenges, SAF remains the most immediate and effective solution for decarbonizing aviation, especially since alternative technologies like electric and hydrogen-fueled aircraft for long-haul flights are still in developmental stages, with hydrogen-electric powered flights expected to commence for small passenger numbers by 2026.

Flexiforming technology, pioneered by Unifuel.tech, has emerged as a game-changing solution that integrates with existing infrastructure, like idle hydrotreaters or reformers. This innovation significantly reduces capital expenditure and carbon intensity.

Moreover, the advent of bio-based aromatics production has enabled aircraft to be fueled with higher volumes of SAF oils, including the potential for 100% SAF, which has been successfully tested by airlines such as United Airlines and Virgin Atlantic. The 'drop-in' nature of SAF minimizes the need for extensive modifications to aircraft fleets, airports, and fueling infrastructure. The pursuit of a multi-fuel future, as underscored by an analysis that predicts bio-SAF and synthetic kerosene could meet 86% of aviation fuel demand by 2050, underscores the need for abundant low-carbon hydrogen, cost reductions, and innovation. The global aviation industry is poised for a transformation, with SAF at the helm of this green revolution, supported by a concerted effort from airlines, fuel producers, governments, and stakeholders.

Conclusion

In conclusion, Sustainable Aviation Fuel (SAF) is a crucial component in the aviation industry's mission to achieve net-zero carbon emissions by 2050. SAFs, derived from sustainable sources such as waste oils and agricultural residues, offer a seamless transition to greener skies without requiring modifications to existing aircraft engines. Despite challenges of high production costs and limited supply, the industry is making significant strides towards incorporating SAF as a standard fuel option.

The production of SAF is evolving with innovative technologies like flexiforming, which allows for the conversion of diverse sustainable feedstocks into high-grade aviation fuel. This flexible approach optimizes capital expenditure and reduces carbon intensity, enabling operators to effectively manage their decarbonization trajectory. While there are challenges in terms of limited supply and high costs, the industry is committed to overcoming these obstacles.

Successful case studies from around the world demonstrate the potential for significant emissions reduction through initiatives like using used cooking oil or agricultural residues as feedstocks for SAF production. The future of sustainable aviation lies in balancing demand, supply, and environmental impact. The urgency for SAF deployment is clear as alternative technologies are still in developmental stages.

Flexiforming technology and bio-based aromatics production enable higher volumes of SAF oils to be used, minimizing the need for extensive modifications to aircraft fleets and infrastructure. Overall, SAF represents a transformative solution that aligns with the aviation industry's goal of reducing its environmental footprint. With continued innovation, collaboration, and commitment from stakeholders, SAF has the potential to revolutionize the aviation sector and pave the way for a greener future.