Introduction

Sustainable Aviation Fuels (SAFs) have emerged as a crucial tool in reducing the aviation industry's carbon footprint. With the goal of achieving net zero carbon emissions by 2050, the industry is turning to alternative fuels derived from renewable feedstocks.

However, the production process of SAFs is energy-intensive and expensive, making them 3-4 times costlier than conventional jet fuel. Despite these challenges, SAFs offer minimal adjustments to existing aircraft engines and infrastructure, making them an attractive option for sustainability.

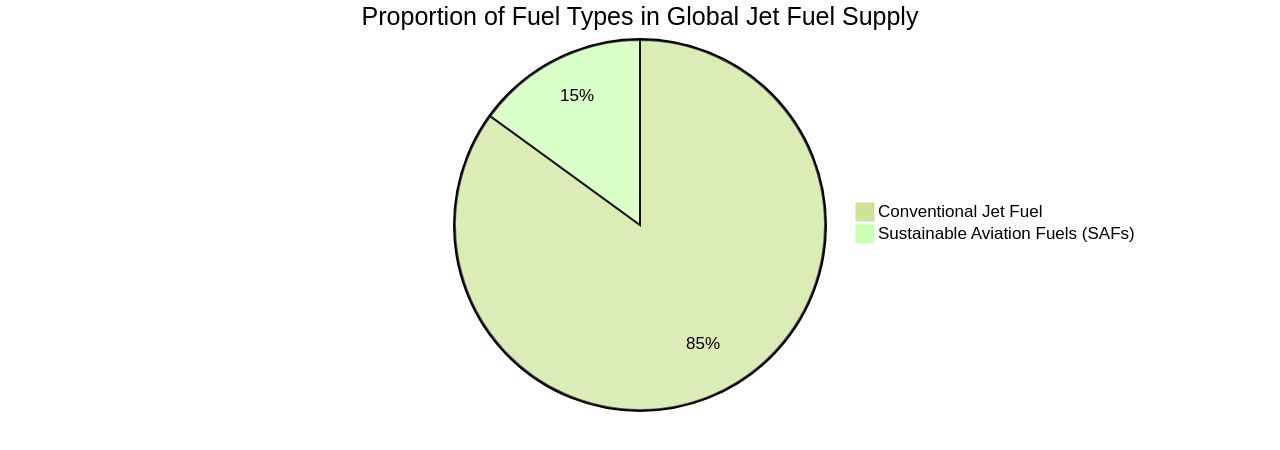

Currently, SAFs only account for less than 0.2% of the global jet fuel supply, highlighting the significant gap in supply and demand. Government support, clear incentives, and advancements in infrastructure are crucial for the economic viability and widespread adoption of SAFs. As the aviation industry looks towards a greener future, the certification and approval processes for SAFs play a vital role in ensuring their safety and quality. Although challenges remain, such as the high cost and limited availability, the potential of SAFs to significantly reduce emissions and improve air quality makes them a promising solution for the aviation industry's decarbonization journey.

Understanding Sustainable Aviation Fuels (SAF)

Sustainable Aviation Fuels (SAFs) are the primary tools for reducing the aviation industry's carbon footprint, which contributes 2-3% of global CO2 emissions. These alternative fuels are derived from renewable feedstocks, such as biomass, waste oils, and agricultural residues.

Despite the infancy of the technology, the International Civil Aviation Organization has set ambitious goals for the industry to achieve net zero carbon emissions by 2050. The production process of SAFs involves refining these feedstocks, purifying them into a clean raw material ready for conversion into fuels.

This process, however, is energy-intensive and expensive, which makes Safe 3-4 times more costly than conventional jet fuel. Despite this, Safe are a crucial component in the aviation industry's pursuit of sustainability.

SAFs are attractive because they require minimal adjustments to existing aircraft engines and infrastructure. Yet, as of 2022, they account for less than 0.2% of the global jet fuel supply, highlighting the significant gap in supply and demand.

This underscores the need for progress in supplying alternative fuels that are beneficial for the climate. Although the production costs and market risks of SAFs deter private investment, government support and clear incentives are vital for their economic viability. Additionally, the infrastructure for distribution and blending with conventional jet fuel requires further development. Lastly, the low aromatic hydrocarbon content in Safe can compromise seal integrity in older aircraft engines, necessitating the development of new, compatible seal technologies. In the coming decades, SAFs are expected to take center stage in the industry's climate progress, as several test flights powered by 100% SAFs have already taken off. However, expanding the supply of SAFs is a significant challenge, and much progress is needed to make these alternative fuels a viable solution for the climate.

The Certification and Approval Process for Sustainable Aviation Fuels

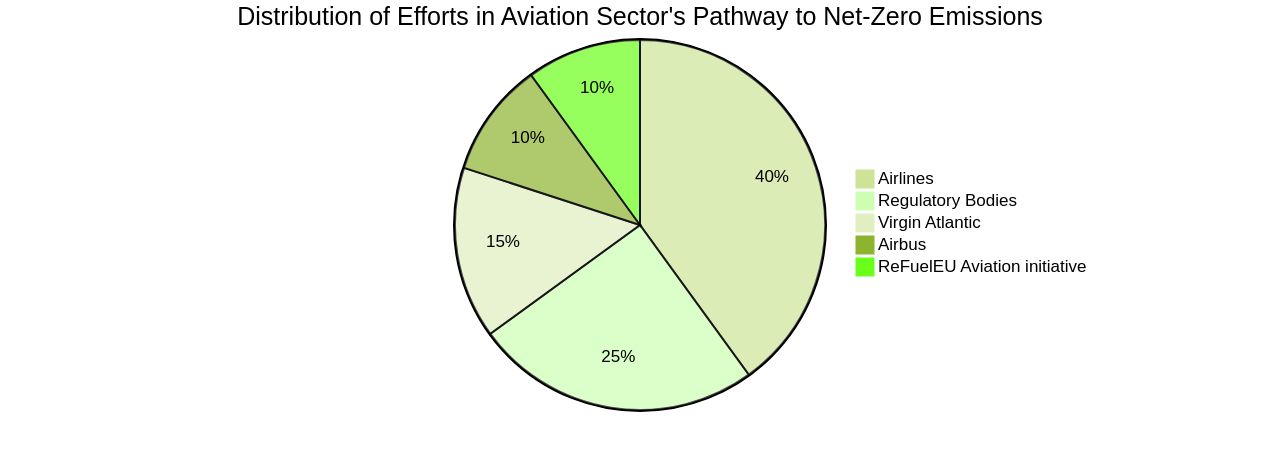

The aviation sector's pathway to achieving net-zero emissions is significantly dependent on the adoption of Sustainable Aviation Fuels (SAFs). Rigorous certification and approval processes ensure that Safe meet the requisite safety and quality benchmarks, encompassing performance evaluation, emissions attributes, and compatibility with the existing infrastructure.

Regulatory bodies like the FAA and ICAO play a crucial role in setting these certification parameters and ensuring the viability and safety of SAFs. Noteworthy progress has been made within the SAF domain, with Virgin Atlantic leading the charge.

The airline showcased the safe utilization of SAF as a drop-in fuel within existing infrastructures, engines, and airframes, and is spearheading an industry consortium to complete the first 100% SAF transatlantic flight. This initiative underscores the urgent need for scaling SAF production, a goal that Virgin Atlantic is actively supporting through widespread collaboration across the energy chain, aiming for commercialization by 2030.

However, the adoption of SAFs is not without challenges. Currently, SAF is three to four times more expensive than conventional fuel, making it not yet viable on a large scale.

To significantly reduce aviation's overall carbon emissions, stakeholders across the industry, including passengers, can contribute by buying extra SAF, which is then added to the fuel system at various airports. Airbus is also contributing to the SAF transition by targeting to make all its aircraft 100% SAF-capable by 2030, reflecting the company's commitment to pioneering sustainable aerospace. In addition, the ReFuelEU Aviation initiative, part of the ‘Fit for 55’ package, is working towards reducing the EU's net greenhouse emissions by at least 55% by 2030 compared to 1990 levels, with a goal of achieving climate neutrality in 2050. In conclusion, the transition to SAFs is a critical step in the aviation industry's decarbonization journey. Industry leaders and regulatory bodies are key players in this transformation, as highlighted by the initiatives from Virgin Atlantic, Airbus, and the ReFuelEU Aviation initiative.

Benefits of Using Sustainable Aviation Fuels to Reduce Emissions

The aviation industry is increasingly leaning towards Sustainable Aviation Fuels (SAFs) as a cornerstone of its ecological conservation strategies. The capability of SAFs to decrease carbon emissions by approximately 80% aligns with the sector's carbon reduction goals, as defined by the International Civil Aviation Organization. SAFs not only lower carbon emissions but also reduce particulate matter production, contributing to improved air quality and health.

This was observed during an experiment at Copenhagen Airport, involving SAS, which showcased SAFs' role in enhancing local air quality and mitigating CO2 emissions and contrails. SAFs, derived from renewable sources like used cooking oil, encourage a transition away from fossil fuel reliance, setting the stage for a more resilient and sustainable future. Despite the challenges associated with the shift to Safe, their potential in decarbonizing the aviation sector is significant.

Currently, SAFs are 3 to 4 times more expensive than conventional jet fuel, mainly due to their limited availability on a large scale. In 2022, SAFs accounted for just 0.2% of the global jet fuel supply, indicating a need for major advancements in the supply of these alternative fuels. Technologies like Unifuel.tech's flexiforming are poised to play a crucial role in overcoming these challenges.

Flexiforming offers the flexibility to decide the pace of decarbonization and can be implemented in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. With an amalgamation of such technological innovations, financial investments, and supportive policies, Safe can significantly reduce the aviation industry's environmental impact. Achieving a greener aviation future is a collective endeavor, and with industry-wide support, it is an attainable goal.

Risks and Challenges in Increasing SAF Uptake: Feedstock Costs, Processing Costs, and Monetization

While the aviation industry, responsible for 2-3% of global CO2 emissions, views Sustainable Aviation Fuel (SAF) as an essential tool in achieving the International Civil Aviation Organization's net-zero carbon emissions objective by 2050, its infancy and high cost have constrained its worldwide adoption, with SAF currently constituting less than 0.1% of global aviation fuel. Issues hindering SAF adoption encompass energy-intensive refining processes and environmental repercussions of procuring feedstocks, such as groundwater depletion and ecosystem degradation.

The price premium of Safe over conventional jet fuel also presents a considerable obstacle. Despite these hurdles, the compatibility of SAF with existing aircraft and infrastructure makes it a potential 'drop-in' solution.

Several initiatives are in progress to finance biofuel technologies, including the Section 9003 program. Yet, these programs often fall short due to restricted funding.

The impending reauthorization of the farm bill provides a chance to modernize these programs, expedite the deployment of advanced biofuels, and position the United States as a bioeconomy hub. Innovation holds the key to reducing costs and enhancing SAF availability.

Various SAF production methods, including deriving it from sunlight and bio-based aromatics, are being investigated. However, large-scale production necessitates substantial investments and regulatory support. Unifuel.tech's Flexiforming technology emerges as a solution here. This technology, which can be integrated into an idle hydrotreater or reformer, reduces both capital expenditure and carbon intensity. Moreover, Unifuel.tech offers to find the optimal application for Flexiforming based on the operator's feeds, target products, and existing facilities, promising to respond to inquiries within 24 hours. Thus, despite existing challenges, technologies like Flexiforming provide a promising pathway to achieving net-zero carbon emissions in the aviation sector by 2050.

Policy Support: The Need for Strong Policy Measures to Shift to Sustainable Aviation Fuels

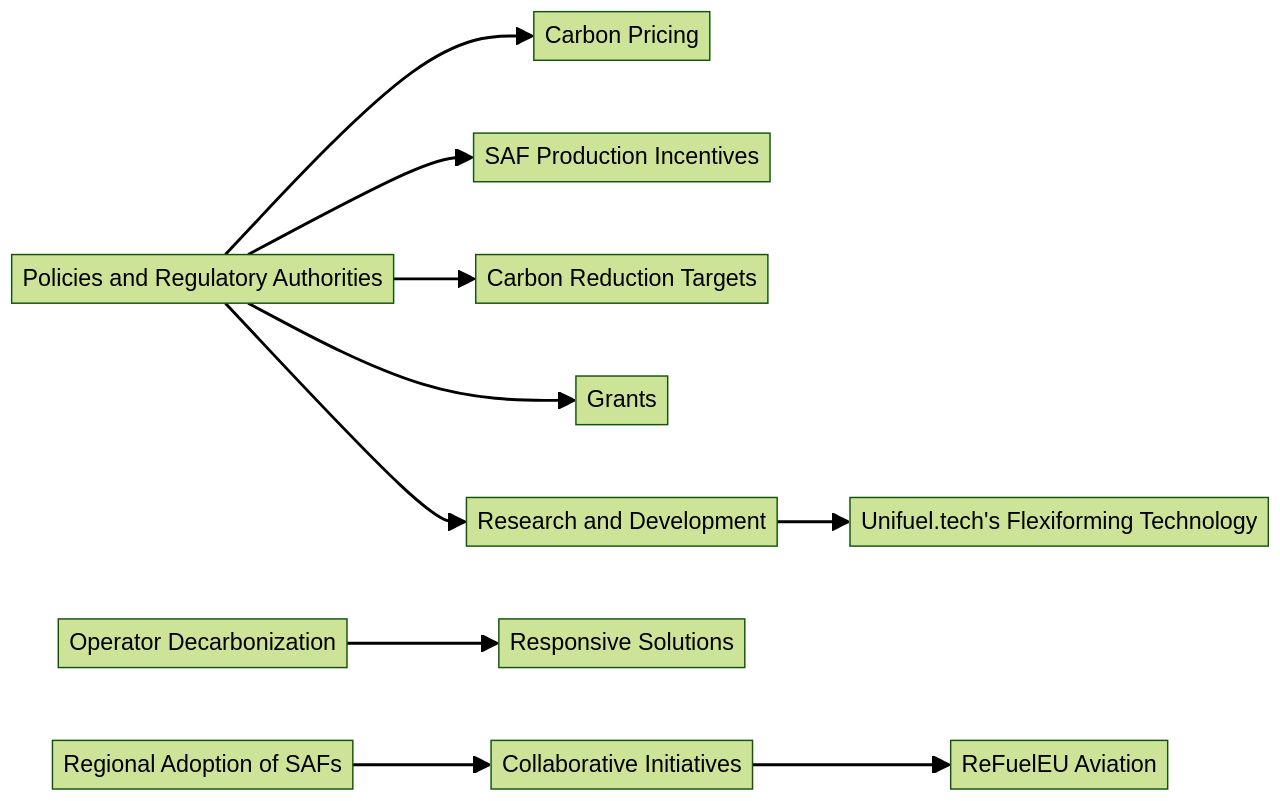

Transitioning towards Sustainable Aviation Fuels (SAFs) is a multifaceted endeavor requiring firm policy support. Regulatory authorities and governments play a pivotal role in fostering an environment favorable for SAF production and use through mechanisms such as carbon pricing, SAF production incentives, ambitious carbon reduction targets, and grants.

Policy initiatives should also stimulate research and development to improve the efficiency and scalability of SAF production technologies. A pertinent example is Unifuel.tech's Flexiforming technology, which can be deployed in idle hydrotreaters or reformers, thus reducing capital expenditure and carbon intensity.

Operators are given the flexibility to choose their speed of decarbonization, which can greatly assist in managing fuel inventory and dealing with market fluctuations. Unifuel.tech's responsive nature, promising to respond to inquiries within 24 hours, further adds to its appeal for operators looking for reliable and cost-effective solutions.

Regional areas such as the Great Lakes and the Rocky Mountains are already leveraging SAF, bringing about transformation in local industries and alignment with environmental objectives. Collaborative initiatives like the Council in Canada are spurring innovation across the SAF value chain, increasing SAF usage. Measures like ReFuelEU Aviation, aiming for significant greenhouse gas emission reductions, herald a new era in aviation. Consequently, policy measures, in tandem with technologies like Flexiforming, can fuel the shift towards a greener aviation industry.

Conclusion

In conclusion, Sustainable Aviation Fuels (SAFs) are crucial for reducing the aviation industry's carbon footprint. Despite their higher cost, SAFs offer minimal adjustments to existing infrastructure, making them an attractive option. However, the current supply of SAFs falls short of demand, necessitating government support and incentives for economic viability and widespread adoption.

Certification processes ensure the safety and quality of SAFs, while industry leaders like Virgin Atlantic and Airbus are driving the transition through initiatives and collaborations. Technologies like Unifuel.tech's Flexiforming show promise in overcoming challenges by reducing costs and improving availability. Policy measures, such as carbon pricing and incentives, are necessary to foster an environment conducive to SAF production and use.

With collective efforts from stakeholders, SAFs have the potential to significantly reduce emissions and improve air quality in the aviation industry. In summary, achieving a greener aviation future requires continued innovation, investment, and policy support. By embracing SAFs, the industry can make a substantial impact on its environmental footprint while maintaining operational efficiency.