Introduction

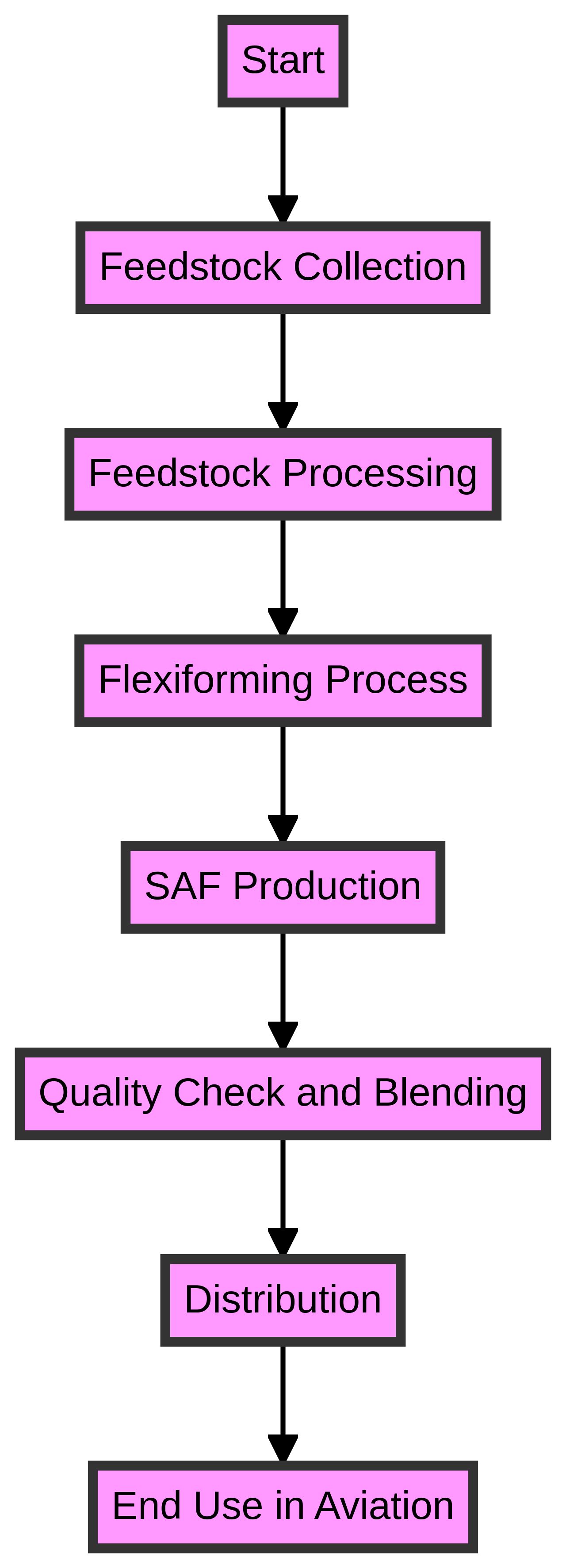

The quest for sustainability in aviation is gaining momentum with technologies like Flexiforming, offered by Unifuel.tech, contributing to the scalability of Sustainable Aviation Fuel (SAF). Flexiforming presents a strategic advantage by enabling the deployment in existing infrastructure such as idle hydrotreaters or reformers.

This adaptability not only mitigates the capital expenditure required for SAF production but also substantially reduces the carbon intensity of the process. As the aviation industry seeks to meet the International Civil Aviation Organization's target for net-zero carbon emissions by 2050, solutions like Flexiforming are instrumental in accelerating the adoption of SAF, ultimately fostering a more sustainable future for global aviation.

The Importance of Sustainable Aviation Fuel in Reducing Environmental Impact

The quest for sustainability in aviation is gaining momentum with technologies like Flexiforming, offered by Unifuel.tech, contributing to the scalability of Sustainable Aviation Fuel (SAF). Flexiforming presents a strategic advantage by enabling the deployment in existing infrastructure such as idle hydrotreaters or reformers. This adaptability not only mitigates the capital expenditure required for SAF production but also substantially reduces the carbon intensity of the process.

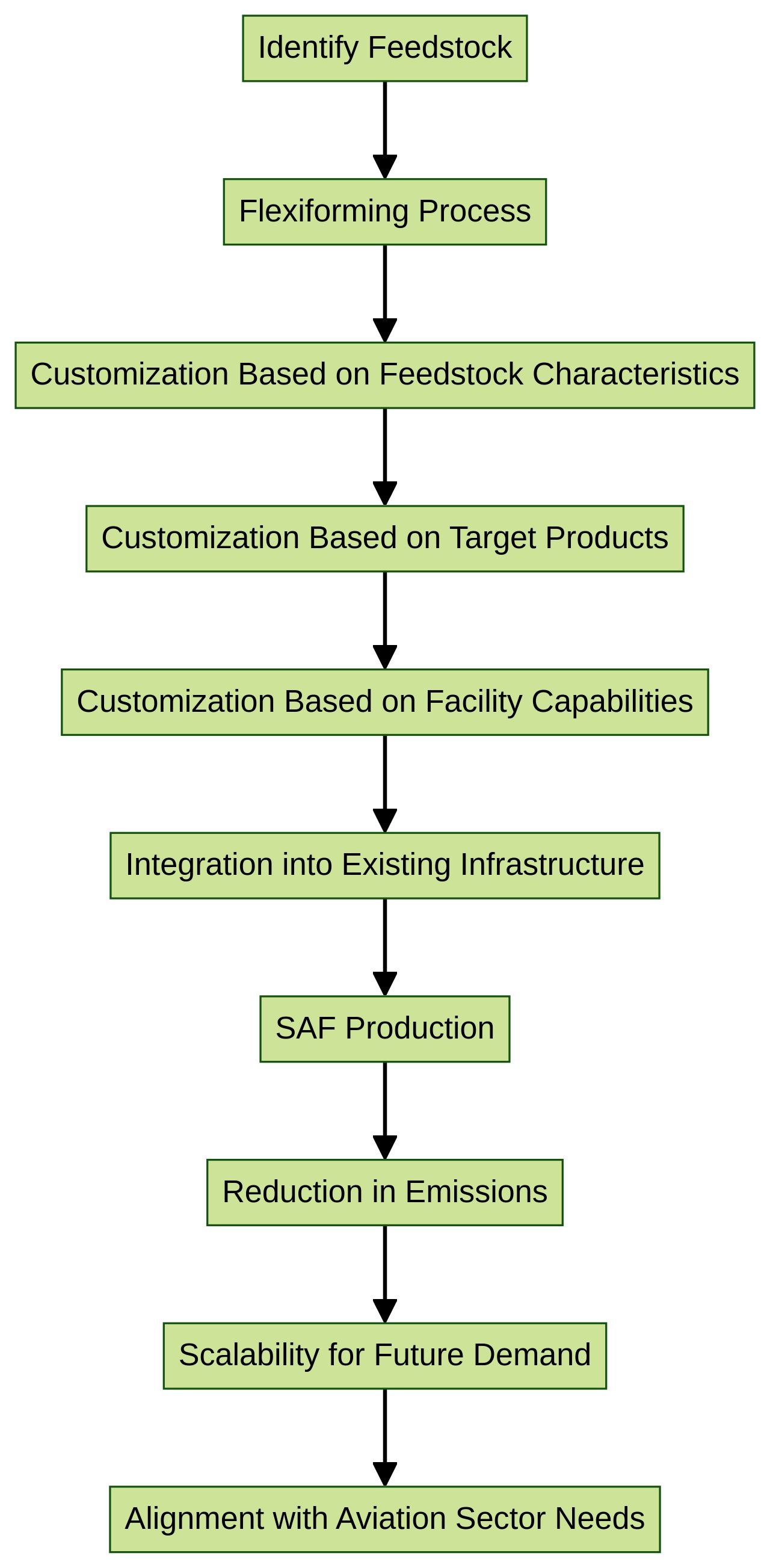

The approach taken by Unifuel. Tech is marked by responsiveness and customization; they commit to acknowledging inquiries within 24 hours, ensuring a swift progression from query to implementation. Furthermore, by analyzing specific customer data pertaining to feeds, target products, and existing facilities, Unifuel.

Tech can tailor the application of Flexiforming to optimize decarbonization pathways. This level of personalized service and the ability to integrate with current setups could play a pivotal role in addressing the affordability challenge of SAF, potentially reducing its cost disparity with conventional jet fuel. As the aviation industry seeks to meet the International Civil Aviation Organization's target for net-zero carbon emissions by 2050, solutions like Flexiforming are instrumental in accelerating the adoption of SAF, ultimately fostering a more sustainable future for global aviation.

Challenges in Meeting Sustainable Aviation Fuel Targets

In the quest to meet stringent decarbonization targets, the SAF industry is exploring innovative solutions to overcome production limitations. One such solution is Flexiforming technology offered by Unifuel.tech, which presents a strategic opportunity to expedite the scale-up of SAF production.

Flexiforming can be seamlessly integrated into existing infrastructure, such as idle hydrotreaters or reformers, thereby reducing the capital expenditure typically associated with scaling new technologies. This approach not only minimizes the carbon intensity of the fuel production process but also supports a more cost-effective transition to SAF.

Given the urgency to expand SAF availability, the ability of Unifuel. Tech to rapidly respond to inquiries and assess the suitability of Flexiforming for specific operational contexts is invaluable.

By analyzing the characteristics of various feedstocks, target products, and facility capabilities, Unifuel. Tech is poised to customize Flexiforming applications, aligning with the diverse needs of the aviation sector. This responsiveness is critical in a market where demand for SAF is escalating and where every step towards carbon-neutral aviation is pivotal. As operators grapple with the dual pressures of environmental regulations and the economic implications of transitioning to SAF, technologies like Flexiforming could play a decisive role in shaping a sustainable path forward for the aviation industry.

Methodology for Quantifying the Impact of Repurposing Existing Manufacturing Facilities

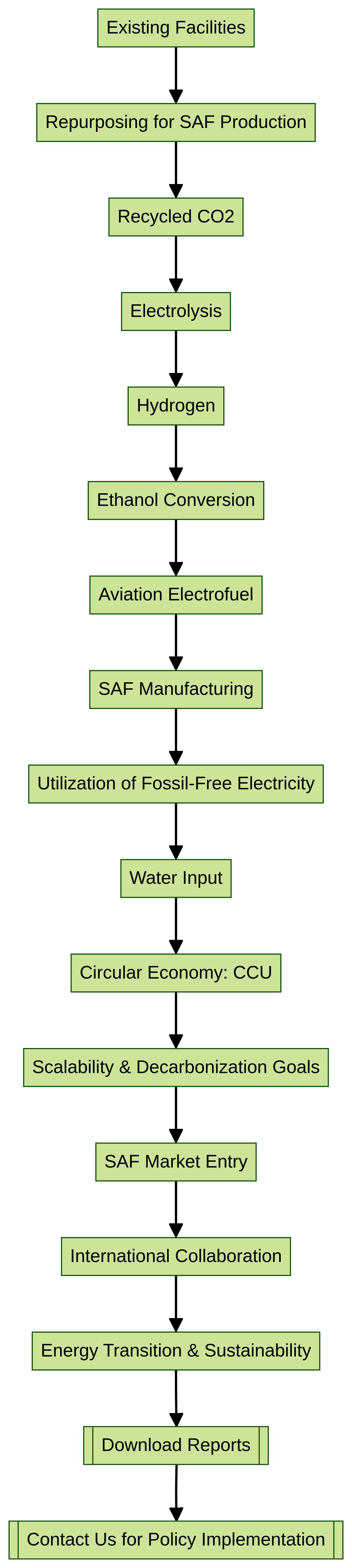

Innovative repurposing strategies are being evaluated for transforming existing facilities, such as pulp and paper mills, into hubs for sustainable aviation fuel (SAF) production. By capitalizing on established infrastructure and expertise, the transition to SAF manufacturing can be expedited, offering a more immediate solution to the aviation industry's decarbonization goals.

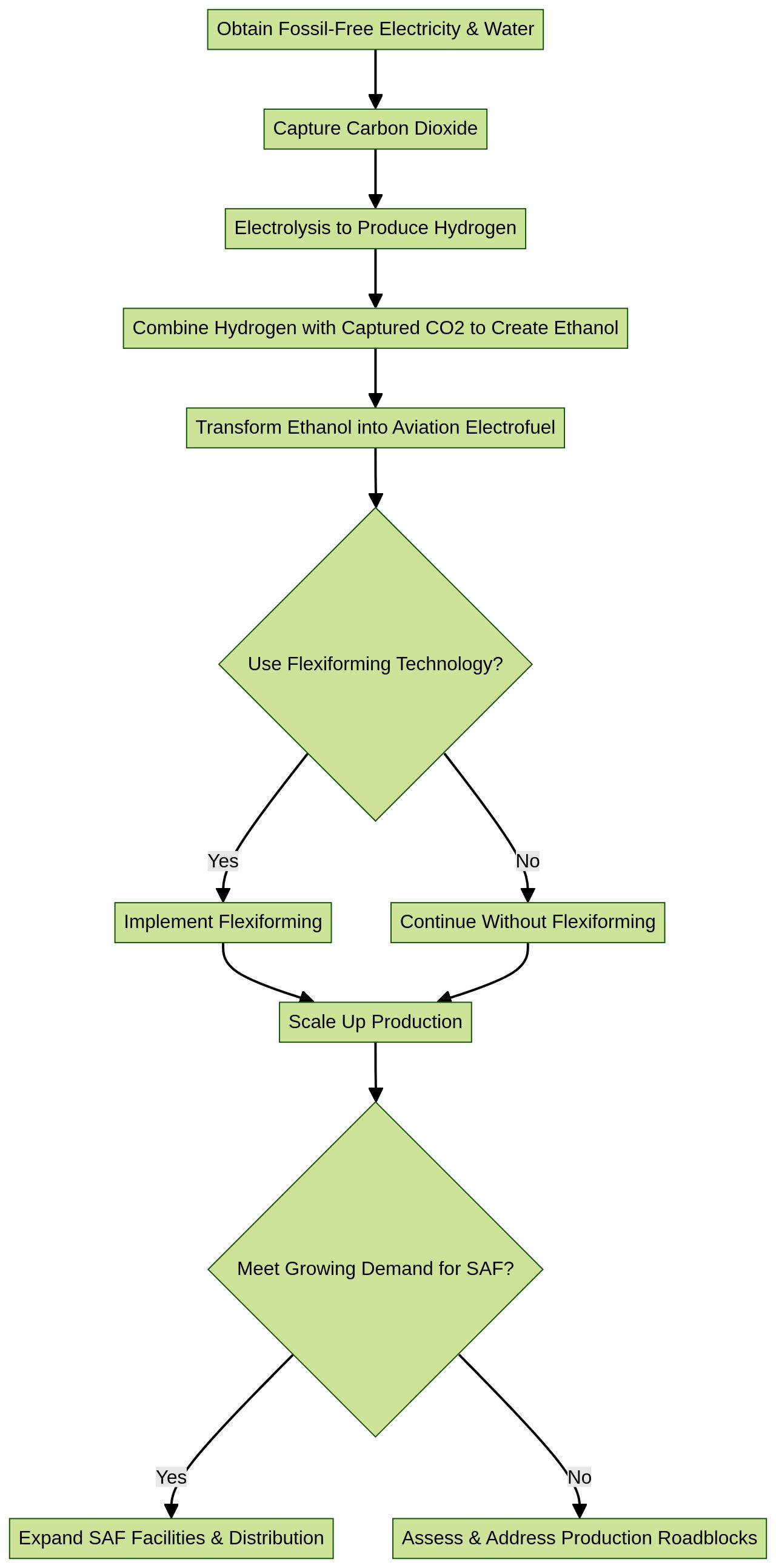

A case in point is a proposed facility near Forsmark, Sweden, which plans to leverage the site's existing grid connection to produce electrofuel—a form of SAF. This electrofuel will be synthesized using fossil-free electricity, water, and recycled carbon dioxide, a carbon capture usage (CCU) approach that underscores the circular economy.

The recycled CO2, sourced from a district heating facility, will be transformed into hydrogen via electrolysis and then converted into ethanol, which is subsequently processed into aviation electrofuel. When utilized in aircraft, the carbon dioxide is used a second time before being released into the atmosphere, thus reducing the lifecycle emissions of the fuel.

The anticipated output of this facility is significant, aiming to fulfill approximately 5% of Sweden's current jet fuel demand and 20% of its projected SAF needs by 2030. This venture is a testament to the potential for existing industrial sites to pivot towards SAF production, which is essential as the US aviation sector, a major emitter, seeks to transition to 100% SAF by 2050.

The scalability of such endeavors is critical, as demonstrated by companies like Twelve, which, with the backing of Alaska Airlines and Microsoft, aims to increase its SAF production from an initial 40,000 gallons to 1 million gallons annually. While global airlines consumed 95 billion gallons of jet fuel in 2019, current SAF production methods—such as those using used cooking oil—have limited growth potential, emphasizing the need for innovative production techniques like electrofuel. In line with these innovative approaches, Unifuel. Tech offers a technology called Flexiforming, which can be integrated into existing facilities, such as idle hydrotreaters or reformers, to produce SAF. This technology not only allows operators to control the speed of their decarbonization efforts but also reduces capital expenditures and carbon intensity. Unifuel.tech's responsive approach to inquiries and their request for specific information about feeds, target products, and existing infrastructure ensures a tailored application of Flexiforming, aligning with the industry's push towards efficient and scalable SAF production.

Case Study: Repurposing Pulp and Paper Facilities for Sustainable Aviation Fuel Production

The implementation of sustainable aviation fuel (SAF) production is a critical step towards decarbonizing the aviation industry. A project underway in Sweden exemplifies this initiative, utilizing electrofuel—a category of SAF produced through a carbon-neutral process. This innovative approach employs fossil-free electricity, water, and recycled carbon dioxide, avoiding the use of virgin fossil feedstocks.

The planned facility, slated to begin operations around 2030, will leverage the existing infrastructure of the Forsmark nuclear power plant to obtain the necessary electricity. The process involves electrolysis to produce hydrogen, which is then combined with captured carbon dioxide to create ethanol, ultimately transforming into aviation electrofuel. This carbon capture usage (CCU) strategy is a pivotal component in reducing the aviation sector's carbon footprint, although the exact percentage of emission reduction is yet to be determined.

In parallel, Fulcrum's expansion into the UK market, following its success in the United States, underscores the global momentum towards SAF adoption. The project, significantly bolstered by a UK Government Grant, encompasses comprehensive engineering and planning efforts to facilitate the transition to a net-zero transport fuel economy. The annual output of 80,000 tons of SAF from the Swedish project is projected to satisfy 5% of Sweden's current jet fuel demand and 20% of its anticipated needs by 2030, marking a substantial stride in meeting industry requirements.

However, the challenge remains in scaling up production to meet the burgeoning demand for SAF, which is currently limited and can cost substantially more than conventional jet fuel. To address this, Unifuel. Tech introduces Flexiforming technology, which presents a scalable and economically viable pathway for SAF production.

By integrating Flexiforming into existing infrastructure, such as idle hydrotreaters or reformers, operators can significantly reduce capital expenditures and carbon intensity. This flexibility allows for a tailored approach to decarbonization, aligning with the variable production capacities and market demands. Unifuel.tech's commitment to swift communication and collaboration ensures operators can rapidly identify and implement the optimal Flexiforming application, thereby accelerating the SAF production ramp-up needed to meet future fuel requirements.

Conclusion

In conclusion, Unifuel.tech's Flexiforming technology offers a strategic advantage in the production of Sustainable Aviation Fuel (SAF). By leveraging existing infrastructure, such as idle hydrotreaters or reformers, Flexiforming enables scalable SAF production with reduced capital expenditure and carbon intensity. This adaptability addresses the affordability challenge of SAF, accelerating its adoption and fostering a more sustainable future for global aviation.

Unifuel.tech's responsive approach and customization capabilities ensure tailored applications of Flexiforming, optimizing decarbonization pathways to meet specific operational contexts. This personalized service bridges the cost gap between SAF and conventional jet fuel, making SAF more economically viable. Repurposing existing manufacturing facilities is also a promising avenue for SAF production.

Projects like the one in Sweden showcase the transformation of established sites into hubs for SAF production. Through innovative processes like electrofuel production using renewable resources, these facilities contribute to reducing lifecycle emissions of aviation fuel. Unifuel.tech's Flexiforming technology aligns with the industry's push towards efficient and scalable SAF production.

Their responsive approach and integration with existing infrastructure allow operators to control decarbonization efforts while reducing capital expenditures and carbon intensity. Overall, solutions like Flexiforming and repurposing existing facilities play a pivotal role in accelerating the adoption of Sustainable Aviation Fuel. They address the affordability challenge, drive decarbonization efforts, and pave the way for a more sustainable future in global aviation.