Introduction

The global aviation industry is increasingly turning to sustainable aviation fuels (SAF) as a means to reduce emissions and achieve decarbonization. With the limitations of electrification and alternative fuels, SAF derived from various carbon sources present a compelling alternative.

However, challenges in affordability, sustainability, and production scale need to be addressed. This article explores the government research, academic studies, optimization techniques, and environmental impact of sustainable jet fuel production. It also highlights the role of Flexiforming technology in the decarbonization process and the commitment of industry leaders such as Virgin Atlantic and Bank of America to sustainable business travel.

Government Research on Sustainable Jet Fuel Production

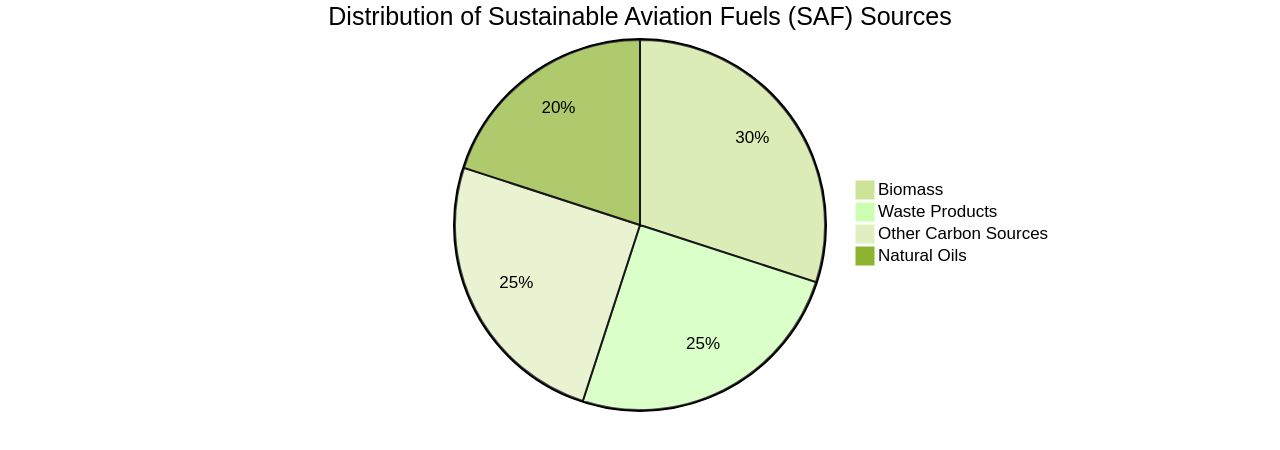

As the global energy system faces volatility, the aviation industry is increasingly turning to sustainable aviation fuels (SAF) for emissions reduction. With electrification and alternative fuels such as green hydrogen not yet viable for long-haul flights, SAF derived from biomass, waste products, natural oils, and other carbon sources present a compelling alternative. Although SAFs are capable of reducing carbon emissions by 60 to 100 percent compared to conventional jet fuels, the industry confronts challenges in affordability, sustainability, and production scale.

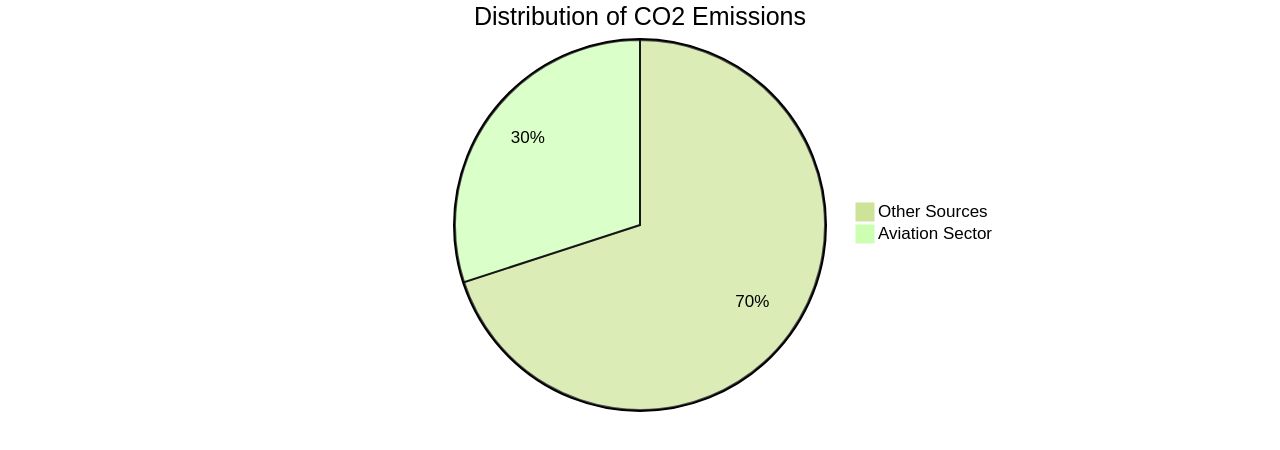

Australian initiatives indicate a promising domestic SAF industry leveraging local feedstocks, yet supply chain constraints and regulatory standards pose hurdles to be addressed. These renewable fuels are not only essential for reducing the industry's carbon footprint, which accounts for 2 to 3 percent of global emissions, but also for supporting the International Civil Aviation Organization's goal of net-zero carbon emissions by 2050. However, current planned production capacity for Safe falls short of the growing demand, necessitating a surge in investments and supportive policies.

The recent Virgin Atlantic flight, powered entirely by SAF, underscores the practical viability of these fuels in existing jet engines. With advancements such as Unifuel.tech's flexiforming technology, the industry can accelerate the decarbonization process, adapting to variable feedstocks and integrating into existing infrastructure with minimal modifications. Flex forming, a technology that can be implemented in an idle hydrotreater or reformer, offers operators the flexibility to choose their speed of decarbonization while reducing capital expenditures and carbon intensity.

Unifuel. Tech provides a responsive service, aiming to address inquiries within 24 hours and assist in finding the optimal application for flexiforming based on the user's feeds, target products, and existing facilities. This innovation, alongside increased global uptake and strategic collaborations like the Aviation Impact accelerator and Supergen Bioenergy Hub, positions SAF as a pivotal component in the aviation sector's sustainability trajectory.

Academic Studies on Sustainable Jet Fuel and Flexiforming

The Flexiforming technology, pioneered by Unifuel.tech, is making significant strides in the production of sustainable aviation fuel (SAF), offering a path to decarbonize the aviation sector. As aviation contributes approximately 2% to global carbon emissions, the integration of Flexiforming into existing infrastructure like idle hydrotreaters or reformers presents an opportunity to curb capital expenditure while reducing carbon intensity.

This innovation is critical as the sector moves toward eco-friendly alternatives to meet the rising demand for SAF and address environmental concerns. The versatility of Flexiforming allows operators to tailor the pace of their decarbonization efforts.

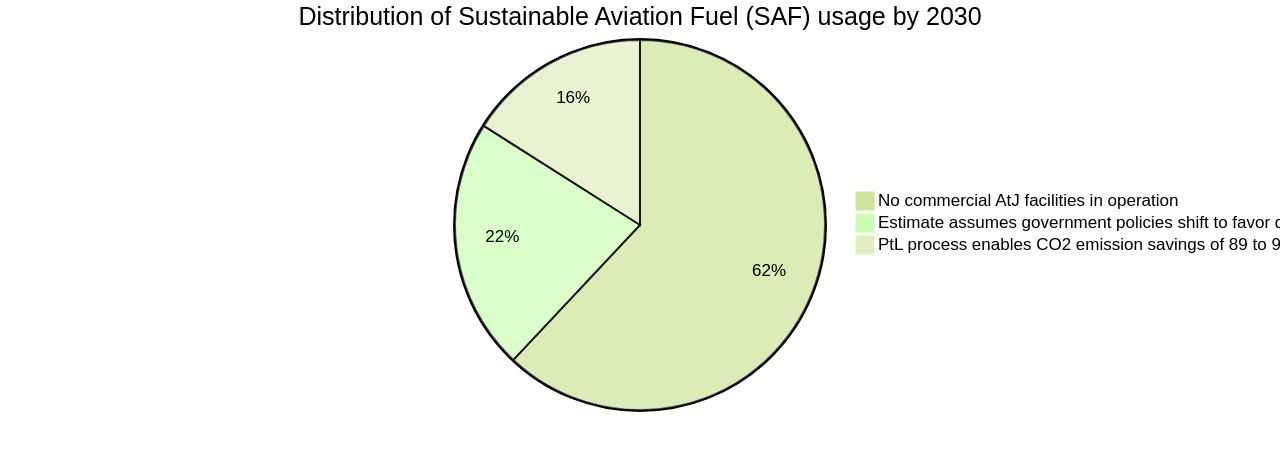

By 2030, this technology is expected to make a substantial impact on Sweden's SAF requirements, aligning with the broader goal to reduce CO2 emissions. However, the transition to SAF is not without its obstacles, such as the need for enhanced distribution and blending infrastructure.

Additionally, the low aromatic hydrocarbon content in SAF could affect seal integrity in older aircraft engines, highlighting the necessity for advancements in seal technologies. Virgin Atlantic's recent Flight100, powered entirely by SAF, exemplifies the industry's commitment to decarbonization and the feasibility of SAF as a direct substitute for fossil-derived jet fuel.

This milestone underscores the urgent need for increased SAF production and investment, backed by regulatory support to achieve scale. With a target of 10% SAF usage by 2030 and plans for the first commercial synthetic kerosene factory in Amsterdam, Flexiforming is poised to be instrumental in helping European aviation companies transition to synthetic SAF by 2050. This shift promises not only environmental benefits but also economic advantages by reducing oil import dependence and supply risks. Unifuel.tech, a subsidiary of Universal Fuel Technologies, is at the forefront of Flexiforming application, customizing the technology to suit operators' specific feedstock, product targets, and facility capabilities. Unifuel.tech's commitment to responsive customer service within 24 hours and their readiness to provide optimal applications based on the operator's requirements underscore their leading position in the field of SAF production technologies.

Optimization Techniques for Sustainable Renewable Jet Fuel Production

Flexiforming technology is revolutionizing the production of sustainable aviation fuel (SAF), a critical component in the aviation industry's quest for decarbonization. By synthesizing fuel from carbon dioxide and green hydrogen, flexiforming leverages advanced algorithms and models to optimize SAF yield, ensuring that the environmental impact and energy usage are minimized.

The process intricacies, such as feedstock selection and system efficiency, are carefully managed to create a fuel that aligns with the stringent specifications of jet fuel. The aviation sector, currently responsible for approximately 2% of global carbon emissions, is actively seeking greener alternatives to conventional jet fuel.

The digital twin technology, employed by companies like ORLEN in partnership with Yokogawa, exemplifies the industry's commitment to environmental sustainability. This virtual replica of the production facility enables the fine-tuning of the synthesis process, ensuring that the most economically viable and environmentally sustainable methods are employed.

ORLEN's goal to produce 70 thousand tons of synthetic fuels annually by 2030 underscores the industry's dedication to this initiative. These synthetic fuels boast properties nearly identical to their fossil fuel counterparts, allowing them to be used with existing aircraft without modifications.

This compatibility is crucial, as the global aviation infrastructure, including fueling systems, is designed around these specifications. The challenge, however, is not insignificant.

Aviation fuel regulations are stringent, ensuring safety and reliability for aircraft operations. SAF must meet these standards to be viable. With the development of catalysts that can convert ethanol into components suitable for aviation fuel, researchers are paving the way for fuels that can be seamlessly integrated into the current system. Unifuel.tech's flexiforming technology represents a promising solution, offering operators the ability to control their decarbonization rate while utilizing existing infrastructure. The technology's implementation in idle hydrotreaters or reformers illustrates how innovation can reduce both capital expenditure and carbon intensity. As the industry navigates the complexities of adopting SAF, continued research and development are essential for achieving significant reductions in the aviation industry's carbon footprint.

Environmental Impact of Sustainable Aviation Fuels

Flexiforming technology stands at the forefront of producing Sustainable Aviation Fuel (SAF), a critical component in the aviation industry's journey towards decarbonization. With the capability to convert renewable feedstocks into SAF, Flexiforming presents a promising solution to the pressing challenge of reducing greenhouse gas emissions.

The technology is instrumental in enabling a transition from fossil fuels, thus bolstering the industry's sustainability efforts. Recent case studies highlight the urgency of this shift, with Sweden's planned SAF output aimed at meeting a significant portion of its jet fuel demand by 2030, emphasizing the need for increased production and adoption of SAF to achieve substantial carbon dioxide emission reductions.

However, the current production levels of SAF are insufficient to make a marked impact on global aviation emissions, with costs remaining a significant barrier to widespread use. Despite these challenges, aviation giants like Airbus are working towards making their fleets 100% SAF-capable within this decade, signifying robust industry support for SAF as the path to net-zero emissions by 2050.

Innovative partnerships are emerging to scale up SAF production, as evidenced by the collaborative efforts in Germany to establish production capacities for eSAF based on green hydrogen. These initiatives aim to make aviation climate-neutral by mid-century and underline Germany's pivotal role in advancing sustainable aviation technologies.

The anticipated production of eSAF could lead to a considerable reduction in CO2 emissions, with potential facilities strategically located to serve key airports efficiently. Furthermore, the development of 'digital twins' for production facilities underscores the industry's commitment to optimizing economic and environmental outcomes in the synthesis of synthetic fuels.

Such advancements in SAF technology and infrastructure are vital to achieving the aviation industry's ambitious decarbonization targets, with Flexiforming playing a central role in this transformative endeavor. Universal Fuel Technologies' Unifuel. Tech provides a strategic advantage in this context, offering a tailored approach to SAF production. Their Flexiforming technology allows for adaptation to existing infrastructure, such as idle hydrotreaters or reformers, reducing both capital expenditure and carbon intensity. This adaptability enables operators to tailor their decarbonization pace effectively. With a commitment to responsive customer service, Unifuel. Tech ensures queries are addressed within 24 hours, facilitating a seamless integration process for clients seeking to optimize their feedstock and product targets within their facilities.

Case Study: Bank of America and Sustainable Business Travel

The aviation industry, which contributes approximately 2-3% of global CO2 emissions, is in the midst of a transformative shift towards sustainability. Virgin Atlantic, a front-runner in the sector, is spearheading this change with ambitious goals, including a Net Zero target by 2050.

Demonstrating its commitment, Virgin Atlantic has realized a 35% reduction in absolute emissions over the past decade. The integration of fuel-efficient A330-900neos into its fleet and the planned 100% sustainable aviation fuel (SAF) transatlantic flight in 2023 are concrete steps towards this commitment.

These initiatives highlight the viability of SAF as a compatible fuel with existing aviation infrastructure. However, expanding SAF production to meet the industry's growing demand remains a significant hurdle.

Recognizing this, solutions like Flexiforming technology by Unifuel. Tech present a path forward, leveraging existing refinery assets to lower both capital costs and carbon intensity.

Such innovations are vital as the industry navigates towards decarbonization, and as Sir Richard Branson of Virgin Atlantic aptly puts it, embody the spirit of innovation that propels the sector forward. Despite these advances, the industry faces challenges in scaling up SAF production.

As per recent statistics, alternative fuels constituted less than 0.2% of the global jet fuel supply in 2022, emphasizing the need for drastic progress. Sir Richard Branson's vision of innovation and the UK Transport Secretary's endorsement of the historic 100% SAF-powered flight underscore the industry's commitment to decarbonization. Similarly, Airbus's goal to make all aircraft 100% SAF-capable by 2030 and Emirates' partnership reflect the collective effort to advance the SAF market. The success of Flight100, as stated by Virgin Atlantic's CEO, proves Saf's potential as a drop-in replacement for fossil-derived jet fuel and calls for increased investment and regulatory support for large-scale production. Unifuel.tech's Flexiforming technology facilitates this transition by enabling operators to retrofit idle hydrotreaters or reformers, thus accelerating the pace of decarbonization without incurring prohibitive costs. The company's promptness in addressing inquiries and providing tailored solutions underscores their commitment to advancing SAF technology and its accessibility for the aviation industry.

Conclusion

The global recognition of sustainable jet fuel's importance in environmental strategies is growing. Unifuel.tech's flexiforming technology offers a potential solution to challenges in sustainable jet fuel production, enabling operators to control their decarbonization pace while reducing capital expenditure and carbon intensity. Sustainable aviation fuels (SAF), derived from biomass and waste products, deliver the same performance as petroleum-based jet fuel but with a significantly reduced carbon footprint.

However, hurdles persist regarding affordability, sustainability, competition for feedstocks, and economically efficient production scales. Unifuel.tech's flexiforming technology can be implemented in idle hydrotreaters or reformers, reducing both capital expenditure and carbon intensity. The company provides tailored solutions and responsive customer service to meet customers' specific needs.

Optimization techniques play a crucial role in sustainable renewable jet fuel production through flexiforming. These techniques increase SAF yield while minimizing environmental impact and energy usage. Sustainable aviation fuels significantly reduce greenhouse gas emissions compared to traditional jet fuels.

They employ renewable feedstocks that ease pressure on limited resources and lessen dependency on fossil fuels. Unifuel.tech's flexiforming technology allows operators to control their decarbonization rate while reducing capital expenditure and carbon intensity. The company's commitment to responsive customer service ensures quick responses to inquiries about feeds, target products, and existing facilities.

In conclusion, Unifuel.tech's flexiforming technology holds great promise in addressing the challenges faced in sustainable jet fuel production. It offers a scalable solution for operators to control their decarbonization pace while reducing costs and environmental impact. With continued advancements and industry collaboration, the aviation sector can achieve significant reductions in its carbon footprint and move towards a more sustainable future.