Introduction

The aviation industry is undergoing a significant shift towards sustainability, with a focus on Sustainable Aviation Fuel (SAF) to reduce greenhouse gas emissions. However, the widespread adoption of SAFs faces challenges such as limited production, high costs, and feedstock competition.

In this article, we explore the current status, advantages and disadvantages, feedstock options, production pathways, storage and transportation, case studies, economic and environmental analysis, future prospects, and challenges of SAFs. We will also discuss innovative solutions like flexiforming technology offered by Unifuel.tech, which aims to optimize SAF production. Join us as we delve into the technical insights and analysis of the renewable fuels industry.

Current Status of Sustainable Aviation Fuel

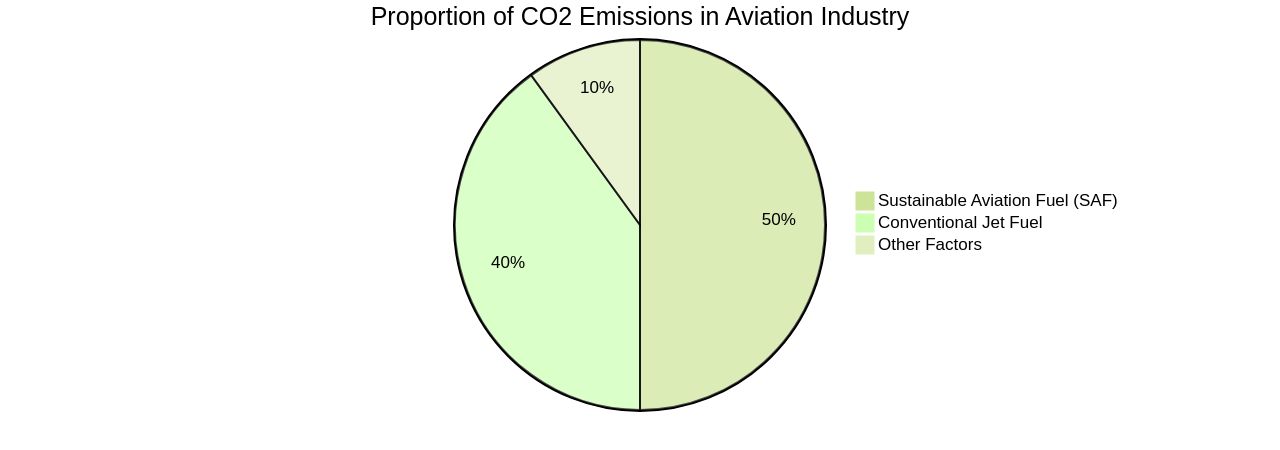

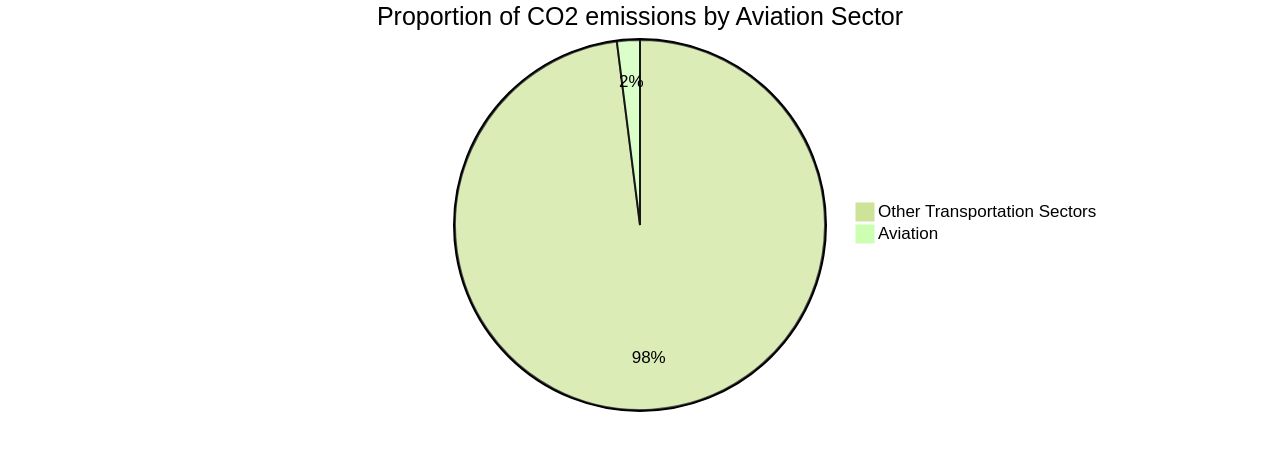

The aviation industry, which contributes to 2.5% of global CO2 emissions, is undergoing a significant shift toward sustainability. The spotlight is now on Sustainable Aviation Fuel (SAF), an innovative technology aimed at reducing greenhouse gas emissions from aircraft.

SAFs, biofuels sourced from diverse feedstocks such as plant oils, agricultural waste, and municipal refuse, offer the potential to help airlines and their corporate clients achieve their carbon neutrality objectives. In spite of the infancy of the technology and the cost being three to five times higher than conventional jet fuel, the International Civil Aviation Organization (ICAO) has established ambitious net-zero carbon emission targets for the aviation industry by 2050.

Under ICAO's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), the aim is to cut aviation's CO2 emissions by half by 2050. Achieving these targets necessitates substantial efforts in research and development, as well as commercial production and global adoption of SAFs.

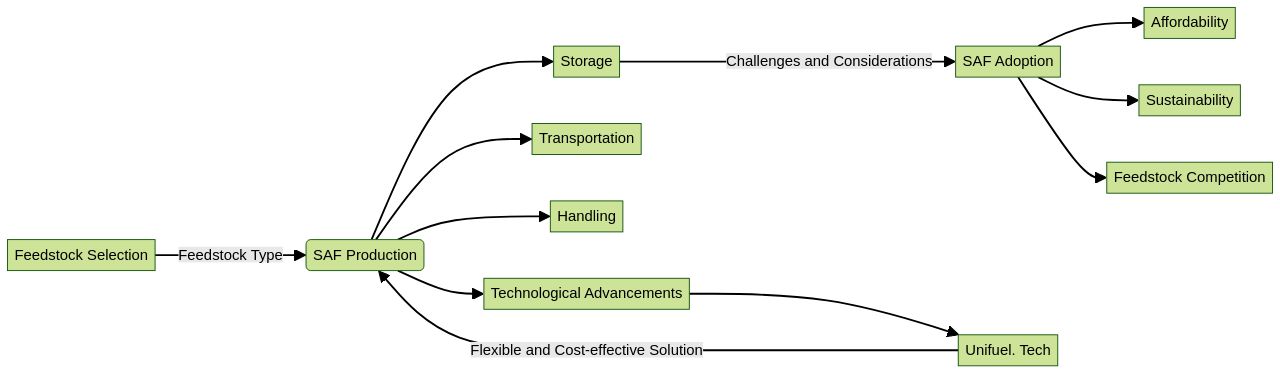

In this context, companies like Unifuel.tech are stepping in with solutions like flexiforming. This technology, which can be installed in a dormant hydrotreater or reformer, helps reduce both capital expenditure and carbon intensity.

By analyzing information about the operator's feeds, target products, and existing facilities, Unifuel. Tech can determine an optimal application for flexiforming. The future of SAFs could be further bolstered by advancements in alternative fuel sources, as demonstrated by a transatlantic flight powered by sugar and fat. However, the widespread adoption of SAFs is not without challenges. For example, in the U.S., sustainable fuel production has only met less than 0.2% of the airline industry’s fuel requirements in the past year. As the sector transitions to Safe and potentially to electric and hydrogen-fueled planes in the long term, stakeholders will be confronted with the complex task of decarbonizing this vital service while ensuring its ongoing growth and prosperity.

Advantages and Disadvantages of Bio-aviation Fuel (BAF)

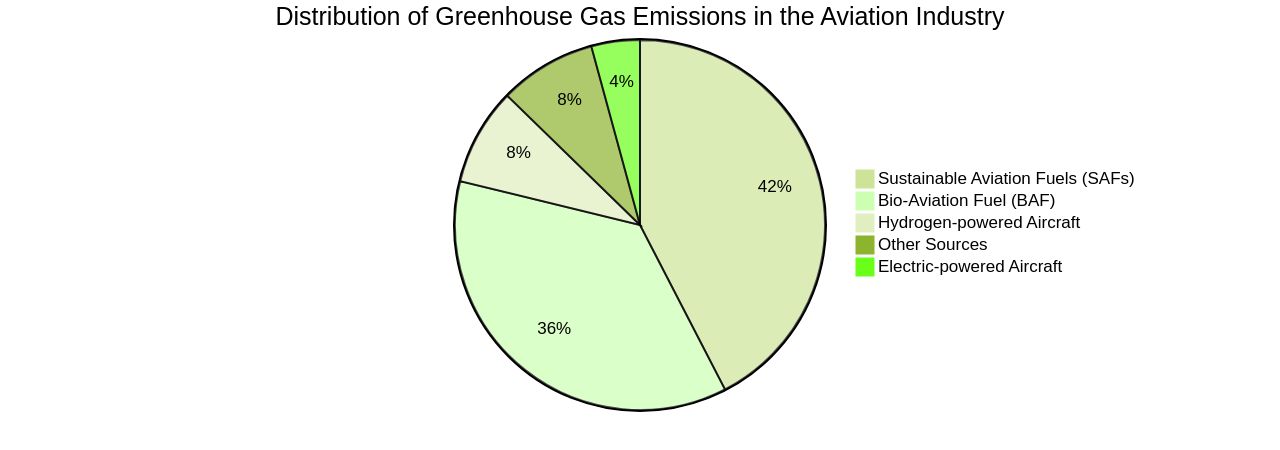

The aviation industry, responsible for approximately 2.5% of total worldwide emissions, urgently requires effective measures to reduce its greenhouse gas footprint. Bio-aviation fuel (BAF) is a potential solution, offering substantial carbon dioxide reductions and compatibility with existing aviation engines and infrastructure, negating the need for costly fleet modifications.

However, BAF also presents challenges, including feedstock availability, high production costs, and land use and food security issues. In spite of these hurdles, sustainable aviation fuels (SAFs) present an immediate and practical solution in harmony with current aircraft.

Importantly, technological advancements have facilitated the production of bio-based aromatics for aviation. Unifuel.tech's Flexiforming technology, for example, allows operators to control their decarbonization speed, minimizing both capital expenditure and carbon intensity.

Flexiforming can be deployed in an idle hydrotreater or reformer, further reducing costs and environmental impact. However, to fully decarbonize, the sector must also investigate other technologies, such as hydrogen and electric-powered aircraft. While SAFs currently constitute less than 0.2% of the global jet fuel supply, it is expected that SAFs will represent the majority of the industry’s climate solutions in the forthcoming decades. Consequently, increasing the SAF supply is a vital challenge that must be addressed.

Feedstock for Bio-aviation Fuel Production

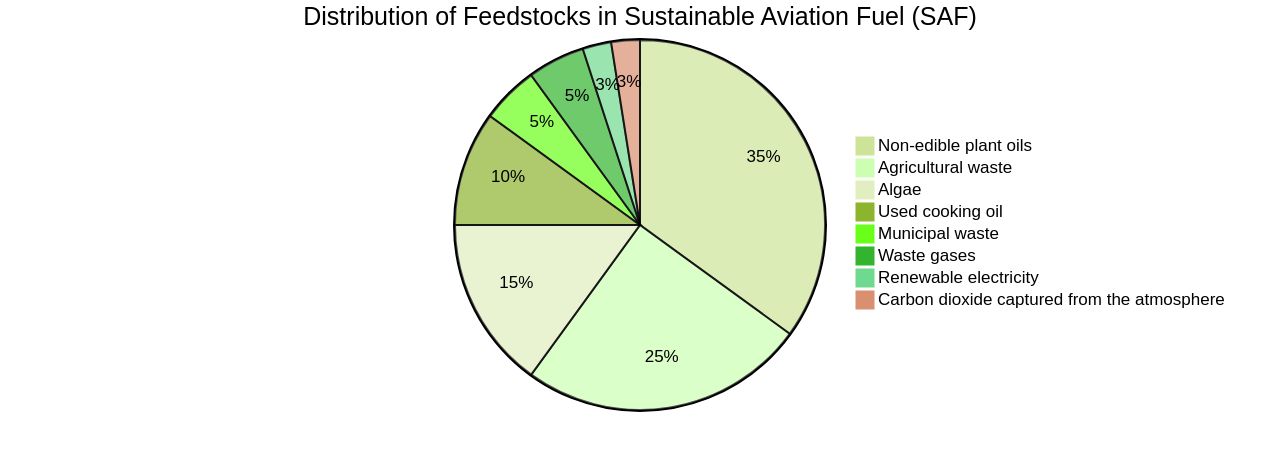

The path to a sustainable aviation future is paved with the production and utilization of Sustainable Aviation Fuel (SAF). This renewable energy source harnesses a variety of feedstocks, such as non-edible plant oils, agricultural waste, and even algae.

The choice of these feedstocks hinges on their availability, sustainability, and potential for large-scale production, with regional factors like climate, soil conditions, and land availability playing a significant role. The aviation industry's pledge to reduce emissions, along with the difficulties associated with electrification or alternative fuels like green hydrogen for long-haul flights, renders the use of biofuels crucial.

However, despite the soaring demand for SAF in regions like Europe, the UK, and the USA, the restricted global production has led to a supply-demand gap. Countries like Australia, a significant exporter of biofuel feedstocks, can aid in bridging this gap by diversifying feedstock sources and amplifying SAF production.

Moreover, the recent introduction of a process that yields bio-based aromatics has opened the doors for using larger volumes of SAF, including 100% SAF in aircraft. This discovery is a turning point for the aviation industry, providing a feasible solution for decarbonizing global aviation without drastic alterations to global aircraft fleets, airports, and fueling infrastructure.

The solution to these challenges lies in technologies like Flexiforming, developed by Unifuel.tech. This technology allows operators to select their speed of decarbonization and can be deployed in an idle hydrotreater or reformer, reducing capital expenditure and carbon intensity. However, the affordability and sustainability of SAF, competition for feedstocks, and the necessity for economically efficient production scales remain as hurdles that the industry needs to overcome. The sheer volume of biomass required to power a fuel-intensive industry like aviation is another significant challenge. Nevertheless, the use of SAF is a stride towards a greener future for the aviation industry. The ongoing research and development in this sector, coupled with the commitment of industry stakeholders, is key to surmounting these hurdles and achieving a sustainable aviation future.

Production Pathways for Bio-aviation Fuel

The production of bio-aviation fuel is an intricate process, involving methods such as hydrotreating, Fischer-Tropsch synthesis, and alcohol-to-jet processes. With the goal of reducing carbon emissions, Electrofuel has emerged as a notable advancement, utilizing captured carbon dioxide from district heating facilities.

The aviation sector, however, still grapples with challenges in achieving emission reduction commitments. Electrification and alternative fuels like green hydrogen are not yet feasible options, particularly for long-haul segments.

As a result, the industry must lean on sustainable aviation fuels (SAFs) derived from various feedstocks. Yet, with global production limited, the demand for Safe is expected to outstrip supply, leading to concerns about affordability and sustainability.

A recent breakthrough in the production of bio-based aromatics has enabled the use of greater volumes of SAFs in aircraft, even up to 100%. This 'drop-in' solution is a practical approach to decarbonizing global aviation without the need for extensive modifications to aircraft fleets, airports, and fueling infrastructure.

In this landscape, Flexiforming, a technology developed by Unifuel.tech, emerges as a promising solution. It provides operators the flexibility to dictate their pace of decarbonization, and can be implemented in an idle hydrotreater or reformer, reducing capital expenditure and carbon intensity. With responsive customer service and a request for information about the operator's feeds, target products, and existing facilities, Unifuel. Tech aims to find the optimal application for Flexiforming. This innovative approach may well lay the groundwork for the future of SAFs.

Storage and Transportation of Bio-aviation Fuel

The aviation industry's commitment to carbon emission reduction has led to a spotlight on sustainable aviation fuel (SAF). Derived from various feedstocks like biomass, waste products, and natural oils, SAF provides a viable pathway to decarbonization. Unlike alternatives such as hydrogen, SAF requires minimal changes to existing fleets and fueling infrastructure, making it a practical 'drop-in' solution.

The need for a robust SAF infrastructure is critical, covering production, storage, transportation, and handling. Existing storage tanks can hold SAF with precautions to prevent contamination. Similarly, SAF transportation requires modifications to prevent cross-contamination with conventional fuel.

Dedicated supply chains are also essential for widespread SAF adoption. SAF's promise is reinforced by the industry's dedication to emission reduction. For instance, electrofuel, a type of SAF, uses fossil-free electricity, water, and recycled CO2, resulting in no new fossil CO2 emissions, highlighting SAF's inherent sustainability.

Yet, challenges remain. Even with aggressive adoption timelines, demand may outstrip limited global production. Questions about affordability, sustainability, and feedstock competition linger.

However, with industry efforts and technological advancements, the future looks promising. One such advancement is Unifuel. Tech by Universal Fuel Technologies.

This technology enables operators to choose their decarbonization pace and can be deployed in idle hydrotreaters or reformers, reducing capital expenditure and carbon intensity. By providing information about feeds, target products, and existing facilities, Unifuel. Tech can find an optimal application for flexiforming, contributing to a cleaner, greener aviation industry powered by SAF.

Case Studies of Biofuel-Powered Flights

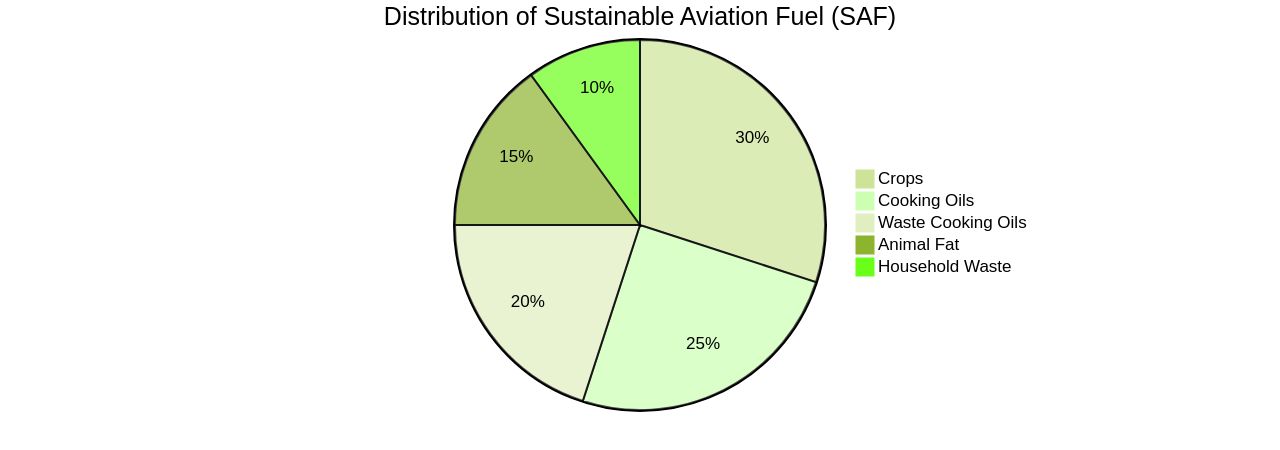

The potential for Sustainable Aviation Fuel (SAF) to revolutionize the aviation industry and significantly reduce its carbon footprint has been successfully demonstrated through real-world applications. A remarkable example is the Virgin Atlantic Boeing 787 that made a historic flight from London Heathrow to New York's JFK, entirely powered by SAF, primarily derived from waste cooking oils and animal fat.

This achievement slashed carbon emissions by 70%, marking a significant milestone in aviation history as the first transatlantic commercial flight powered entirely by SAF. However, the path to sustainability in aviation is not without its challenges.

The supply of SAF is currently limited, posing a significant hurdle. The International Civil Aviation Organization (ICAO) has set a goal to reduce CO2 emissions from the aviation sector by 50% by 2050.

To achieve this, a substantial increase in SAF usage is required, along with the integration of other technologies. The aviation industry is increasingly embracing SAF as the most effective means of addressing CO2 emissions.

For instance, Airbus aims to make all its aircraft 100% SAF-capable by 2030 and is collaborating with partners to expand the global SAF market. However, our research indicates that the rate of fleet renewal may not be sufficient to meet the industry's decarbonization targets by 2050. This underscores the need for a comprehensive approach, including improvements in engine and aircraft efficiency, optimizing operations, and most importantly, the extensive adoption of SAF. Nonetheless, SAF currently makes up less than 0.2% of the global jet fuel supply, indicating a long road ahead. The challenge lies in expanding the supply of SAF, which can be derived from various sources, including crops, household waste, and cooking oils. Despite these challenges, Saf's potential to act as a 'drop-in' solution, requiring minimal adjustments to aircraft and airport infrastructure, makes it an attractive prospect for the aviation industry.

Economic and Environmental Analysis of Bio-aviation Fuel Supply Chain

Aviation, responsible for 2-3% of global CO2 emissions, is urgently compelled to decarbonize. Increased demand for air travel and freight transport only magnifies this need.

Sustainable Aviation Fuels (SAF), derived from diverse feedstocks like biomass, waste products, and natural oils, are seen as the primary instrument for this change, particularly for long-haul flights where full electrification or hydrogen-fueled aircraft aren't commercially viable yet. Despite the industry's ambitious targets and aggressive timelines, current SAF production levels fail to match global demand, raising questions about affordability, sustainability, and competition for feedstocks.

Scaling production to meet demand carries economic implications. Yet, the shift towards SAF offers the aviation industry a unique chance to lower its carbon footprint and contribute to global emissions reduction targets.

In this context, Unifuel.tech's Flexiforming technology emerges as a crucial tool. Flexiforming, which can be implemented in an idle hydrotreater or reformer, reduces both capital expenditure and carbon intensity. By providing information about feeds, target products, and existing facilities, operators can utilize Unifuel.tech's expertise to find an optimal application for Flexiforming. This highlights the importance of comprehensive economic and environmental analysis in ensuring the long-term viability of the SAF supply chain. Unifuel.tech, a product of Universal Fuel Technologies, guarantees a response within 24 hours to inquiries, underscoring their commitment to fostering a sustainable aviation future.

Future Prospects of Sustainable Aviation Fuel

The aviation sector, despite contributing to approximately 2% of global CO2 emissions, is actively seeking solutions to achieve carbon neutrality. The increasing emphasis on sustainable aviation fuels (SAFs), derived from a variety of feedstocks including biomass and waste products, signifies this shift.

However, the production of SAFs is limited and unable to meet the growing demand, leading to challenges related to affordability, sustainability, and feedstock competition. While the industry explores alternative fuels like green hydrogen, solar fuels, and electric planes, their commercialization is still years away.

In the meantime, bio-aviation fuels, supported by policy and regulatory frameworks, are emerging as a viable interim solution. However, the SAF industry is still in its infancy, with few producers worldwide, leading to high costs for airlines.

This is where innovative solutions like flexiforming technology offered by Unifuel. Tech come into play.

Flexiforming allows operators to control their decarbonization speed by deploying the technology in idle hydrotreaters or reformers. This approach significantly reduces capital expenditure and carbon intensity. The company, owned by Universal Fuel Technologies, promptly responds to inquiries and requests for information about feeds, target products, and existing facilities to optimize flexiforming applications. Despite the challenges, the aviation industry remains hopeful about the future of SAFs. Airbus, a pioneer in alternative fuel research, is implementing strategies to reduce environmental footprints, including a focus on ferry flights. Such initiatives highlight the potential of SAFs and the industry's commitment to a sustainable future.

Challenges and Recommendations for Sustainable Aviation Fuel Development

The Sustainable Aviation Fuel (SAF) is a vital instrument in mitigating climate change. The adoption of biofuels for aviation, faced by the aviation industry, responsible for approximately 2% of global carbon emissions, does encounter hurdles such as limited feedstock, high production costs, and the need for large-scale production structures. Regulatory barriers and inconsistent standards also add to the complexity.

Yet, the industry's resilience is evident in its commitment to reducing emissions, guided by the CORSIA regulations from the International Civil Aviation Organization (ICAO) and a carbon neutrality goal by 2050. Globally, the uptake of SAF is accelerating, particularly in regions like Europe, the UK, and the USA. Leading airlines like Virgin Atlantic are setting ambitious targets, such as 100% SAF flights.

To achieve these carbon-neutral targets and overcome these challenges, a collaborative effort is needed from governments, airlines, fuel producers, research institutions, and the development of biofuels for aviation. Strategic investments in R&D, incentivizing feedstock production, and supportive policy frameworks can speed up the development and deployment of SAF. In the context of biofuels for aviation, advanced solutions such as the flexiforming technology from Universal Fuel Technologies' subsidiary, Unifuel.tech, presents a promising path.

The use of biofuels for aviation in a flexiforming system, which can be deployed in an idle hydrotreater or reformer, enables operators to regulate their decarbonization speed, thereby lowering capital expenditure and carbon intensity. Upon assessing feeds, target products, and existing facilities, Unifuel. Tech can identify an optimal application for flexiforming, ensuring a swift response within 24 hours to inquiries.

Conclusion

In conclusion, the aviation industry is embracing Sustainable Aviation Fuel (SAF) to reduce greenhouse gas emissions and achieve carbon neutrality. Challenges such as limited production and high costs persist, but innovative solutions like Unifuel.tech's flexiforming technology offer optimization opportunities.

The choice of feedstocks, including non-edible plant oils and agricultural waste, plays a crucial role in SAF production. Storage and transportation infrastructure are vital for widespread adoption.

Case studies have demonstrated the potential of SAFs in reducing carbon emissions, but increasing supply remains a challenge that requires diversifying feedstock sources. Economic and environmental analysis is essential for the viability of the bio-aviation fuel supply chain.

Unifuel.tech's Flexiforming technology enables operators to control decarbonization pace while minimizing costs and environmental impact. While alternative fuels like green hydrogen and electric planes show promise, bio-aviation fuels supported by policy frameworks are practical interim solutions. Collaboration among governments, airlines, fuel producers, and research institutions is necessary to overcome challenges. In conclusion, the aviation industry's transition towards SAFs holds promise for achieving carbon neutrality goals. Continued innovation and collaboration are key to realizing a greener future for aviation.