Introduction

The aviation industry is making significant strides towards achieving carbon neutrality by 2050 with the use of sustainable aviation fuel (SAF). This innovative approach, utilizing renewable biomass, waste resources, or a mix of captured carbon dioxide and green hydrogen, can lead to a substantial reduction in greenhouse gas emissions compared to conventional jet fuel.

The integration of bio-based aromatics into SAF blends further enhances its potential, allowing for aircraft to operate on up to 100% SAF without compromising safety parameters. With the operational compatibility of SAF with existing infrastructure, emissions can be cut by 60 to 100%, addressing the industry's challenge of increasing fuel consumption while striving for carbon neutrality.

To ensure the success of SAF, production must be powered by renewable energy, and international acceptance and rigorous certification processes are crucial. Technologies like Unifuel.tech's flexiforming offer a versatile solution to decarbonization challenges, allowing for efficient and personalized integration into SAF production. As the aviation sector transitions towards a greener future, the FT pathway and technologies like flexiforming play a pivotal role in advancing sustainable fuel solutions.

Shrinking Jet Fuel's Carbon Footprint

Sustainable aviation fuel (SAF) is indeed a significant stride towards achieving carbon neutrality in the aviation sector by 2050. The utilization of renewable biomass, waste resources, or a mix of captured carbon dioxide and green hydrogen for SAF production aligns with carbon-neutral or negative pathways, absorbing or preventing CO2 emissions.

This innovative approach can lead to a significant reduction in lifecycle greenhouse gas emissions when compared to conventional jet fuel. The integration of bio-based aromatics into SAF blends is particularly noteworthy, enabling aircraft to operate on up to 100% SAF without compromising essential safety parameters.

In light of these developments, the operational compatibility of SAF with existing infrastructure is a key advantage, offering the potential to cut emissions by 60 to 100%. This is critical for an industry that is facing the dual challenge of increasing jet fuel consumption and striving for carbon neutrality.

For instance, Sweden's commitment to SAF production is poised to meet a considerable portion of its jet fuel demand in the coming years, with tangible initiatives like Virgin Atlantic's planned 100% SAF transatlantic flight later in 2023 demonstrating real-world applications. To ensure the success of SAF, production must be powered by renewable energy to foster a circular fuel economy.

This involves sourcing all carbon compounds from atmospheric CO2 and powering production equipment with zero-emission electricity. International acceptance and rigorous certification processes, including lifecycle greenhouse gas assessments, are essential for SAF to contribute effectively to emissions reduction. Moreover, technologies like Unifuel.tech's flexiforming offer a versatile solution to decarbonization challenges. By enabling operators to retrofit existing hydrotreaters or reformers, flexiforming reduces both capital expenditure and carbon intensity. This approach allows for a tailored decarbonization pace and promises rapid response times for inquiries, ensuring that the integration of such technologies into SAF production is both efficient and personalized to specific operational needs.

Pathway to Fischer-Tropsch Synthetic Paraffinic Kerosenes

The Fischer-Tropsch (FT) synthesis process is pivotal in advancing the sustainable aviation fuel (SAF) agenda, transforming a variety of renewable feedstocks into synthetic paraffinic kerosene (FT-SPK). This bio-aviation fuel is a seamless substitute for its conventional counterpart, adhering to the strict specifications required for jet fuel, thus ensuring full compatibility with current aircraft engines and fuel distribution systems.

Amidst the global shift towards SAF, driven by heightened environmental consciousness and stringent emission reduction commitments, the FT pathway stands out as a beacon of sustainability. With the aviation sector facing limitations in adopting electrification and alternative fuels for long-haul flights in the immediate future, FT-SPK serves as a crucial bridge in the industry's transition towards a greener future.

The incorporation of bio-based aromatics further elevates the potential of SAF, allowing for higher blending ratios and even the prospect of 100% SAF flights, as demonstrated by recent trans-Atlantic crossings. Nevertheless, the burgeoning demand for SAF outpaces the current production capacity, underscoring the need for scalable, economically viable solutions.

Australia, with its robust feedstock production capabilities, is poised to become a significant player in the SAF market, complemented by its burgeoning hydrogen economy. Meanwhile, cutting-edge developments in electrofuel production, utilizing fossil-free electricity, water, and recycled carbon dioxide, mark a significant stride in SAF technology, exemplifying the integration of carbon capture usage (CCU) in the fuel's life cycle. Innovations such as Unifuel.tech's flexiforming technology present an adaptable solution, enabling operators to retrofit existing infrastructure like idle hydrotreaters or reformers. This adaptability assists in minimizing capital expenditures while also reducing the carbon intensity of fuel production. Unifuel.tech's commitment to rapid response and tailored application of their technology underscores the ongoing efforts to meet the rising demand for SAF and to overcome the challenges of scalability and economic viability in the production of FT-SPK and other SAF pathways.

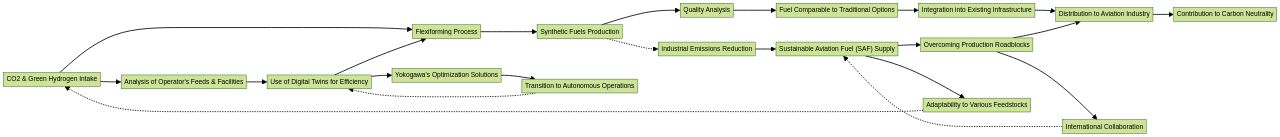

Flexiforming: Flexible Fuel Production

Flexiforming technology, a product from Unifuel.tech, is gaining traction in the sustainable aviation fuel (SAF) market for its exceptional adaptability in feedstock utilization. This technology can be seamlessly integrated into existing infrastructure, such as an idle hydrotreater or reformer, thus mitigating capital expenditures and lowering the carbon intensity of fuel production.

Unifuel.tech's approach allows operators to tailor their decarbonization trajectory, providing a versatile solution that aligns with their operational needs and environmental goals. The technology's application in producing SAF through various pathways is a testament to its role in aviation's decarbonization.

By utilizing Flexiforming, operators can transform carbon dioxide and green hydrogen into synthetic fuels. These fuels are comparable to traditional petroleum-based options and can be used without modifications in current combustion engine vehicles.

The digital twin concept, as seen in the ORLEN and Yokogawa alliance, exemplifies the potential of Flexiforming to enhance production efficiency and sustainability. Unifuel.tech's commitment to customer service, including a 24-hour inquiry response time and a detailed analysis of an operator's feeds, target products, and existing facilities, ensures a tailored application of the Flexiforming technology. This customer-centric approach, combined with the strategic use of digital twins, positions Unifuel. Tech as a key player in the SAF production landscape, contributing to the industry's goal of achieving carbon neutrality. With projected capacities and the anticipated role of bio-SAF and synthetic kerosene in meeting future fuel demands, the importance of scalable, efficient technologies like Flexiforming cannot be overstated.

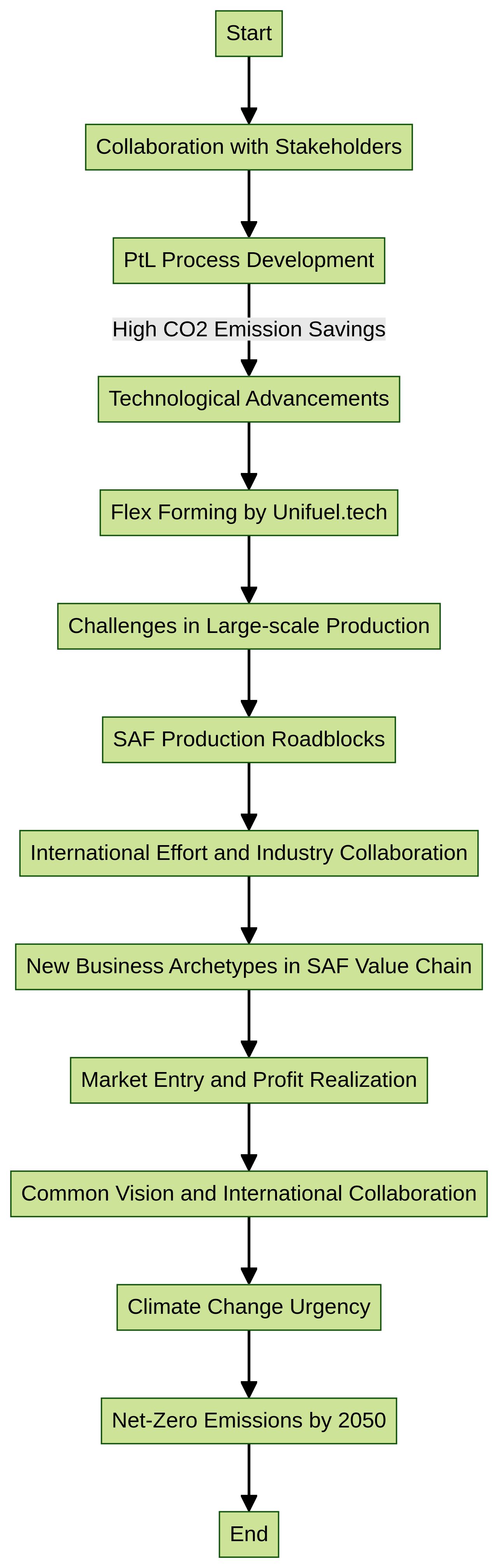

Collaborative Efforts for a Sustainable Future

In the pursuit of lowering carbon emissions, the aviation industry is progressively integrating sustainable aviation fuel (SAF) into its operational framework. This commitment is fortified by technological advancements, such as the flex forming process offered by Unifuel.tech, which is instrumental in the production of SAF. Flexiforming, a proprietary technology, facilitates the conversion of traditional hydrocarbon streams into lower-carbon fuels, aligning with the sector's aim for net-zero emissions by 2050.

The technology's flexibility is evident in its ability to be integrated into existing infrastructure, such as idle hydrotreaters or reformers, thus reducing the need for new capital investments while simultaneously diminishing carbon intensity. The significance of this innovation is underscored by milestones like Virgin Atlantic's reduction in carbon emissions and its transition to a next-generation fleet. Similarly, Airbus's target for SAF-capable aircraft by 2030 echoes the industry's direction towards sustainable fuel solutions.

Unifuel.tech's rapid response to inquiries within 24 hours and its requirement for detailed operational parameters indicate a tailored approach to SAF production. The company's commitment to optimizing the application of flexiforming based on individual customer needs supports the overarching goal of producing SAF from environmentally responsible sources. As the aviation industry continues to advance towards a sustainable future, technologies like flexiforming from Universal Fuel Technologies serve as critical enablers in this transformative journey.

Conclusion

In conclusion, the aviation industry is making significant strides towards carbon neutrality by 2050 through the use of sustainable aviation fuel (SAF). SAF, derived from renewable biomass and waste resources, offers a substantial reduction in greenhouse gas emissions compared to conventional jet fuel.

The integration of bio-based aromatics into SAF blends allows for aircraft to operate on up to 100% SAF without compromising safety. This compatibility with existing infrastructure enables emissions to be cut by 60 to 100%, addressing the challenge of increasing fuel consumption while striving for carbon neutrality.

To ensure success, SAF production must be powered by renewable energy and undergo rigorous certification. Technologies like Unifuel.tech's flexiforming offer efficient and personalized integration into SAF production.

Flexiforming reduces capital expenditure and carbon intensity by retrofitting existing infrastructure. The Fischer-Tropsch (FT) pathway plays a pivotal role in advancing sustainable aviation fuel solutions.

FT-SPK, derived from renewable feedstocks, ensures compatibility with current aircraft engines and distribution systems. The incorporation of bio-based aromatics further enhances SAF's potential, allowing for higher blending ratios and even 100% SAF flights.

Collaborative efforts are crucial for a sustainable future. Technological advancements like flexiforming contribute to lowering carbon emissions and achieving net-zero goals. The flexibility of this innovation reduces capital investments while diminishing carbon intensity. In summary, with the integration of sustainable aviation fuel and innovative technologies like flexiforming, the aviation sector is on track towards achieving its goal of carbon neutrality by 2050. These advancements reduce greenhouse gas emissions and provide tailored solutions that address specific needs. Collaboration between stakeholders is essential in driving forward sustainable fuel solutions as we transition towards a greener future.