Introduction

The aviation industry is on the brink of a transformation as it seeks to reduce its carbon emissions and move towards a more sustainable future. One key area of focus is the development of Sustainable Aviation Fuels (SAF), which offer a potential solution to the industry's environmental impact. These fuels, derived from renewable feedstocks such as biomass and waste oils, have the potential to significantly reduce carbon emissions compared to traditional jet fuels.

However, the production and adoption of SAF face challenges such as limited supply, high costs, and competition for feedstocks. Despite these hurdles, the emergence of SAF signals a significant step towards sustainability in the aviation industry. In this article, we will explore the different types of jet fuel, key differences between jet fuel and gasoline, an overview of sustainable aviation fuels, bio-aviation fuel production and feedstocks, production pathways for synthetic paraffinic kerosene, storage and transport technologies for bio-aviation fuel, economic and environmental analysis of the bio-aviation fuel supply chain, challenges and opportunities for bio-aviation fuel, and policy recommendations for bio-aviation fuel deployment.

Types of Jet Fuel

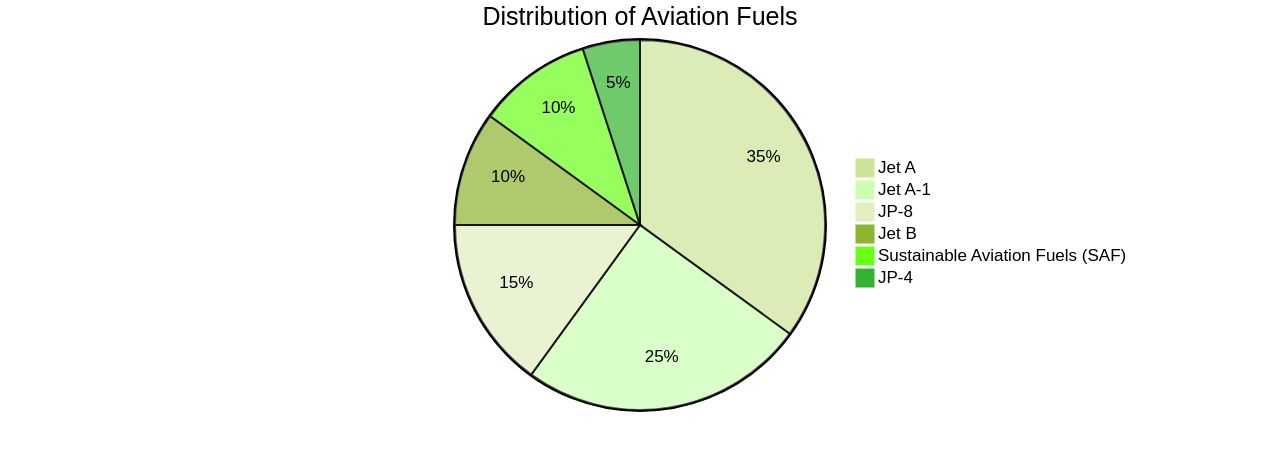

The aviation fuel landscape is diverse, with the predominantly used Jet A, a kerosene-based fuel, and its variant Jet A-1, distinguished by a slightly lower freeze point. There are different types of jet fuel available, with Jet A and Jet A-1 being the primary ones. When it comes to specific military aircraft and cold-weather operations, Jet B is the preferred type of jet fuel due to its higher flashpoint.

Jet fuel types like JP-4 and JP-8 are primarily utilized in military contexts. However, the advent of Sustainable Aviation Fuels (SAF) is signaling a new era.

A standout example is a novel fuel developed by Firefly, with a 90% lower carbon footprint compared to standard jet fuel. This development is crucial in an industry that accounts for approximately 2% of global carbon emissions.

The fuel, developed in partnership with Cranfield University, matches fossil-based kerosene in its chemical structure but is entirely fossil carbon-free. Despite the energy consumption involved in its production, the life cycle energy usage is significantly less than that of fossil fuels. The aviation industry, on the brink of a transformation, is looking to evolve its fuel type after relying on virtually the same jet fuel types for the past seven decades. According to Robert McCormick from the National Renewable Energy Laboratory (NREL), the concept of developing new jet fuel types is a novel idea for the industry. This shift towards SAF, despite its potential learning curve, is driven by the promise of a more sustainable future.

Jet Fuel vs Gasoline: Key Differences

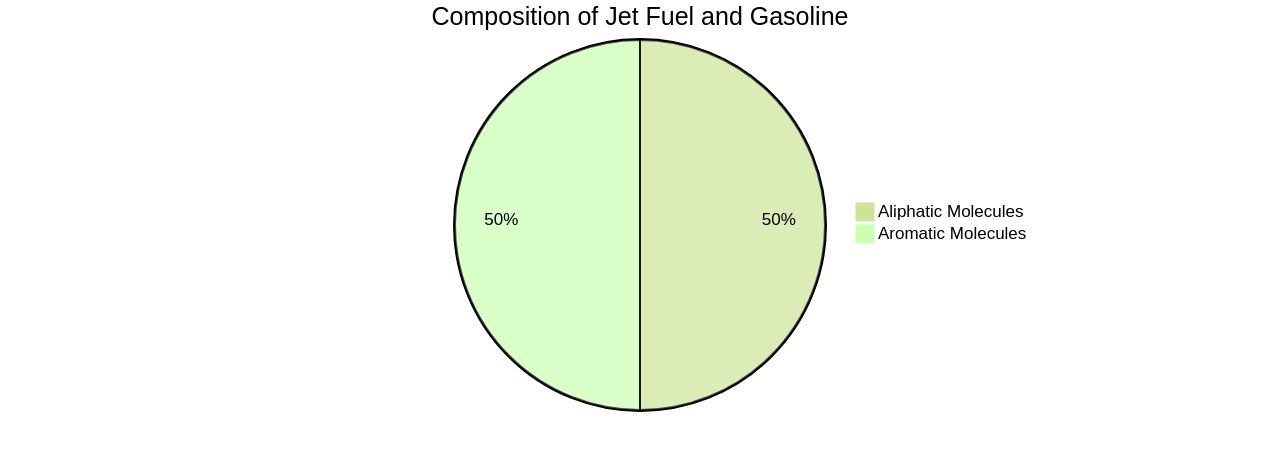

Jet fuel and gasoline, both derived from crude oil, exhibit unique compositional and property differences. Jet fuel consists predominantly of aliphatic molecules, forming 75 to 90 percent of its make-up, akin to diesel fuels, while aromatic molecules make up the remainder. The physical and combustion characteristics of the fuel rely heavily on these molecules.

Gasoline, on the other hand, is composed of volatile liquids and a variety of hydrocarbon compounds, the product of crude oil distillation or different petroleum processing techniques. The refining process and the type of petroleum used dictate the chemical composition of gasoline, usually resulting in an alkane blend. Jet fuel has a higher energy density than gasoline, providing more power per unit of volume, making it more efficient.

Furthermore, jet fuel's higher flash point and lower vapor pressure make it safer for aviation use. However, burning these fuels in engines has environmental implications, such as the production of carbon monoxide, soot, and nitrogen or sulfur oxides. The aviation industry is making progress towards sustainability.

A consortium led by Virgin Atlantic aims to demonstrate SAF (Sustainable Aviation Fuel) as a 100% replacement for fossil fuel. Meanwhile, the International Civil Aviation Organization has set a target for the industry to achieve net-zero carbon emissions by 2050. However, the journey to sustainable fuel involves reversing combustion, converting water and CO2 back into fuel while restoring oxygen to the air.

Sustainable Aviation Fuels: An Overview

A transformative wave is sweeping across the aviation sector with the advent of Sustainable Aviation Fuels (SAF), derived from renewable feedstocks such as biomass, waste oils, and agricultural by-products. These fuels offer a potential pathway to address the industry's carbon emissions, which currently contribute to approximately 2-3% of global CO2 emissions. The attractiveness of SAFs is not limited to their environmental advantages.

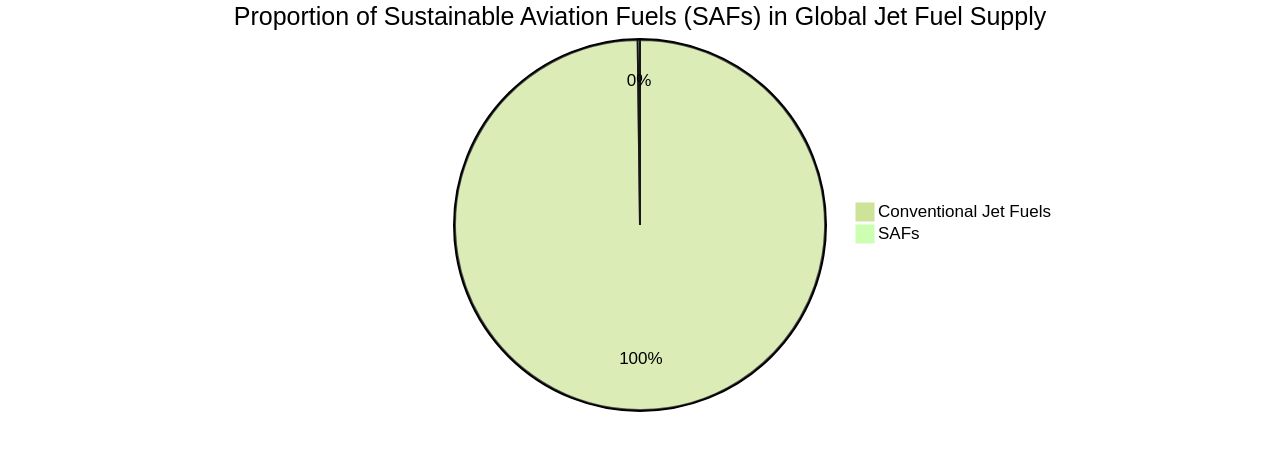

As 'drop-in' solutions, they require minimal changes to current aircraft and airport infrastructure. Nevertheless, SAFs, despite powering successful flights, represent less than 0.2% of the global jet fuel supply, highlighting the necessity for an expanded supply chain. The industry's attention is also turning towards synthetic SAF production via 'green' hydrogen and atmospheric CO2.

Leading aerospace companies, such as Airbus, are setting ambitious goals to render their fleets 100% SAF-compatible by 2030. Pioneering industry participants like Unifuel.tech are leveraging innovative technologies like flexiforming. This technology allows operators to manage their decarbonization rate, and it can be integrated into idle hydrotreaters or reformers, thus reducing capital expenditure and carbon intensity.

To find the optimal application for flexiforming, Unifuel. Tech requests information about the operator's feeds, target products, and existing facilities, with a commitment to respond within 24 hours. Despite the challenges of limited supply and high costs, the emergence of SAF as a primary tool for reducing aviation emissions signals a significant step towards sustainability.

Bio-aviation Fuel: A Comprehensive Review

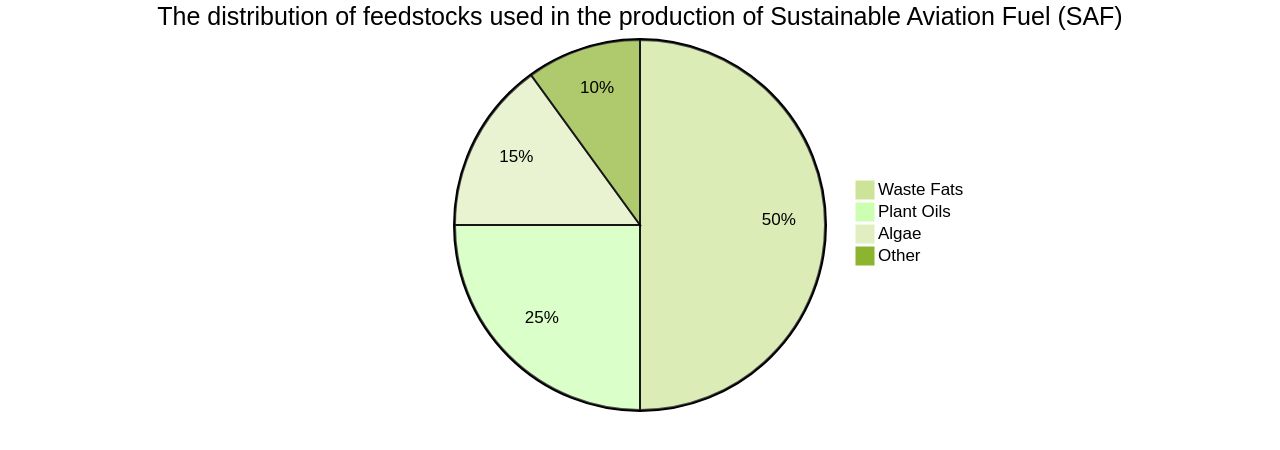

Sustainable Aviation Fuel (SAF), a type of green aviation fuel, originates from diverse biological feedstocks, including plant oils, waste fats, and algae. These feedstocks are cultivated in specific regions, transported for treatment, and converted into eco-friendly raw materials. SAF's key benefit lies in its capacity for significant carbon emission reduction.

Currently, aviation accounts for 2-3% of global CO2 emissions, a fraction that is rapidly expanding. While electric and hydrogen-electric aircraft are under development, the mass air travel industry remains years, if not decades, from being powered by completely new technology. Therefore, SAF is presently viewed as the most viable way to address CO2 emissions in the aviation industry.

However, SAF production faces challenges. Demand is exceeding supply, especially in Europe, the UK, and the USA, leading to concerns about affordability, sustainability, and competition for feedstocks. Despite these hurdles, SAF could play a significant role in the future of aviation, with organizations like the Bioenergy Technologies Office (BETO) of the US Department of Energy working to overcome barriers to its extensive deployment.

Unfortunately, SAF is currently 3 to 4 times more expensive than conventional fuel due to limited availability. Despite usage in military aircraft and a rising demand for air cargo transport, high costs remain a barrier to market progress. Despite these challenges, Saf's potential in the future of aviation is significant, particularly in countries like Australia, which already produce substantial amounts of biofuel feedstocks.

Feedstocks for Bio-aviation Fuel Production

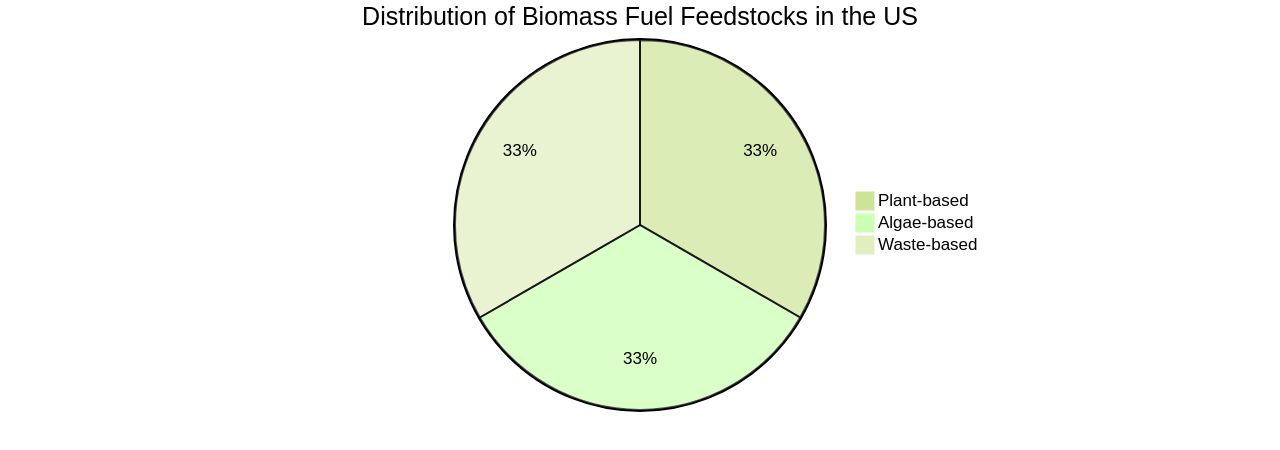

Biomass fuels, which made up approximately 5% of the US's total primary energy consumption in 2017, are derived from three main types of feedstocks: plant-based, algae-based, and waste-based. Plant-based feedstocks include crops such as oil palm, soybean, and jatropha, which are grown specifically for fuel production.

Algae-based feedstocks utilize microalgae as an oil source, which is then converted into bio-aviation fuel. Meanwhile, waste-based feedstocks make use of various waste oils and fats, such as used cooking oil and animal fats, which are repurposed for fuel production.

The recent technological advancements have facilitated the production of Sustainable Aviation Fuel (SAF) from inexpensive organic waste feedstocks like biogas. This innovation has led to a global surge in its use for electricity generation, with an increase of approximately 90%.

The attractiveness of biogas lies not only in its economic viability but also in its environmental impact, as it greatly reduces carbon dioxide emissions. In the quest to decarbonize global aviation, SAF has emerged as the most practical solution.

The 'drop-in' nature of SAF allows it to be integrated into the existing fueling infrastructure, eliminating the need for extensive modifications to aircraft fleets and airports. This is a significant advantage, given the strict specifications for quality and composition that jet fuel must meet. Furthermore, SAF substantially reduces carbon dioxide emissions, as the lifecycle greenhouse gas (GHG) emissions of SAF are much lower than traditional jet fuel. This is attributed to the carbon dioxide absorption properties of the crops providing the feedstocks and the repurposing of waste that would have otherwise ended up in landfills. In addition to these environmental benefits, SAF also brings about a transformative change to the aviation industry by allowing up to 100% SAF to be used to power airplanes, a feat recently accomplished by Virgin Atlantic. This achievement highlights the crucial role that SAF will play in the future of the aviation industry.

Production Pathways for Synthetic Paraffinic Kerosene

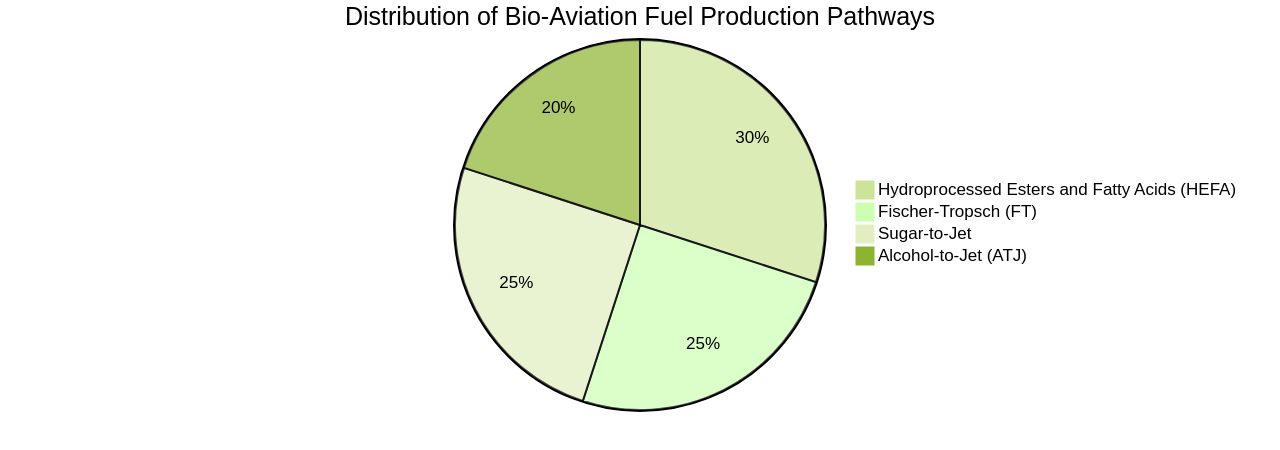

Bio-aviation fuel, such as Synthetic Paraffinic Kerosene (SPK), is typically produced through various pathways, each having unique processes and feedstock prerequisites. The most common production pathways include Hydroprocessed Esters and Fatty Acids (HEFA), Fischer-Tropsch (FT), Alcohol-to-Jet (ATJ), and Sugar-to-Jet, yielding high-quality bio-aviation fuel that meets the stringent aviation standards.

The FT pathway, utilized in regions like South Africa and China, stands out due to its ability to generate hydrocarbons from syngas derived from coals, biomass, and waste plastics. The resulting products, primarily paraffin and olefin with slight oxygenates, are molecularly distinct from petroleum.

A recent breakthrough in the process of creating bio-based aromatics has enabled higher SAF volumes in aircraft fueling, including 100% SAF. SAF offers a practical 'drop-in' solution, eliminating the need for major modifications of global aircraft fleets, airports, and fueling infrastructure.

However, it's vital to remember that alternative fuel production can contribute to CO2 emissions, either from the energy required for their production or their ecosystem impact. Some biofuels might even generate more overall CO2 emissions than fossil fuels. The Power-to-Liquid (PtL) process, although nascent, promises significant CO2 emission savings of 89 to 94%. Despite the readiness and understood cost structure of most relevant technologies for SAF production, the current supply of sustainable aviation fuel is insufficient. Therefore, addressing the identified roadblocks to escalate SAF production is a critical concern.

Hydroprocessed Esters and Fatty Acids (HEFA) Production Pathway

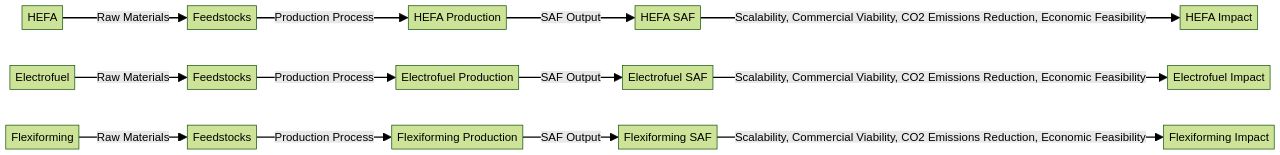

The dominance of the Hydroprocessed Esters and Fatty Acids (HEFA) pathway in the quest for sustainable aviation fuel (SAF) can be attributed to its scalability and commercial viability, which are crucial factors in determining the success of different jet fuel types. However, The SAF production landscape is diversifying, with innovations such as electrofuel, which utilizes various jet fuel types, including carbon-neutral fuel from fossil-free electricity, water, and recycled carbon dioxide. This carbon capture usage (CCU) method is revolutionizing the industry by significantly reducing aviation carbon dioxide emissions.

Virgin Atlantic demonstrates the potential of larger quantities of Sustainable Aviation Fuel (SAF) in aircraft fuel, specifically in the jet fuel types, through their first trans-Atlantic flight using 100% SAF, showcasing the advancements in novel production methods for bio-based aromatics. Jet fuel types, such as SAF, play a crucial role in aviation decarbonization as they require no modification to aircraft fleets, airports, or fueling infrastructure. However, economic feasibility remains a major concern for large-scale SAF production.

Although the HEFA pathway is the most competitive technology for SAF production, it is important to conduct a comprehensive comparison with other production pathways, including different jet fuel types. The limited production of jet fuel types is predicted to cause issues surrounding affordability, sustainability, and competition for feedstocks as the global demand for jet fuel types outstrips supply. Unifuel.tech, a subsidiary of Universal Fuel Technologies, offers flexiforming, a solution that empowers operators to control their decarbonization pace by utilizing different jet fuel types in response to these challenges.

Different types of jet fuel can implement flexiforming in an idle hydrotreater or reformer, resulting in a decrease in capital expenditure and carbon intensity. The company guarantees a quick reply, within 24 hours, to inquiries and requests for information on jet fuel types, as well as details about feeds, target products, and existing facilities, in order to determine an optimal application for flexiforming. Despite the hurdles, advancements in SAF production technologies, such as flexiforming, hold the promise of a greener future for aviation.

Fischer-Tropsch (FT) Production Pathway

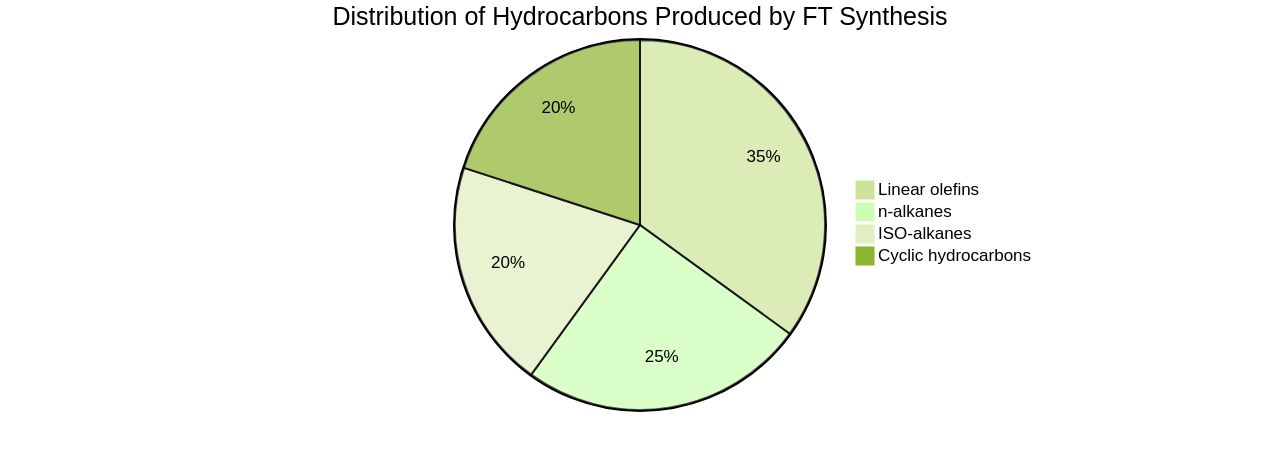

The Fischer-Tropsch (FT) synthesis has garnered attention as a potential solution in the face of dwindling petroleum resources, which currently account for a significant portion of global energy consumption. This catalytic process facilitates the production of a wide range of hydrocarbons, predominantly n-alkanes and linear olefins, along with ISO-alkanes and cyclic hydrocarbons.

The process can convert syngas, derived from various feedstocks like biomass, coal, and natural gas, into liquid hydrocarbons. These hydrocarbons, known as FT-SPK, not only possess exceptional thermal stability but can also be readily integrated with conventional jet fuel.

One of the main advantages of the FT pathway is the flexibility in feedstock usage. Recent innovations have enabled the production of synthetic aromatics, clearing the path for using higher percentages of Sustainable Aviation Fuel (SAF) within existing fleets and fueling infrastructure.

For instance, the BioForming process, which transforms sugars into aromatics, enabled a transatlantic flight by Virgin Atlantic to be powered by 100% SAF. This method can utilize various plant sugars, indicating that it does not rely on a limited feedstock source. Despite these advancements, large-scale SAF production through this method may not be economically feasible in the near future. However, it remains a promising solution for sustainable aviation fuel (SAF), offering a practical strategy for the decarbonization of global aviation without necessitating extensive modifications to global aircraft fleets, airports, and fueling infrastructure.

Alcohol-to-Jet (ATJ) Production Pathway

The transformation of alcohols into hydrocarbon mix compatible with bio-aviation fuel is a major progress in the renewable fuels sector, with the Alcohol-to-Jet (ATJ) pathway at the forefront. The final product, ATJ-SPK, is a near-identical alternative to conventional jet fuel, offering an immediate replacement.

The ATJ pathway's distinguishing feature is its ability to utilize alcohol feedstocks from renewable sources like corn or sugarcane. The BioForming process, a recent breakthrough, expands the potential of plant sugars, allowing synthetic aromatics to be produced from a variety of these sources.

This has facilitated increased use of Sustainable Aviation Fuel (SAF) in existing fleets and fueling infrastructure, even enabling Virgin Atlantic's first 100% SAF Transatlantic flight. Notably, the fuel's performance equals that of conventional jet fuel, and no engine modifications are required.

This advancement is crucial as it eliminates the need for conventional jet fuel to meet the ASTM international standards' aromatic percentage in jet fuel. The flexibility of the process accommodates diverse resources across various regions.

The imminent commissioning of LanzaJet’s Freedom Pines Fuels facility in Soperton, GA, the world's first commercial ATJ facility, marks a significant milestone in the SAF industry. Innovations such as Unifuel.tech's flexiforming technology further streamline the decarbonization process. The technology can be installed in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. Unifuel. Tech also offers rapid responses and works closely with operators to find the best application for flexiforming based on their feeds, target products, and existing facilities. Universal Fuel Technologies, the owner of Unifuel.tech, provides contact information for inquiries on its website.

Sugar-to-Jet Production Pathway

Jet fuel types, such as bio-aviation fuel, can be produced through the bioconversion process called the Sugar-to-Jet pathway, which involves converting sugars derived from biomass feedstocks such as corn or sugarcane. The process of jet fuel production involves fermenting the sugars into alcohol, which is then converted into a hydrocarbon mixture that meets the standards for different jet fuel types. Utilizing synthesized sugar as a raw material, this groundbreaking approach, known as the first of its kind, represents a significant milestone in biomanufacturing for jet fuel types.

This innovation tackles the 21st-century global challenge of excessive usage of fossil fuels and the greenhouse gas emissions linked to it, particularly those caused by various jet fuel types. The production of 1st generation biomass through agricultural processes, a concern often associated with competing with food resources, can be addressed by the biomanufacturing process, which provides a sustainable alternative and doesn't compete with food resources. Another area where the biomanufacturing process can have an impact is in the production of jet fuel types. The viability of the Sugar-to-Jet pathway is further enhanced by the advent of bio-based aromatics, which enables a higher percentage of sustainable aviation fuel (SAF) to be incorporated. This advancement in jet fuel types further supports the use of bio-based aromatics in the Sugar-to-Jet pathway.

Even though Saf's potential to reduce greenhouse gas emissions is significant, in line with the industry's goal of producing 3 billion gallons of jet fuel types per year by 2030, the higher costs cannot be ignored. The development of strategically located feedstocks to minimize transport and infrastructure costs is also being encouraged by the Sugar-to-Jet pathway, which aims to develop various jet fuel types. The potential of this pathway to contribute to net emissions reduction, especially when powered by renewable energy, underscores its importance in the renewable fuels industry.

Storage and Transport Technologies for Bio-aviation Fuel

In the pursuit of emission reduction, the aviation industry is increasingly focusing on sustainable aviation fuels (SAFs) generated from diverse feedstocks such as biomass, waste products, natural oils, fats, and other carbon sources. However, the escalating demand for SAFs is currently outstripping supply, causing concerns about affordability, sustainability, and feedstock competition.

Specifically, the aviation industry is keen on hydrogen as a potential fuel source. For instance, Hydrogen Airport conducts feasibility studies for airports keen on transitioning to hydrogen, assessing hydrogen requirements, supply chain modeling, land management implications, and cost estimates.

Furthermore, the development of hydrogen-electric propulsion systems for aircraft is gaining traction. The HY4, the world’s first hydrogen-electric passenger aircraft, exemplifies the potential of this technology for future aviation.

However, altering the extensive network of underground fueling infrastructure to accommodate new fuels and technologies could be a monumental task. Additionally, the need for aromatics in aviation fuel currently restricts the percentage of SAF that can be added. Yet, recent breakthroughs in producing bio-based aromatics are enabling greater SAF volumes to be used, including 100% SAF. In this evolving landscape, the safe and efficient handling, storage, and transport of different jet fuel types will remain paramount, necessitating continuous innovation in storage and transport technologies, as well as rigorous handling and maintenance practices.

Economic and Environmental Analysis of Bio-aviation Fuel Supply Chain

The process of producing and distributing various types of jet fuel, including sustainable aviation fuel (SAF), involves a complex lifecycle from feedstock production to fuel generation, storage, and distribution. Each stage is critical to SAF's feasibility, with comprehensive evaluations encompassing both economic and environmental aspects. In these evaluations, the key factors include jet fuel types, such as feedstock availability, production costs, energy consumption, and greenhouse gas emissions.

Currently, the production limitations of jet fuel types are causing the supply to be outweighed by the escalating global demand for SAF, especially in regions such as Europe, the UK, and the USA. This imbalance provokes questions about affordability, sustainability, and feedstock competition. Amidst these challenges, countries with substantial production of feedstock and emerging economies focused on hydrogen, such as Australia, have the potential to play a crucial role in the production of Sustainable Aviation Fuel (SAF) utilizing various types of jet fuel.

The aviation industry, which significantly contributes to global CO2 emissions, is urgently seeking methods to decrease its environmental footprint by exploring different jet fuel types. The supply of SAF as a potential solution is currently limited by the economic feasibility of different feedstocks and competition from other sectors, affecting the availability of various jet fuel types. Hence, the journey towards a sustainable aviation industry is intricate, necessitating the careful consideration of multiple factors.

Challenges and Opportunities for Bio-aviation Fuel

The aviation industry, in its quest for carbon neutrality, faces a unique challenge. The potential of bio-aviation fuel is evident, but hurdles such as feedstock availability, large-scale production, and economic viability persist. These challenges, however, are driving innovative solutions and collaborations, accelerating the shift to bio-aviation fuel.

The promise of Sustainable Aviation Fuels (SAF) is increasingly recognized globally, particularly in regions like the Great Lakes, Rocky Mountains, Europe, the UK, and the USA. Despite this growing acceptance, the projected demand for SAF is likely to surpass its supply due to limited global production, emphasizing the need for scalable production techniques and sustainable feedstock sources. Unifuel.tech's Flexiforming technology offers a promising solution to this problem.

Flexiforming allows operators to control the pace of their decarbonization journey and can be implemented in idle hydrotreaters or reformers, significantly reducing capital expenditure and carbon intensity. Unifuel.tech encourages customers to share details about their feeds, target products, and existing facilities, enabling the company to tailor Flexiforming to their specific needs. The aviation sector, particularly long-haul flights, is heavily reliant on SAF for reducing emissions.

Alternatives like electric or hydrogen power are currently not viable. The industry's goal of achieving net-zero carbon dioxide emissions by 2050 largely depends on the successful development and deployment of SAF. Amid these challenges, it's crucial to remember that the clock is ticking on climate change, and we must keep pace.

Policy Recommendations for Bio-aviation Fuel Deployment

Sustainable aviation fuels (SAF) are emerging as a major player in the reduction of emissions in the aviation industry. Accounting for approximately 7% of total emissions, the US aviation sector is rapidly expanding and is the third-largest source of transportation emissions in the country.

Emissions are projected to further rise as demands for air travel and freight transport continue to grow. Given the average lifespan of commercial aircrafts, which is 20 to 30 years, relying solely on improvements in aircraft design and efficiency or the electrification of aircrafts would not suffice in decarbonizing the sector.

Hence, the most feasible option for achieving decarbonization by mid-century could be the use of SAF. The aviation industry is committed to reducing emissions.

However, in the absence of viable alternatives like electrification or green hydrogen, particularly for long-haul segments, commercial airlines and defense forces will have to rely on SAF. These fuels are derived from a variety of feedstocks such as biomass, waste products, natural oils and fats, other carbon sources, and hydrogen.

Despite high SAF volume targets and aggressive adoption timelines, global production is limited, and demand is expected to surpass supply. This presents challenges in terms of affordability, sustainability, and competition for feedstocks. Countries like Australia could play a significant role as a source of feedstocks and as a SAF producer, given its current production of significant quantities of feedstocks exported for biofuel production. Establishing a conducive environment for the expansion of the bio-aviation fuel industry is crucial, and policies play a pivotal role in this. An example of this is the ReFuelEU Aviation initiative, part of the ‘Fit for 55’ package, which aims to reduce the EU's net greenhouse gas emissions by at least 55% by 2030 compared to 1990 levels and achieve climate neutrality by 2050. Thus, a comprehensive approach involving government strategies, academic-industry collaborations, and public awareness initiatives is essential to encourage the adoption of bio-aviation fuel and pave the way for a cleaner, greener aviation industry.

Conclusion

In conclusion, Sustainable Aviation Fuels (SAF) offer a promising solution to reduce carbon emissions in the aviation industry. Derived from renewable feedstocks like biomass and waste oils, SAF represents a significant step towards sustainability.

Despite challenges such as limited supply and high costs, the development of SAF signals a transformative shift in the aviation industry. Different types of jet fuel have distinct properties compared to gasoline, and SAF offers a more efficient and environmentally friendly alternative.

Bio-aviation fuel production relies on diverse feedstocks like plant oils, waste fats, and algae. While demand for SAF exceeds supply, advancements in technology can help overcome these limitations and increase production.

Different production pathways for synthetic paraffinic kerosene (SPK) include HEFA, FT, ATJ, and Sugar-to-Jet methods. Each pathway has unique processes and feedstock requirements.

Storage and transport technologies are crucial for handling different jet fuel types safely and efficiently. Innovations in producing bio-based aromatics enable greater volumes of SAF to be used without extensive modifications to existing infrastructure.

Economic and environmental analyses are essential for evaluating the feasibility of bio-aviation fuel supply chains. Challenges related to feedstock availability, large-scale production, and economic viability persist but drive innovation within the industry. Policy recommendations play a vital role in supporting the deployment of bio-aviation fuel. Government strategies, collaborations between academia and industry, along with public awareness initiatives are necessary to create an environment conducive to the expansion of the bio-aviation fuel industry. In conclusion, sustainable aviation fuels offer a promising solution to reduce carbon emissions in the aviation industry. Despite challenges related to supply chain limitations and cost competitiveness with conventional fuels, continued advancements in technology and supportive policies will pave the way for a cleaner and greener future in aviation.