Introduction

The aviation industry's commitment to decarbonization has led to a growing interest in Sustainable Aviation Fuel (SAF) as a renewable alternative to conventional jet fuel. SAF, produced from sustainable sources such as biomass and renewable hydrogen, has shown the ability to significantly reduce greenhouse gas emissions and mitigate the environmental impact of air travel.

However, the path to a greener aviation sector is not without challenges. SAF currently faces limitations in terms of cost and availability on a large scale.

To achieve the industry's goal of net-zero carbon emissions by 2050, innovative solutions are needed. In this context, Unifuel.tech's Flexiforming technology offers a promising solution. By allowing operators to control their decarbonization pace and utilizing existing facilities, Flexiforming reduces capital expenditure and carbon intensity. As the industry strives to boost SAF production and achieve a sustainable aviation future, the collaboration of all stakeholders is vital.

Background: Sustainable Aviation Fuel (SAF)

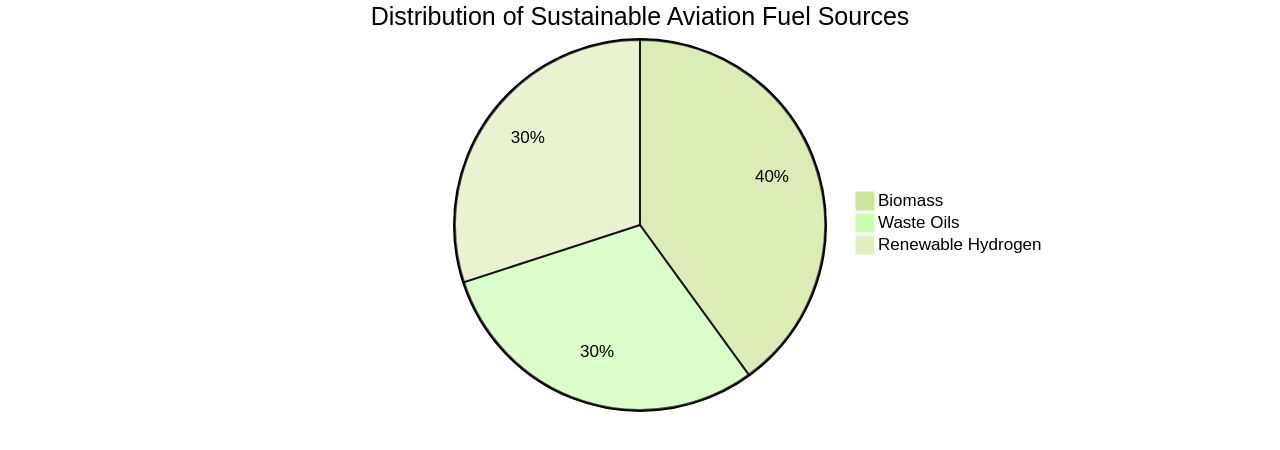

The burgeoning interest in Sustainable Aviation Fuel (SAF) is a response to the urgent need for cleaner aviation. As a renewable alternative to conventional jet fuel, SAF is produced from sustainable sources such as biomass, waste oils, and renewable hydrogen. The ability of SAF to reduce greenhouse gas emissions and lessen the environmental impact of air travel is substantial, as demonstrated by Virgin Atlantic's Flight 100, which was powered entirely by SAF derived mostly from waste cooking oils and animal fat, thereby reducing carbon emissions by 70%.

This trailblazing initiative is a testament to the aviation industry's commitment to decarbonisation. Nevertheless, the path to a greener aviation sector is fraught with challenges. Currently, SAF is 3 to 4 times costlier than regular fuel and its large-scale availability is limited.

The aviation sector, contributing 2-3% of global CO2 emissions, is aiming for net-zero carbon emissions by 2050, according to the International Civil Aviation Organization. This ambition underscores the necessity of SAF, even though the technology is still developing. Countries like Australia are formulating certification processes for SAF, including lifecycle greenhouse gas assessments.

This, along with the need for processing plants to operate on renewable energy for maximum emission reduction, constitutes challenges. Despite these hurdles, SAF has surfaced as the main method of reducing emissions in the aviation industry, with the potential to lower CO2 emissions by 89-94% through the PtL process. As the industry confronts these issues, the combined effort of all participants is crucial in boosting SAF production and realizing a sustainable aviation future.

In this context, Unifuel.tech's Flexiforming technology offers a promising solution. Flexiforming allows operators to control their decarbonization pace and can be installed in an idle hydrotreater or reformer, thereby reducing capital expenditure and carbon intensity. By providing information about feeds, target products, and existing facilities, operators can explore the optimal application for Flexiforming with Unifuel.tech, which promises to respond within 24 hours of inquiry.

Challenges and Opportunities in SAF Production

The journey towards sustainable aviation fuel (SAF) is a complex dance of opportunities and challenges. Scalability remains a significant hurdle.

With the aviation sector contributing 2-3% of global CO2 emissions, the urgency for greener solutions is evident. The industry's goal for net-zero carbon emissions by 2050 requires a substantial leap in innovation and technology.

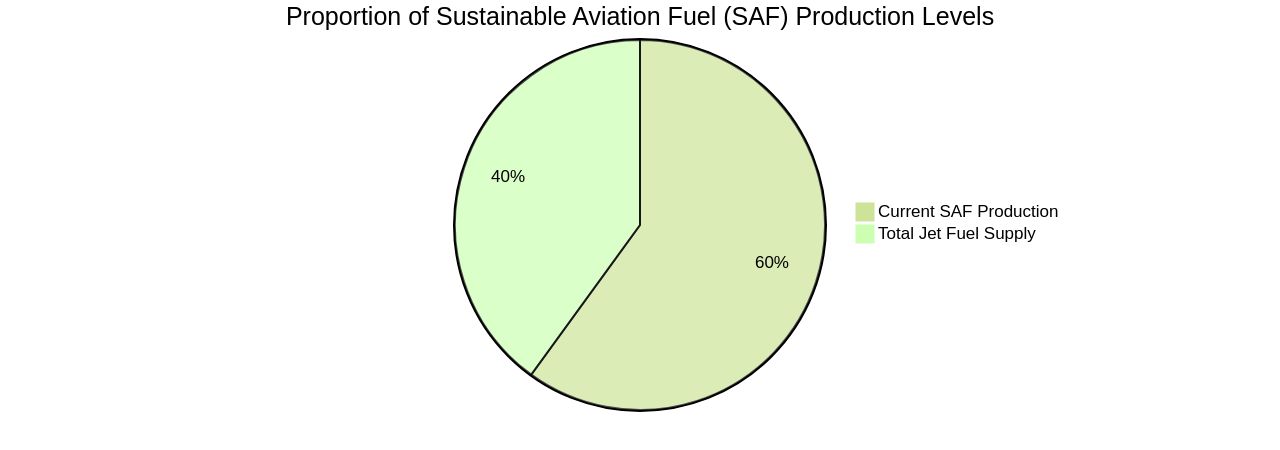

Presently, SAF production levels are less than 0.2% of the global jet fuel supply, a stark comparison to the expected demand. This disparity emphasizes the need for a strategic expansion of supply chains, which can be met through the creation of efficient and scalable production methods.

In this light, Universal Fuel Technologies' Flexiforming technology emerges as a promising solution. Flexiforming allows operators to choose their decarbonization speed, offering a flexible and efficient approach to SAF production.

The technology can be deployed in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. There are positive signs that the industry can overcome the challenges. For instance, Virgin Atlantic's recent flight powered entirely by SAF signifies the progress made towards decarbonization. Additionally, stakeholders are actively collaborating to foster innovation and boost SAF production scale. The pursuit of SAF production is not merely a challenge but an opportunity to redefine the future of aviation. In the words of Sir Richard Branson, Founder of Virgin Atlantic, 'The world will always assume something can't be done, until you do it.'

Methodology for Quantifying the Impact of Repurposing Existing Manufacturing Facilities

The scalability challenge of Sustainable Aviation Fuel (SAF) production is progressively being addressed by innovative technologies such as flexiforming offered by Unifuel.tech. This technology allows operators to control their decarbonization pace and can be integrated into idle hydrotreaters or reformers, thereby reducing capital expenditure and carbon intensity.

Aiming to establish a new production facility by 2030, the strategy is influenced by factors such as facility size, location, and infrastructure requirements. The selected site, near Forsmark nuclear power plant, leverages its grid connection for fossil-free electricity, predominantly used for hydrogen production via electrolysis, a crucial element in creating ethanol for aviation electrofuel.

This initiative embodies carbon capture usage (CCU), capturing carbon dioxide from a district heating facility for electrofuel production. Despite the industry's commitment to emission reduction, limitations in global SAF production suggest that demand will soon exceed supply.

Concerns persist around affordability, sustainability, feedstock competition, and economically efficient production scales. Achieving scale in SAF production will necessitate significant investment and supportive regulations. As the SAF industry is still emerging, there are a few global producers, making this alternative fuel a costly option for most airlines. However, the industry is committed to overcoming these challenges through various initiatives and collaborative platforms, aiming to foster innovation, production, and the use of SAF globally. Unifuel.tech's responsive customer service and its commitment to finding optimal applications for flexiforming technology contribute to these industry-wide efforts.

Case Studies: Repurposing Pulp and Paper Facilities for SAF Production

The potential for converting existing pulp and paper facilities for Sustainable Aviation Fuel (SAF) production has been explored in multiple case studies, yielding positive outcomes. A joint study proposes a novel production facility proximate to Forsmark on Sweden's east coast. The chosen site's advantage lies in its access to fossil-free electricity from the Swedish electricity mix, vital for electrofuel production, an SAF category.

Electrofuel production necessitates fossil-free electricity, water, and recycled carbon dioxide procured from a district heating facility. The electricity is primarily employed to generate hydrogen via electrolysis, which when integrated with carbon dioxide, transforms into ethanol and then aviation electrofuel. In parallel, Fulcrum, a firm committed to producing net-zero transport fuels from waste, has successfully established its inaugural plant in the United States and is now pursuing international expansion.

Their first commercial-scale project in the UK received substantial support from a UK Government Grant under the Advanced Fuels Fund (AFF), emphasizing the increasing focus on SAF production. When utilized for aircraft, electrofuel significantly curtails carbon dioxide emissions compared to fossil fuel. While an accurate reduction percentage is currently unattainable, the aviation industry's dedication to emissions reduction and the rising global adoption of SAFs, especially across Europe, the UK, and the USA, signal a promising future for this sustainable solution.

Yet, the issues of affordability and sustainability, competition for feedstocks, and economically efficient production scales persist. Despite these hurdles, countries like Australia, which already generates substantial feedstock quantities for biofuel production export, could play an instrumental role in the SAF industry. In a similar vein, Unifuel.tech, a subsidiary of Universal Fuel Technologies, has introduced Flexiforming, a technology that enables operators to dictate their decarbonization pace.

This technology can be implemented in an idle hydrotreater or reformer, thereby lowering capital expenditure and carbon intensity. Unifuel. Tech is committed to responding to inquiries within 24 hours, providing optimal Flexiforming applications based on the operator's feeds, target products, and existing facilities.

Financial Impact of Manufacturing SAF using Repurposing Value Levels

The economics of Sustainable Aviation Fuel (SAF) production, particularly from repurposed facilities, is a complex calculation involving various factors. These include the initial capital expenditure for retrofitting facilities, ongoing operational costs, and the current SAF market price.

Yet, converting existing facilities into SAF production units has shown substantial cost savings compared to building new ones. The aviation industry, accounting for 2-3% of global CO2 emissions, is actively pursuing decarbonization.

SAF is considered instrumental in achieving the International Civil Aviation Organization's goal of net-zero carbon emissions by 2050. However, the nascent stage of SAF technology and the associated costs are significant hurdles.

The US aviation industry, a considerable contributor to the country's transportation emissions, is growing rapidly, escalating the emission levels. Given the average lifecycle of commercial aircraft (20-30 years), achieving decarbonization solely through efficiency improvements or electrification seems challenging.

Thus, SAF presents a viable mid-century decarbonization strategy. Nonetheless, obstacles persist.

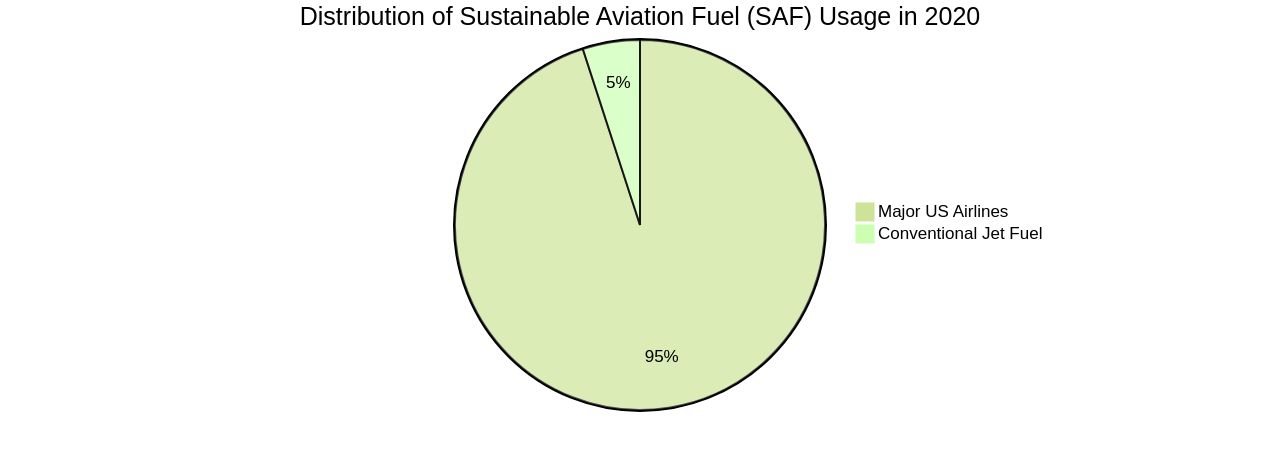

SAF supplies are scarce and can be 2-5 times more costly than conventional jet fuel. In 2020, SAF accounted for only 0.1% of the total jet fuel used by major US airlines.

The Biden administration aims to produce 3 billion gallons of SAF per year by 2030, necessitating a nearly 100-fold increase. Despite these challenges, promising developments are emerging. For example, a Nevada-based factory is transforming waste into synthetic crude oil for jet fuel production, and a Brooklyn-based startup is converting CO2 into jet fuel. These initiatives, along with others, are helping build a more sustainable aviation industry through SAF production. However, the environmental benefits of these alternative fuels largely depend on their production process. Among these developments, Unifuel.tech's Flexiforming technology stands out. It enables operators to choose their decarbonization pace and can be deployed in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity. The company responds promptly to inquiries, seeking information about feeds, target products, and existing facilities to identify the optimal application for Flexiforming, thereby contributing to the industry's decarbonization goals.

Regional Impact Analysis of SAF Production from Repurposed Facilities

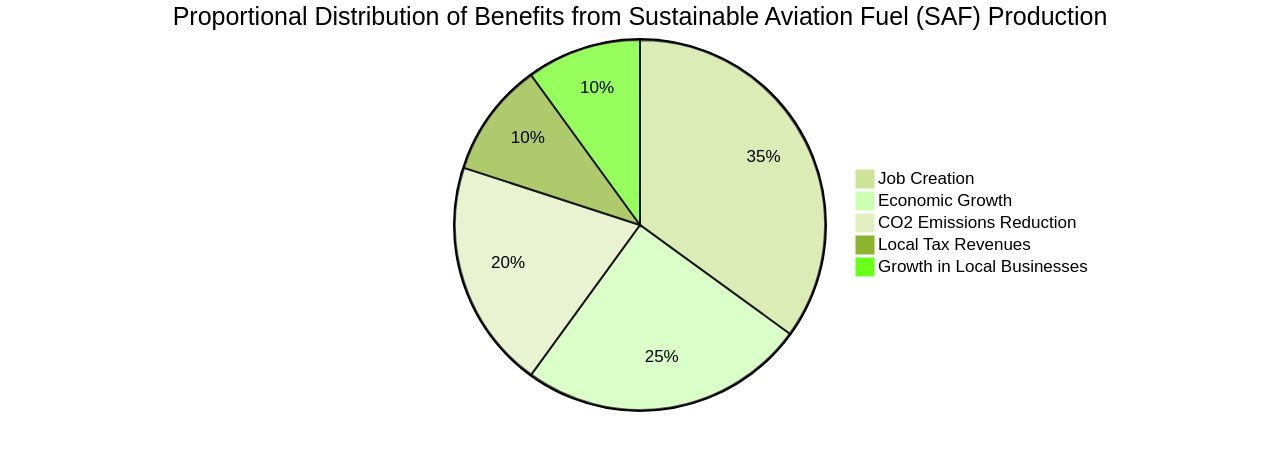

The potential benefits of Sustainable Aviation Fuel (SAF) production from repurposed facilities have been analyzed, with a focus on regional impact. This analysis considers various factors including job creation, economic growth, and environmental impact.

It is important to note that while this form of economic analysis is common in industry, it may not be suitable for long-term economic forecasting due to inherent assumptions related to pollution and external costs. Despite this, the results demonstrate that repurposing facilities for SAF production can lead to positive regional impacts.

This includes contributing to local economies through direct and indirect job creation and investment, as well as reducing CO2 emissions, which is a significant challenge in the aviation sector. The production of SAF also brings about increased local tax revenues, benefiting institutions such as schools and police departments, and stimulating growth in local businesses in various sectors, from manufacturing to services. Furthermore, the production of SAF aligns with the International Civil Aviation Organization's goal of achieving net zero carbon emissions by 2050. It is also worth noting that the uptake of SAF by airlines is seen as a priority by a significant majority of stakeholders, further highlighting the potential benefits of this transition.

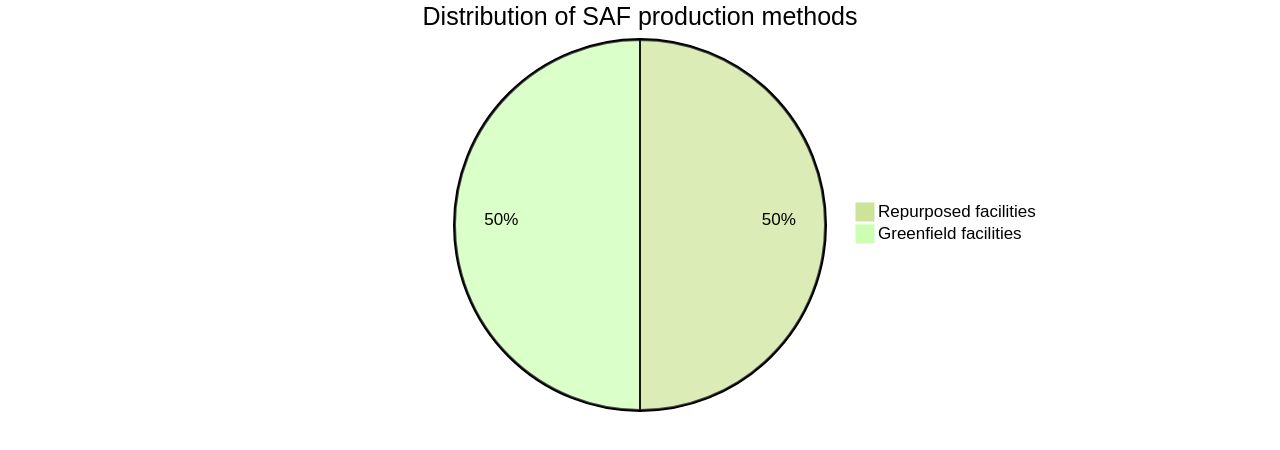

Comparison with Greenfield Facilities

Examining the potential for SAF production, one must weigh the merits between using repurposed facilities and initiating greenfield facilities. The former offers the advantage of reduced construction time and initial investment costs, while the latter is custom-built for SAF production, potentially offering higher efficiency and productivity. The case of the proposed production facility near Forsmark on Sweden's east coast illustrates the potential of repurposed facilities.

It's expected to produce 80,000 tons of SAF annually, fulfilling 5% of Sweden's jet fuel demand today and projected to meet 20% of its SAF need by 2030. This facility employs a carbon capture usage (CCU) system, capturing CO2 from a district heating facility for electrofuel production. Similarly, in the US, a retired coal-fired power plant site in Wyoming is being considered for a sodium-cooled fast reactor, offering displaced coal workers employment opportunities.

However, SAF production also faces challenges. Despite promising tests, alternative fuels only constituted less than 0.2% of the global jet fuel supply in 2022. Sustainable aviation fuels, which reduce CO2 emissions by up to 85%, are still expensive to produce and are in limited supply.

While refineries are gradually being converted to renewable fuel production, this process is complex, challenging, and viable for only a few dozen refineries. However, the petroleum industry is increasingly interested in modifying existing refineries to produce renewable diesel and SAF, which could be more economical than constructing new facilities. In conclusion, both repurposed and greenfield facilities have their advantages and challenges, and the choice between the two would depend on various factors, including location, available resources, and economic considerations.

Environmental Impact Assessment of SAF Production Pathways

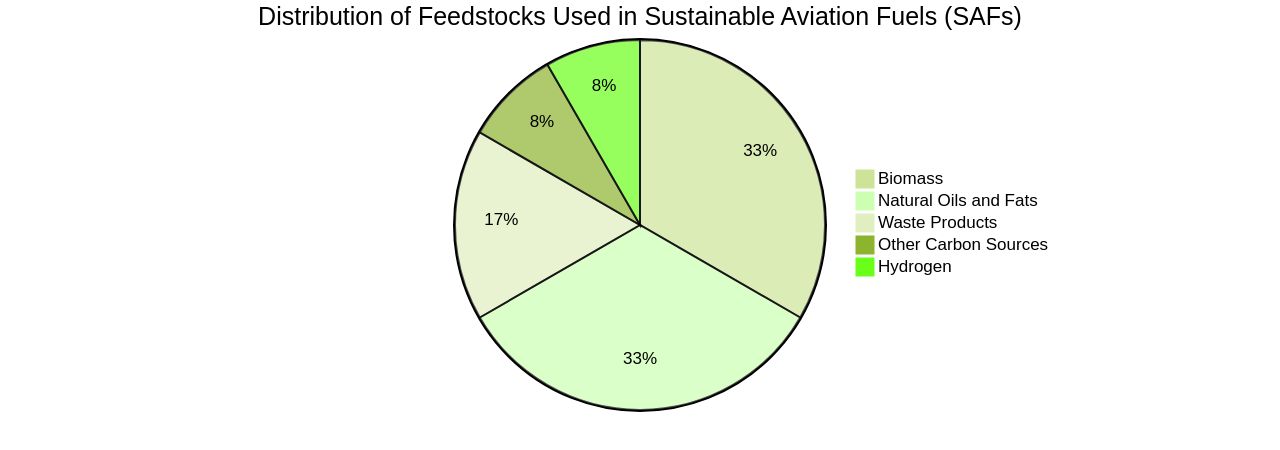

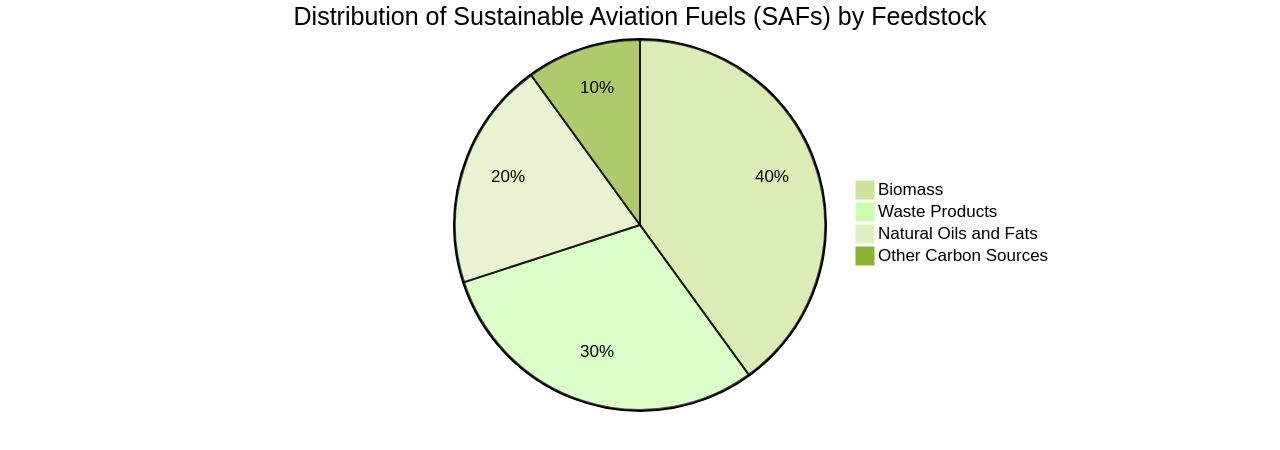

The aviation industry is under pressure to reduce emissions, with sustainable aviation fuels (SAF) emerging as a promising solution. SAFs are derived from a variety of feedstocks, including biomass, waste products, natural oils and fats, other carbon sources, and hydrogen. However, the global production of SAFs is currently limited, and demand is expected to surpass supply.

This is particularly the case in Europe, the UK, and the USA, where there is an increasing uptake of SAFs. The environmental impact of SAF production is a crucial consideration. An assessment of factors such as carbon emissions, land use, and water consumption reveals that SAFs produced from repurposed facilities can have a significantly lower environmental impact compared to traditional aviation fuel.

Nevertheless, the aviation sector's commitment to emissions reduction raises key questions about the affordability and sustainability of Safe, as well as competition for feedstocks and economically efficient scales of production. The International Civil Aviation Organization has set an ambitious goal for the industry to achieve net-zero carbon emissions by 2050, further emphasizing the need for innovative solutions like SAFs. As the US aviation sector, the third-largest source of US transportation emissions, continues to grow, the decarbonization of the sector becomes increasingly challenging.

SAFs represent a viable option for mid-century decarbonization, especially considering commercial aircraft operate on average for 20 to 30 years. Given these complexities, research is essential to optimize resource allocation, identify and resolve bottlenecks in maintaining a consistent feedstock supply, and understand the effects of various emissions and the effectiveness of emission reduction technologies. Ultimately, SAFs present a promising pathway to reduced greenhouse gas emissions, contributing to the global effort to combat climate change.

Socio-Technical System Approach in Prospective Life Cycle Assessment

In the face of a strained global energy system, the aviation industry must consider alternative means of energy production, supply, and security. Sustainable Aviation Fuels (SAFs) have emerged as a viable solution, especially for long-haul segments that cannot leverage electrification or alternative fuels in the immediate future.

These fuels, derived from a variety of feedstocks such as biomass, waste products, natural oils and fats, and other carbon sources, present a promising avenue for emissions reduction. The global uptake of SAFs is on the rise, particularly in regions like Europe, the UK, and the USA.

However, with aggressive adoption timelines and high volume targets, production is struggling to keep pace with demand. This raises important questions about the affordability and sustainability of Safe, as well as competition for feedstocks and economically efficient production scales.

To truly understand the potential benefits and challenges of SAF adoption, a socio-technical system approach must be adopted. This approach, which encompasses technical, social, and economic aspects, provides a holistic perspective on SAF production. It also underscores Australia's potential role as a key player in the SAF industry, both as a source of feedstocks and a producer of SAFs. The country already exports significant quantities of feedstocks for biofuel production and is well-placed to expand this into a diversified portfolio of feedstock sources. Furthermore, Australia's burgeoning hydrogen economy could supply the clean hydrogen needed in several fuel production processes.

Potential SAF Technology Pathways and Environmental Performances in Sweden

Sweden's commitment to carbon neutrality in the aviation sector is driving the exploration of various Sustainable Aviation Fuel (SAF) production technologies. One promising pathway is the production of electrofuels, a type of SAF, which uses fossil-free electricity, water, and recycled carbon dioxide.

This process, known as Carbon Capture Usage (CCU), employs electricity to create hydrogen via electrolysis. This hydrogen, combined with captured carbon dioxide, is converted into aviation electrofuel.

The planned raw materials are fossil-free electricity from the Swedish grid and carbon dioxide collected from Vattenfall’s combined heat and power plant in Uppsala, which has the potential to recover 200,000 tons of carbon dioxide annually. This method keeps fossil raw materials in the ground and virtually eliminates new fossil carbon dioxide emissions.

Additionally, Stockholm Exergi's biomass-based combined heat and power plant, operational since 2016, will expand its operations to include a carbon capture unit, liquefaction, and intermediate storage by 2025. This expansion is expected to remove up to 800,000 tons of CO₂ from the atmosphere annually. The production of electrofuels and other Safe is crucial in achieving the International Civil Aviation Organization's goal for the industry to reach net zero carbon emissions by 2050. These initiatives in Sweden are part of a broader global trend, with an increasing adoption of safe across Europe, the UK, and the USA.

Implications for Policy and Investment Decision Making

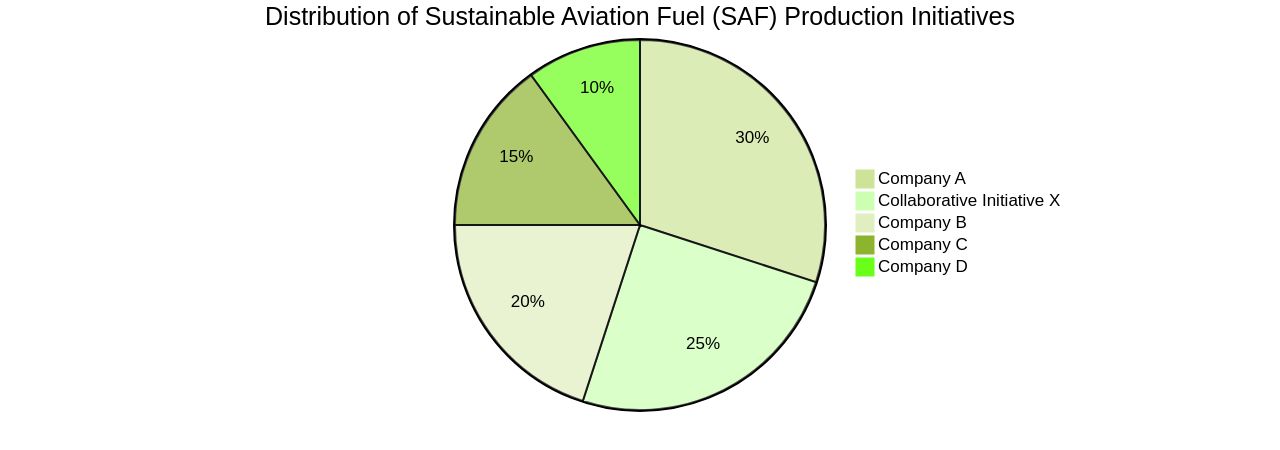

The shift towards Sustainable Aviation Fuel (SAF) production in existing manufacturing facilities marks a significant stride in the decarbonization of the aviation industry, which currently accounts for 2-3% of global CO2 emissions. The efficacy of these repurposing initiatives is substantiated by numerous case studies, particularly from regions like South Australia, where a holistic approach involving government, industry, education, and community stakeholders is actively promoting a resilient, knowledge-based, green economy. Companies such as Fulcrum, Airbus, and a collaborative initiative between Alaska Airlines, Microsoft, and Twelve, have set the precedent for the feasibility of repurposing for SAF production.

Fulcrum, focusing on net-zero transport fuels from waste, has successfully established its first plant in the US and is expanding globally, bolstered by government grants and strategic alliances. Airbus has initiated a program to examine the infrastructure prerequisites for low-carbon airport operations, engaging with partners and airports across ten countries. The collaboration between Alaska Airlines, Microsoft, and Twelve aims to scale up SAF production, targeting the production of 1 million gallons of fuel annually.

In the wake of these advancements, Unifuel.tech offers a groundbreaking technology called Flexiforming. This technology enables operators to determine their decarbonization pace and can be deployed in idle hydrotreaters or reformers, thereby reducing capital expenditure and carbon intensity. This innovative solution requires information about the operator's feeds, target products, and existing facilities to identify an optimal application for Flexiforming.

While these developments underscore the viability of repurposing as a strategy to augment SAF production capacity, the role of policymakers and investors in providing adequate support and funding to expedite this transition cannot be understated. This support encompasses fiscal incentives, fostering platforms for collaboration, and innovation within the SAF value chain. With the International Civil Aviation Organization aiming for net-zero carbon emissions by 2050, these strategic investments are key to realizing this objective.

Conclusion

In conclusion, the aviation industry's commitment to decarbonization has led to a growing interest in Sustainable Aviation Fuel (SAF) as a renewable alternative to conventional jet fuel. SAF has shown significant potential in reducing greenhouse gas emissions and mitigating the environmental impact of air travel.

However, challenges such as cost and availability on a large scale need to be addressed for SAF to become a widespread solution. To achieve the industry's goal of net-zero carbon emissions by 2050, innovative solutions are crucial.

Unifuel.tech's Flexiforming technology offers a promising solution by allowing operators to control their decarbonization pace and utilize existing facilities. This reduces capital expenditure and carbon intensity, making SAF production more efficient.

Collaboration among all stakeholders is vital in boosting SAF production and achieving a sustainable aviation future. Strategic expansion of supply chains, supportive regulations, and investment in SAF production are necessary steps.

Despite challenges like affordability, sustainability, feedstock competition, and economically efficient production scales, the industry is committed to overcoming them through initiatives and collaboration. Unifuel.tech's responsive customer service and commitment to finding optimal applications for Flexiforming technology contribute to these efforts. In conclusion, the aviation industry is determined to realize a sustainable future through the adoption of SAFs. Repurposing existing manufacturing facilities for SAF production can lead to positive regional impacts by creating jobs, stimulating economic growth, reducing CO2 emissions, and increasing local tax revenues. With the support of policymakers, investors, governments, and industry players, the vision of a greener aviation sector powered by SAFs can become a reality. By working together towards this common goal, we can pave the way for a sustainable aviation future that benefits both the industry and the environment.