Introduction

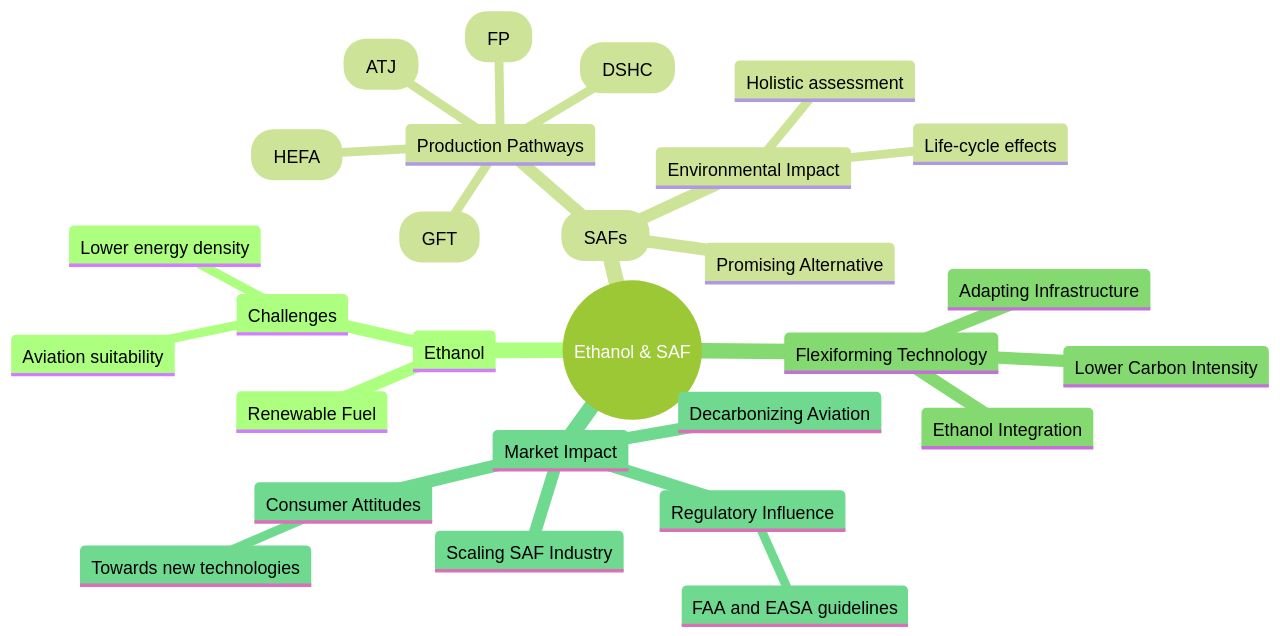

Ethanol's role as a renewable fuel in the energy sustainability sector is well-established, but its potential as a jet fuel alternative is still being explored. Ethanol has lower energy density compared to conventional gasoline, making its adoption in aviation a subject of careful study. However, advancements in technology and the emergence of sustainable aviation fuels (SAFs) are offering promising solutions.

Unifuel.tech's flexiforming technology, for example, presents a scalable approach to integrating ethanol into the SAF framework. With the industry's focus on decarbonization and net-zero emissions, innovations like flexiforming could play a pivotal role in shaping the future of ethanol in the sustainable aviation fuel market. This article delves into the advancements, benefits, challenges, and future directions of ethanol-to-jet fuel technology, providing technical insights and analysis for those with a deep understanding of the renewable fuels industry.

Ethanol Fuel Basics

Ethanol's role as a renewable fuel is well-established, with its production from corn and sugarcane making significant strides in energy sustainability. However, its adoption in aviation, particularly as a jet fuel alternative, is being carefully studied due to its lower energy density compared to conventional gasoline. In the U.S., ethanol production is efficient, with a positive energy balance.

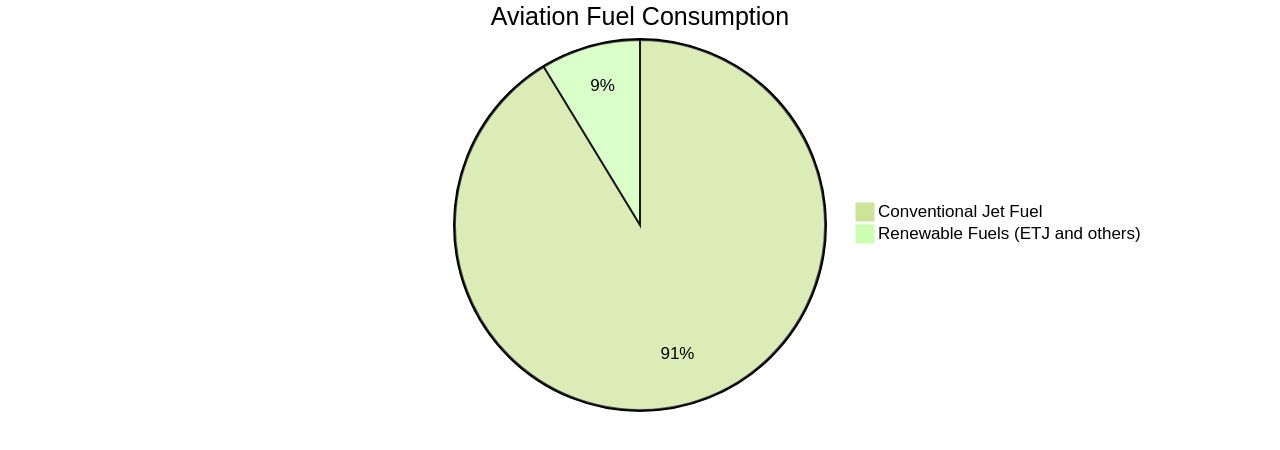

Yet, the environmental impact of corn cultivation for ethanol, including potential CO2 emissions from land-use changes, is a point of contention. Sustainable aviation fuels (SAFs) are emerging as a promising alternative, with less than 1% market penetration but significant potential to reduce CO2 emissions without overhauling existing infrastructure. Airbus's commitment to SAF compatibility by 2030 exemplifies the industry's move towards net-zero emissions by 2050.

Amidst these developments, Unifuel. Tech introduces flexiforming technology, a versatile solution that enables the adaptation of idle hydrotreaters or reformers for producing lower carbon intensity fuels. This innovation aligns with the industry's decarbonization efforts and offers a scalable approach to integrating ethanol into the SAF framework.

The technology's rapid response capability and customization based on specific feedstocks, target products, and facility configurations underscore its potential to optimize ethanol's use in the aviation sector while addressing concerns over its environmental impact. With the Biden administration's proposed guidelines incentivizing climate-friendly practices, flexiforming by Unifuel. Tech could play a pivotal role in shaping the future of ethanol in the sustainable aviation fuel market.

Advancements in Ethanol-to-Jet Fuel Technology

The renewable fuels sector is witnessing a transformative era with the emergence of ethanol-to-jet (ETJ) fuel technologies. ETJ harnesses the potential of ethanol, a biofuel derived from corn and other biomass, to create jet fuel that can seamlessly integrate with existing aviation infrastructure. Engine Test Journals (ETJs) play a pivotal role in this development, ensuring that these sustainable aviation fuels (SAFs) meet rigorous performance and emissions standards.

Despite ethanol containing about 30% less energy per gallon than gasoline, recent breakthroughs in catalysis have enabled the efficient conversion of ethanol into butene, an intermediary compound that refines into jet fuel identical to its petroleum-based counterpart. The U.S. has produced a modest quantity of ETJ, less than 0.1% of the total jet fuel consumed by major airlines, highlighting the nascent stage of this technology. Nonetheless, the compelling advantage of ETJs lies in their compatibility with current jet engines, requiring no significant modifications, thus presenting a viable pathway to reducing the aviation industry's carbon footprint.

A notable initiative by researchers at the Whiting School of Engineering and their collaborators, funded by a $2.5 million grant from the Department of Energy, underscores the commercial viability of plant-based jet fuel. This SAF, derived from CO2-absorbing plants, offers the dual benefit of environmental sustainability and compliance with emerging greenhouse gas regulations. As the industry navigates challenges such as limited supplies and higher costs compared to conventional jet fuel, the progress in ETJ technology signals a promising future for reducing aviation's carbon emissions.

Innovations like Unifuel.tech's Flexiforming technology align with these advancements by providing a decarbonization path that is adaptable to the operator's timeline. Through the utilization of existing infrastructure, such as idle hydrotreaters or reformers, Flexiforming offers a cost-effective way to incorporate SAFs, like ETJ, into the fuel supply chain with reduced capital expenditure and carbon intensity. Unifuel.tech's commitment to rapid communication and tailored solutions, with a 24-hour response guarantee, further supports the industry's transition to more sustainable fuel options.

Benefits of Ethanol-to-Jet Fuel for Aviation

The integration of ethanol-to-jet (ETJ) fuel is a significant stride towards achieving aviation's net-zero emissions goal by 2050. ETJ not only offers the potential to slash carbon emissions but also enhances fuel supply diversity and is seamlessly compatible with current aircraft engines and infrastructure.

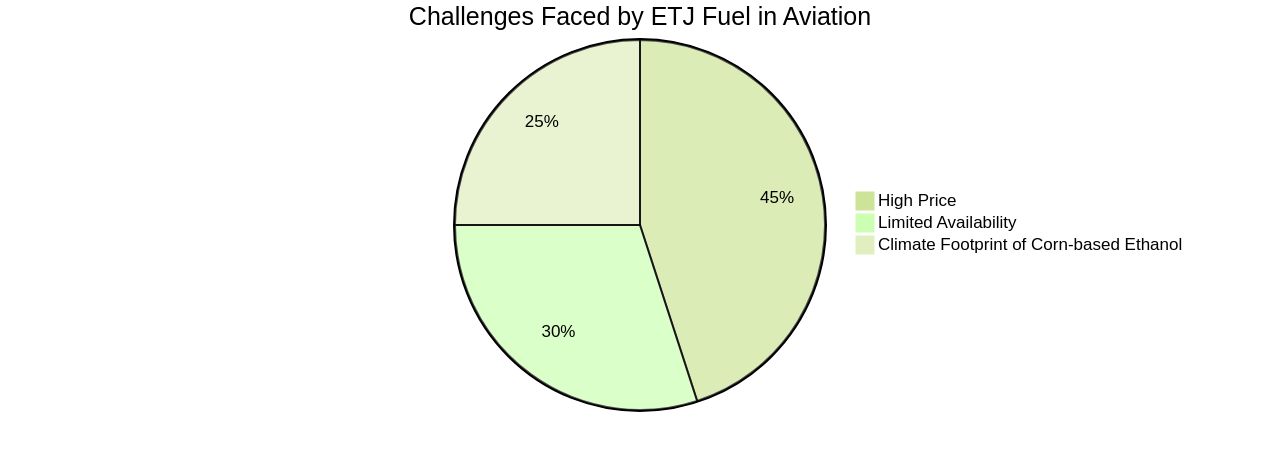

Airbus, a pioneer in sustainable aerospace, is actively working towards making its aircraft fully compatible with Sustainable Aviation Fuel (SAF) by 2030, in alignment with their partnership endeavors with Emirates to expand the SAF market. While ETJ can substitute or mix with traditional kerosene-based jet fuel, it faces the hurdle of limited availability and a price tag that is currently two to five times higher than conventional jet fuel.

The U.S. production of ETJ remains a fraction of what is needed, with the Biden administration targeting a substantial increase to 3 billion gallons annually by 2030. This ambitious goal is underscored by the Freedom Pines Fuels facility's expected contribution, which, upon commencement, will produce millions of gallons of ETJ, alongside renewable diesel.

Despite the challenges, the potential energy balance of ethanol production from corn presents a positive outlook, with 94% of U.S. ethanol derived from corn starch. However, the ethanol industry must navigate the complexities of corn-based ethanol's climate footprint, as it incites debate over land-use change and associated emissions.

The aviation industry's shift towards SAF blends, which includes ETJ, necessitates a transformation of global aircraft fleets, airports, and fueling infrastructure, a task that demands significant investment and coordination. In light of these factors, the journey towards decarbonizing aviation through ETJ and other Safe is underway, with each step forward marking progress towards a more sustainable future in air travel.

Amidst this transformative landscape, Unifuel. Tech emerges as a notable player with its Flexiforming technology, enabling operators to tailor their decarbonization trajectory. This innovative solution can be integrated into idle hydrotreaters or reformers, thus optimizing capital expenditure and diminishing carbon intensity. Unifuel.tech's commitment to rapid response and tailored solutions exemplifies the proactive approach required to meet the aviation industry's decarbonization challenges. As part of Universal Fuel Technologies, Unifuel. Tech stands as a testament to the dynamic advancements propelling the SAF market forward.

Challenges and Future Directions for Ethanol-to-Jet Fuel Adoption

The quest for sustainable aviation fuel (SAF) is gaining momentum as the industry seeks to mitigate its carbon footprint. SAF, which includes ethanol-to-jet (ETJ) fuel, is viewed as a promising alternative to conventional jet fuel.

Although it represents a mere fraction of the market, Saf's compatibility with existing engines and infrastructure positions it as a viable transitional energy source. The production of SAF from ethanol is particularly interesting because it leverages the established ethanol industry, offering a pathway to incorporate renewable content into aviation fuel.

However, realizing the potential of ETJ fuel involves overcoming significant challenges. These include ensuring the sustainability of feedstock production, which is currently dominated by corn, a crop that is water-intensive and has raised concerns over land-use and carbon-emission implications.

The commercial readiness of ETJ fuel also hinges on the ability to convert ethanol into aviation-grade fuel economically, with researchers actively developing catalysts to facilitate this transformation. Yet, the current production of SAF falls short of the aviation industry's demand, with the U.S. producing less than 0.2 percent of the required jet fuel consumption in this category. The Biden administration's ambitious goal of achieving 100 percent SAF by 2050 underscores the urgency to scale up production and reduce costs. Moreover, the adoption of SAF, including ETJ, must navigate public policy incentives and regulatory hurdles, as the industry works to prove that these fuels can meet stringent safety and performance standards without necessitating infrastructural overhauls. As the industry grapples with these complexities, the pursuit of SAF continues, driven by the imperative of transitioning to greener energy sources to power the future of aviation.

Conclusion

In conclusion, ethanol's potential as a jet fuel alternative is being explored, and advancements in technology, like Unifuel.tech's flexiforming technology, offer a scalable approach to integrating ethanol into the sustainable aviation fuel (SAF) framework. ETJ fuel technologies are transforming the renewable fuels sector by efficiently converting ethanol into jet fuel identical to petroleum-based fuel. These fuels are compatible with current jet engines, reducing the industry's carbon footprint.

Integrating ETJ fuel not only reduces carbon emissions but also enhances fuel supply diversity and seamlessly integrates with existing aircraft infrastructure. Unifuel.tech's flexiforming technology provides a cost-effective solution for incorporating ETJ into the fuel supply chain while reducing capital expenditure and carbon intensity. However, challenges remain in ensuring sustainable feedstock production and developing catalysts for economically converting ethanol into aviation-grade fuel.

Scaling up production and reducing costs are crucial to meeting the aviation industry's demand for sustainable fuels. In conclusion, innovations like flexiforming technology by Unifuel.tech have the potential to shape the future of ethanol in the sustainable aviation fuel market. The pursuit of sustainable aviation fuels continues as the industry aims for decarbonization and net-zero emissions, driving the transition to greener energy sources for aviation's future.