Introduction

Air-based fuel production is revolutionizing the renewable fuels industry, offering a transformative solution to reduce carbon emissions and mitigate climate change. This article explores the role of air in sustainable fuel production, advancements in air-based fuel production techniques, the science behind these processes, and the benefits and challenges associated with this innovative approach. With a focus on technical insights and analysis, this article provides a comprehensive overview of the potential of air-based fuel production and its impact on the future of renewable fuels.

The Role of Air in Sustainable Fuel Production

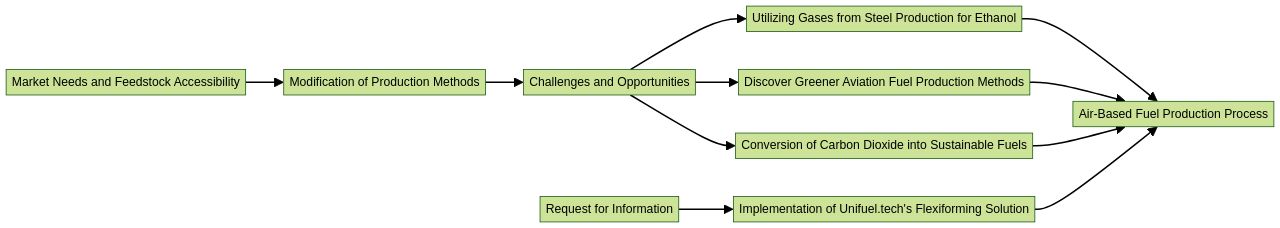

Air's role in sustainable fuel production is transformative, serving as a catalyst for greener practices within the industry. The emergence of novel technologies capable of harnessing air has led to the production of sustainable fuels with significantly reduced carbon emissions. A notable example is the technology developed by LanzaTech at the Ghent steel mill, which ferments gases produced during steel production into ethanol, a process that presents both challenges and opportunities.

The aviation industry, a significant contributor to global warming, is turning to these alternative fuels, known as sustainable aviation fuels (SAFs), to mitigate their climate impacts. The potential of SAFs is significant, with the industry setting its sights on achieving net-zero carbon dioxide emissions by 2050. The production of SAFs, utilizing a diverse range of feedstocks such as biomass, waste products, natural oils, fats, carbon sources, and hydrogen, is gaining traction globally.

The challenge, however, is fulfilling the escalating demand due to limited global production, thereby raising concerns about affordability and sustainability. Understanding these fuels' environmental impacts is crucial. Life cycle assessments, such as those developed by E4tech, offer insights into these fuels' environmental performance, providing a comparative analysis of their greenhouse gas emissions and potential environmental implications.

This information aids policymakers and stakeholders in making informed decisions about the future energy mix. A potential solution to these challenges is the flex forming technology offered by Unifuel.tech. This technology allows operators to choose their speed of decarbonization and can be implemented in an idle hydrotreater or reformer, reducing both capital expenditure and carbon intensity.

Unifuel.tech's commitment to respond to inquiries within 24 hours, along with their willingness to find an optimal application for flexiforming based on feeds, target products, and existing facilities, demonstrates a proactive approach to tackling the challenges of sustainable fuel production. While the journey towards sustainable fuel production is filled with challenges, the potential environmental benefits make it a worthwhile pursuit. The key to success lies in continuous innovation, comprehensive environmental impact assessments, and a steadfast commitment to a greener future.

Advancements in Air-Based Fuel Production

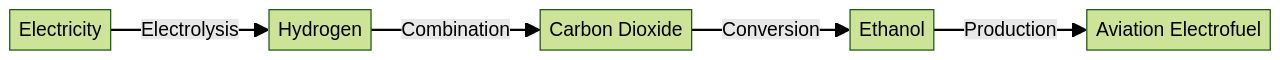

The renewable fuels sector is witnessing a revolutionary shift, with air-based fuel production serving as the cornerstone of this transformation. Innovative techniques are emerging that leverage air as a feedstock for fuel production, which in turn facilitates the creation of sustainable aviation fuel (SAF) and other renewable fuels. A prime example of such innovation is electrofuel, an SAF variant that relies on fossil-free electricity, water, and recycled carbon dioxide.

This process involves the conversion of electricity into hydrogen via electrolysis, which is then combined with carbon dioxide to produce ethanol, eventually yielding aviation electrofuel. This method captures and repurposes carbon dioxide from district heating facilities, thus preventing its release into the atmosphere and significantly reducing carbon dioxide emissions. The potential of renewable fuels is staggering, as illustrated by a study revealing the U.S.'s wind and solar energy potential to be 100 times the country's current total liquid fuel consumption.

This is particularly crucial for industries like aviation and heavy-duty transport, which face significant challenges in decarbonization. Moreover, renewable fuels are compatible with our existing infrastructure and also pave the way for the development of new infrastructure and technologies. Consider, for instance, the HyFlexPower project, which showcases the feasibility of converting renewable energy into green hydrogen.

This technology can supply industrial sites with electricity derived from renewable sources like solar or wind, marking a significant stride towards industrial decarbonization. In this context, Unifuel.tech emerges as a promising solution offering flexiforming, a method that allows operators to choose their decarbonization pace. Flexiforming can be deployed in an idle hydrotreater or reformer, thereby reducing capital expenditure and carbon intensity.

Universal Fuel Technologies, the company behind Unifuel.tech, responds to inquiries within 24 hours, requesting details about the operator's feeds, target products, and existing facilities to find an optimal application for flexiforming. Such advancements underscore the promise of SAF and other renewable fuels in leading the way towards a cleaner, more sustainable future. However, continued research and development efforts are essential to further enhance the efficiency and scalability of these technologies.

The Science Behind Air-Based Fuel Production

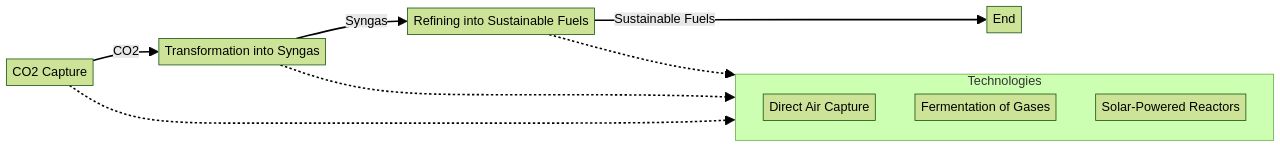

The multi-stage scientific process of air-based fuel production commences with carbon dioxide (CO2) capture from the air. This CO2 undergoes transformation into syngas via direct air capture (DAC) and electrochemical methods. Further refining of the syngas into sustainable fuels is achieved through technologies such as Fischer-Tropsch synthesis or hydroprocessed esters and fatty acids (HEFA) pathways.

LanzaTech's unique technology, as exemplified by the ethanol production process at a Ghent steel mill, is a notable instance of this. It involves fermenting gases produced during steel production chemistry by microbes to generate ethanol, creating a novel fuel production pathway. Despite the challenges it presents, this method offers significant innovation opportunities within the renewable fuels industry.

Another remarkable development is the solar-powered reactor, developed by researchers at the University of Cambridge, capable of transforming captured CO2 and plastic waste into sustainable fuels and valuable chemical products using solar energy. The reactor has been tested successfully to capture CO2 from real-world sources, such as industrial exhaust or the air, and convert it into sustainable fuel. Sustainable aviation fuel (SAF) production is another innovative area.

SAF comprises two broad classes of chemical compounds—aliphatic and aromatic molecules. While most transportation fuels aim to eliminate aromatic hydrocarbons due to their polluting properties, some aromatic molecules are necessary in aviation fuels for their physical and combustion properties. The renewable fuels industry faces challenges in producing sustainable fuels, but the potential for innovation and advancement is immense.

As technology and processes evolve, the 'Air and Opportunity' potential in the context of renewable fuels becomes increasingly clear. A cutting-edge solution presented by Unifuel.tech is the flexiforming technology that permits operators to select their decarbonization speed. It can be implemented in an idle hydrotreater or reformer, thus reducing capital expenditure and carbon intensity.

Unifuel. Tech offers an optimal flexiforming application based on the operator's feeds, target products, and existing facilities, with a response time of 24 hours. This innovative approach further underscores the potential of 'Air and opportunity in the renewable fuels industry.

Benefits and Challenges of Air-Based Fuel Production

Air-based fuel production signifies a transformative shift in the energy industry, with the potential to redefine our approach to renewable fuels. It carries the promise of mitigating climate change, reducing fossil fuel reliance, and fostering energy independence.

The adaptability offered by air as a feedstock allows plant operators to modify production methods in line with market needs and feedstock accessibility. However, this potential is not devoid of hurdles.

Addressing the high energy requirements for carbon capture and the issues of scalability and cost efficiency is imperative. Factors such as electricity costs and the location of the CO2 source significantly influence the production of renewable methanol from CO2.

An example of such innovation is the process developed by LanzaTech for ethanol production at the Ghent steel mill. This method, which utilizes gases produced during steel production, diverges from existing commercial ethanol production technologies, presenting unique challenges and opportunities.

Transportation, accounting for nearly a quarter of global carbon dioxide emissions in 2021, relies heavily on fossil fuels. The aviation industry is a major contributor, with jet fuel consumption predicted to double by 2050.

Hence, the urgency to discover greener aviation fuel production methods is paramount. Despite these challenges, progress is being made.

Research indicates the potential to convert carbon dioxide into clean, sustainable fuels using solar energy. This technology, though still requiring advancements for industrial-scale use, represents a significant move towards clean fuel production without damaging oil and gas extraction. Enter Unifuel.tech, with its Flexiforming solution, enabling operators to control the pace of decarbonization. This technology can be implemented in idle hydrotreaters or reformers, leading to reduced capital expenditure and carbon intensity. To find the best application of Flexiforming, Unifuel.tech requests information about the operator's feeds, target products, and existing facilities, aiming to respond within 24 hours. To conclude, air-based fuel production offers immense promise in the pursuit of sustainable and renewable fuels. To fully harness its potential, ongoing research, innovation, and resolution of existing challenges are crucial.

Conclusion

Air-based fuel production is revolutionizing the renewable fuels industry, offering a transformative solution to reduce carbon emissions and mitigate climate change. Innovative techniques leveraging air as a feedstock are creating sustainable aviation fuel (SAF) and other renewable fuels.

Advancements like electrofuel and utilizing wind and solar energy potential demonstrate the promise of renewable fuels for a cleaner, more sustainable future. The science behind air-based fuel production involves capturing carbon dioxide from the air and refining it into sustainable fuels using various technologies.

Challenges exist, such as high energy requirements and scalability issues, but the benefits make it worthwhile. Air-based fuel production can mitigate climate change, reduce fossil fuel reliance, and foster energy independence.

Ongoing research, innovation, and overcoming hurdles are crucial to fully harnessing the potential of air-based fuel production. Solutions like Unifuel.tech's flexiforming technology give operators control over decarbonization while reducing costs and carbon intensity. In conclusion, air-based fuel production holds immense promise for a greener future in renewable fuels. Leveraging innovative techniques with air as a feedstock enables the creation of sustainable aviation fuel and other renewables. Despite challenges, ongoing research and technological advancements continue to drive progress towards a cleaner, more sustainable future powered by air-based fuel production.