Introduction

Jet fuel, derived from crude oil, is a vital component of the aviation industry. However, with the industry's commitment to achieving net-zero emissions by 2050, there is a growing need for sustainable alternatives.

This article explores the various options for renewable jet fuels, including Sustainable Aviation Fuels (SAFs), synthetic fuels, hydrogen and ammonia-powered flights, and fully electric aircraft. It also delves into the challenges and opportunities associated with each technology. With a tone geared towards technical insights and analysis, this article provides a comprehensive overview of the renewable fuels industry and its potential to revolutionize aviation.

Understanding Jet Fuel: Composition and Properties

Jet fuel, predominantly composed of hydrocarbons, is derived from crude oil through fractional distillation, with the nature of hydrocarbon molecules determining its characteristics and performance. The majority of jet fuel is made up of aliphatic molecules, similar to diesel fuels, while the remainder comprises aromatic molecules, which are crucial in establishing the physical and combustion properties of aviation fuels. The aviation industry, in a bid to achieve net-zero emissions by 2050, is leaning towards Sustainable Aviation Fuel (SAF), a renewable and energy-dense fuel.

This shift requires extensive testing of SAF under various conditions to gather comprehensive data on its response and to build an accurate combustion simulation. In a significant breakthrough, Virgin Atlantic recently completed the first transatlantic flight powered entirely by SAF, proving its viability as a drop-in fuel compatible with existing infrastructure, engines, and airframes. This achievement opens pathways for greater SAF usage in current fleets and fueling infrastructure.

The BioForming process, which converts sugars to aromatics, enables the production of synthetic aromatics from a wide range of plant sugars and other soluble carbohydrates. However, the transition to SAF alone will not achieve decarbonization. For a fuel blend to qualify as SAF, it must substantially reduce emissions.

In this context, Unifuel. Tech offers a technology known as Flexiforming that enables operators to choose their pace of decarbonization. This technology can be deployed in an idle hydrotreater or reformer, thereby reducing capital expenditure and carbon intensity.

Unifuel. Tech promises a swift response time of 24 hours to inquiries regarding feeds, target products, and existing facilities to find an optimal application for Flexiforming. Despite the early stage of SAF development and application, the potential of SAF to deliver the performance of petroleum-based jet fuel, but with a significantly reduced carbon footprint, is promising.

Jet Fuel Production: Traditional and Alternative Methods

The aviation sector is undergoing a significant shift towards Sustainable Aviation Fuels (SAFs), which are key in reducing emissions. These fuels, derived from renewable resources such as biomass, waste products, and natural oils, are gaining traction due to the limitations of alternatives like green hydrogen or electrification for long-distance flights.

However, the demand for Safe is exceeding the supply, particularly in regions such as Europe, the UK, and the USA, with challenges around affordability, sustainability, and feedstock competition still present. Despite these challenges, the compatibility of SAFs with existing infrastructure and their potential to significantly lower carbon emissions are drawing increased attention.

Innovations in SAF production, including the introduction of bio-based aromatics in the blend, have paved the way for 100% SAF use in aircraft, a notable advancement from the previous 50% blend limit with traditional jet fuels. A notable example of this innovation is the flexiforming technology offered by Unifuel.tech.

This technology, deployable in idle hydrotreaters or reformers, can reduce both capital expenditure and carbon intensity. It empowers operators to dictate their decarbonization speed, making it a vital tool in the aviation industry's decarbonization journey. Unifuel. Tech assures a response within 24 hours when provided with details about feeds, target products, and existing facilities, leading to an optimal application for flexiforming. Therefore, SAFs are not just substitutes for traditional jet fuels, but a crucial component in the aviation industry's quest to reach its ambitious 2050 net-zero emissions goal.

Sustainable Aviation Fuels (SAF): Overview and Benefits

Sustainable Aviation Fuels (SAFs), derived from renewable feedstocks, hold immense potential in the mission to decarbonize the aviation sector, offering significant reductions in lifecycle greenhouse gas emissions compared to traditional jet fuel. They can be integrated into existing fuel systems with minimal modifications, either as a blend with traditional jet fuel or a direct substitute.

Despite this potential, SAFs currently account for less than 0.2% of the global jet fuel supply, highlighting the need for expansion. The annual planned SAF output only satisfies a fraction of global jet fuel demand, with the output of 80,000 tons making up approximately 5% of Sweden's total jet fuel demand.

This output would only meet 20% of Sweden's projected SAF requirements by 2030. Furthermore, SAFs are 3 to 4 times costlier than conventional fuel, acting as a significant barrier to their widespread adoption.

However, the industry remains committed to enhancing the use of SAFs. Virgin Atlantic, for example, is leading an industry consortium to execute the first 100% SAF flight across the transatlantic, demonstrating the industry's commitment to scaling up SAF production. Airbus also plans to make all its aircraft 100% SAF-capable by 2030. The aviation industry's goal of achieving net-zero emissions by 2050 is heavily dependent on the adoption of SAFs. Despite the challenges, the industry's commitment and the potential of SAFs to significantly reduce aviation's carbon footprint provide a promising outlook for sustainable aviation's future.

Bio-SAF Production: Hydro-processed Esters and Fatty Acids (HEFA)

The Hydroprocessed Esters and Fatty Acids (HEFA) technology is a key contributor in the production of Sustainable Aviation Fuels (SAF). This technology converts feedstock such as animal fats or vegetable oils into hydrocarbon-based fuel through a hydroprocessing conversion process, removing oxygen and producing a fuel similar to conventional jet fuels.

HEFA fuels have been approved for commercial aviation use after rigorous testing. Recent breakthroughs in bio-based aromatics have created opportunities for increasing SAF volumes in aircraft, including the potential for 100% SAF.

These advancements have been trialed by several airlines, demonstrating the possibility for a major transition from conventional fuel blending to a 100% SAF solution. SAF is seen as a practical approach to decarbonizing global aviation due to its 'drop-in' nature, which doesn't require modifications to current aircraft fleets, airports, or fueling infrastructure.

BioForming technology plays a vital role in this transition, providing necessary aromatics for jet fuel while significantly reducing carbon emissions. This technology not only meets jet fuel standards but also shows potential for a vast reduction in carbon emissions, indicating a significant shift in the aviation industry and global environmental efforts. Despite the promising potential, the economic feasibility of large-scale production remains a challenge in the near term. However, the low conversion costs of triglycerides and high product yield make HEFA the most competitive technology for SAF production at present.

Synthetic Fuels: Syngas and Fischer-Tropsch Conversion

The Fischer-Tropsch process, a catalytic method turning syngas into a broad spectrum of hydrocarbons, presents a promising alternative amidst dwindling crude oil reserves. This process's adaptability to various carbon sources like biomass, natural gas, and industrially captured carbon dioxide underpins its versatility.

Sustainable Aviation Fuel (SAF) production, specifically electrofuel, is being planned near Forsmark on Sweden's east coast by 2030. This facility will utilize fossil-free electricity, water, and recycled carbon dioxide in the Fischer-Tropsch process.

Simultaneously, advancements in Finnish technology have enabled e-diesel production, an electrofuel derived from green hydrogen and carbon dioxide, on a pre-commercial scale. Despite these advances, hurdles persist.

Efficient synthesis of carbon monoxide, a crucial component of syngas, remains a challenge. The standard approach, the reverse water gas shift (RWGS), demands high temperatures to convert increased CO2 into CO, underscoring the need for more effective methods.

In addressing this challenge, Unifuel.tech presents a solution named Flexiforming. It allows operators to dictate their decarbonization pace and can be integrated into an idle hydrotreater or reformer, reducing capital expenditure and carbon intensity. Unifuel. Tech assures responses to inquiries within 24 hours and provides assistance in finding an optimal application for Flexiforming, considering the operator's feeds, target products, and existing facilities. Despite the questions surrounding alternative fuels' scalability and economic viability, faith endures that substantial innovation and investment can significantly decrease aviation's carbon emissions. The US administration's goal of producing 3bn gallons of SAF by 2030 embodies this faith, heralding a shift towards a sustainable future for the aviation industry.

Carbon Sourcing Options for Synthetic Fuels

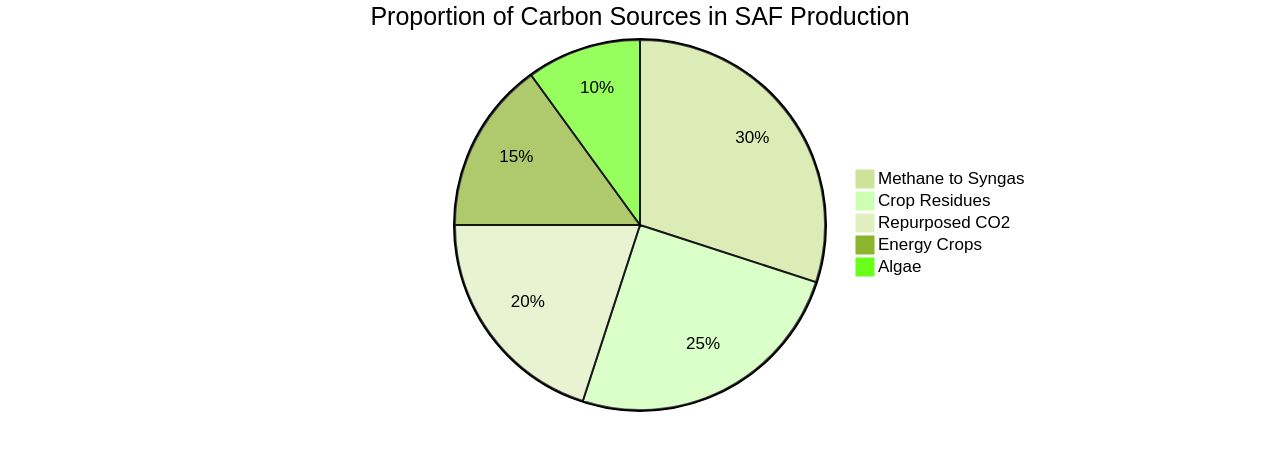

As the aviation industry endeavors to minimize its environmental footprint, significant strides have been made in Sustainable Aviation Fuel (SAF) production, unearthing an array of viable carbon sources. These sources range from organic materials such as crop residues, energy crops, and algae, to repurposing carbon dioxide captured from industrial processes. Methane can also be transformed into syngas, offering an alternative carbon source.

A significant leap forward for the sector has been the successful development and testing of bio-based aromatics production by leading airlines, allowing for an increased use of sustainable fuel in aircraft. This accomplishment is of particular importance given the strict regulations on fuel chemistry and physical properties in the aviation industry. The 'drop-in' characteristic of SAF, which negates the need for considerable modifications to existing infrastructure, is considered the most viable solution for decarbonizing global aviation.

In relation to this, Unifuel.tech's Flexiforming technology gives operators the ability to control the pace of their decarbonization efforts. This technology can be integrated into a dormant hydrotreater or reformer, thereby reducing both capital costs and carbon intensity. Unifuel.tech guarantees a response within 24 hours to inquiries regarding feeds, target products, and existing facilities.

As the aviation industry continues to evolve, further exploration of carbon sources and the development of new technologies, such as Flexiforming, will be crucial in reducing the industry's environmental impact. Universal Fuel Technologies owns the rights to Unifuel. Tech and their technology, with usage terms accessible on their website.

Hydrogen Production for Synthetic Fuels: Current and Future Methods

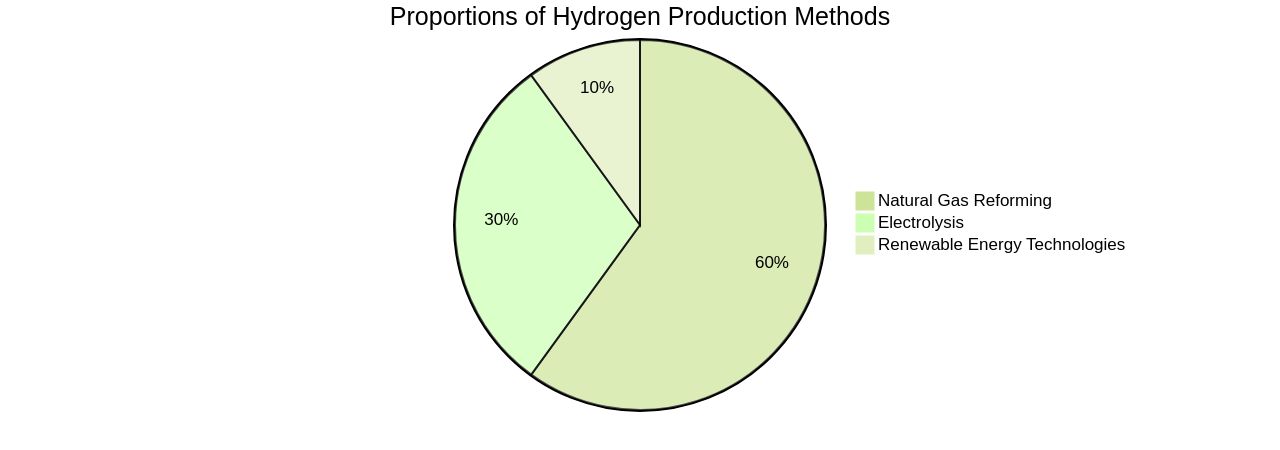

Hydrogen serves as a fundamental component in synthetic jet fuel production, utilized in the syngas for Fischer-Tropsch conversion. Traditional reliance on natural gas reforming for hydrogen production, a carbon dioxide emitting process, is getting a sustainable makeover with advancements in electrolysis and renewable energy technologies.

These improvements are setting the stage for carbon-neutral or even carbon-negative hydrogen production, bolstering the sustainability of synthetic fuel production. Innovative solutions like the EU-funded HyTecHeat project and De Nora's Dragonfly® system exemplify this shift.

The latter, an on-site hydrogen generation unit, is in use in steel production, mitigating environmental impact through increased low-carbon hydrogen usage. ENGIE's HyFlexPower project, which converts renewable electricity into green hydrogen, illustrates the potential of renewable hydrogen in industrial decarbonization.

However, sustainable hydrogen production is not without its hurdles. Conventional water electrolysis methods require precious, rare, and costly metals like platinum as catalysts.

The escalating prices and limited supply have triggered the hunt for alternative electrocatalyst materials. The present comparatively high cost of green hydrogen against fossil fuel-based counterparts poses an adoption barrier. Despite this, investment towards bridging this gap is on the rise, with expenditure on electrolyzers tripling to $8.7 billion last year. In this context, technologies like Unifuel.tech's Flexiforming emerge as potential solutions. Flexiforming enables operators to dictate their decarbonization pace and can be employed in an idle hydrotreater or reformer, bringing down capital expenditure and carbon intensity. Despite these challenges, the progress in hydrogen production technologies and the growing investments in the sector herald a promising future for synthetic fuel production's sustainability.

Synthetic Fuel Costs and Challenges

Navigating the pathway towards eco-friendly synthetic jet fuels often presents hurdles such as cost-effectiveness, scalability, and complex conversion processes. Yet, with technological progress, economies of scale, and supportive policies, the path ahead seems promising. Sustainable Aviation Fuels (SAF) encompass a variety of SAF blends with conventional jet fuels, reducing emissions by a particular percentage.

Their environmental benefits notwithstanding, these alternative fuels remain in limited supply and can cost up to five times more than standard jet fuel. Innovative strategies such as the establishment of a 'digital twin' of a production plant can help mitigate these challenges. This virtual counterpart facilitates simulation and optimization of production processes, emphasizing the selection of the most economically feasible and ecologically sustainable synthesis method.

By 2030, this methodology is anticipated to be functional in a new synthetic fuels production plant. The synthetic fuels produced will possess properties nearly identical to conventional petroleum-derived products, making them compatible with existing combustion engine vehicles without any modifications. However, SAF alone will not achieve decarbonization.

A holistic overhaul of global aircraft fleets, airports, and fueling infrastructure is required, despite the significant challenges in terms of cost, time, logistics, and disruption to air travel. Technologies such as flexiforming, provided by Unifuel.tech, enable operators to dictate their decarbonization pace and can be incorporated into idle hydrotreaters or reformers, reducing both capital expenditure and carbon intensity. The cost and scale of the necessary transition are significant, but the prospect of synthetic fuel production merits serious consideration from industry leaders and policymakers.

The pursuit of greener alternatives to fossil fuel-based kerosene is, indeed, a global endeavor. Unifuel.tech, a Universal Fuel Technologies company, offers a swift response within 24 hours to inquiries about their flexiforming technology, requesting details about feeds, target products, and existing facilities to find an optimal application for flexiforming. All rights are reserved by Universal Fuel Technologies.

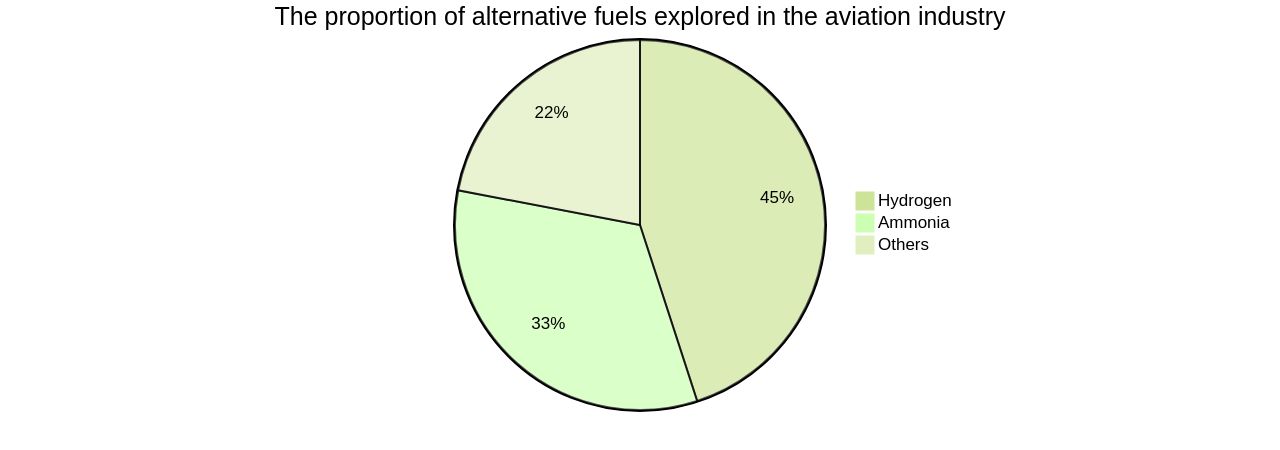

Zero-Carbon Aviation Technologies: Hydrogen and Ammonia-Powered Flight

As aviation seeks to reduce its carbon footprint, hydrogen and ammonia-powered flight technologies are emerging as potential solutions. The HY4, the world's first hydrogen-electric passenger aircraft, took off in 2016, demonstrating the feasibility of this technology. Hydrogen offers potential as a fuel for jet engines and in fuel cells, given its high specific energy and lower operating costs compared to current kerosene-powered aircraft.

Airbus, in collaboration with ArianeGroup, has been working on the HyPERION project, aimed at producing practical hydrogen commercial airliners by 2035. The project tests the use of supercooled liquid hydrogen stored in cryogenic tanks, dispensed into the fuel system, and delivered to the engines at optimal temperature and pressure. Airbus believes hydrogen propulsion to be the technology with the lowest cost per ton of CO2 avoided.

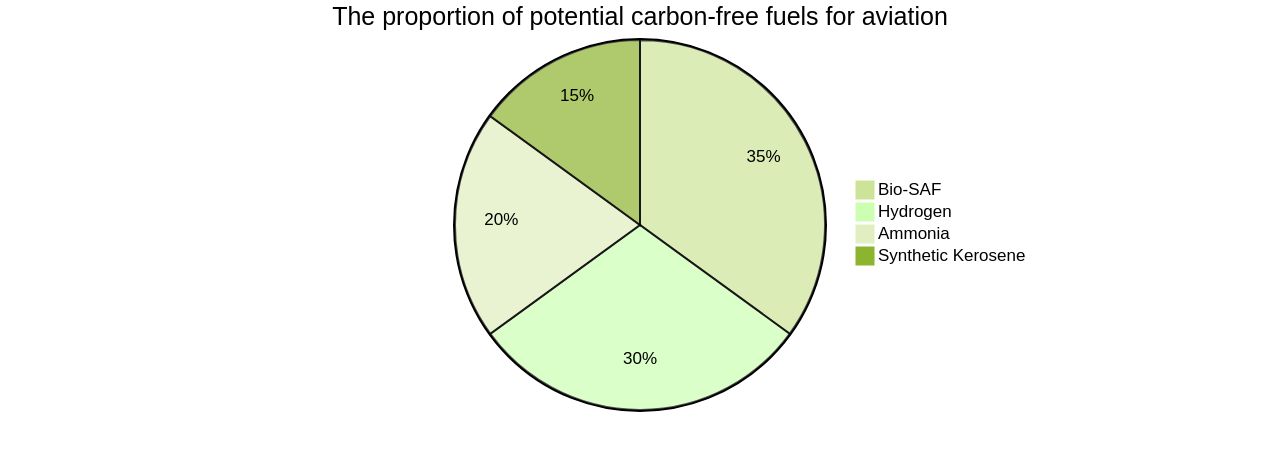

Ammonia, carrying 49% more energy per volume than liquid hydrogen, is another promising carbon-free fuel. However, the realization of a multi-fuel future necessitates significant innovation, cost reductions, and a massive amount of low-carbon hydrogen. By 2050, the aviation industry's potential fuel mix could include bio-SAF, synthetic kerosene, and these zero-carbon technologies.

However, if air traffic continues to outpace global GDP growth, achieving decarbonization at scale by 2050 may be challenging. Thus, it's imperative for leadership teams to discern which solutions will be commercially viable and widely available by the target year. Despite these challenges, the aviation industry, exemplified by Airbus's commitment to hydrogen propulsion, is determined to achieve net-zero emissions by 2050.

Hydrogen-Fueled Aircraft: Infrastructure and Design Challenges

In the quest for decarbonized aviation, Airbus and ArianeGroup's joint venture, the Hyperion project, is making remarkable progress. Their goal is to have hydrogen commercial airliners operational by 2035.

They have successfully tested a system that uses hydrogen as fuel for an aeronautical gas turbine engine, demonstrating hydrogen's potential as a jet fuel substitute. The system stores hydrogen as a supercooled liquid in cryogenic tanks, then converts it back into a gas and delivers it to the engines under optimal conditions.

However, the shift to hydrogen requires extensive system engineering, encompassing not only engine modifications to burn hydrogen, but also the development of infrastructure for hydrogen production, storage, and distribution. Aircraft designs will also need to adapt to the unique properties of hydrogen fuel.

The HY4, the world's first hydrogen-electric passenger aircraft, first flew in 2016 and is expected to transport 40 passengers over distances of up to 2,000 kilometers in the near future. Airbus is also developing a complete hydrogen-fueled propulsion system and a hydrogen Auxiliary Power Unit (APU) for onboard electricity generation. Collaboration across industry, government, and research institutions is key to overcoming these challenges and driving the deployment of hydrogen-fueled aircraft. Initiatives like the Hydrogen Airport are conducting feasibility studies for airports to assess hydrogen needs, supply chain modeling, land management, and cost estimates. The aim is to establish safety protocols for hydrogen use in airports and gradually set up a new sector, moving the aviation industry closer to a future where hydrogen can replace fossil fuels, significantly reducing greenhouse gas emissions and dependence on fossil fuels.

Ammonia-Powered Flight: Energy Density and Toxicity Concerns

In the quest to mitigate CO2 emissions and minimize climate impact, the aviation industry has been exploring alternative fuels. Ammonia, despite its challenges, has emerged as a potential candidate. However, its lower energy density requires larger storage volumes, and its potentially harmful nature necessitates rigorous safety measures.

Innovative projects such as the HyPERION, initiated by Airbus in collaboration with ArianeGroup, are making significant strides in the realm of hydrogen propulsion. Their work involves developing a comprehensive system for delivering hydrogen to an aeronautical gas turbine engine. The system involves storing hydrogen as a supercooled liquid in cryogenic tanks, which is then dispensed and preheated into the fuel system, converting it back into gas for optimal engine delivery.

Airbus has identified hydrogen propulsion as the most cost-effective solution for reducing CO2 emissions in air transport. This, coupled with the potential for lower operating costs and lighter aircraft, makes it an attractive prospect for the future of aviation. An example of this is the HY4, the world's first hydrogen-electric passenger aircraft, which demonstrated the feasibility of this technology when it first took flight in 2016.

Ammonia's ability to be stored as a liquid at manageable temperatures and pressures gives it a distinct advantage over other alternatives like liquid hydrogen and liquefied natural gas. This simplifies the storage process, reducing costs and complexity. Countries like Japan are already setting specific goals for power generation using ammonia, indicating its potential use in the energy sector.

However, transitioning to ammonia fuel will require considerable investment in new aircraft and infrastructure. Moreover, the efficient combustion of ammonia necessitates the development of advanced air-fuel mixing techniques. Despite these challenges, the aviation industry's technological revolution could see ammonia playing a crucial role in the shift towards sustainable aviation.

Fully Electric Aircraft: Battery Energy Densities and eVTOL Technology

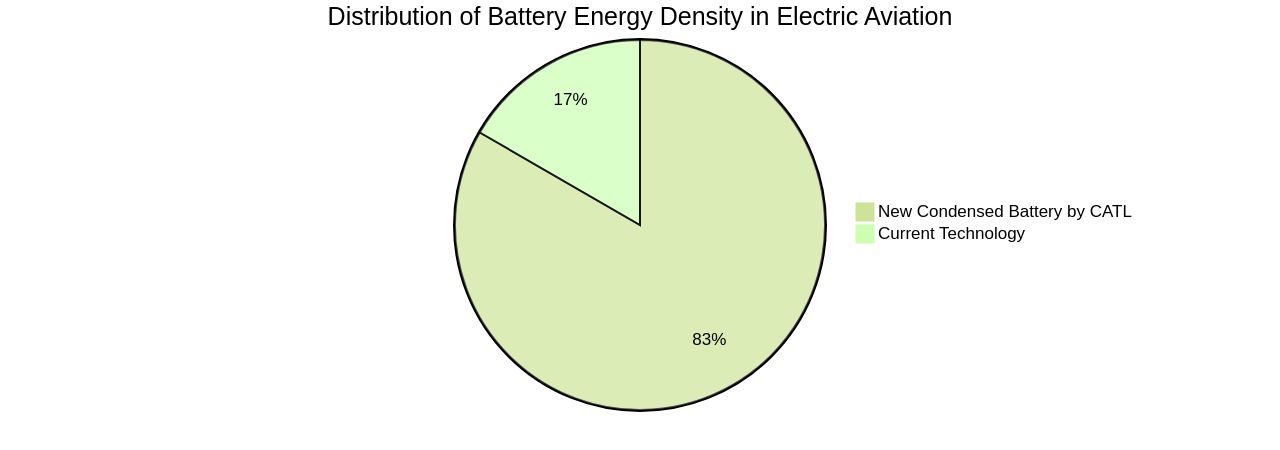

The pursuit of sustainable alternatives in aviation is seeing significant strides, with electric aircraft leveraging battery technology for propulsion. Despite the current energy densities of batteries falling short of liquid fuels, the tide is turning. CATL, a reputable battery manufacturer, has introduced a condensed battery boasting an energy density of 500 Wh/kg - a potential game-changer for electric aviation.

The advent of this technology is particularly promising for Electric Vertical Takeoff and Landing (eVTOL) operations, paving the way for urban air mobility and short-haul flights - domains where electric aircraft could excel. However, the progression of electric aircraft isn't confined to the aircraft themselves. It also involves the establishment of essential supporting infrastructure.

The Department of Energy has recently invested $15 million in 12 teams to develop batteries and energy storage systems with quadruple the energy density of current technologies. This initiative aims to power an aircraft capable of carrying up to 100 passengers for 1,000 miles. Additionally, a team from MIT is developing a 1-megawatt motor as a stepping stone towards electrifying larger aircraft.

Innovations like the E9X, designed by aviation startup Elysian and Delft University of Technology, which can carry 90 passengers up to 500 miles without recharging, signal a promising future for electric aviation. Nevertheless, challenges remain, such as the necessity for electric aircraft to carry additional stored energy to meet reserve fuel requirements and the high power required for takeoff. Therefore, ongoing advancements in battery technology and eVTOL designs are paramount for the widespread adoption of fully electric aircraft.

Scenarios for Achieving Net-Zero Aviation Emissions by 2050

The journey to net-zero carbon emissions in the aviation sector by 2050 is a collaborative effort involving stakeholders across the industry, governments, and other entities. What are key components of this transition? Sustainable Aviation Fuels (SAFs), synthetic fuels, hydrogen, and ammonia-powered flights, and fully electric aircraft. However, what is jet fuel made of?

What is jet fuel made of? SAFs, with their renewable nature and energy density, have the potential to revolutionize the industry, posing a challenge to the traditional jet fuel paradigm that has been in place for over 70 years. However, the transition to Safe presents a significant learning curve, as these fuels must prove safety, reliability, and compatibility with existing jet engines. So, what is jet fuel made of?

Airbus, along with other companies, is working towards achieving 100% SAF-capable aircraft by 2030 and is partnering with others to enhance the global market for sustainable aviation fuel (SAF). What is jet fuel made of? However, the current global jet fuel supply consists of less than 0.2% of SAFs, highlighting the need for breakthroughs in eco-friendly fuel production and supply. What is jet fuel made of?

The rapid growth of air traffic and the current fleet renewal rate could potentially impede the aviation sector's goal of achieving net-zero emissions by 2050. Therefore, it's crucial to identify viable and readily available solutions by 2050, as per research findings.

What is jet fuel made of? The successful implementation of SAFs depends on industry-wide support, favorable policies, and ongoing investment in research and development. Unifuel.tech's flexiforming technology is one such solution that allows operators to set their decarbonization pace. This technology can be incorporated into an idle hydrotreater or reformer, thereby reducing capital expenditure and carbon intensity. Unifuel.tech, a subsidiary of Universal Fuel Technologies, retains exclusive rights to their products and offers a contact form on their website for user inquiries, which are typically responded to within 24 hours. This approach enables operators to find an optimal application for flexiforming based on their feeds, target products, and existing facilities.

Policy Recommendations for Aviation Decarbonization

The aviation sector is steadfast in its pursuit of a green transition, with a bold target of achieving net-zero carbon emissions by 2050. This aspiration is not without its challenges, such as the escalating scale of air traffic and the constraints of current technologies.

Research suggests that future green technologies, like next-generation eco-friendly aircraft, may not reach full operational capacity in time to meet the 2050 deadline, considering the present rate of fleet renewal. This could lead to a gap in meeting the 2050 goal unless a significant decrease in air traffic occurs.

Given these circumstances, the role of policymakers becomes indispensable. The creation of favorable policies and regulations could stimulate the production and use of sustainable aviation fuels (SAF), finance research and development in zero-carbon aviation technologies, and set global standards for emissions reduction.

Achievement of these objectives calls for global collaboration for a unified approach and to drive worldwide efforts towards a sustainable and carbon-neutral aviation industry. This intricate journey demands transparency, adaptability, and a dual focus on immediate and long-term strategies.

Aviation value chain companies can kickstart this process by prioritizing actions that yield the most significant impact and offer a cost-effective route to net-zero emissions. Kenneth P. Quinn, a partner at Clyde & Co. and general counsel to the Flight Safety Foundation, articulated that the aviation sector requires a 'moonshot' to counter climate change, indicating that while the journey is arduous, it is a feasible target. Incorporating innovative solutions such as Unifuel.tech's flexiforming technology into the mix can potentially accelerate this transition. Flexiforming allows operators to dictate their decarbonization pace and can be implemented in a dormant hydrotreater or reformer, thus minimizing capital expenditure and carbon intensity. Unifuel.tech's prompt response time and the availability of an online contact form for optimal application inquiries make it a practical solution in the quest for carbon neutrality in aviation.

Conclusion

In conclusion, the aviation industry is actively pursuing sustainable alternatives to traditional jet fuels in its quest for net-zero emissions by 2050. This article has explored options such as Sustainable Aviation Fuels (SAFs), synthetic fuels, hydrogen and ammonia-powered flights, and fully electric aircraft.

SAFs, derived from renewable feedstocks, offer significant reductions in greenhouse gas emissions. Despite their current limited supply, SAFs have the potential to revolutionize the industry due to their compatibility with existing infrastructure.

Synthetic fuels, produced through processes like Fischer-Tropsch, show promise in reducing carbon emissions. Challenges remain in efficient synthesis of carbon monoxide.

Hydrogen and ammonia-powered flights are emerging as potential solutions for decarbonization. Hydrogen offers high energy density and lower operating costs, while ammonia simplifies storage processes.

Fully electric aircraft leverage battery technology and hold promise for short-haul flights. Advancements in battery energy densities are being made that could revolutionize electric aviation.

Achieving net-zero emissions requires collaboration among stakeholders and policymakers. Industry-wide support and favorable policies are crucial for the adoption of sustainable alternatives like SAFs. Technologies like Unifuel.tech's flexiforming can accelerate the transition by allowing operators to dictate their decarbonization pace. Policymakers play a vital role in creating regulations, stimulating research and development, and setting global standards for emissions reduction. Global collaboration is essential for a unified approach towards a sustainable aviation industry. In conclusion, while challenges remain in terms of scalability and cost-effectiveness, the commitment of the aviation industry towards decarbonization is evident. With ongoing innovation and supportive policies, the future of renewable fuels in aviation looks promising.