Introduction

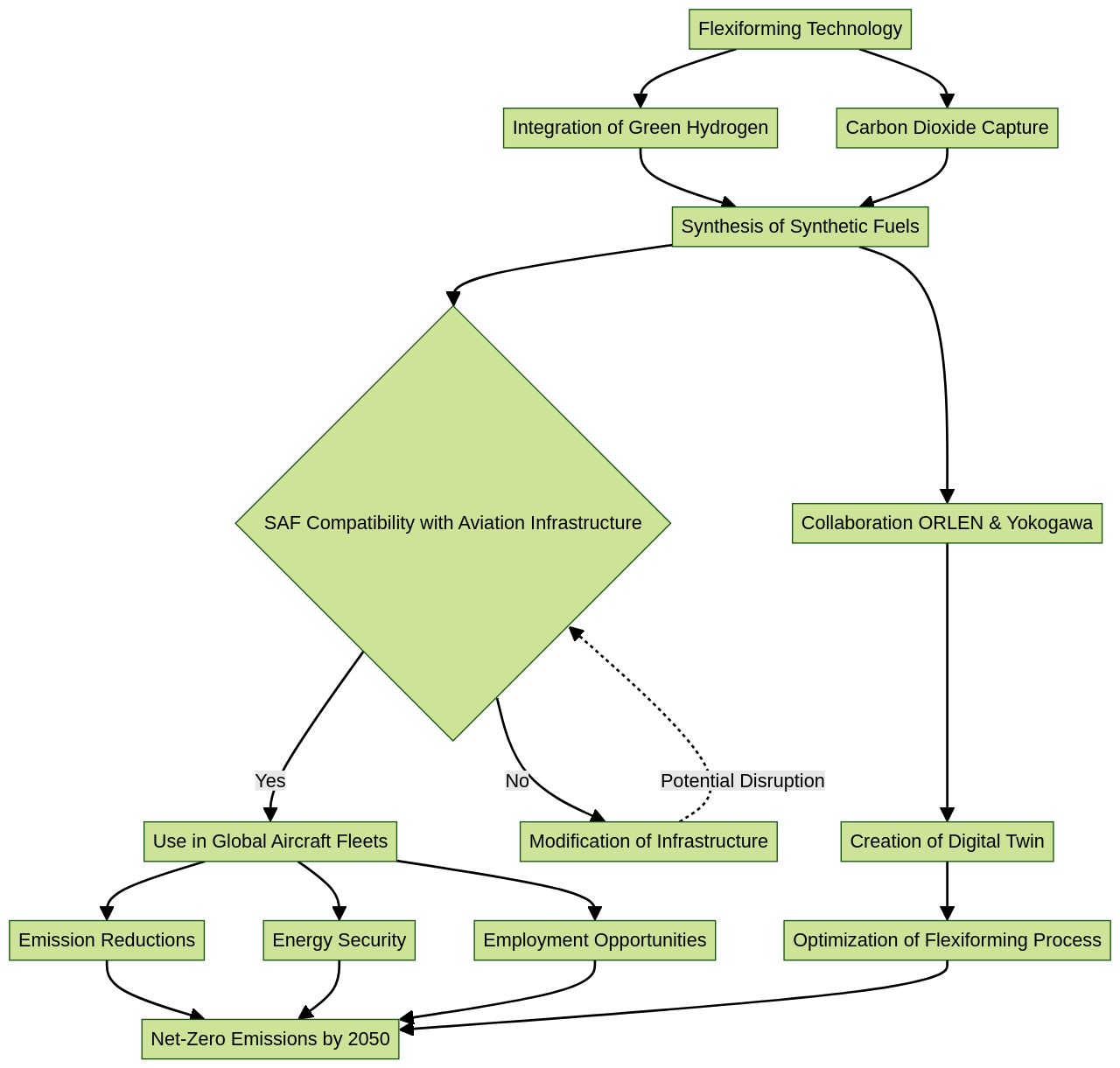

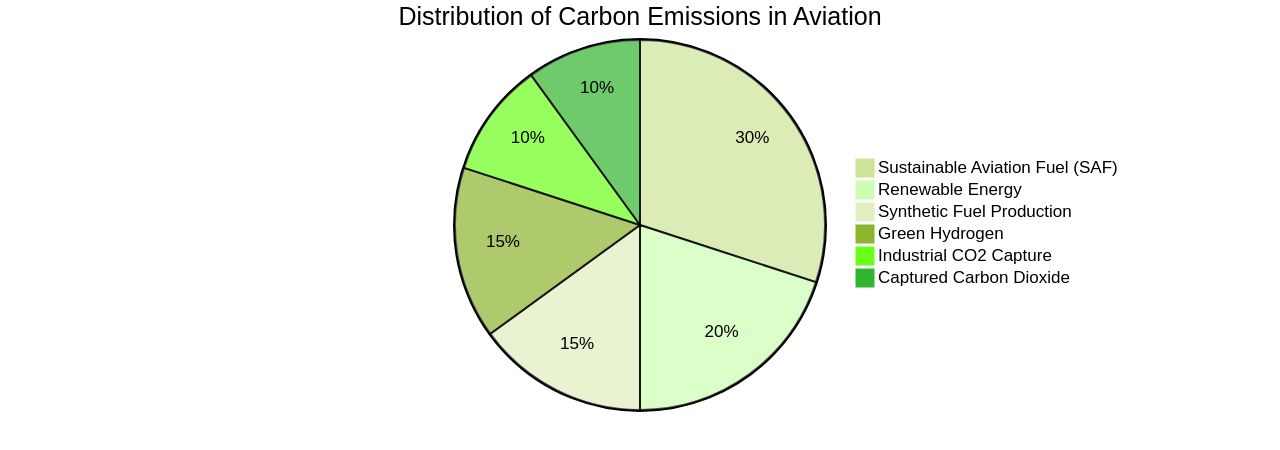

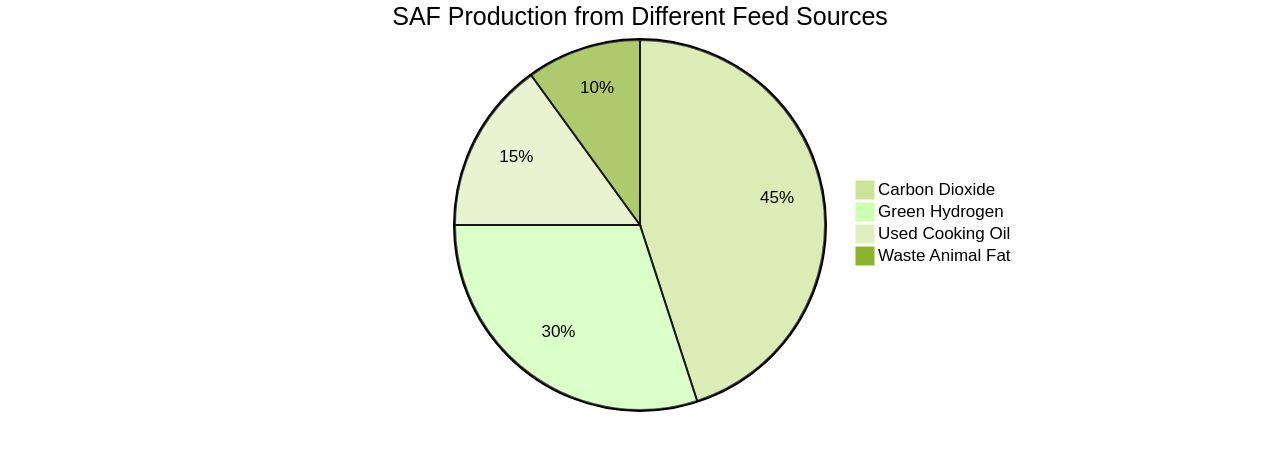

Flexiforming technology has emerged as a game-changer in the renewable fuels industry, particularly in the production of sustainable aviation fuel (SAF). This advanced process combines green hydrogen from renewable sources with carbon dioxide from industrial emissions to create synthetic fuels compatible with existing aviation infrastructure.

In this article, we will explore the implications of Flexiforming, partnerships shaping the future of synthetic fuel production, and the role of Unifuel.tech in revolutionizing SAF production. With a focus on technical insights and analysis, we delve into the environmental impact, benefits, and the potential for a greener aviation sector.

Zero Carbon Fuels: An Overview

Flexiforming technology represents a pivotal advancement in the creation of sustainable aviation fuel (SAF), promoting the aviation industry's goal of decarbonization. The process allows for the integration of green hydrogen, obtained from renewable energy sources, with carbon dioxide from industrial emissions. This synthesis creates synthetic fuels that are compatible with current aviation infrastructure, negating the need for engine or infrastructure alterations.

The collaboration between ORLEN and Yokogawa marks a strategic commitment to synthetic fuel production, aiming for an output of 70 thousand tons by 2030. A crucial aspect of this alliance is the creation of a 'digital twin' to virtually optimize the synthesis process for both economic and environmental benefits. The implications of Flexiforming and synthetic fuels extend beyond emission reductions to enhancing energy security and boosting employment in the industry.

Industry experts, supported by announcements from companies like Virgin Atlantic and Airbus, emphasize the role of SAF in achieving net-zero emissions by 2050. Projections suggest that an annual production of 80,000 tons of SAF could fulfill a substantial portion of Sweden's jet fuel demand by 2030. While SAF's role is significant, it is currently more feasible to use it in blends with conventional jet fuels.

Unifuel.tech, from Universal Fuel Technologies, leads in easing this transition with Flexiforming technology. This solution affords operators the ability to dictate their decarbonization pace by utilizing existing infrastructure such as idle hydrotreaters or reformers. This approach not only reduces capital expenses and carbon intensity but also ensures a personalized response to each operator's specific conditions.

Unifuel. Tech commits to a 24-hour response window for inquiries and encourages operators to provide details about their feeds, target products, and existing facilities to tailor the Flexiforming application precisely. For further information and contact, interested parties are directed to Unifuel.tech's website, where they can also find terms of use.

Flexiforming: Revolutionizing SAF Production

[Unifuel.](https://www.autoevolution.com/news/airbus-takes-saf-powered-flights-to-the-next-level-217804.html)tech's Flexiforming technology stands at the vanguard of aviation's journey towards a reduced carbon footprint. This innovative process seamlessly converts biomass into Sustainable Aviation Fuel (SAF) by amalgamating hydrothermal liquefaction with flexible sheet metal forming.

[Unifuel.](https://www.autoevolution.com/news/airbus-takes-saf-powered-flights-to-the-next-level-217804.html) Tech enhances the feasibility of this technology by enabling it to be deployed in idle hydrotreaters or reformers, thereby reducing both capital expenditure and carbon intensity.

The technology's adaptability allows operators to dictate their decarbonization pace, making it a strategic asset in the aviation industry's commitment to diminishing its environmental impact, which accounts for around 2% of global carbon emissions. Partnerships like the one between ORLEN and Yokogawa are reshaping the future of synthetic fuel production.

Their collaborative efforts in developing a 'digital twin' for prospective facilities will optimize production processes. ORLEN's goal to produce 70 thousand tons of synthetic fuel annually by 2030 will leverage renewable energy and industrial CO2 capture, significantly curtailing greenhouse gas emissions through the use of green hydrogen and captured carbon dioxide.

The aviation sector is poised to increase its SAF utilization, mitigating its carbon footprint as companies like Airbus spearhead initiatives to overcome supply and cost limitations. With the scaling of production, the industry envisions a substantial decline in emissions. Synthetic fuels' compatibility with existing infrastructure and engines streamlines the transition, requiring no alterations and promoting a seamless shift towards sustainability. [Unifuel.](https://www.autoevolution.com/news/airbus-takes-saf-powered-flights-to-the-next-level-217804.html) Tech underscores its commitment to customer service with a 24-hour response guarantee and requests specific information to tailor Flexiforming applications to each operator's needs, substantiating the technology's role in aviation's green transition.

Case Study: Applying Flexiforming to SAF Production

Flexiforming technology, provided by Unifuel.tech, is a pivotal innovation in the sustainable aviation fuel (SAF) sector, driving the industry's urgent shift towards a lower carbon footprint. By enabling the utilization of diverse biomass feedstocks, including agricultural residues and algae, flexiforming demonstrates versatility and ingenuity.

This approach notably leverages dormant hydrotreaters and reformers, diminishing capital investments while concurrently abating carbon intensity. Operators are thus empowered to tailor their decarbonization paths with greater autonomy.

The impact of flexiforming is evident in its contribution to SAF production, anticipated to satisfy a significant portion of Sweden's aviation fuel requirements by 2030. Despite Saf's higher cost compared to conventional jet fuel, its adoption is escalating due to its markedly reduced greenhouse gas emissions over its lifecycle.

The technology's capacity to incorporate bio-based aromatics into SAF blends is a significant advancement, potentially enabling aircraft to operate on up to 100% SAF, a considerable leap from the current blend ceiling. Digital twinning of production facilities further enhances process simulation and optimization, pinpointing the most efficient and sustainable production techniques.

Saf's similarity to traditional jet fuels ensures a smooth transition to eco-friendlier alternatives, without the need for modifications to aircraft or infrastructure. This shift is critical, as aviation is a notable contributor to global carbon emissions, and the quest for sustainable kerosene is becoming a universal mandate. Unifuel.tech, through its flexiforming solution, is leading the charge in synthetic fuel synthesis. The company's commitment is underscored by rapid response times to inquiries and a collaborative approach to identifying the most suitable application of flexiforming based on an operator's specific requirements. This dedication is exemplified by collaborations aiming to significantly enhance SAF production capacities by 2030, reflecting the industry's resolve to attain carbon neutrality in aviation.

Environmental Impact and Benefits

Unifuel.tech's Flexiforming technology is revolutionizing the production of sustainable aviation fuel (SAF), leveraging cutting-edge processes that synthesize fuel from carbon dioxide and green hydrogen. This method aligns with the industry's strategic goal to achieve carbon neutrality by 2050, as it harnesses renewable energy sources and industrial CO2, turning them into synthetic fuels with properties nearly identical to conventional jet fuel.

By doing so, Flexiforming not only contributes to the decarbonization of aviation but also supports the integration of renewable energy into the fuel supply chain, securing a steadfast reduction in greenhouse gas emissions. The technology's adaptability allows it to be integrated into existing infrastructure, such as idle hydrotreaters or reformers, which reduces capital expenditure and carbon intensity, offering operators the flexibility to choose their pace of decarbonization.

Unifuel.tech's responsive approach includes a 24-hour inquiry response time, ensuring potential customers receive timely assistance in evaluating how Flexiforming can be optimally applied to their specific feeds, target products, and existing facilities. The recent collaboration between ORLEN and Yokogawa demonstrates the practical application of this technology, with plans to construct a synthetic fuels production facility by 2030.

This facility aims to satisfy a significant portion of Sweden's SAF needs and a fraction of its total jet fuel demand. The partnership will employ a 'digital twin' to optimize production, ensuring economic and environmental sustainability. As aviation's contribution to global carbon emissions is significant and expected to rise, the development of SAF that meets regulatory standards is critical. Flexiforming technology by Unifuel.tech, a subsidiary of Universal Fuel Technologies, is at the forefront of these efforts, as it offers a scalable and economically viable path towards a greener aviation sector.

Conclusion

In conclusion, Flexiforming technology is revolutionizing the production of sustainable aviation fuel (SAF) by combining green hydrogen and carbon dioxide to create synthetic fuels compatible with existing aviation infrastructure. This process not only supports the decarbonization goals of the aviation industry but also enhances energy security and employment opportunities.

Partnerships, such as the collaboration between ORLEN and Yokogawa, are shaping the future of synthetic fuel production. Their focus on developing a 'digital twin' for production facilities optimizes processes and reduces greenhouse gas emissions through the use of green hydrogen and captured carbon dioxide.

The goal of producing 70 thousand tonnes of synthetic fuel annually by 2030 demonstrates the potential impact of these partnerships in meeting SAF demand. Unifuel.tech's Flexiforming technology plays a crucial role in easing the transition to sustainable aviation fuels.

By enabling operators to utilize existing infrastructure, such as idle hydrotreaters or reformers, capital expenses and carbon intensity are reduced. Unifuel.tech's commitment to personalized customer service ensures that each operator's specific conditions are taken into account when implementing Flexiforming applications.

The environmental impact and benefits of Flexiforming are significant. By harnessing renewable energy sources and industrial CO2, this technology facilitates the integration of renewable energy into the fuel supply chain while reducing greenhouse gas emissions. The adaptability of Flexiforming allows it to be seamlessly integrated into existing infrastructure without requiring modifications to engines or infrastructure. Overall, Flexiforming technology and partnerships like Unifuel.tech are driving the aviation industry towards a greener future. With its scalable and economically viable approach, this technology has the potential to transform the sector's carbon footprint and contribute to achieving net-zero emissions by 2050.